Ball-milling tank and planetary ball mill with same

A ball milling tank and tank bottom technology, applied in grain processing, etc., can solve the problems of low grinding efficiency, insignificant impact effect, and low grinding quality, and achieve the effect of improving grinding quality, grinding efficiency and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

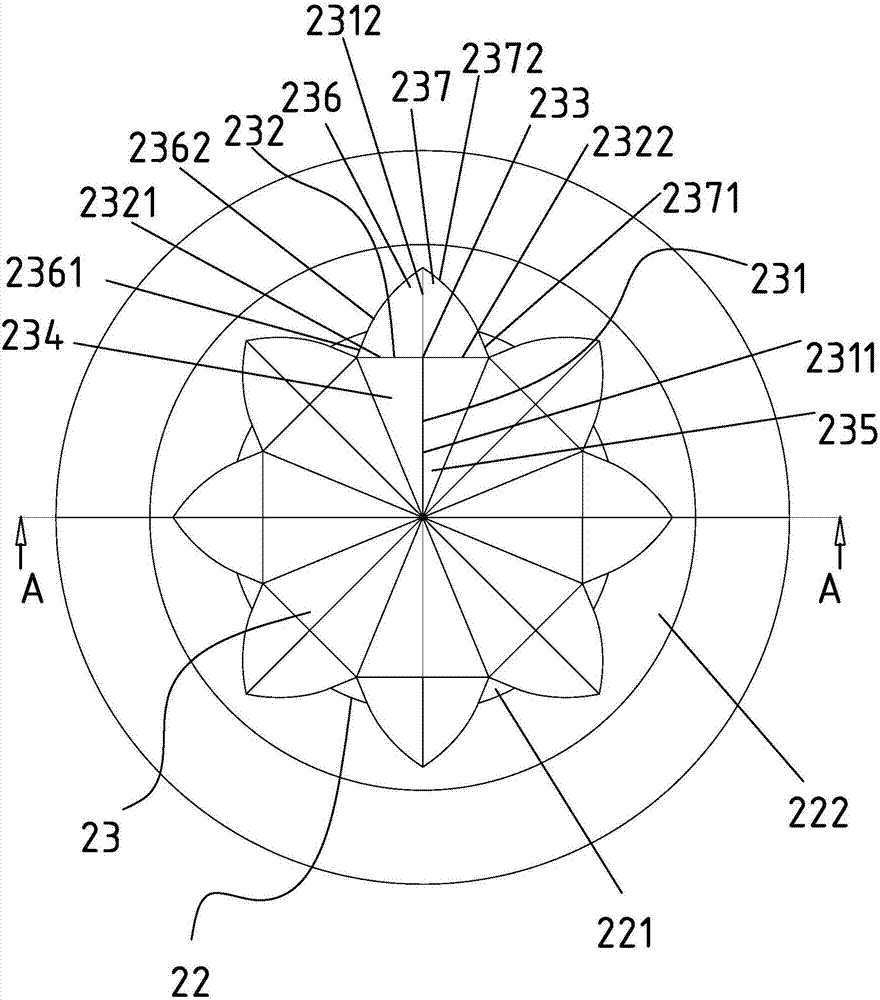

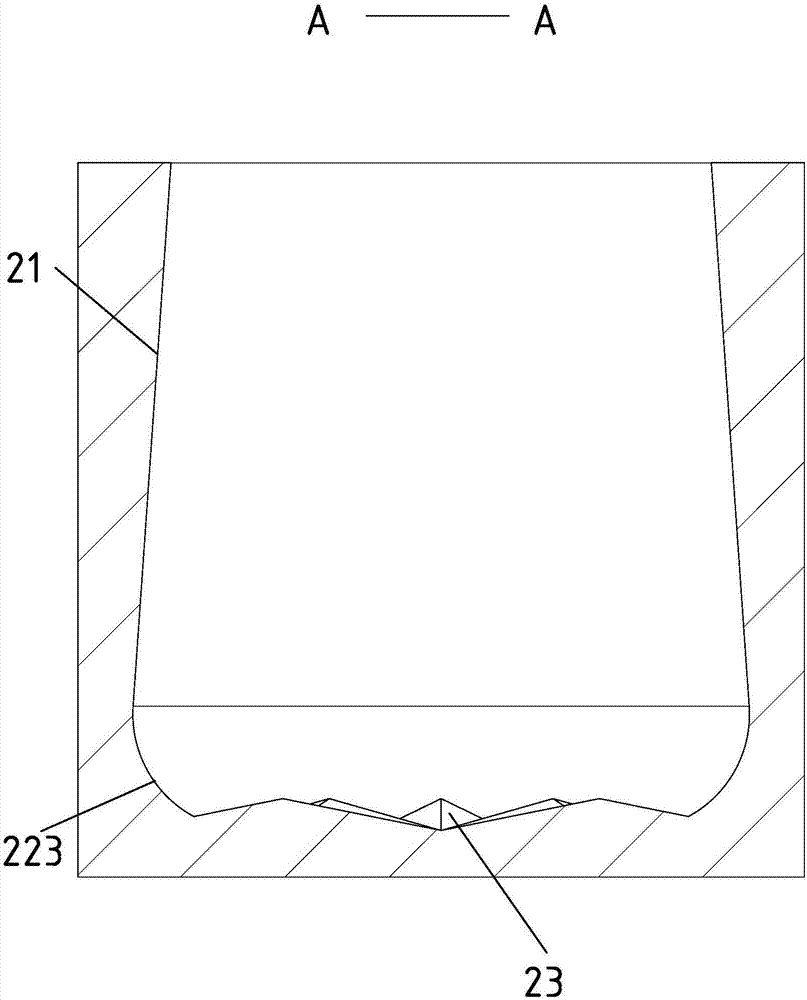

[0032] Such as Figure 1-Figure 4 As shown, a ball milling tank includes a tank cover 1 and a tank body 2, the tank body 2 has a non-cylindrical side wall inner wall 21, and the tank bottom 22 of the tank body 2 has a plurality of tank bottoms 22 The center is the protrusions 23 evenly distributed in the center.

[0033] The orthographic projection of the protrusion 23 on the tank bottom 22 is a kite-like shape 24, and there are common sides between adjacent kite-like shapes 24, that is, each of the kite-like shapes 24 includes A common side I241 and a common side II242, one end of the common side I241 and the common side II242 coincides with the center of the tank bottom 22, and the other end is located at the end of the asymmetrical axis diagonal line 243 of the kite-like shape 24;

