Patents

Literature

85results about How to "Increase impact energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bumper mounting structure

If an impact occurs with an impact energy which exceeds an elastic limit of a bumper while a shock-absorbing member is in a projected position, a bumper stay is forced to move rearward along a first actuating chamber to cause the shock-absorbing member to pivot to a received position. The impact energy is primarily absorbed by an elastic force of a first spring which biases the shock-absorbing member toward the projected position. When the impact energy is not thoroughly absorbed by the first spring, the shock-absorbing member fully pivots into its received position by the bumper stay which is continuously moved rearward. At this time, a second spring which biases the shock-absorbing member forward and is prevented from being stretched forward by the shock-absorbing member, is contacted with the bumper stay via a support plate. Accordingly, the second spring secondarily absorbs the impact energy while being more compressed by the bumper stay which continuously moves rearward after causing the shock-absorbing member to fully pivot to its received position.

Owner:HYUNDAI MOTOR CO LTD

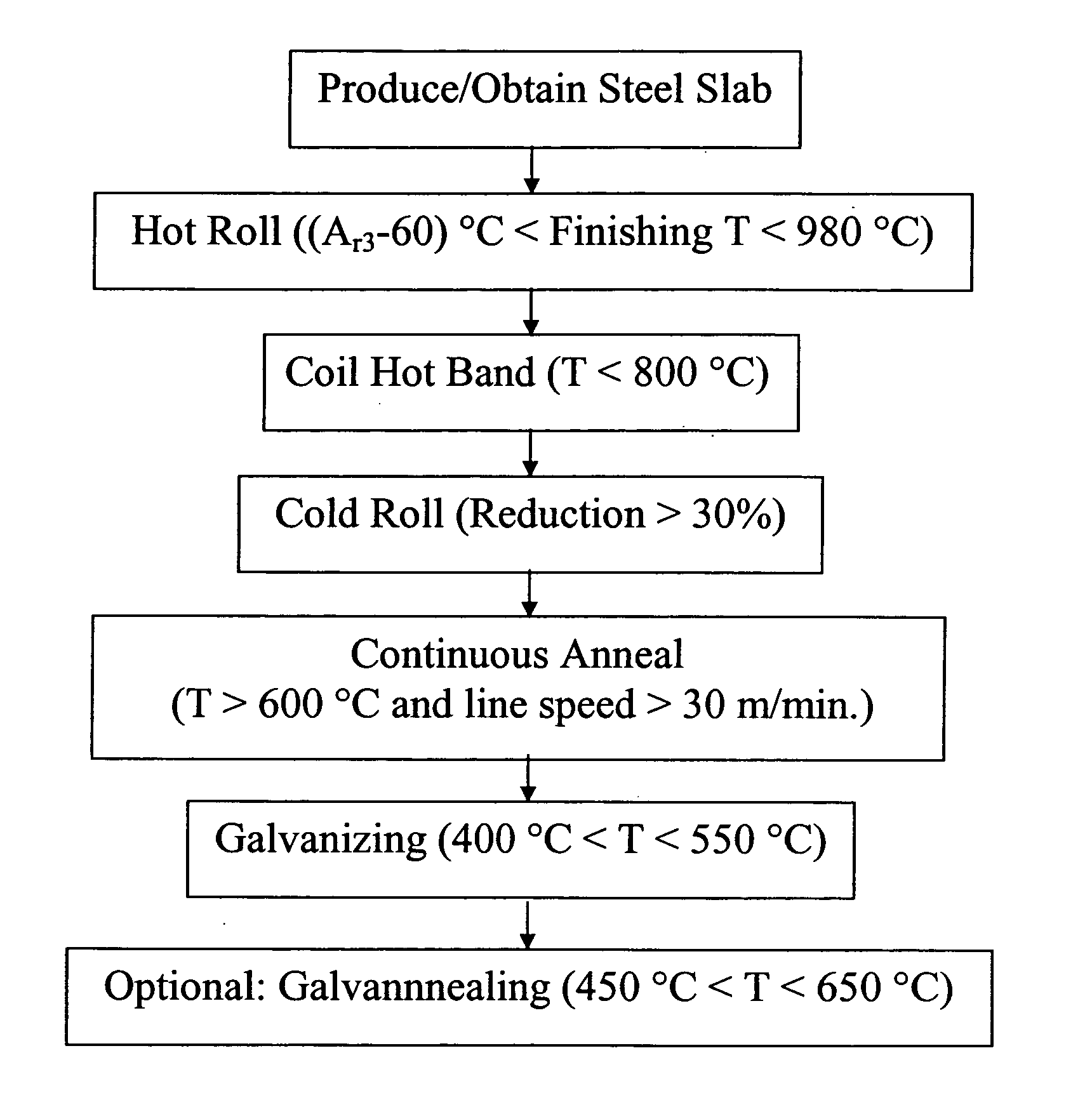

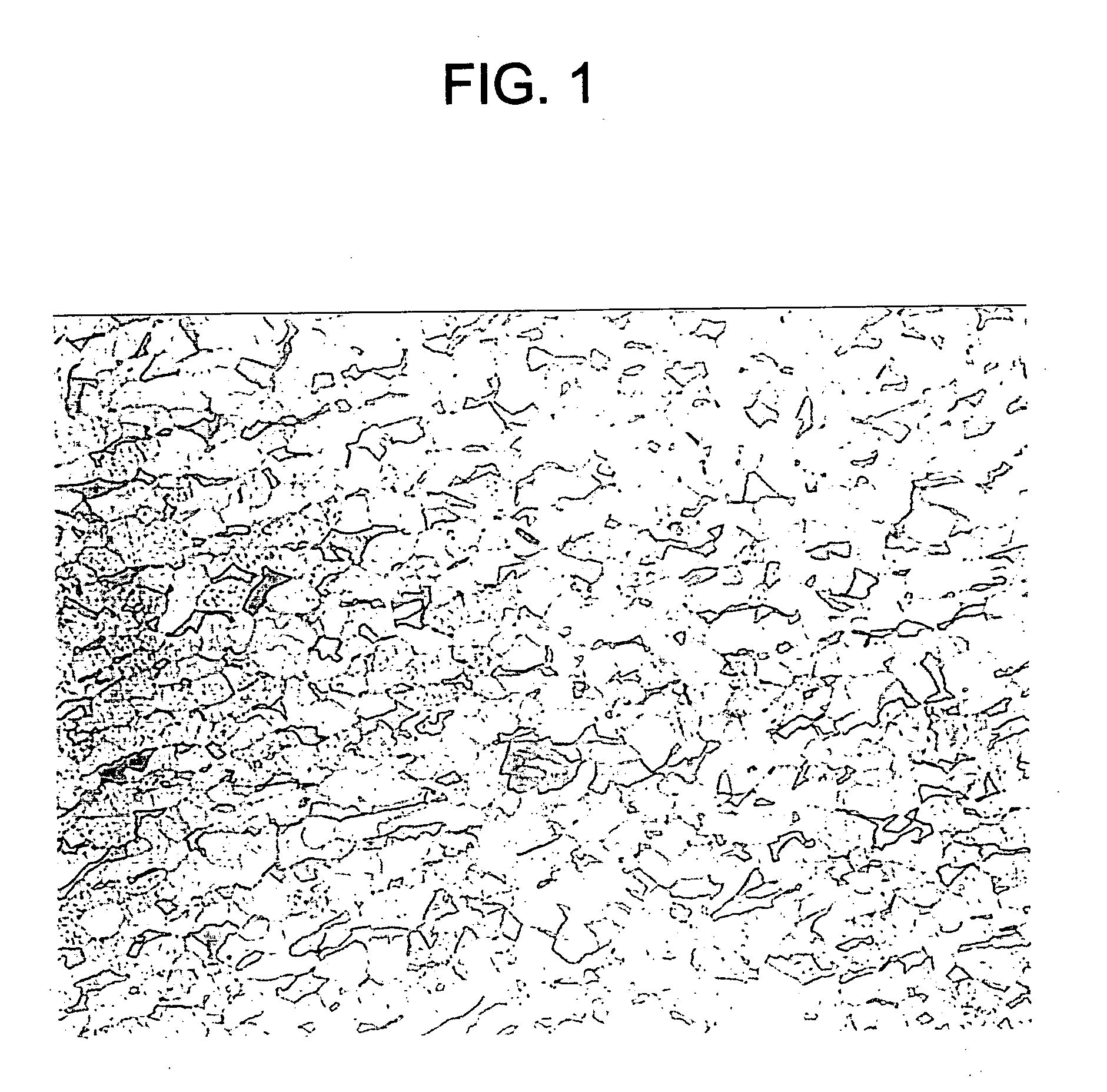

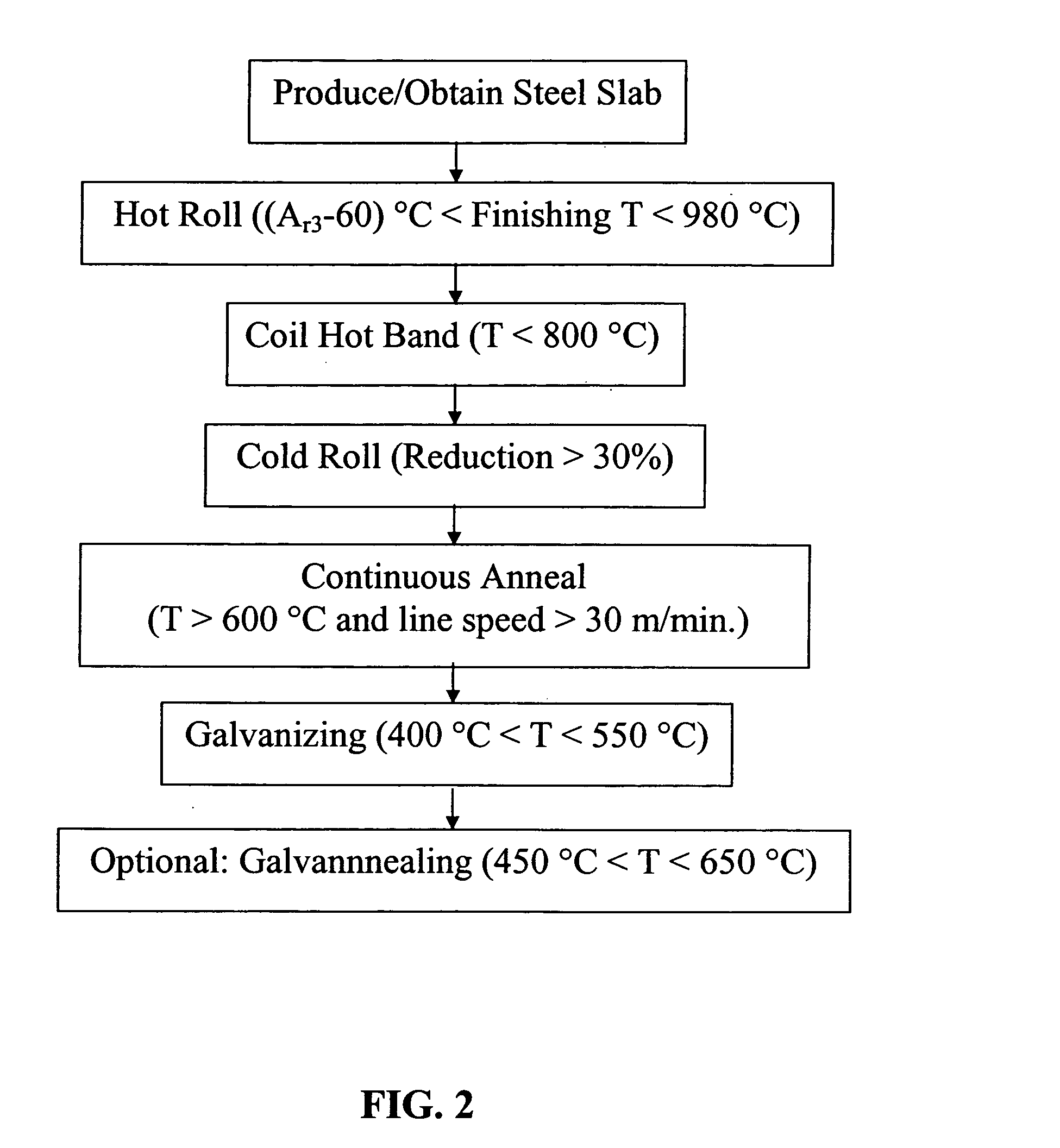

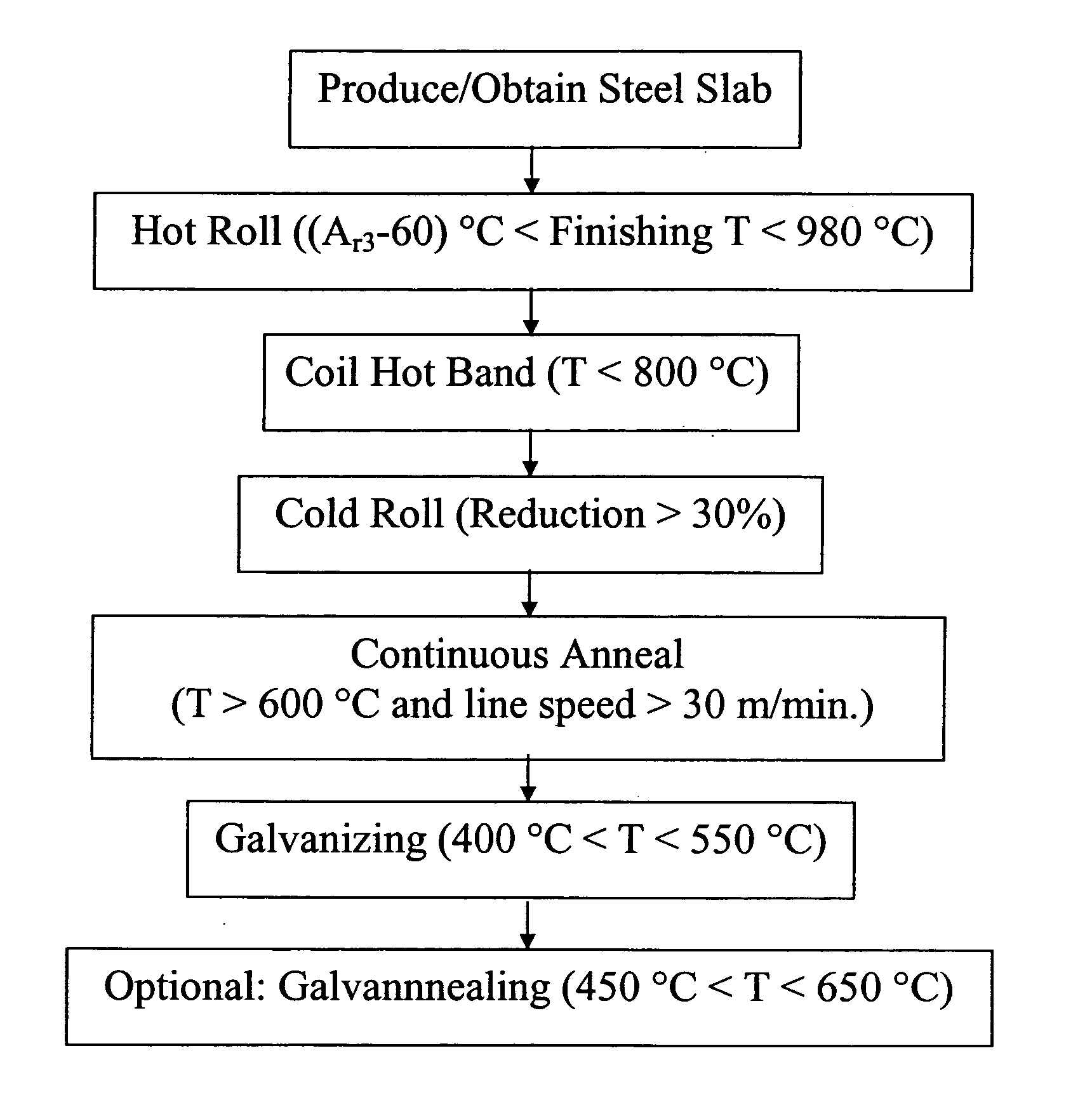

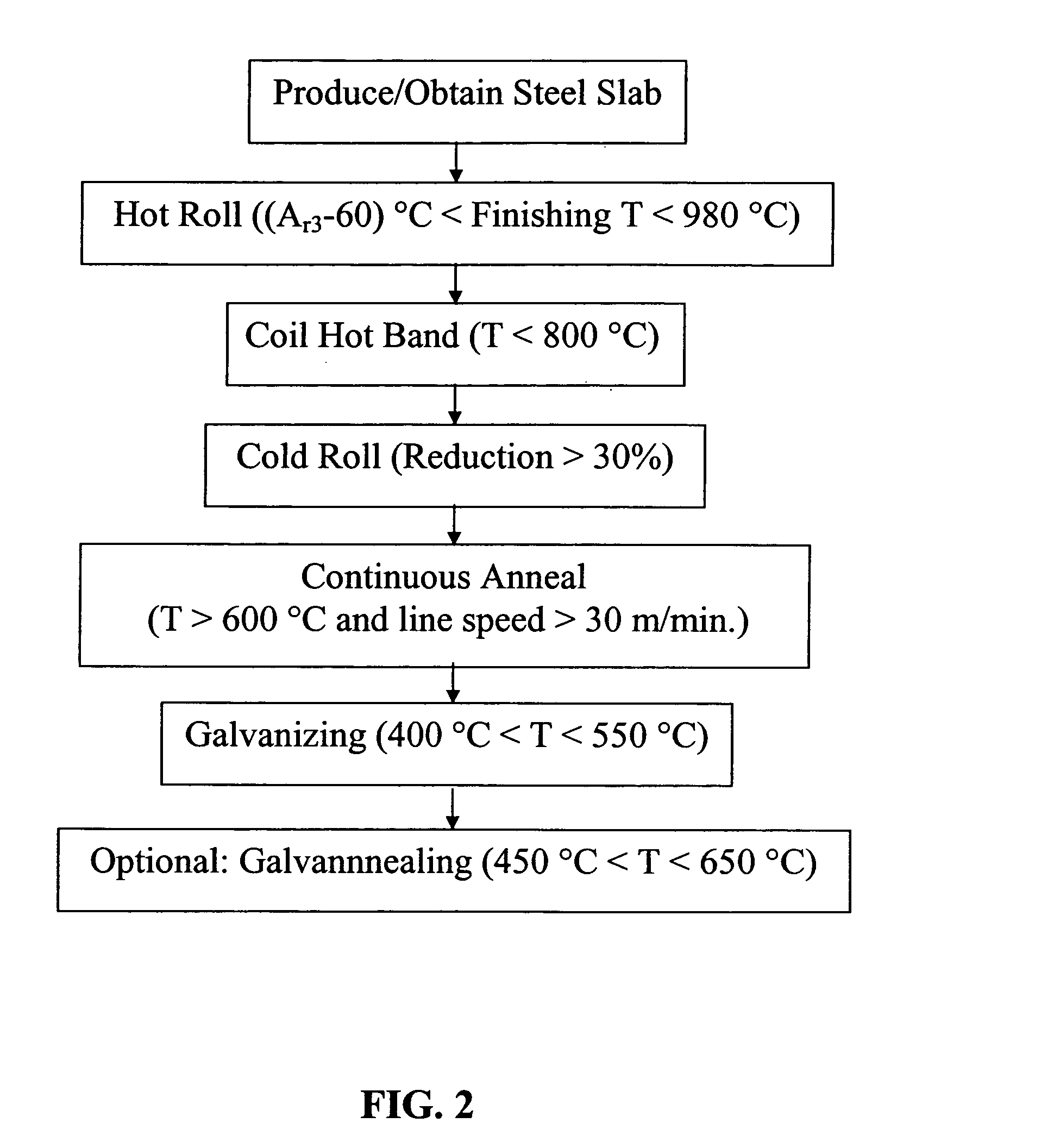

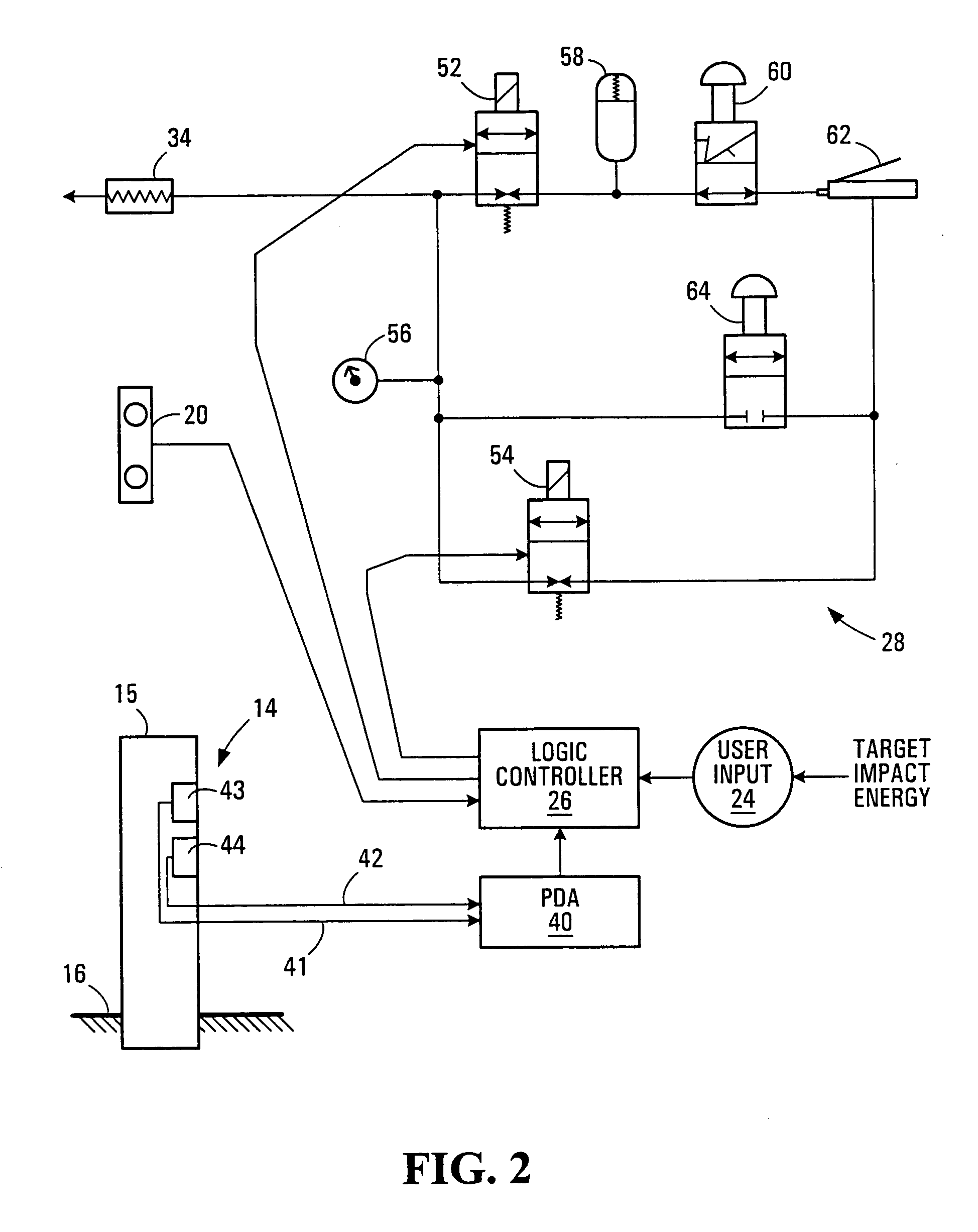

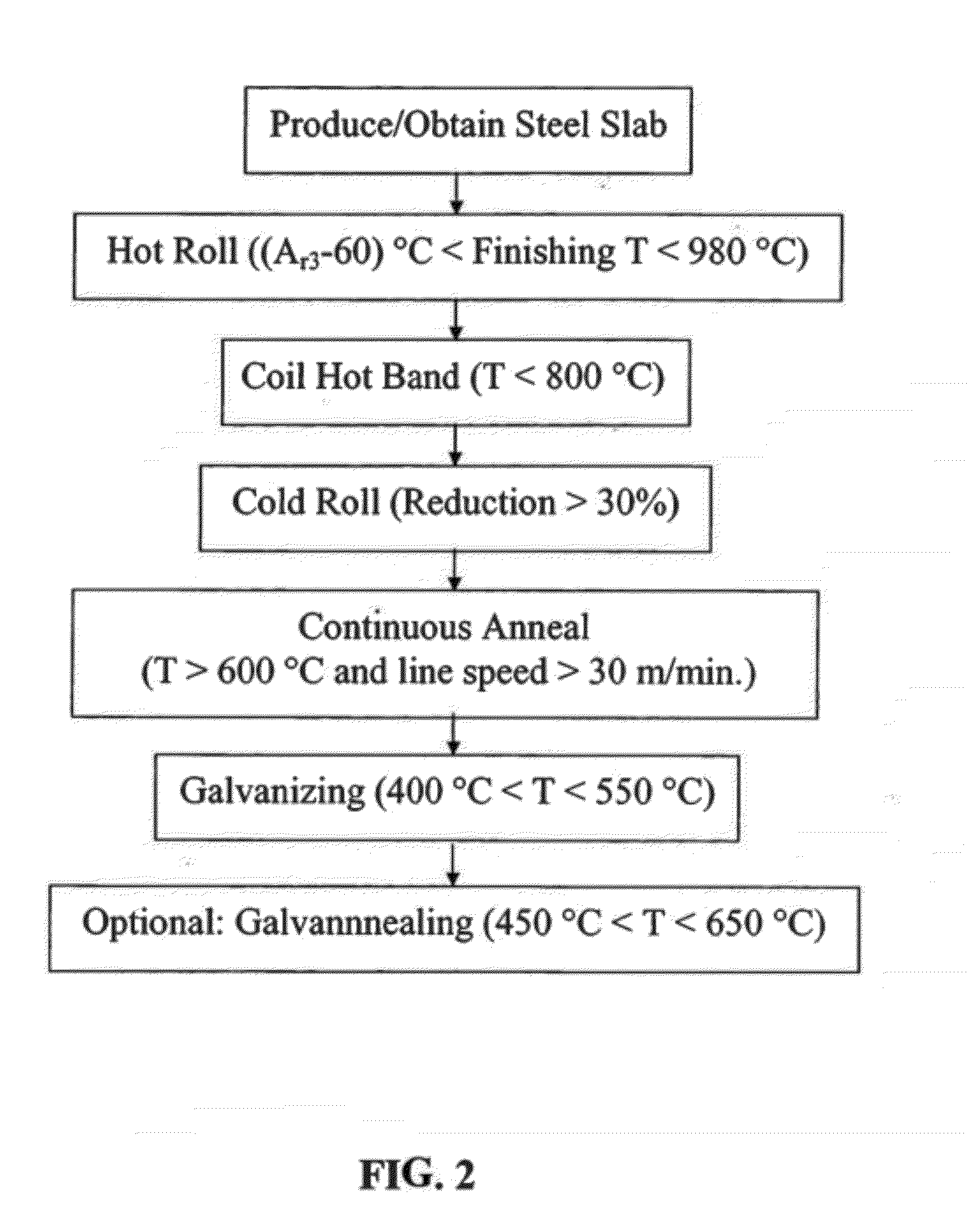

High strength, hot dip coated, dual phase, steel sheet and method of manufacturing same

ActiveUS20080075971A1Good energyGood formabilityHot-dipping/immersion processesFurnace typesNiobiumManganese

A galvanized steel sheet having (a) a dual phase microstructure with a martensite phase and a ferrite phase and (b) a composition containing by percent weight: carbon in a range from about 0.01% to about 0.18%; manganese in a range from about 0.2% to about 3%; silicon ≦ about 1.2%; aluminum in a range from about 0.01% to about 0.1%; one or both of chromium and nickel in a range from about 0.1% to about 3.5%; calcium in a range from about 0.0003% to about 0.01%; phosphorus ≦ about 0.01%; sulfur ≦ about 0.03%; nitrogen ≦ about 0.02%; molybdenum ≦ about 1%; copper ≦ about 0.8%; one or more of niobium, titanium, and vanadium ≦ about 1%; and boron ≦ about 0.006% by weight; and with the balance of the composition being iron and incidental ingredients. In one embodiment, the steel sheet is both galvanized and galvannealed.

