Hydraulic excitation high-frequency linear impact device

An impact device, high-frequency technology, applied in construction, sheet pile wall, foundation structure engineering and other directions, can solve the problems of low impact frequency, small impact force, pile damage, etc., achieve low quality, high impact frequency, improve work efficiency The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

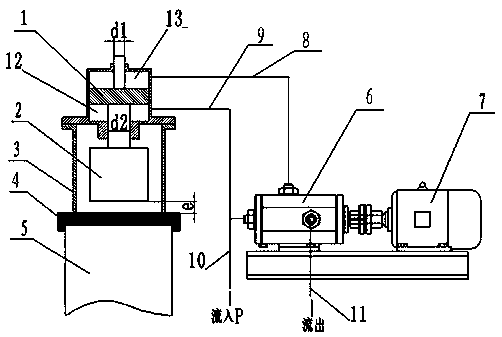

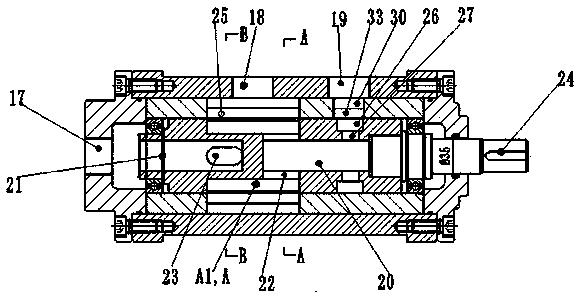

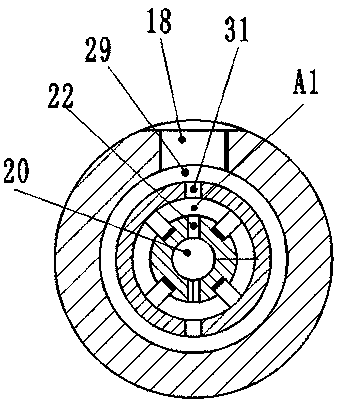

[0050] figure 1 As shown, a hydraulically excited high-frequency linear impact device includes a hydraulic cylinder 1, an impact hammer 2, a sleeve 3, an impact seat 4, and an impacted body. The piston rod of the hydraulic cylinder 1 is connected to the impact hammer 2, and the small-diameter piston of the hydraulic cylinder The rod chamber oil chamber is connected to the control oil pipe, the large diameter piston rod chamber oil chamber of the hydraulic cylinder is connected to the high pressure oil pipe, the high pressure oil pipe is connected to the input oil pipe, the control oil pipe is connected to the shock valve, and the shock valve is connected to the control motor.

[0051] Hydraulic cylinder 1 adopts unequal-diameter double-rod hydraulic cylinder. There is a flange on the cylinder barrel of the hydraulic cylinder 1, and the flange is connected with the sleeve 3. The inner diameter of the cylinder is D, and the diameters of the piston rods on both sides of the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com