Torsion impact device

An impactor and torsion technology, which is applied in the fields of oil drilling and geotechnical drilling and drilling, can solve the influence of the impact torque and impact frequency of the torsion impactor, the narrow outlet water channel of the torsion impactor, and the influence of the working life of the torsion impactor, etc. problems, to achieve the effect of increasing impact torque and impact frequency, less switching channels, and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

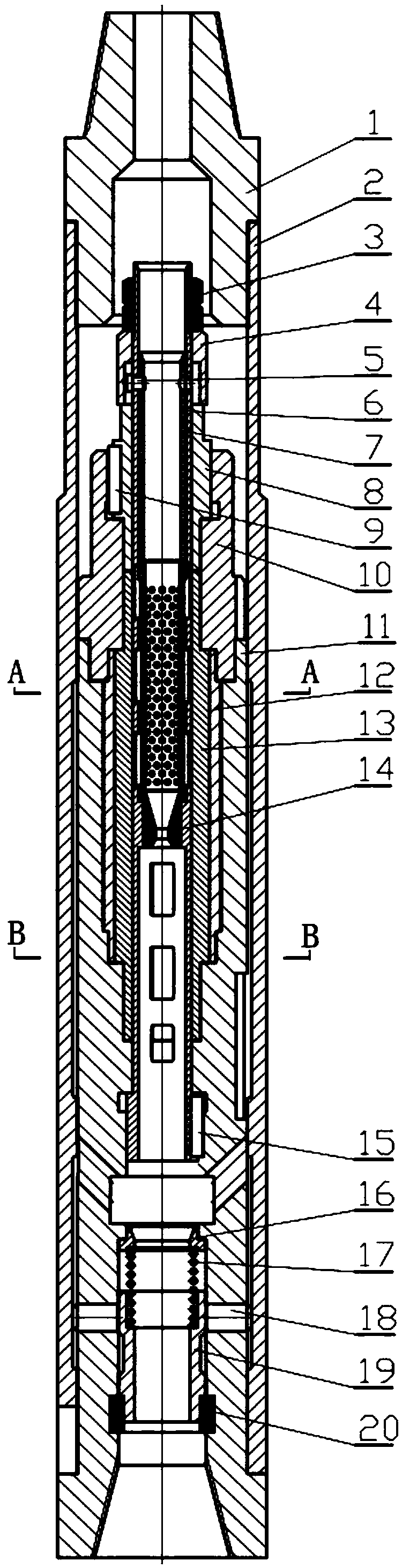

[0046] Embodiment 1: Symmetrical torsion impactor

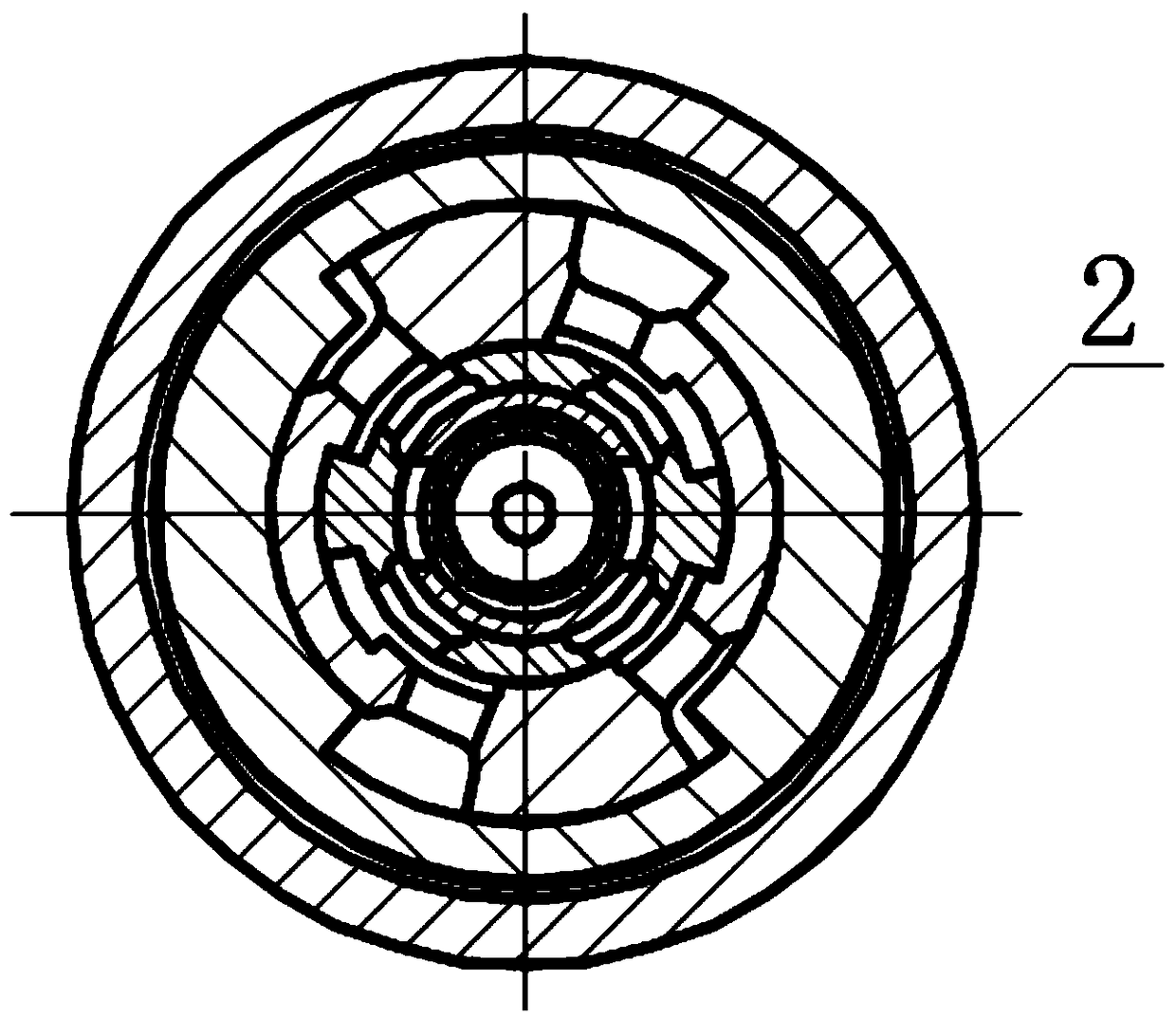

[0047] From the cross-sectional view of the symmetrical torsional impactor, see Figure 5 , The rotary valve 13, the pendulum 12 and the distribution core tube 6 of the symmetrical torsion impactor are all symmetrical structures.

[0048] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , The symmetrical torsion impactor is composed of an upper joint 1, an outer pipe 2, an inner pipe impact assembly and a suspension device. The upper joint 1 is located at the upper end of the torsion impactor and can be connected with the drilling tool, and its lower end is connected with the outer pipe 2 through threads; The inner tube impact assembly is arranged inside the outer tube 2; the suspension device is located inside the lower end of the inner tube impact assembly, and the suspension device fixes the inner tube impact assembly on the outer tube 2 through the suspension pin 18;

[0049] T...