Owner:NUCOR CORP

Glass reinforced polycarbonate-polyester composition

A thermoplastic resin composition is provided comprising a polycarbonate resin, polyester resin, and glass fibers which have been treated with polyolefin wax and optionally a functionalized silane. The nature of the coating on the glass fibers provides the composition with improved impact strength over bonding glass. The composition is useful as a molding material.

Owner:SABIC GLOBAL TECH BV

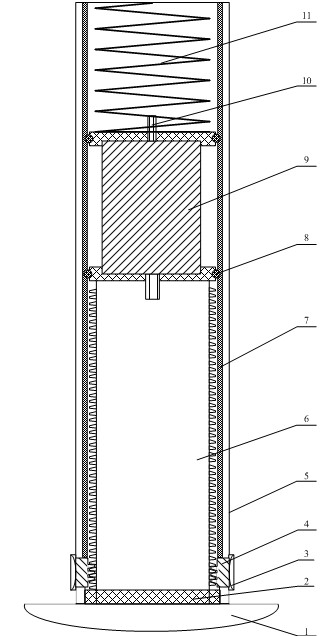

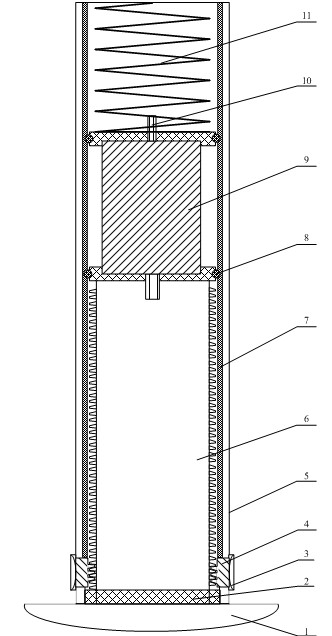

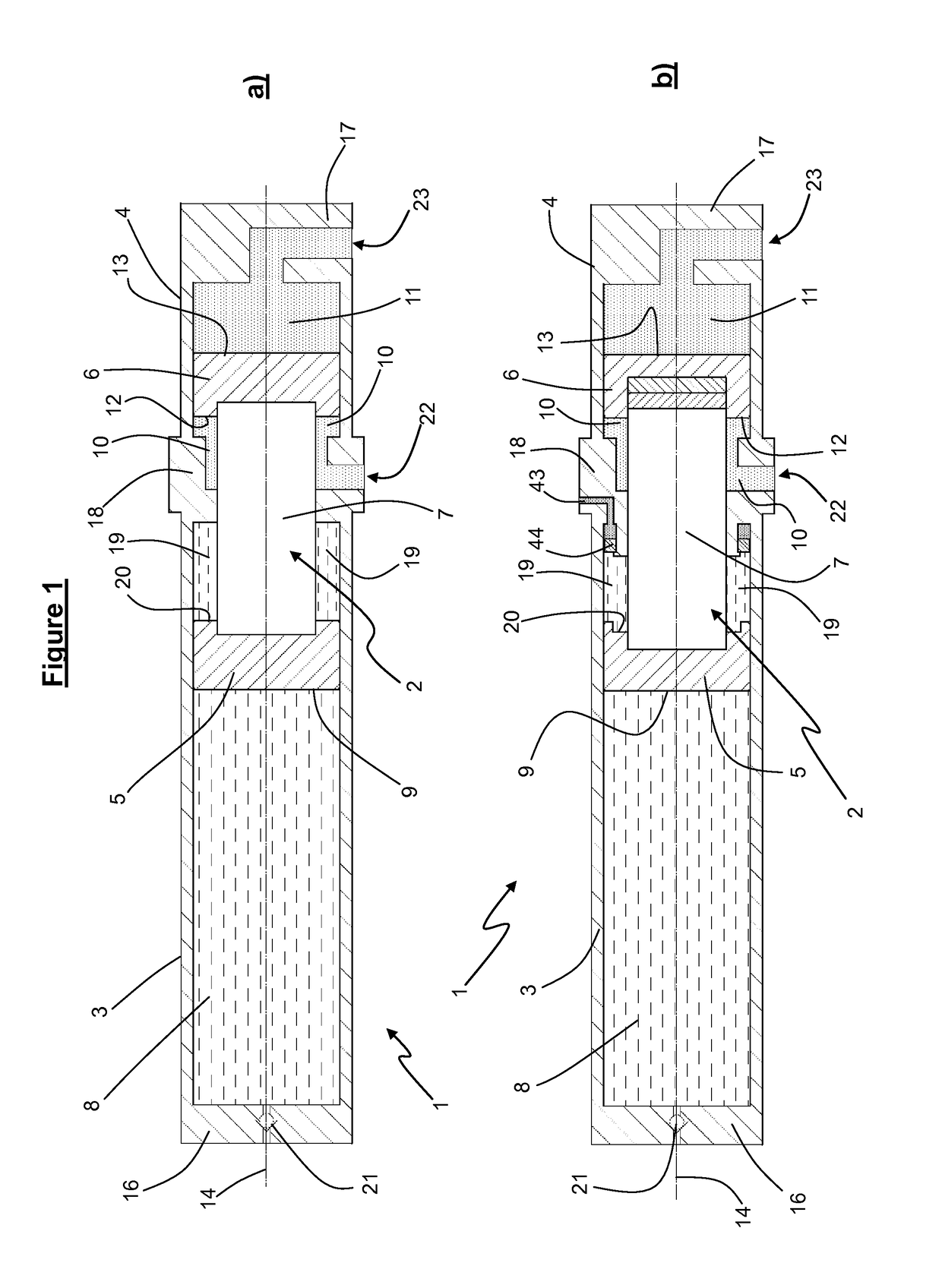

Buffer landing leg for planet detector

InactiveCN102060106AImprove structural rigiditySimple structureExtraterrestrial carsFoot cushionEngineering

The invention discloses a buffer landing leg for a planet detector, which comprises an outer cylinder, an inner cylinder and a foot cushion, wherein a guide rail is arranged on the inner wall of the outer cylinder, a rotating motor is arranged at the upper end of the inner cylinder, an output rotating shaft of the rotating motor is fixedly connected with the inner cylinder, a compression spring is arranged on the upper end of the rotating motor, the upper end of the compression spring is in contact with the top of the outer cylinder, two sides of the rotating motor are also provided with guide wheels matched with the guide rail; and the foot cushion is arranged at the lower end of the outer cylinder, helical convex teeth are arranged on the outer peripheral surface of the inner cylinder, and a pawl matched with the helical convex teeth is arranged on the outer cylinder and compressed in the helical convex teeth through an external elastic member. The invention has the advantages of no interference in processes of installation and movement of the landing leg mechanism, good structural rigidity, lighter mass, simple structure, convenience of processing, long service life, high reliability and capability of absorbing higher impact energy and realizing self-repairing function of buffer postures.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

