Special hammer device for nuclear power station

A special force, nuclear power plant technology, applied in the field of nuclear engineering, can solve problems such as the difficulty in implementing monitoring and diagnosis of loose parts, complex system structure, etc., and achieve the effects of light weight, long effective stroke and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

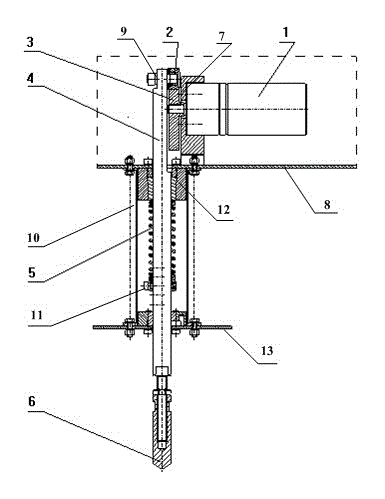

[0025] Such as figure 1 As shown, a special hammer device for nuclear power plants includes a DC motor 1, a roller 2, a lifting cam 3, an impact rod 4, a spring 5, an impact head 6, a motor seat 7, a base 8, a bolt 9, an impact rod sliding sleeve 10, Spring retaining ring 11, impact rod sliding sleeve seat 12 and cover plate 13.

[0026] The DC motor 1 is fixedly mounted on the base 8 through the motor base 7, the output rod of the DC motor 1 is provided with a lifting cam 3, the lifting cam 3 is connected with the roller 2, and the roller shaft of the roller 2 passes through the impact One end of the rod 6 is fixed by a bolt 9, an elastic washer is arranged between the bolt 9 and the impact rod 4, the lower bottom surface of the base 8 is fixedly connected with one end of the impact rod sliding sleeve 10, and the other end of the impact rod sliding sleeve 10 One end is provided with a cover plate 13, the impact rod 4 passes through the base plate and the impact rod s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com