Valveless single-cylinder low or middle wind pressure downhole air hammer

A technology of down-the-hole impactor and single cylinder, which is applied in drilling equipment, earthmoving, driving device for drilling in wellbore, etc. The effect of pressure loss, enlargement of effective working diameter, and simplification of air distribution path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

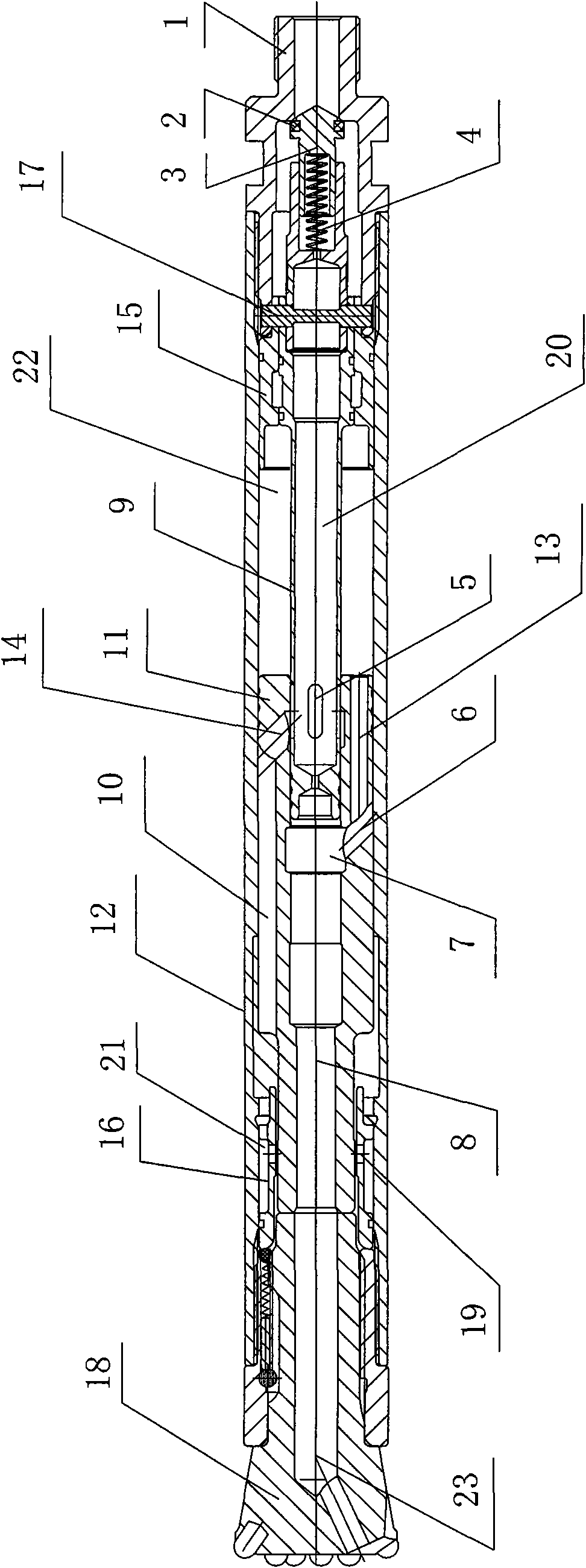

[0010] Such as figure 1 As shown, the present invention includes an outer sleeve 12, one end of the outer sleeve 12 is a rear joint 1, and the other end is a drill bit 18, the rear joint 1 is provided with a tapered thread 2 for connecting with a drill pipe, and the check valve 3 is placed in the outer sleeve In 12, the check valve 3 is provided with a flexible spring 4, and one end of the gas distribution rod 9 is provided with a radial hole 5, and the gas distribution rod 9 is matched with the piston 11, and the piston 11 is provided with a central channel 8, and the central channel 8 is provided with a There is an inner ring groove 7, the lower part of the piston 11 is provided with an upper air hole 13, the upper air hole 13 communicates with the inner ring groove 7 through the inclined hole 6, the upper part of the piston 11 is provided with an air groove 10, one end of the upper inclined hole 14 communicates with the air groove 10, and the other One end is matched with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com