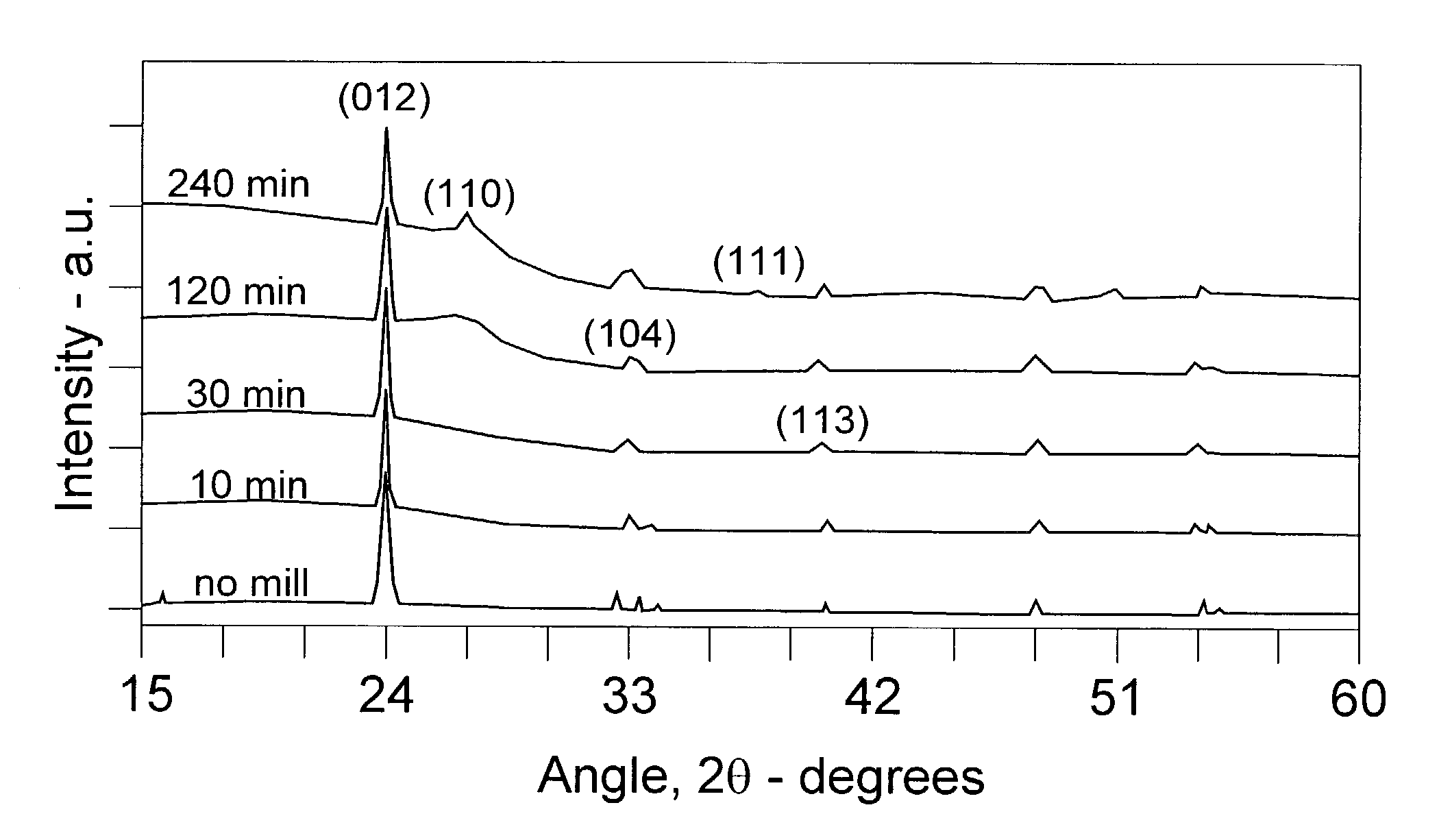

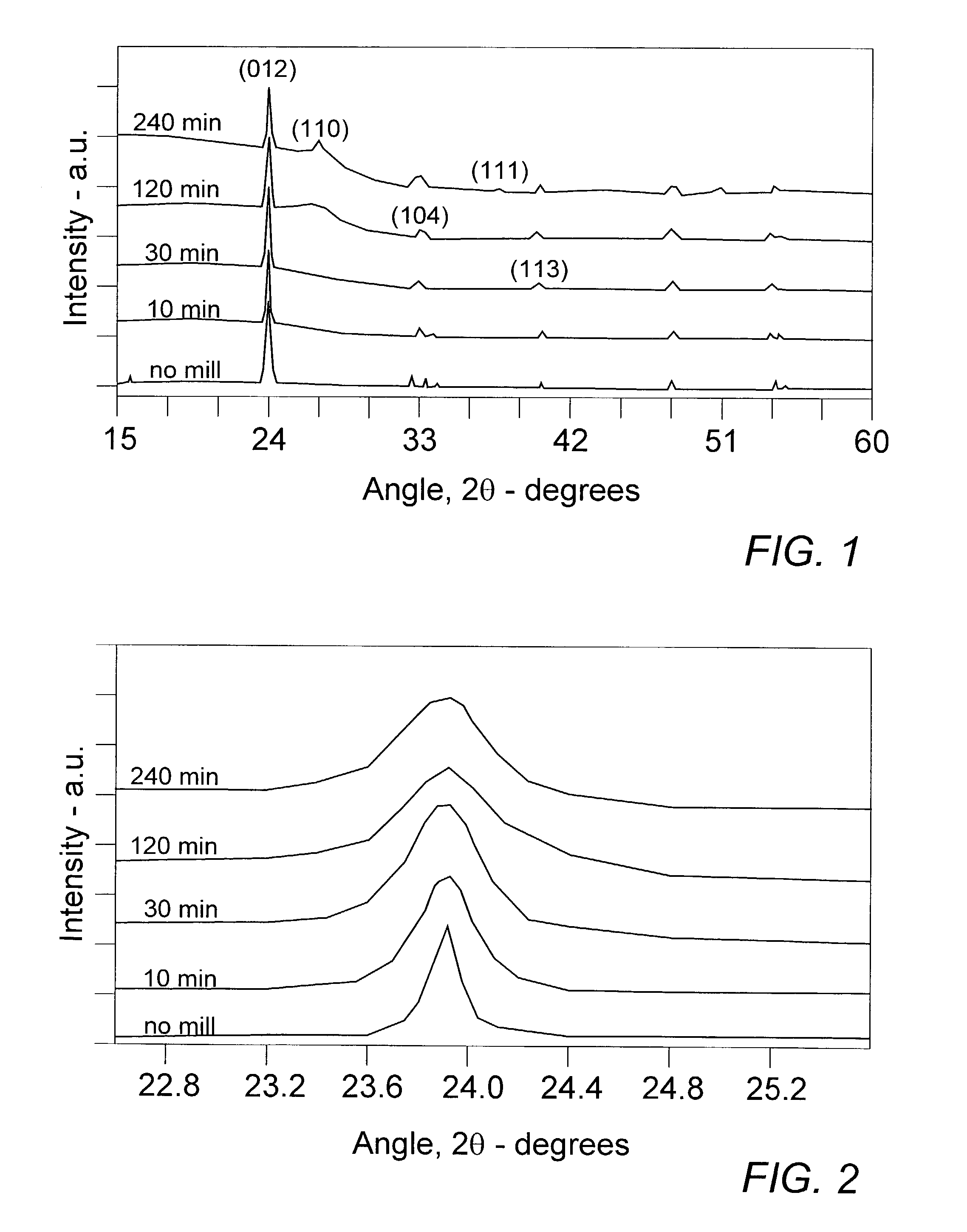

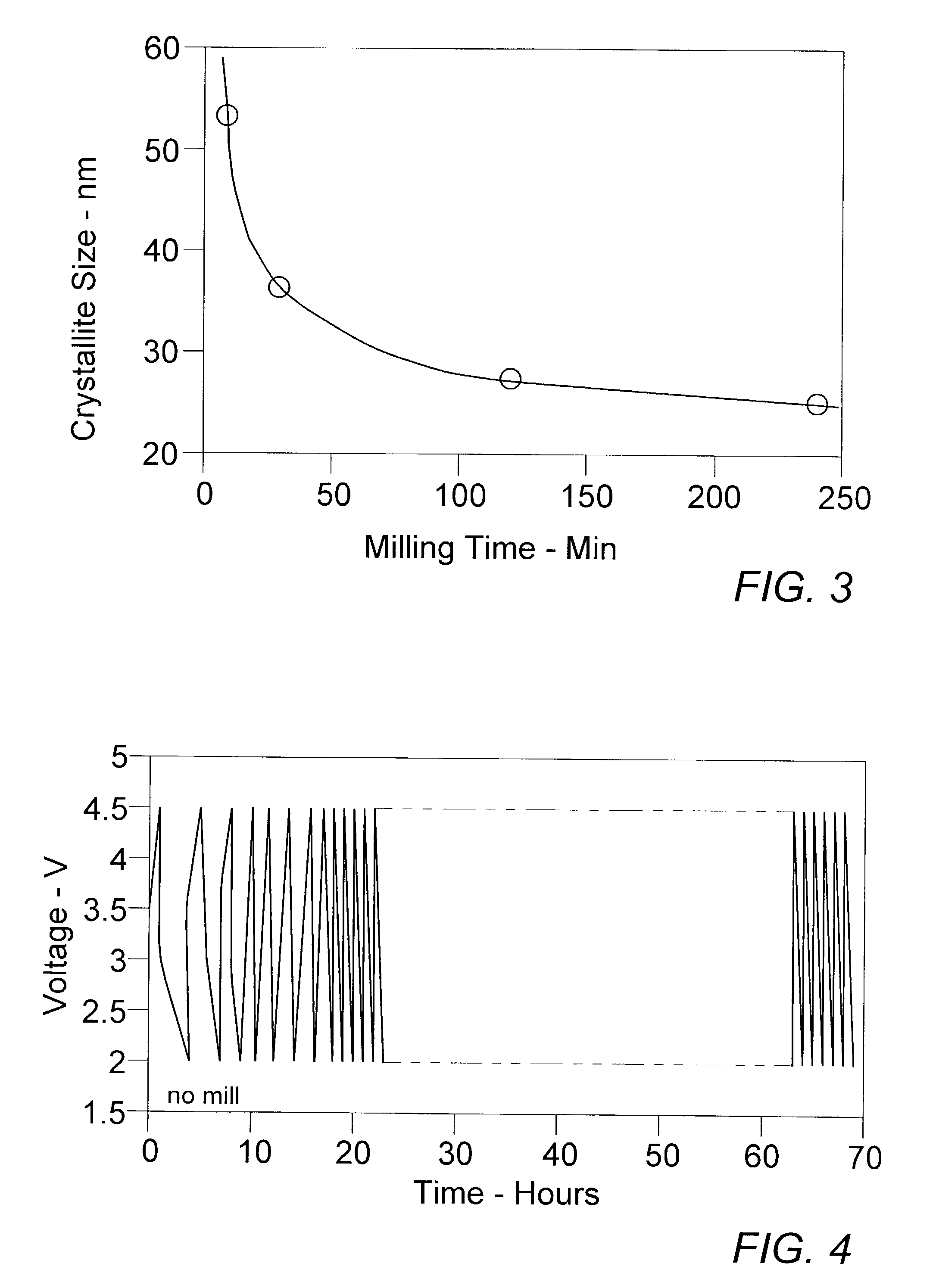

Transition metal fluoride: carbon nanoamalgam rechargeable battery cell electrode material

ActiveUS7625671B2Improve conductivityHigh ionicityOrganic electrolyte cellsPositive electrodesCell fabricationHigh energy

A safe and economical electrochemically active material useful in rechargeable battery cell electrode compositions comprises a nanostructure amalgam of a transition metal fluoride and carbon. The nanoamalgam may be prepared by subjecting a precursor mixture of a transition metal fluoride, such as FeF3, and carbon to extreme, high energy impact comminution milling which results in the conversion of the mixture to a unique and distinct nanostructure material. When incorporated as active electrode material in lithium battery cell fabrications, the nanoamalgam enables the attainment of stable specific discharge capacities in the range of 250 to 500 mAh / g.