[0034] The protrusion 23 has a symmetrical edge 231 corresponding to the symmetric axis diagonal line 244 of the kite-like shape 24 and an asymmetric edge 232 corresponding to the asymmetric ax...

Embodiment 2

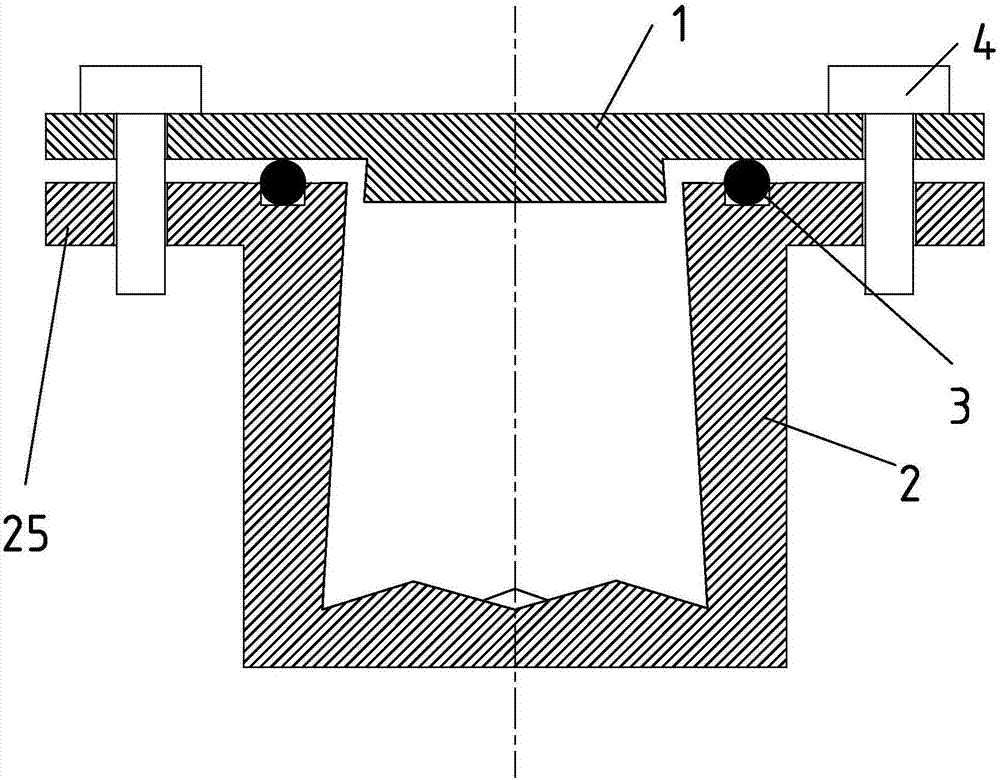

[0048] Such as Figure 5 As shown, a planetary ball mill containing the ball mill jar described in Example 1 includes a drive motor 5, a transmission mechanism 6, a revolving turntable 7 located on the transmission mechanism 6, and a plurality of revolving turntables 7 located on the revolving turntable 7 The rotation shaft 8 on the top, the said rotation shaft 8 is provided with the ball mill jar as described in embodiment 1, the output end of the said driving motor 5 is connected with the input end of the said transmission mechanism 6 through the belt pulley 9, the said rotation shaft 8 The axis is parallel to and not coincident with the axis of the ball mill jar.

[0049] Use the ball mill jar described in Example 1 and the same material ball mill jar (contrast ball mill jar) that the inner wall of the side wall is a smooth cylindrical surface to grind the limestone blocks that are 300g in quality and have the same shape, stop every 60 seconds, and use A 200-mesh sieve scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com