Embodiment 2

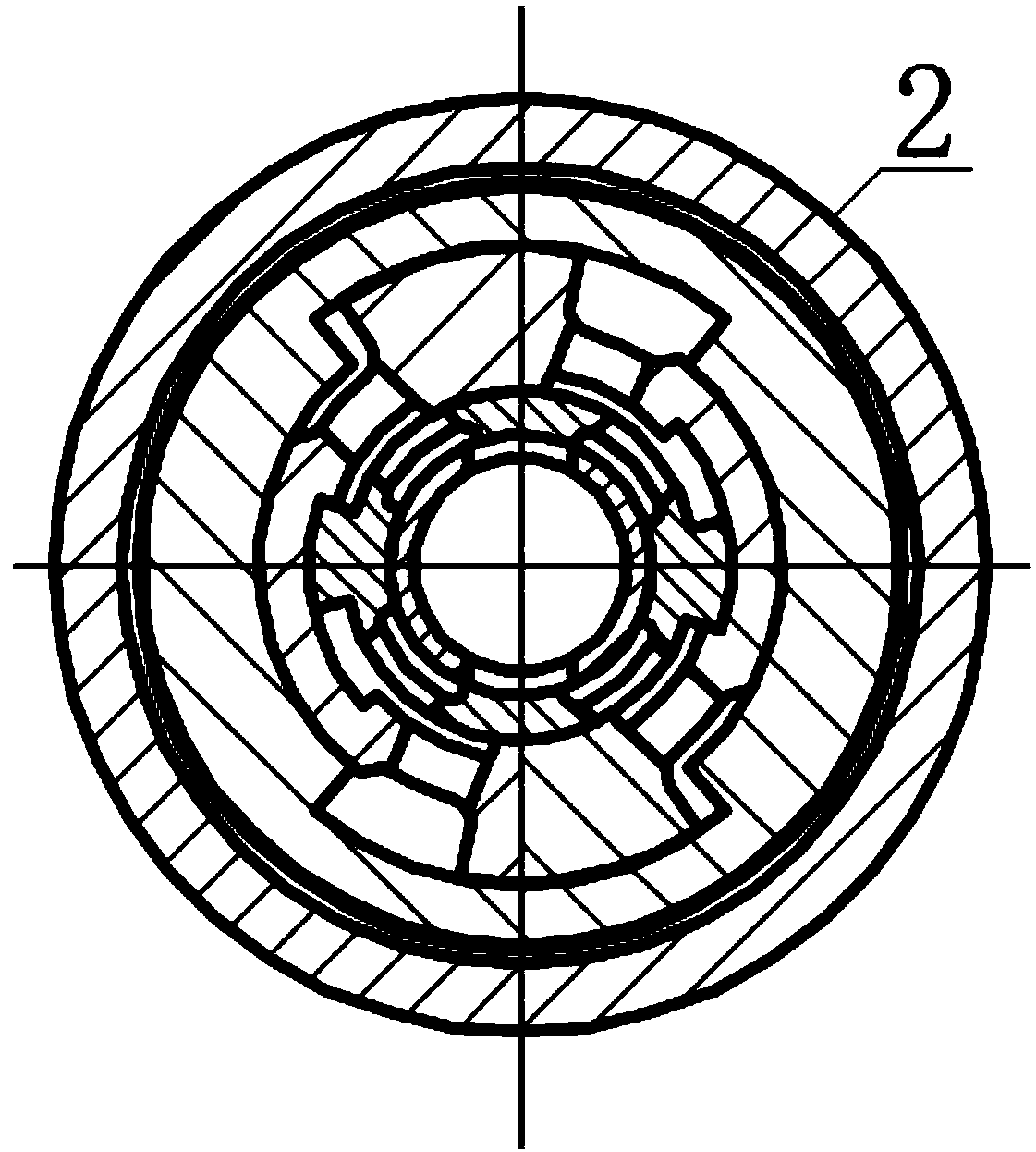

[0056] Embodiment 2: Asymmetric Torsion Impactor

[0057] From the cross-sectional view of the asymmetric torsion impactor, see Figure 9, The rotary valve 13, the pendulum 12 and the distribution core tube 6 of the asymmetric torsion impactor are all asymmetric structures, while the structures of other parts are exactly the same as those of the symmetrical torsion impactor.

[0058] like figure 1 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, the asymmetric torsion impactor is composed of upper joint 1, outer pipe 2, inner pipe impact assembly and suspension device. 2 connection, the outer tube 2 is provided with an inner tube impact assembly, the suspension device is located inside the lower end of the inner tube impact assembly, and the suspension device fixes the inner tube impact assembly on the outer tube 2 through the suspension pin 18; the inner tube impact assembly It consists of distribution core tube 6, filter tube 7, self-locking nut 3, limit s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com