Owner:RUTGERS THE STATE UNIV

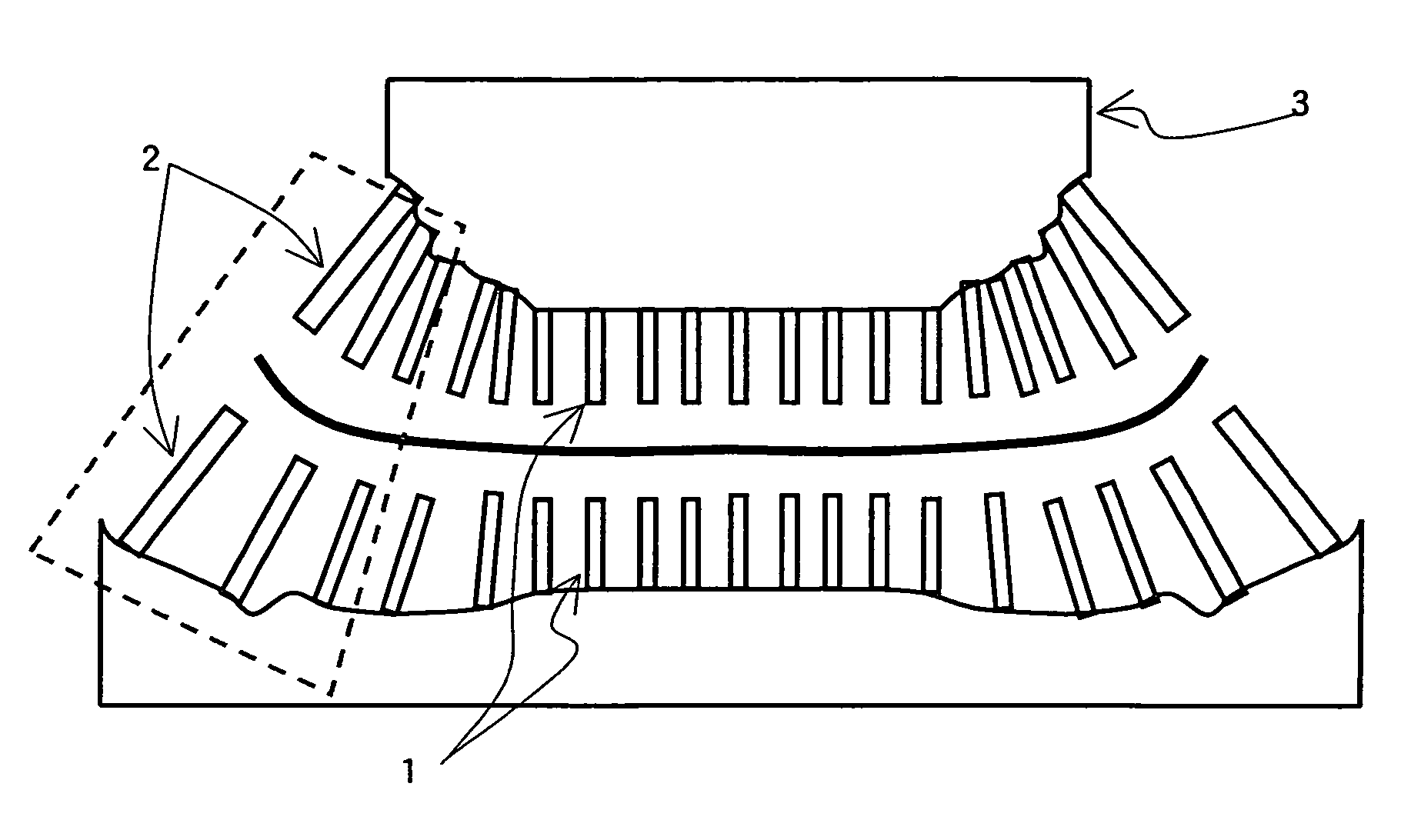

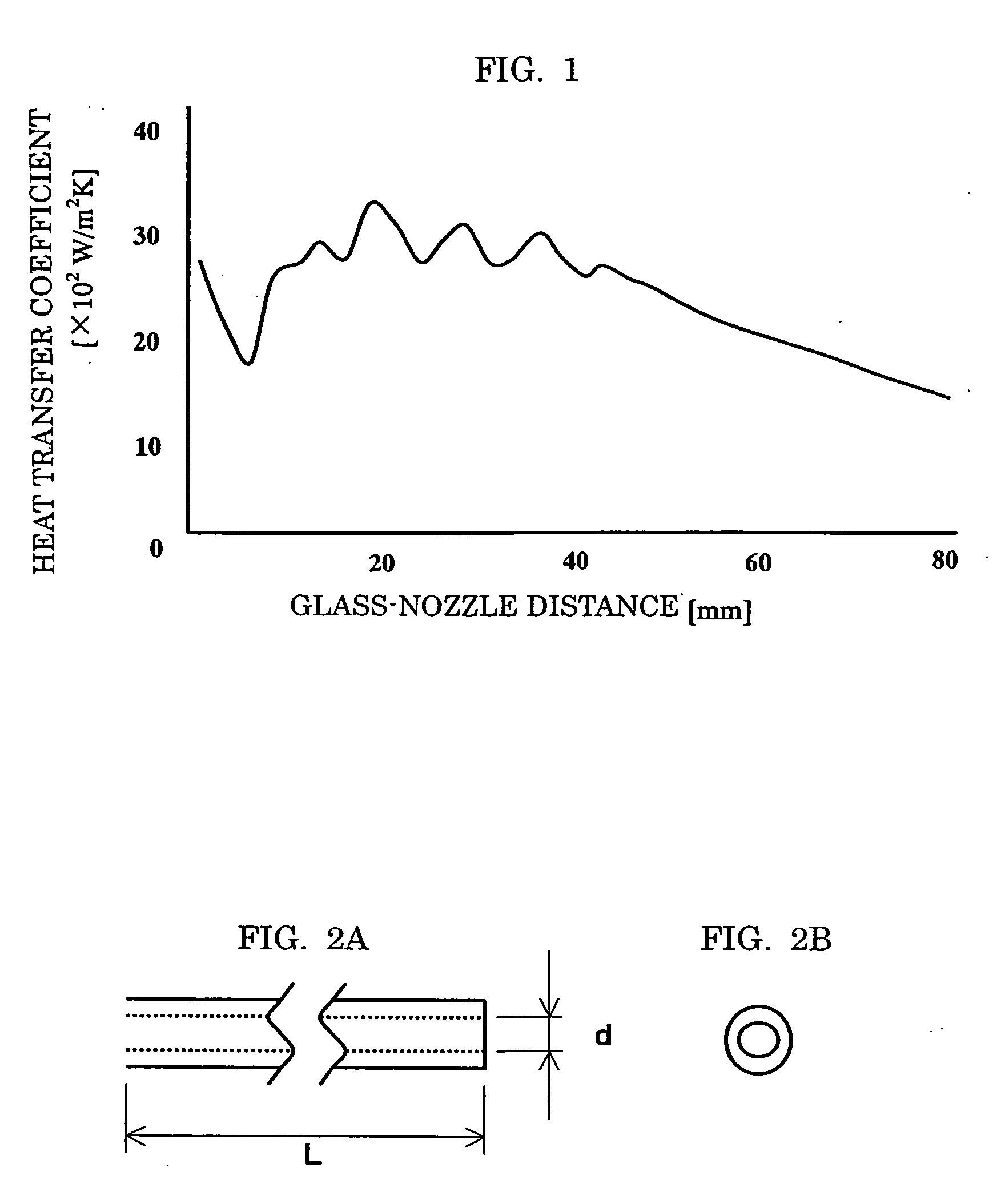

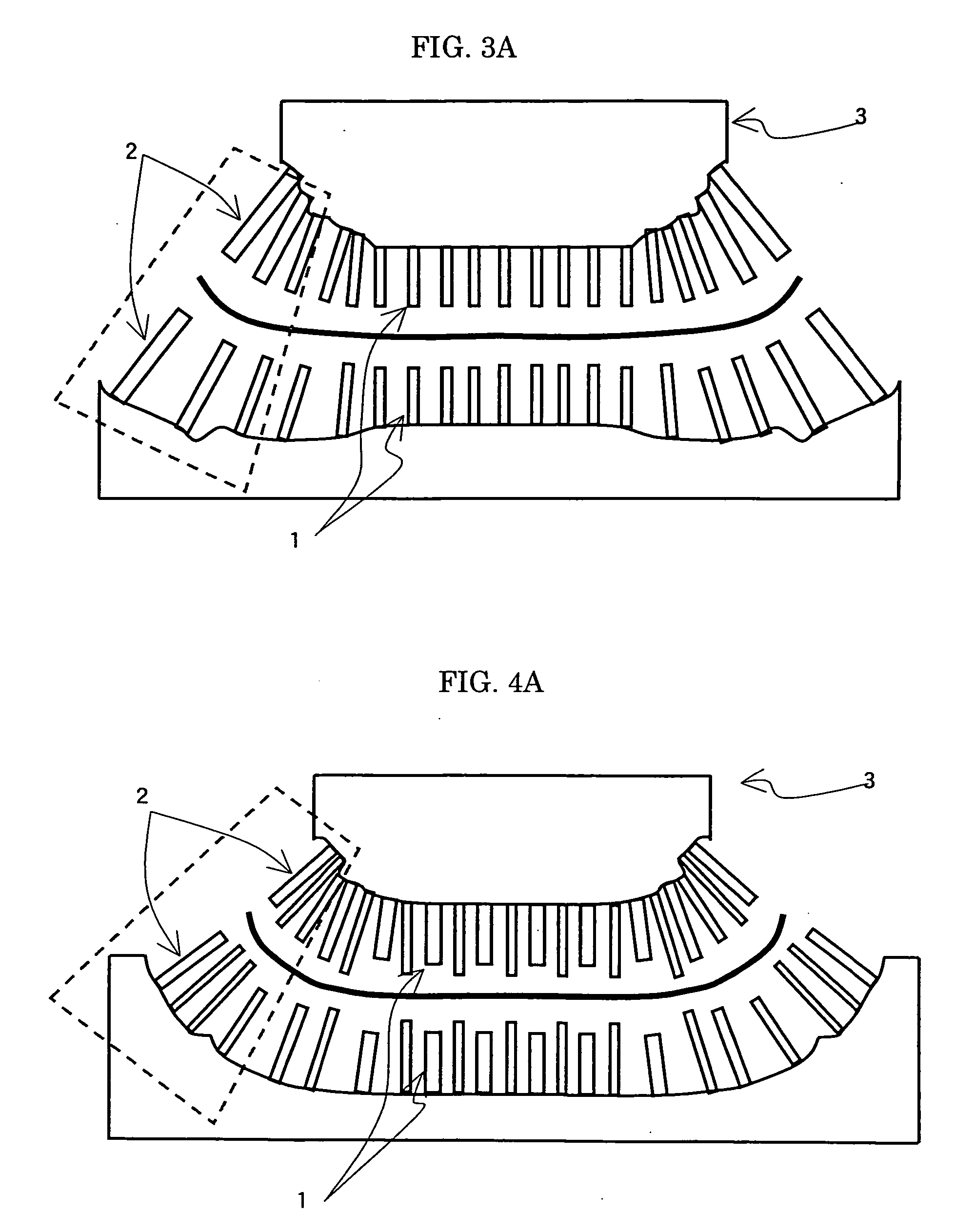

Thermally tempered glass, and method and apparatus for manufacturing the glass

InactiveUS20060121281A1Stable productionReduce distanceGlass/slag layered productsGlass tempering apparatusQuenchingCurve shape

The invention relates, in case that a thermally tempered glass is produced by allowing an impact jet flow from quenching nozzles to blow against the glass, to a process for producing a curved shape, thermally tempered glass, characterized in that a quenching is conducted by simultaneously using at least two types of quenching nozzles having different exit diameters of the quenching nozzles. Furthermore, the invention relates to a curved, thermally tempered glass produced by this process and to an apparatus for producing the thermally tempered glass. In the invention, it is preferable that a exit diameter d is from φ1 mm to φ8 mm, a distance Z between the nozzle and the glass is 1 to 80 mm, a chamber pressure P is in a range of 0.1 to 0.8 MPa, and a heat flux difference is 150 kW / m2 or less. Furthermore, in the thermally tempered glass, it is preferable that a difference of surface compressive stress values within a glass surface is 20 MPa or less.

Owner:CENT GLASS CO LTD

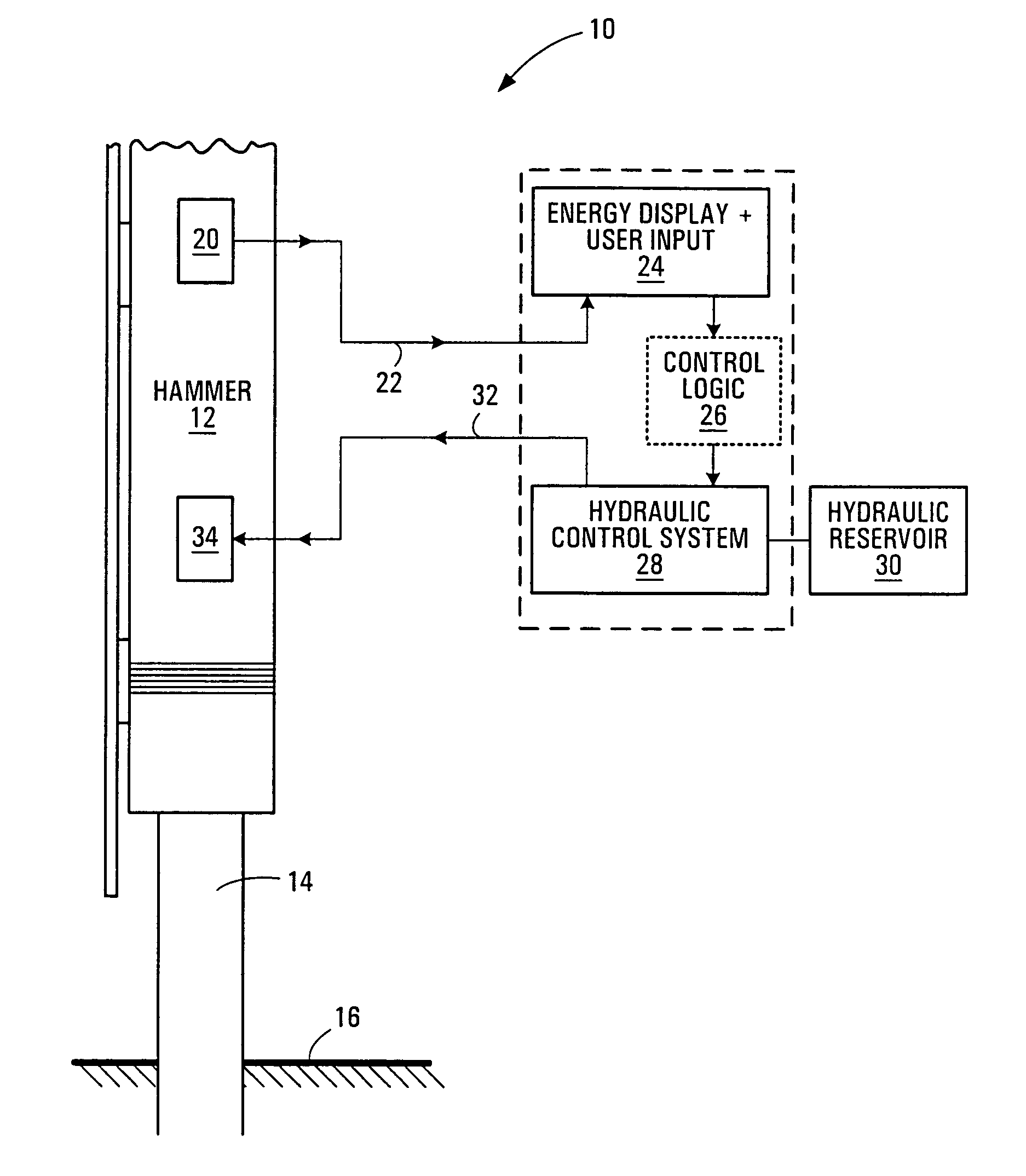

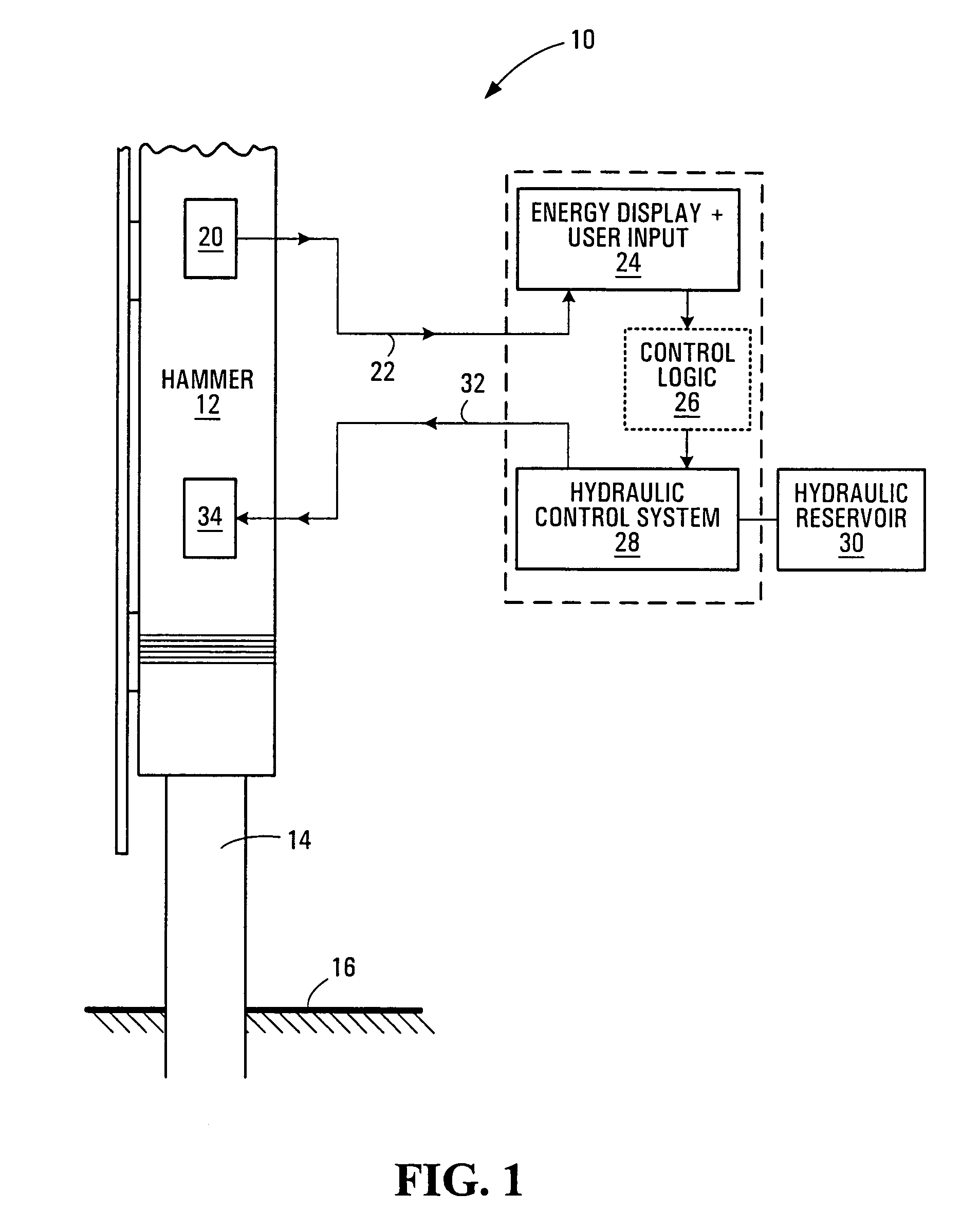

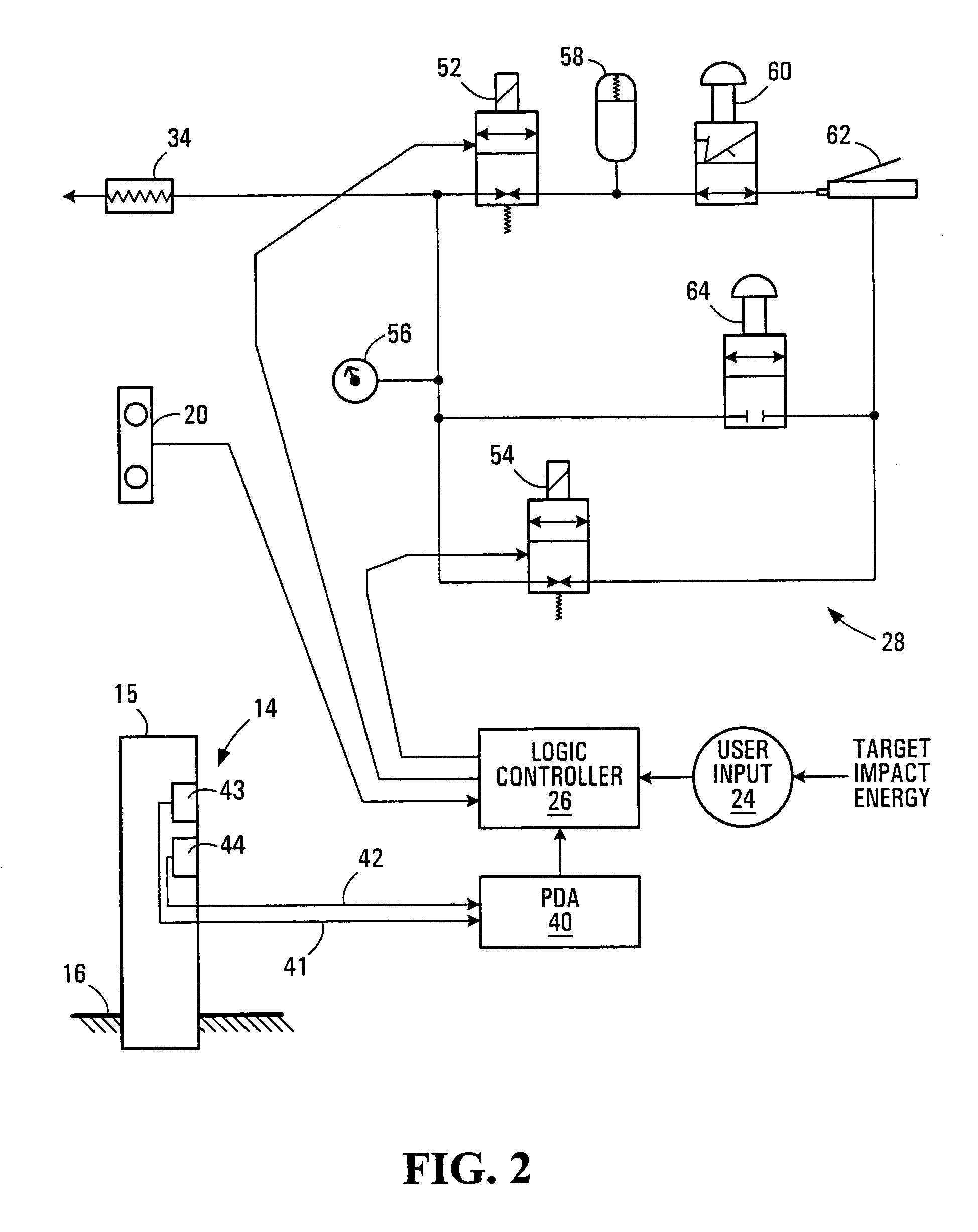

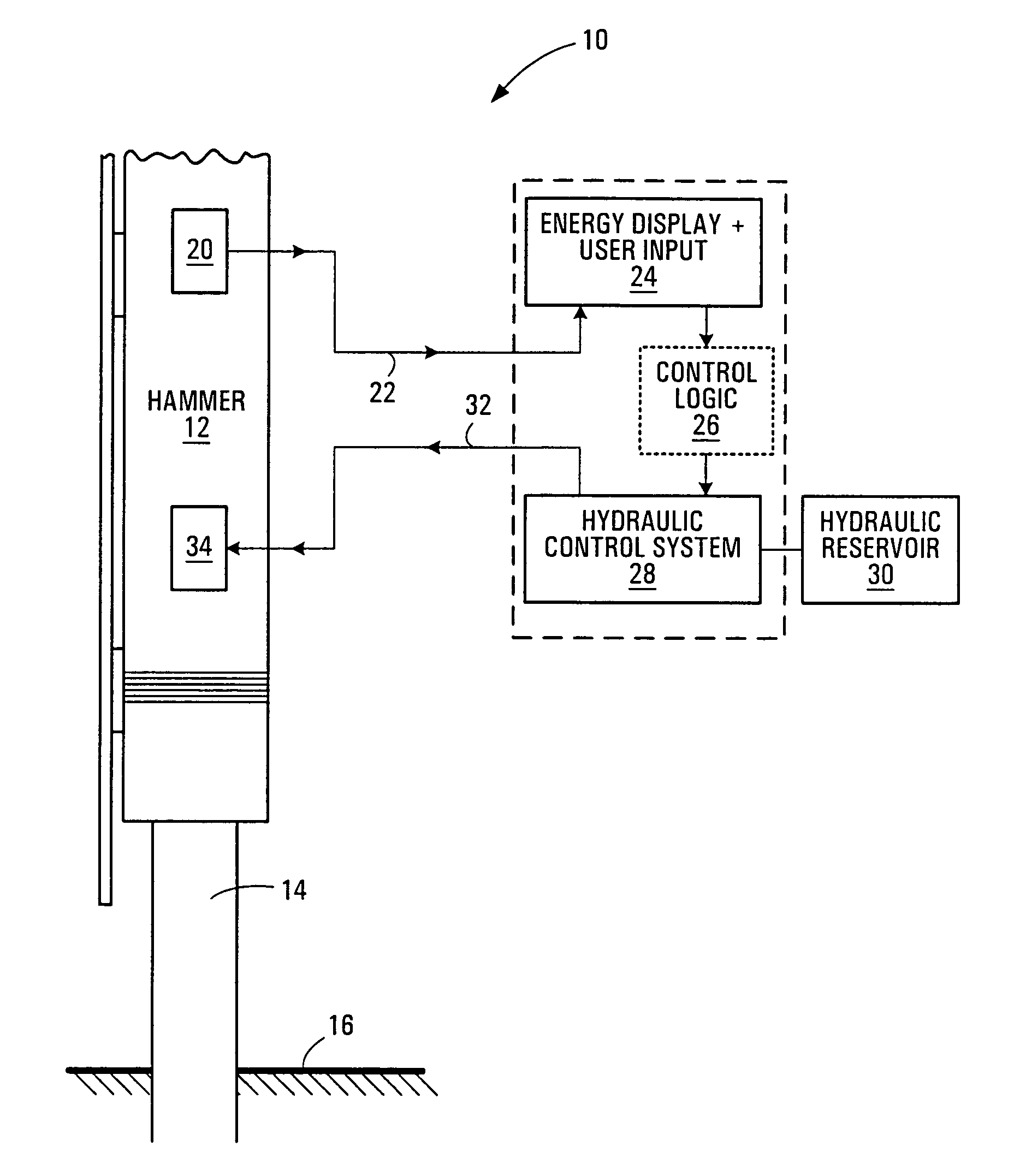

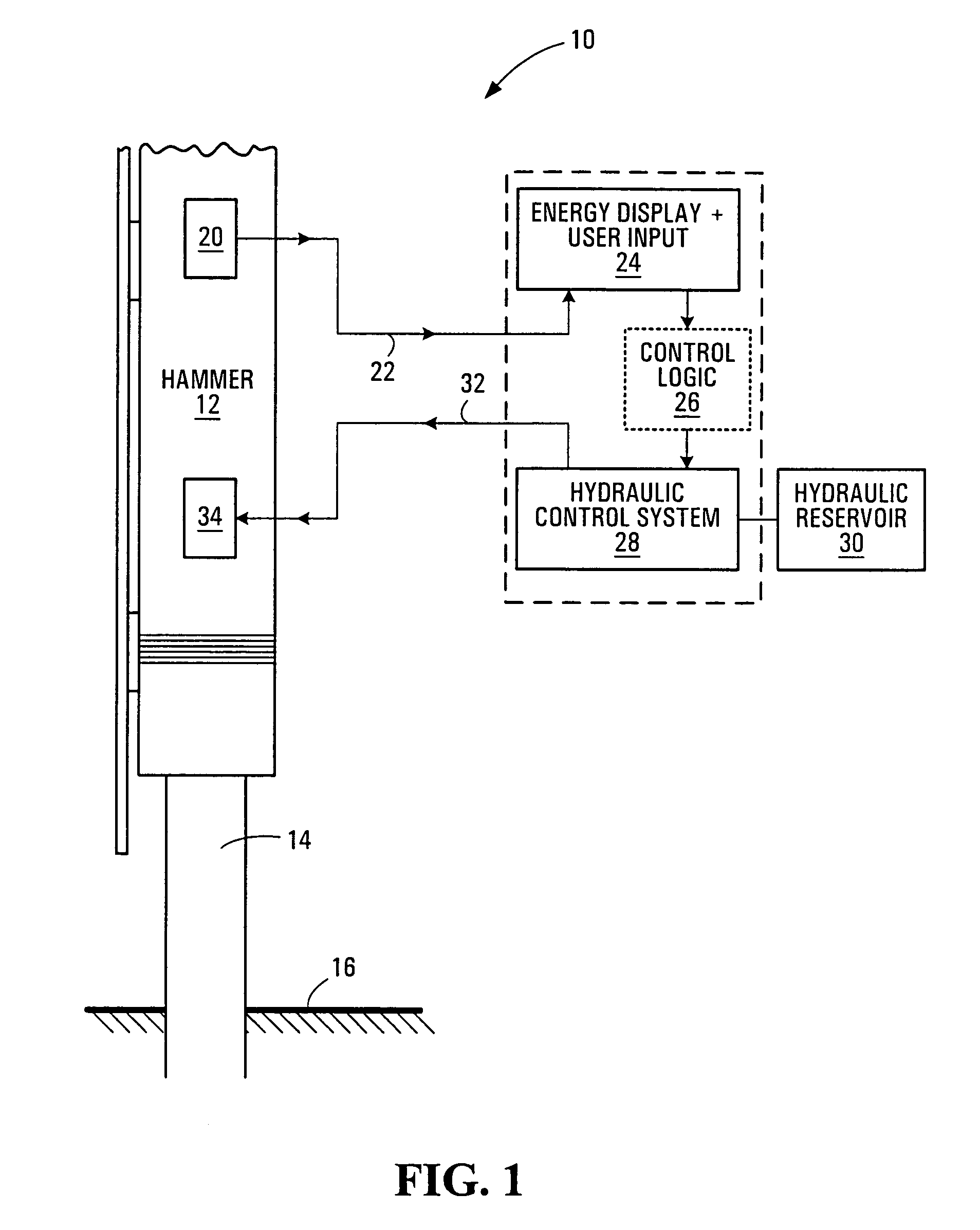

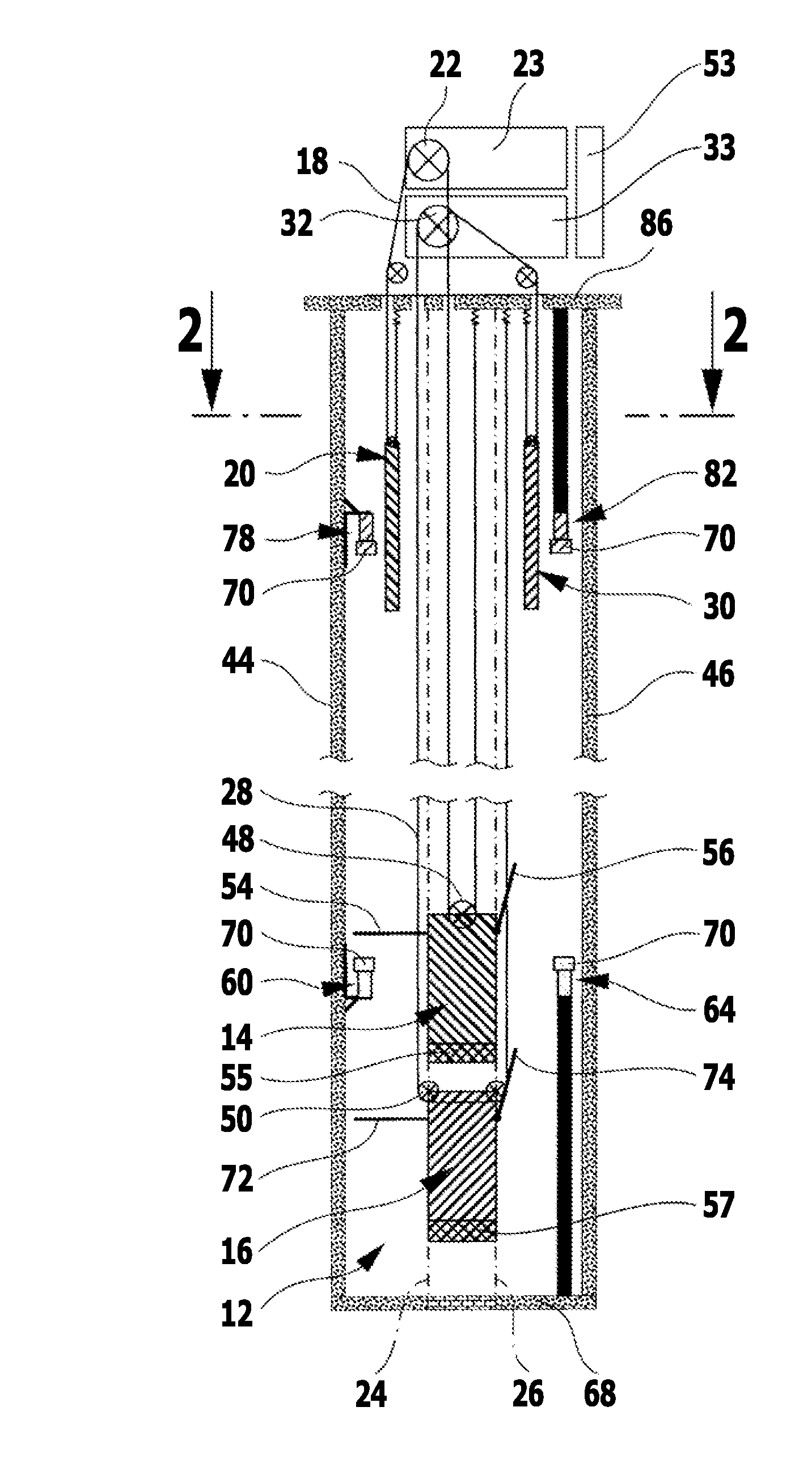

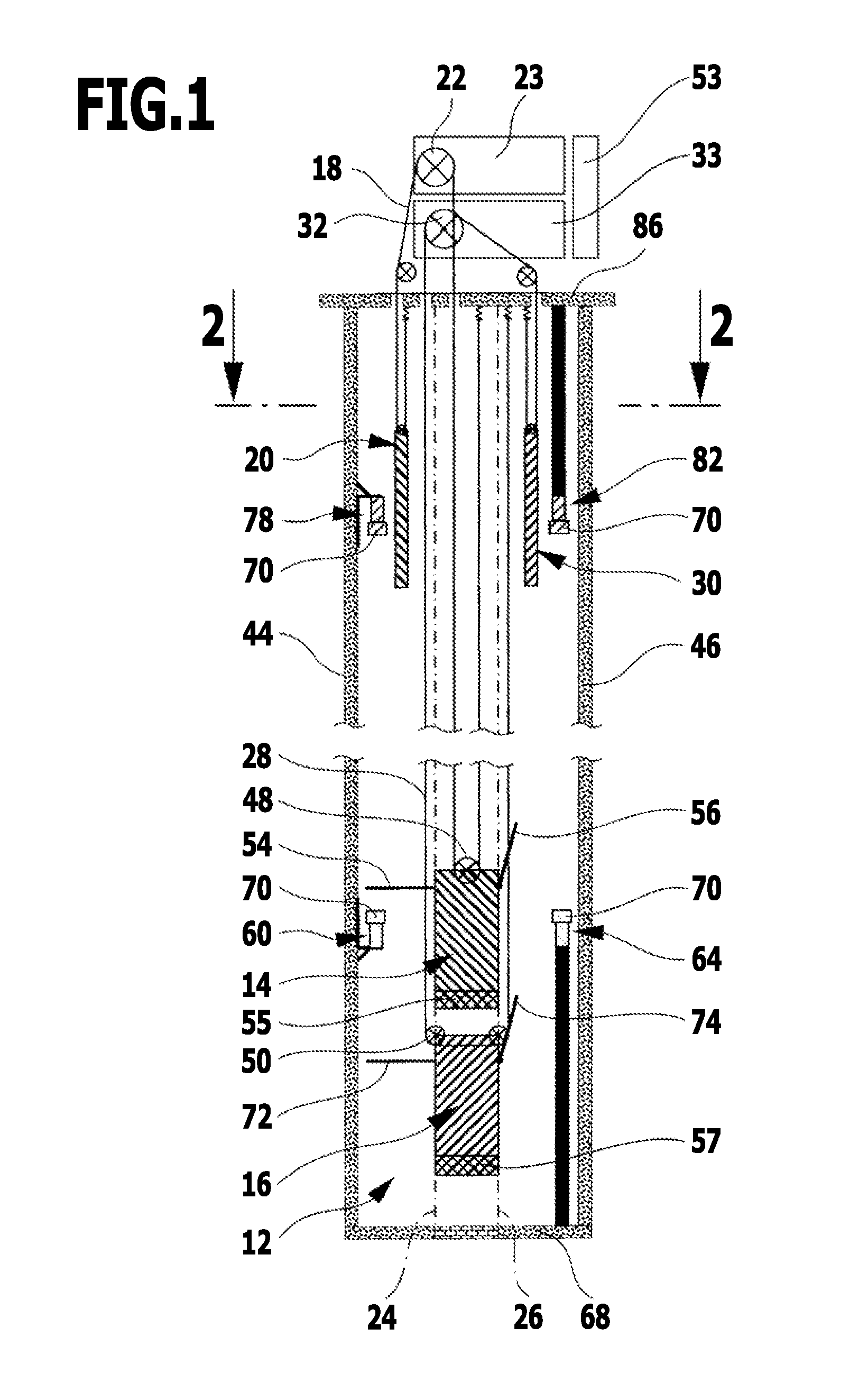

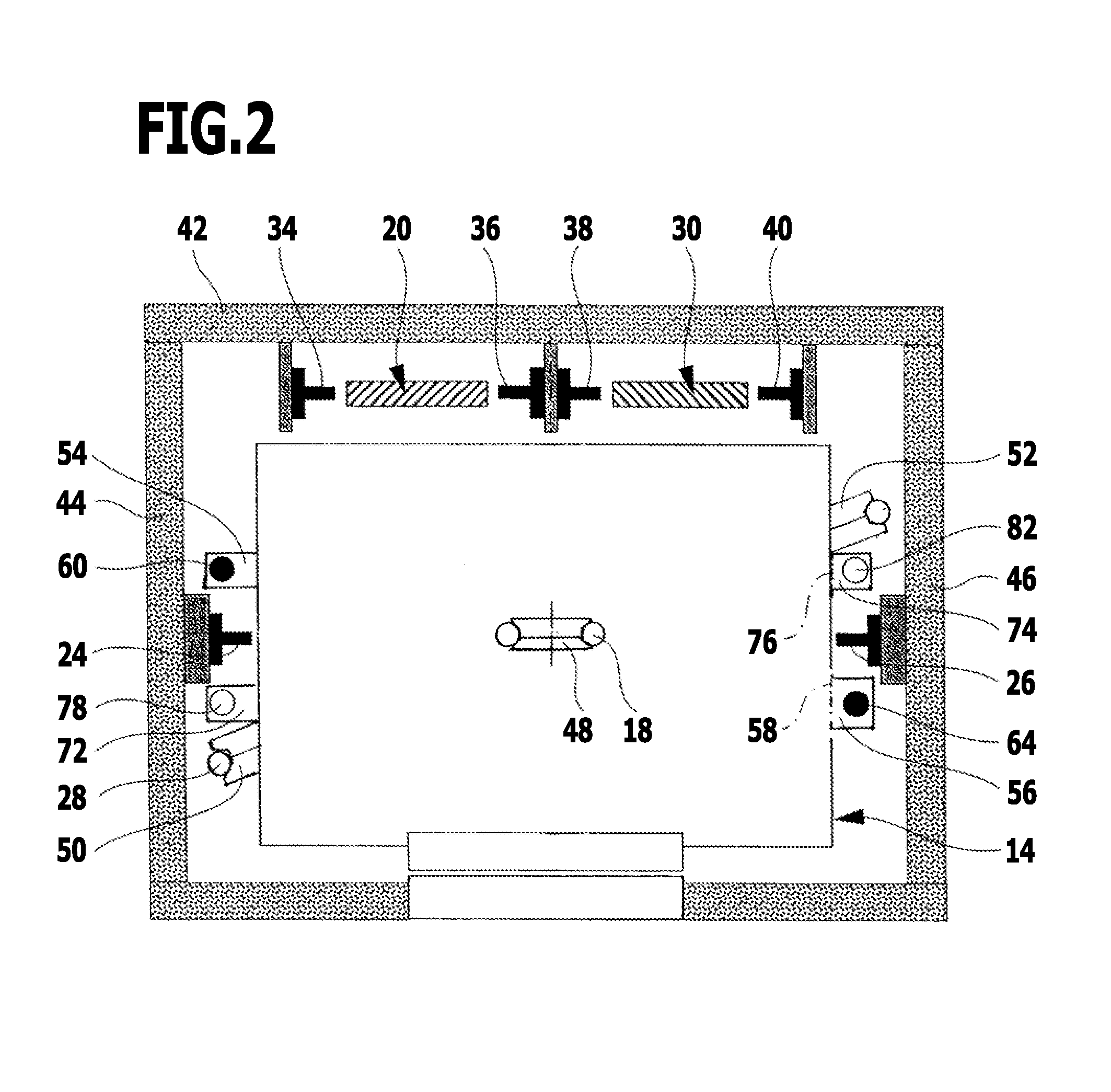

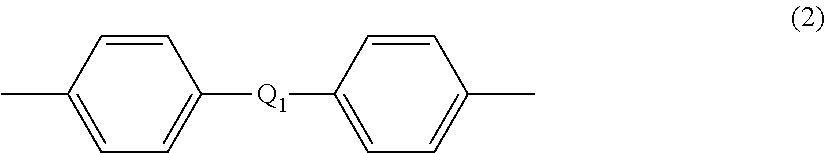

Pile driver with energy monitoring and control circuit

ActiveUS7156188B2Efficient driveIncrease impact energyReciprocating drilling machinesDerricks/mastsAccelerometerControl system

A pile driver comprises a hammer for impacting a pile, a velocity sensor for measuring the velocity at impact, and a control system for adjusting the hammer stroke in accordance with the readings from the velocity sensor so that the optimal impact energy is imparted to the head of the pile. Optionally, the system further comprises a pile driving analyzer (including at least one strain gauge and / or an accelerometer) mounted on the side of the pile itself to determine whether the impact loading on the pile is below the maximum allowable stress. If the pile driving analyzer senses an overload of stress on the pile, the control system will reduce the velocity of the subsequent hammer stroke so that it no longer exceeds the maximum allowable stress.

Owner:BERMINGHAM FOUND SOLUTIONS LTD

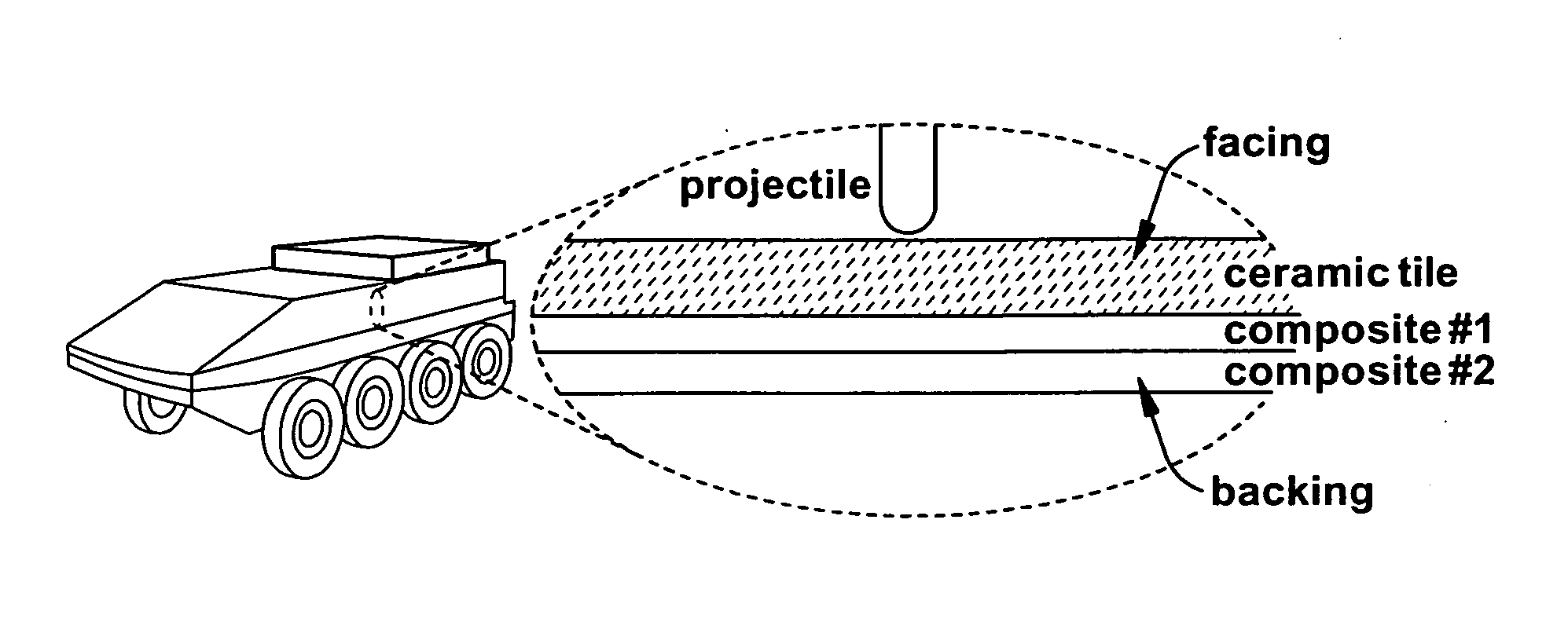

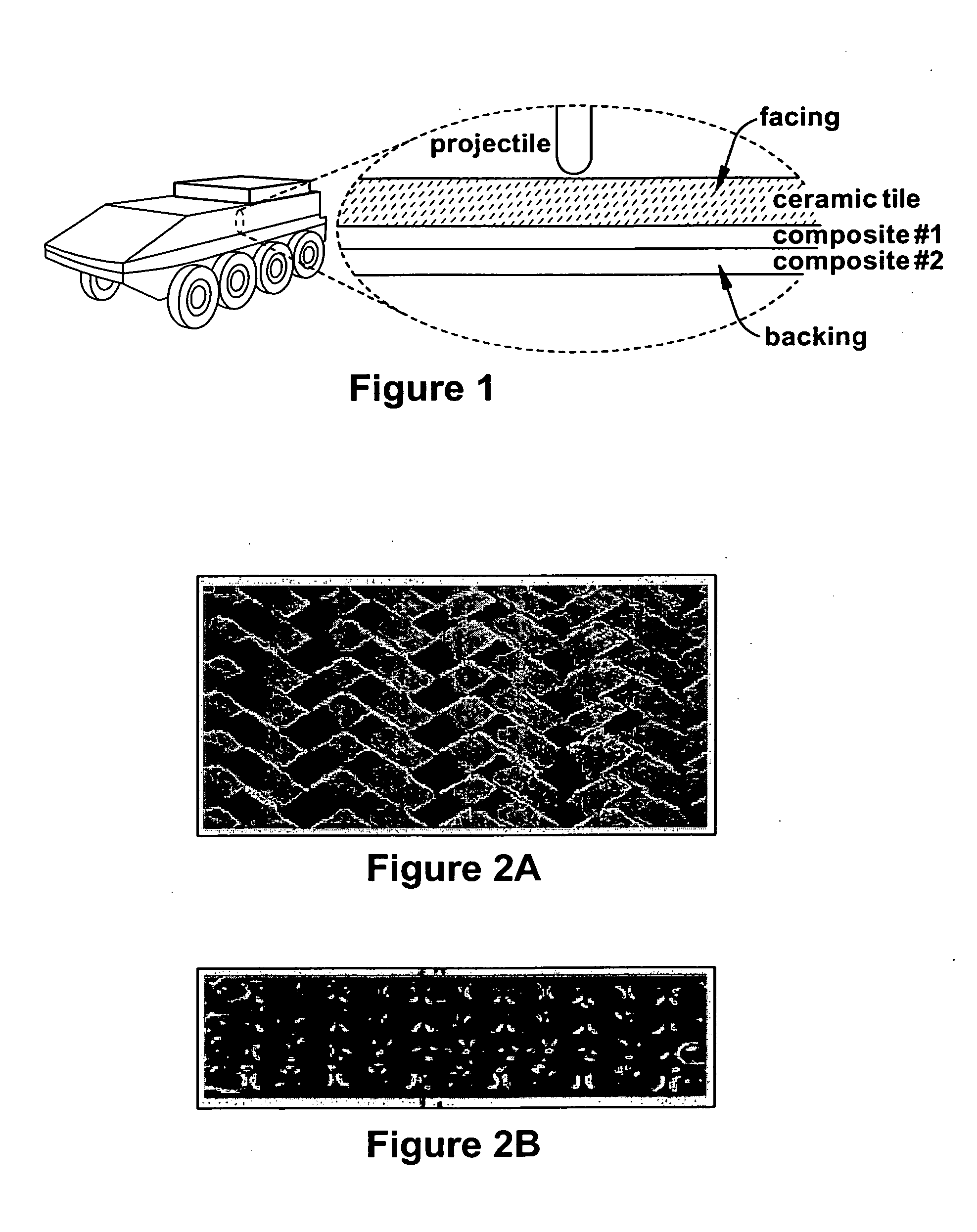

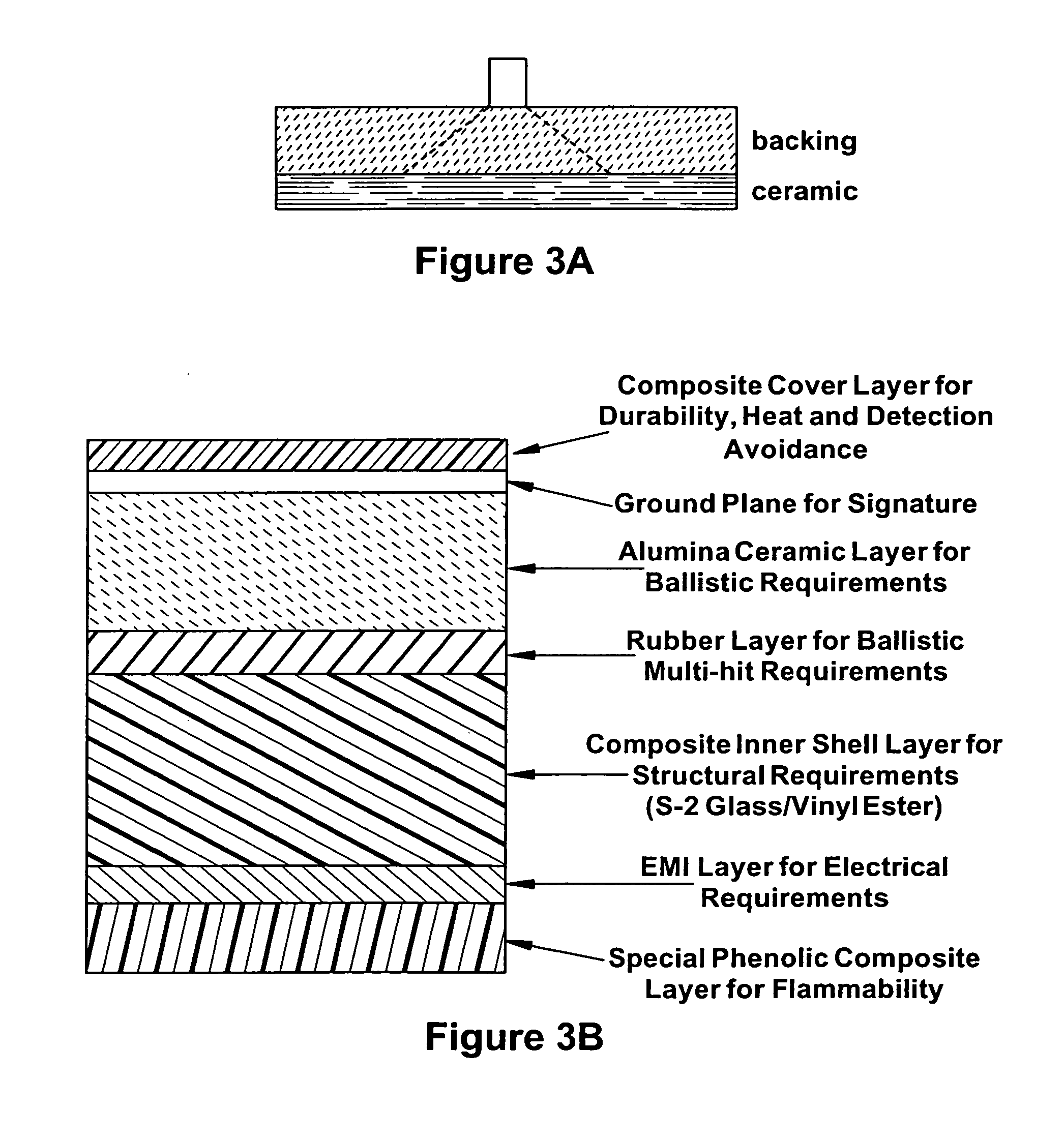

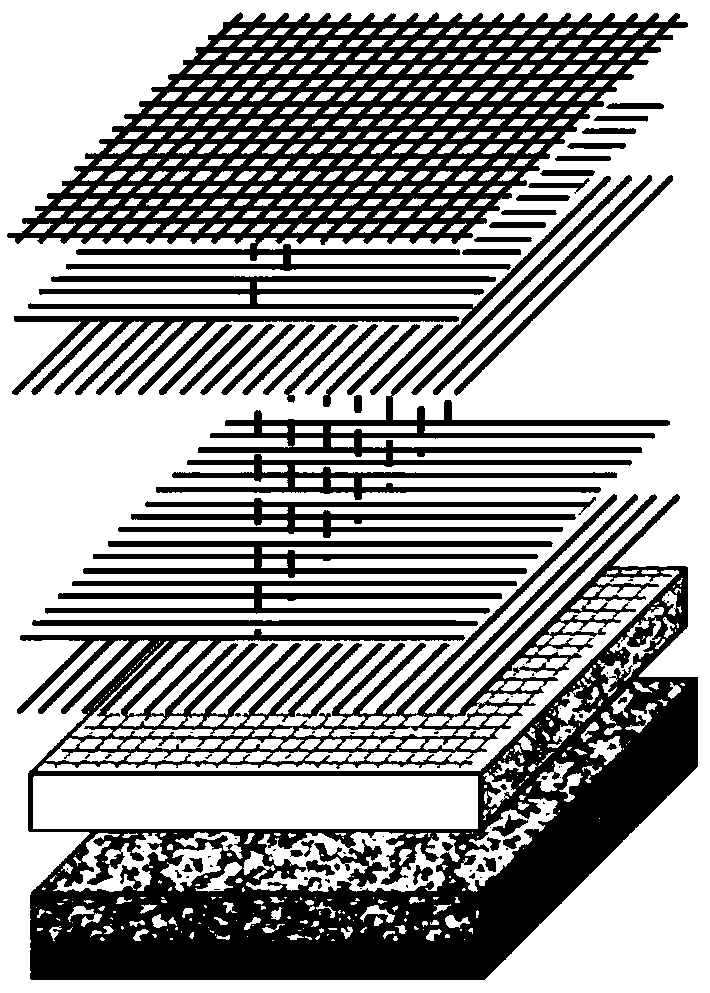

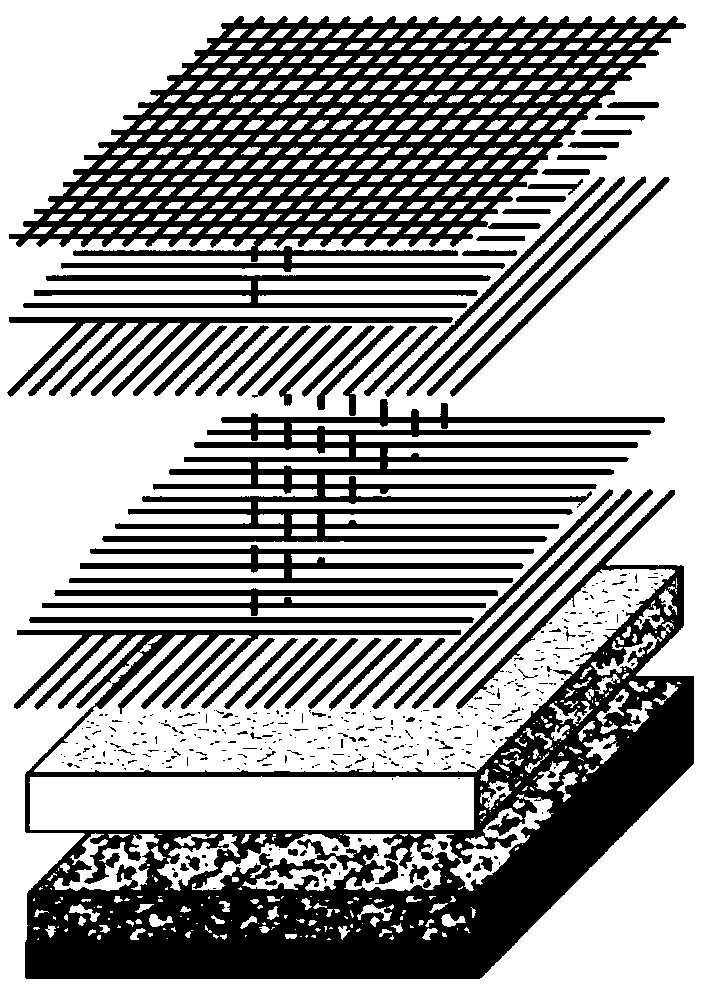

Hybrid composite structures for ballistic protection

InactiveUS20070068377A1Improve impact resistanceImprove energy absorptionArmour platesMechanical engineeringComposite structure

Owner:THE UNIVERSITY OF AKRON

High strength, hot dip coated, dual phase, steel sheet and method of manufacturing same

ActiveUS7608155B2Good energyGood formabilityHot-dipping/immersion processesFurnace typesNiobiumManganese

A galvanized steel sheet having (a) a dual phase microstructure with a martensite phase and a ferrite phase and (b) a composition containing by percent weight: carbon in a range from about 0.01% to about 0.18%; manganese in a range from about 0.2% to about 3%; silicon ≦ about 1.2%; aluminum in a range from about 0.01% to about 0.1%; one or both of chromium and nickel in a range from about 0.1% to about 3.5%; calcium in a range from about 0.0003% to about 0.01%; phosphorus ≦ about 0.01%; sulfur ≦ about 0.03%; nitrogen ≦ about 0.02%; molybdenum ≦ about 1%; copper ≦ about 0.8%; one or more of niobium, titanium, and vanadium ≦ about 1%; and boron ≦ about 0.006% by weight; and with the balance of the composition being iron and incidental ingredients. In one embodiment, the steel sheet is both galvanized and galvannealed.

Owner:NUCOR CORP

Pile driver with energy monitoring and control circuit

ActiveUS20050023014A1Efficient driveIncrease impact energyReciprocating drilling machinesDerricks/mastsAccelerometerControl system

A pile driver comprises a hammer for impacting a pile, a velocity sensor for measuring the velocity at impact, and a control system for adjusting the hammer stroke in accordance with the readings from the velocity sensor so that the optimal impact energy is imparted to the head of the pile. Optionally, the system further comprises a pile driving analyzer (including at least one strain gauge and / or an accelerometer) mounted on the side of the pile itself to determine whether the impact loading on the pile is below the maximum allowable stress. If the pile driving analyzer senses an overload of stress on the pile, the control system will reduce the velocity of the subsequent hammer stroke so that it no longer exceeds the maximum allowable stress.

Owner:BERMINGHAM FOUND SOLUTIONS LTD

High strength, hot dip coated, dual phase, steel sheet and method of manufacturing same

ActiveUS20120138194A1Good energyGood formabilityHot-dipping/immersion processesThin material handlingNiobiumManganese

A galvanized dual phase steel sheet with a martensite phase and a ferrite phase and a composition containing within the following ranges by weight: carbon from about 0.01% to about 0.18%; manganese from about 0.2% to about 3%; silicon≦about 1.2%; aluminum from about 0.01% to about 0.1%; one or both of chromium and nickel from about 0.1% to about 3.5%; calcium from about 0.0003% to about 0.01%; phosphorus≦about 0.1%; sulfur≦about 0.03%; nitrogen≦about 0.02%; molybdenum≦about 1%; one or more of niobium and titanium≦about 1%; and boron≦about 0.006% by weight; and with the balance of the composition being iron and incidental ingredients. The steel sheet may be both galvanized and galvannealed.

Owner:NUCOR CORP

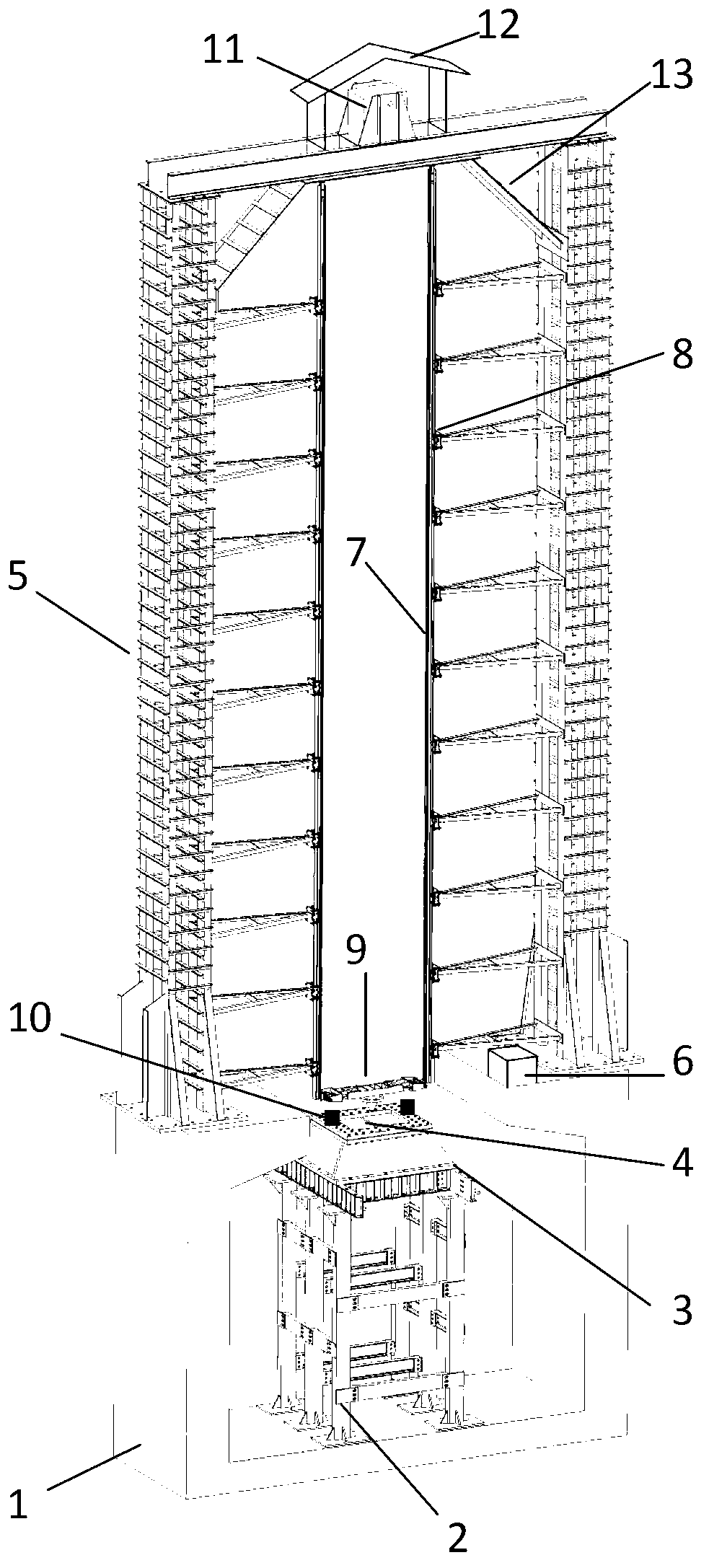

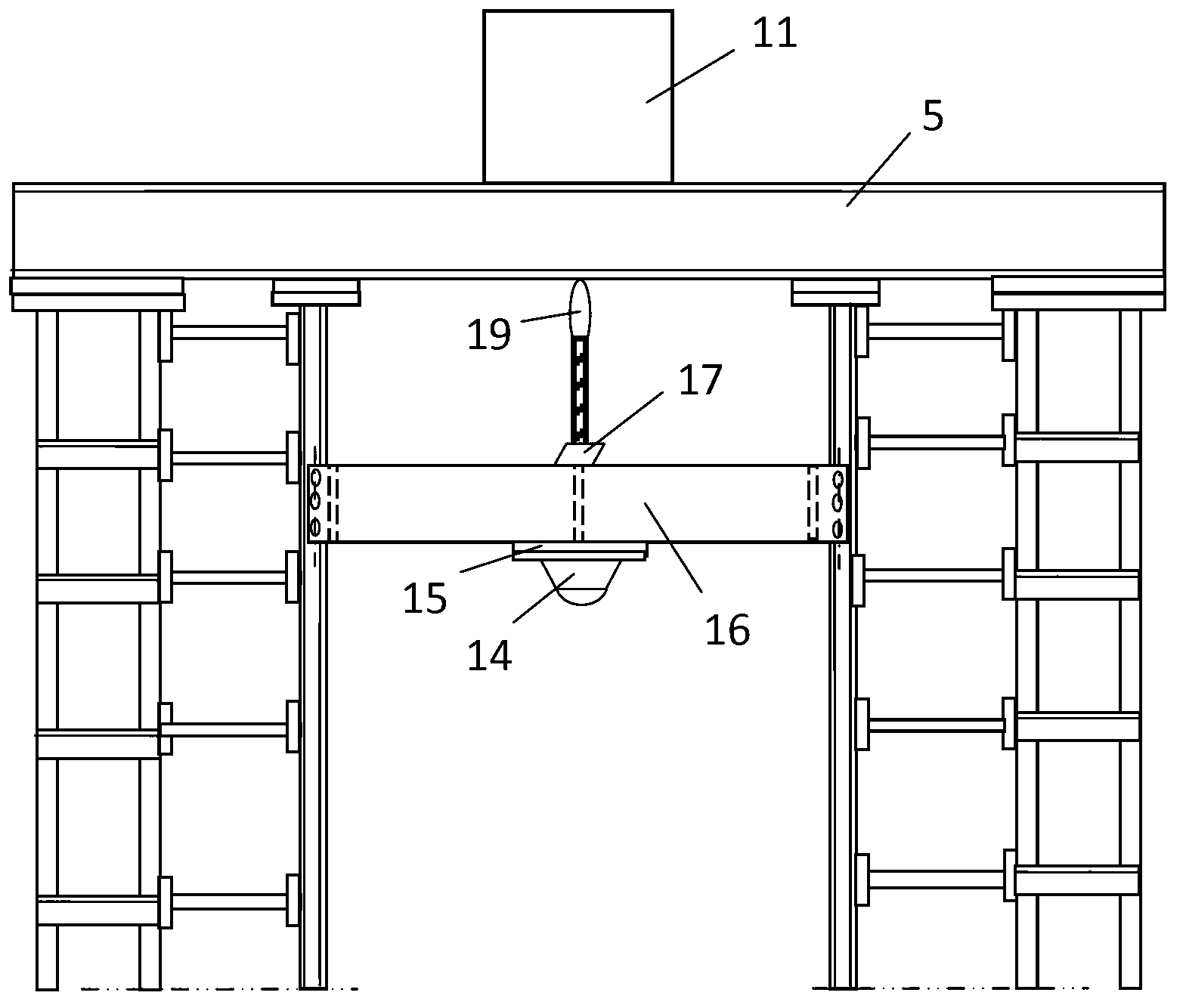

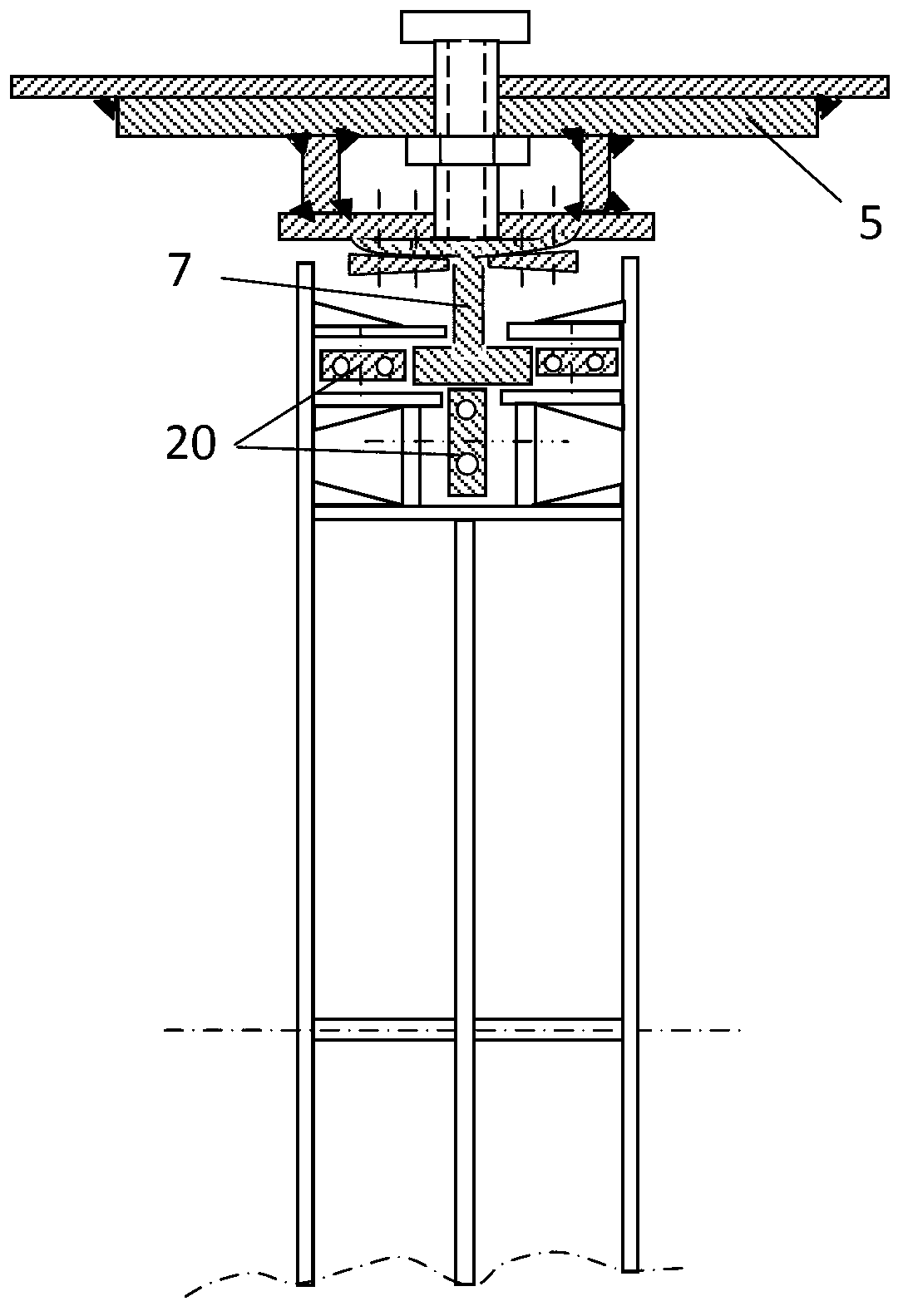

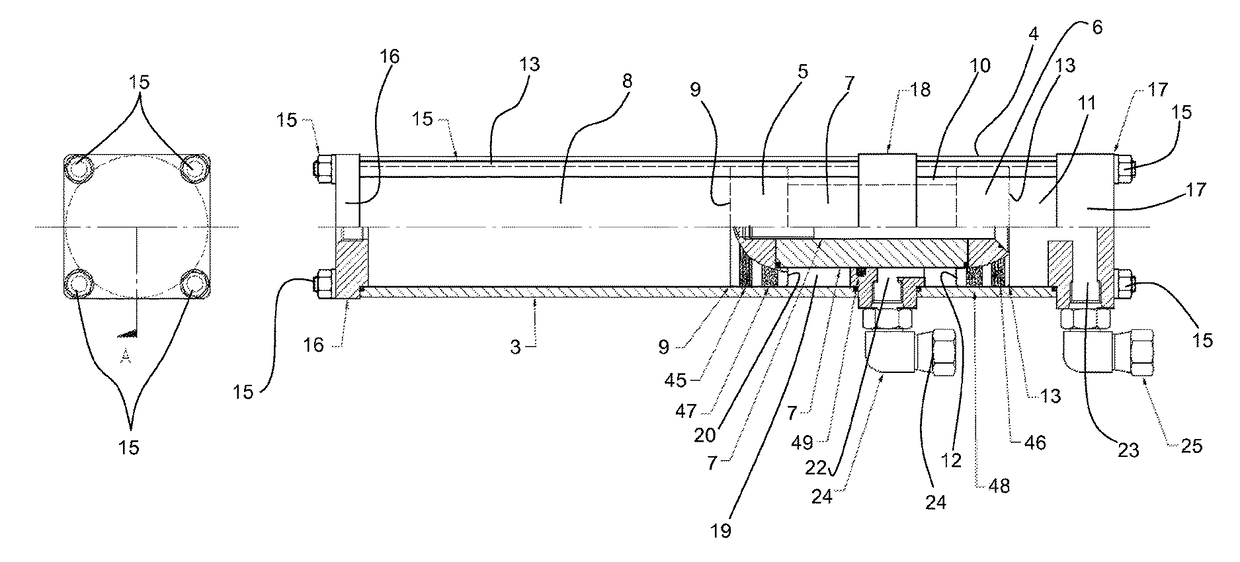

Drop hammer impact testing apparatus

The invention discloses a drop hammer impact testing apparatus which is used for impact test of specimens in water. The apparatus comprises a base (2) which is disposed in a water pool (1), a fixing platform (3) which is arranged on the base (2) and used for fixing a to-be-tested specimen (4); a guiding rail (7) which is vertically disposed on the water pool (1) via a tower frame (5) and is above the base (2); and a free falling assembly (9) which is arranged on the guiding rail (7) and falls down from height along the guiding rail (7) so as to impact the specimen (4) placed in water. The apparatus can realize impact test with high impact energy by accurately adjusting the vertical degree of the rail and a test impact speed, and can perform underwater impact tests in different water depth.

Owner:HUAZHONG UNIV OF SCI & TECH

Elevator installation

InactiveUS20130118837A1Travel path can be limitedReduce impact speedElevatorsBuilding liftsArresting gearAutomotive engineering

An elevator installation is provided. The installation includes a shaft in which at least two cars are arranged above one another and are movable vertically separately. Each car has a drive device and a brake device. A safety device is provided for monitoring the cars. At least one travel path limiting device is provided, comprising at least one stop element arranged on at least a first car and an associated retaining element arranged in the shaft. In a stop position, the stop element protrudes laterally from the car and interacts with the associated retaining element. All other cars movable in the shaft may pass this retaining element unobstructed. The brake device or its braking action is deactivatable if the car falls below a limit speed, and the stop and retaining elements may brake the car to a standstill at speeds up to at most the limit speed.

Owner:THYSSENKRUPP ELEVATOR AG (DE)

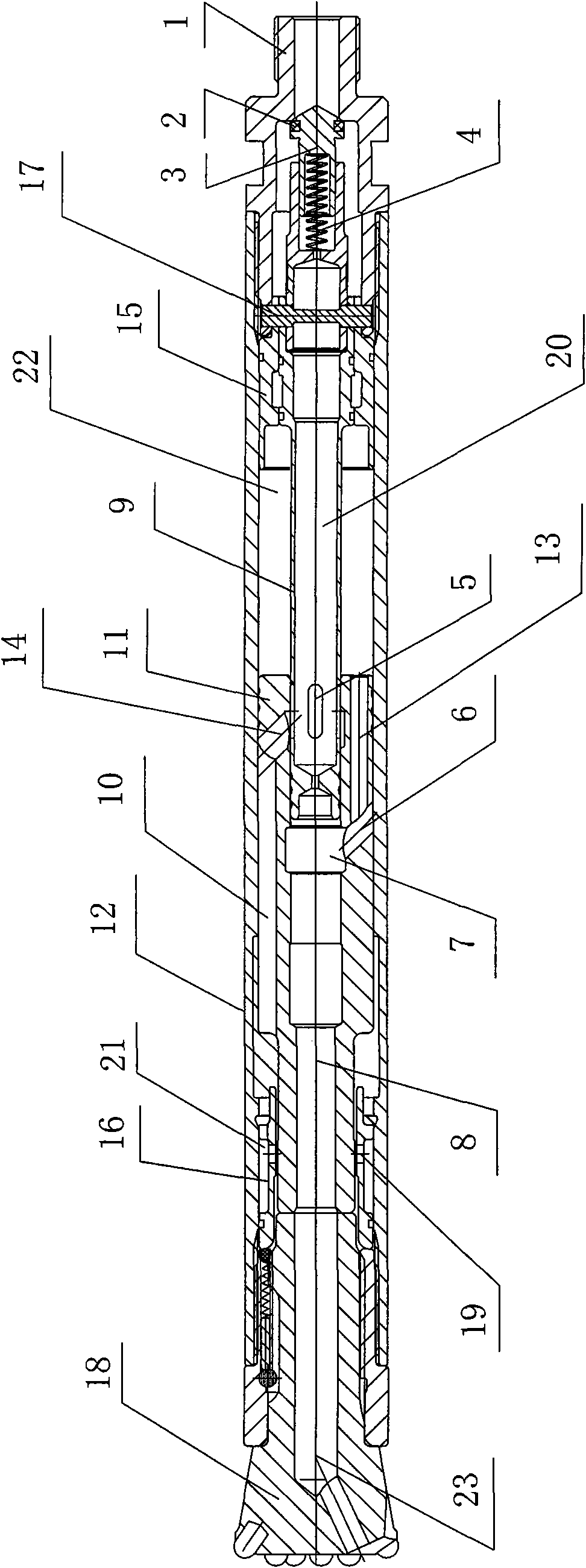

Valveless single-cylinder low or middle wind pressure downhole air hammer

InactiveCN101575941AGuaranteed uptimeExpand the effective working diameterBorehole drivesCheck valveAir cavity

A valveless single-cylinder low or middle wind pressure downhole air hammer comprises an outer sleeve with one end being a rear joint and the other end being a drill bit. A check valve is arranged in the outer sleeve and internally provided with a flexible spring. One end of an air distribution pole is provided with a radial hole and matched with a piston in which a central pore path is arranged. The central pore path is provided with an inner ring groove thereon. The lower part of the piston is provided with an upper air hole that is communicated with the inner ring groove through a slant hole, while the upper part thereof is provided with an air duct. One end of an upper slant hole is communicated with the air duct, while the other end thereof is matched with the radial hole. The piston is matched with the drill bit and a guide sleeve. A valve seat is provided with a locating device. The air hammer enlarges the effective working diameter of the cylinder body, causes the piston to obtain high impact energy, simplifies an air distribution path, reduces gas pressure loss, can be used under low or middle wind pressure to improve the down-the-hole rock drilling efficiency and reduce energy consumption. The locating device solves the locating and guiding problem of the air distribution pole, thus causing the hammer to operate with high efficiency and stability.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

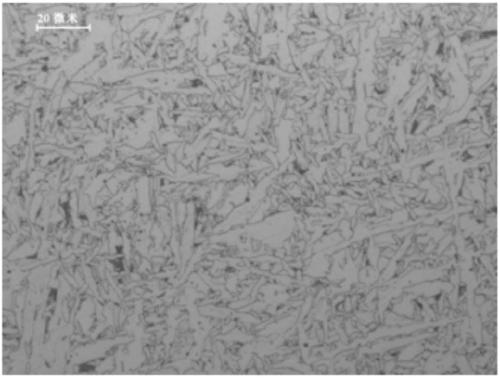

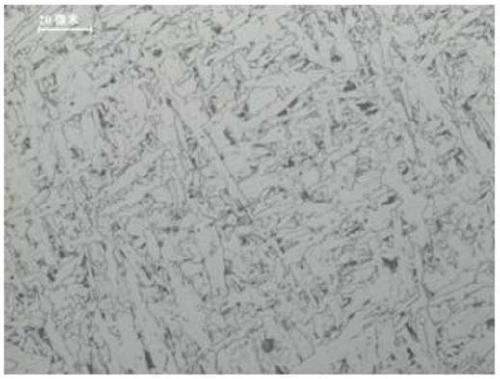

Large heat input energy welding high-strength EH36 steel plate and making method thereof

The invention relates to a large heat input energy welding high-strength EH36 steel plate which is made of the following components in percentage by weight through smelting: 0.06-0.18% of C, 0.15-0.50% of Si, 1.10-1.60% of Mn, less than or equal to 0.012% of P, less than or equal to 0.003% of S, 0.10-0.40% of Ni, 0.010-0.030% of Nb, less than or equal to 0.010% of Al, 0.010-0.030% of Ti, 0.001-0.010% of Ca and the balance of Fe and inevitable impurities. The maximum thickness of the steel plate is 100mm, the yield strength of the steel plate is greater than or equal to 355MPa, the tension strength of the steel plate is greater than or equal to 510MPa, and the low-temperature impact absorption energy KV2 of the steel plate at minus 40 DEG C is greater than or equal to 150KJ. A production method of the steel plate comprises the following steps: carrying out smelting, LF / RH (Ladle Furnace / Ruhrstahl Heraeus) refining, continuous casting, heating, rolling, and rapid cooling, thereby obtaining a finished product of the steel plate. The steel plate produced by using the method provided by the invention has the characteristics of high purity, high strength, good low-temperature impact resistance, good toughness when the maximum input line energy is 300KJ / CM, and the like, can be widely applied to fields such as shipbuilding, bridges and building structures, and has wide application prospects.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

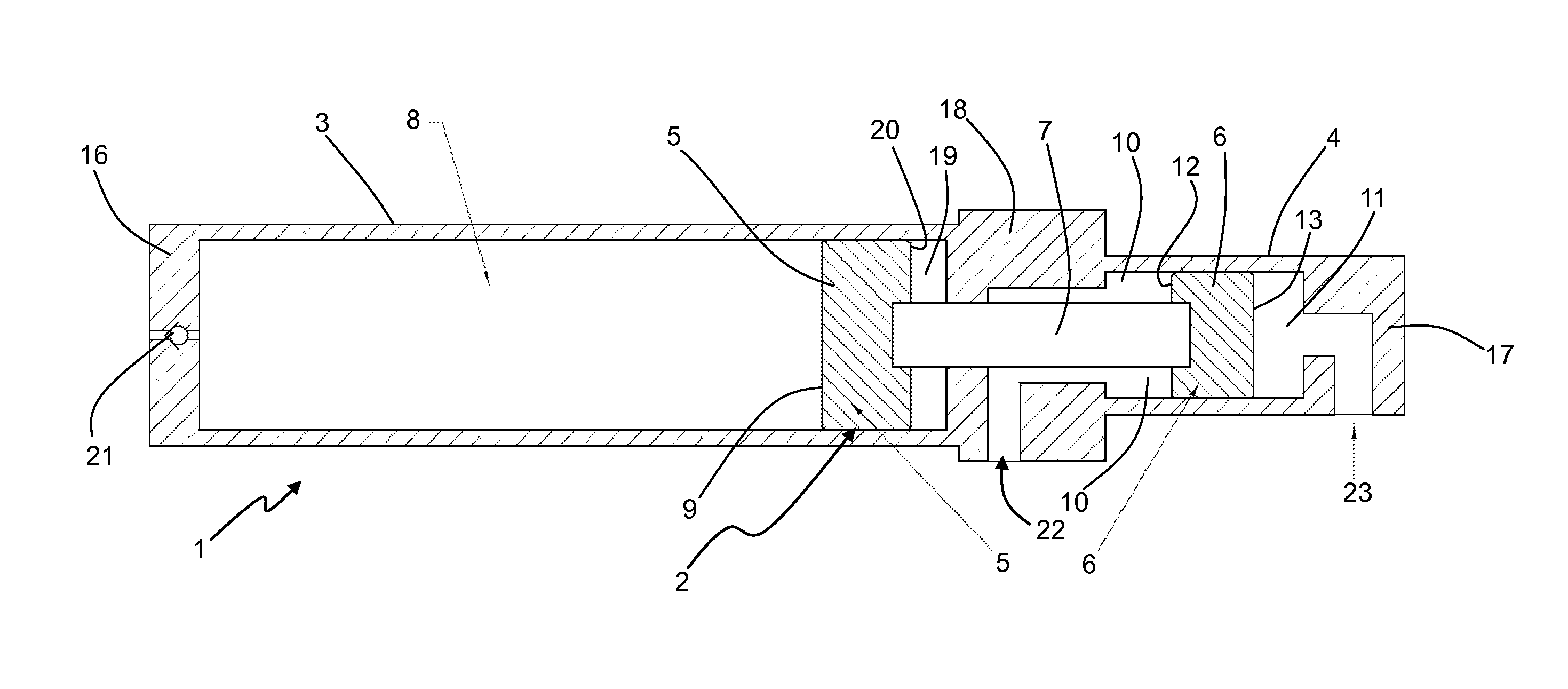

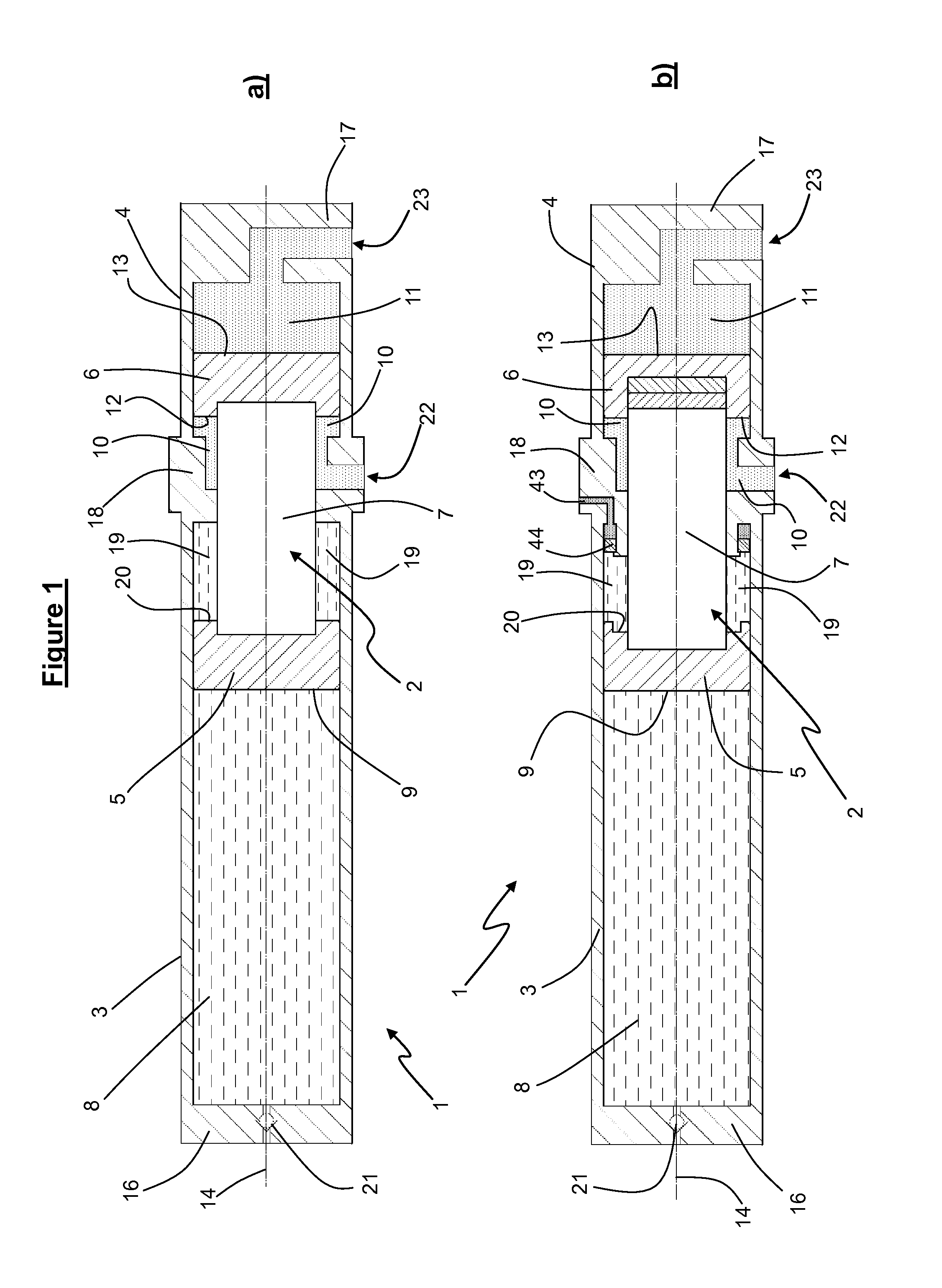

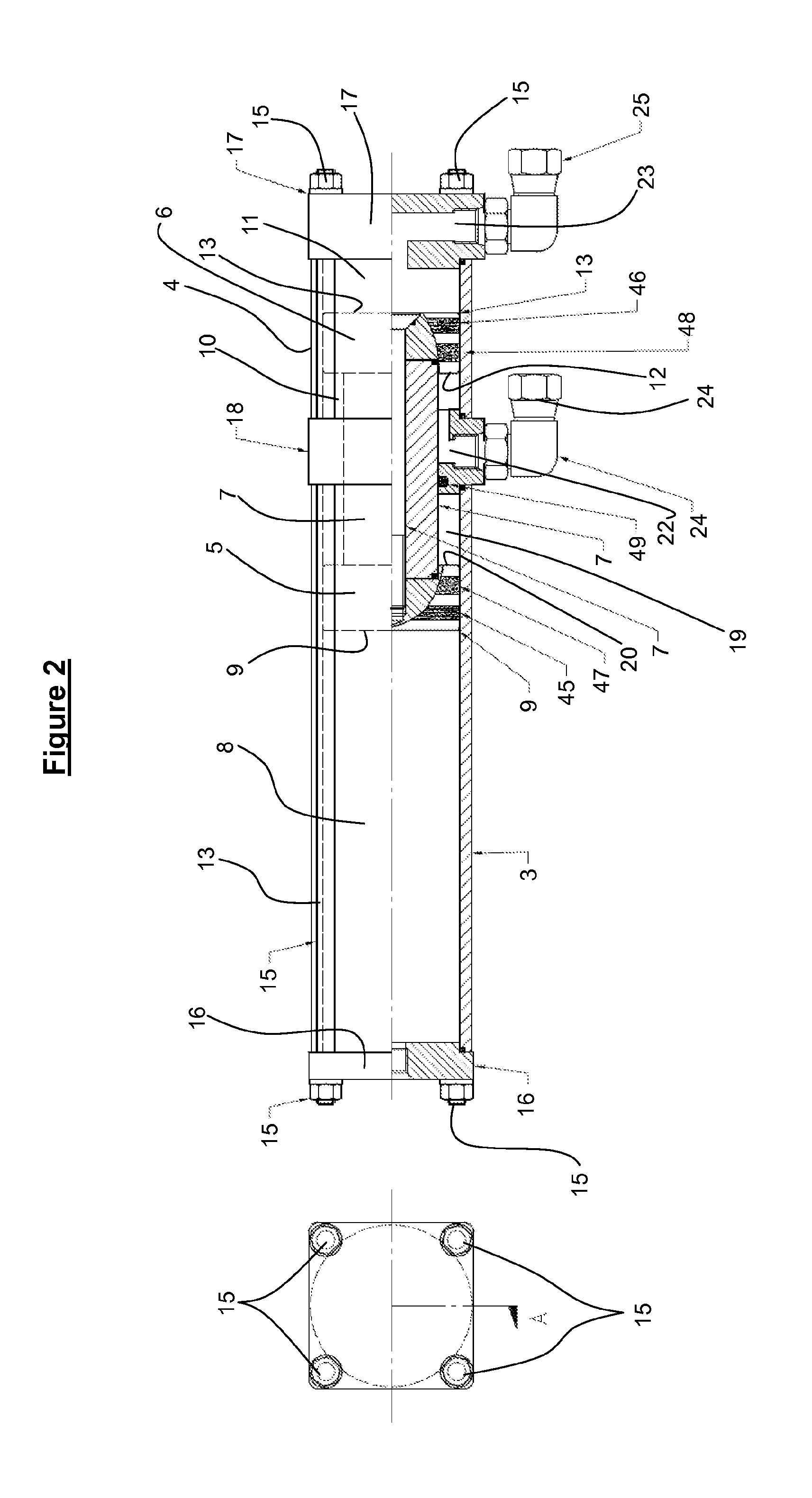

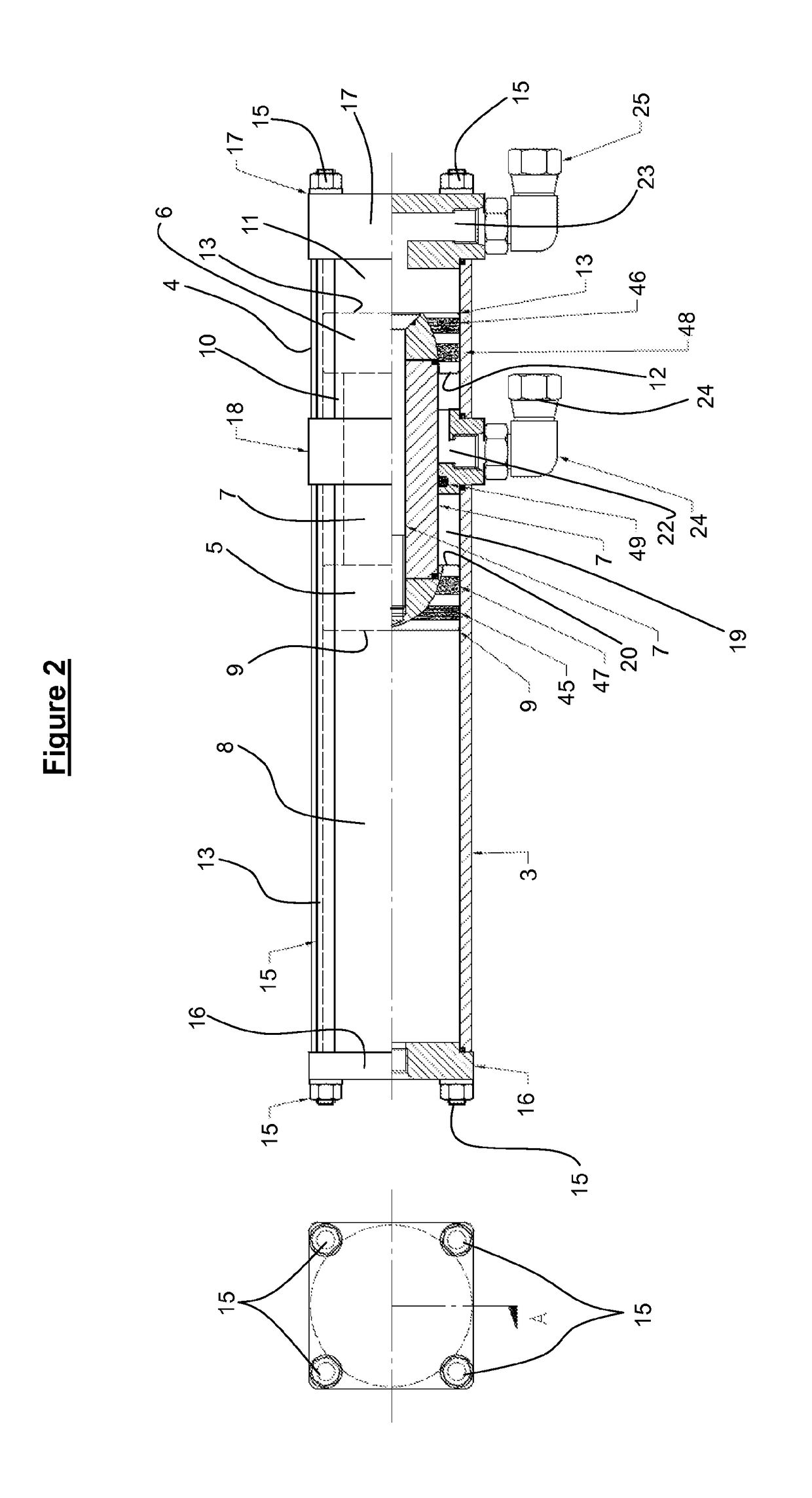

Accumulator

ActiveUS20140290972A1Promote resultsImprove efficiencyFluid couplingsAccumulator installationsEngineeringMechanical engineering

A hydraulic accumulator including an energy storage apparatus with a first piston face configured to reversibly compress an energy storage medium and a second piston face forming at least part of an inner surface of a corresponding second fluid chamber reversibly expandable by movement of the second piston face. A third piston face forms at least part of an inner surface of a corresponding third fluid chamber reversibly expandable by the third piston face. The first, second and third piston faces are coupled together.

Owner:ROBSON ANGUS PETER

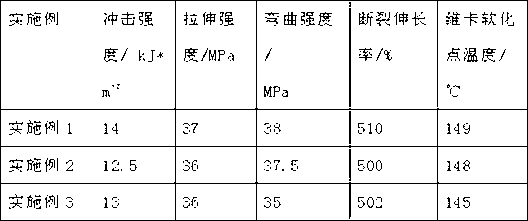

Sun-proof composite modified polypropylene pipe for power cable protection

InactiveCN103012956AImprove heat stabilityReduce dosageInsulated cablesInsulated conductorsElastomerPolyolefin

The invention relates to a sun-proof composite modified polypropylene pipe for power cable protection. The pipe comprises the following components in percentage by weight: 73 to 78 percent of PP (Propene Polymer), 10 to 15 percent of POE (Polyolefin Elastomer), 4.8 to 5.2 percent of nano calcium carbonate, 0.3 to 0.4 percent of nucleating agent, 0.2 to 0.25 percent of coupling agent and 0.5 to 1 percent of sun-proof lubricating composite functional master batch. Not only does the pipe have better low-temperature impact resistance, wherein impact energy in a falling weight impact test at a temperature of minus 5 DEG C is improved by over 2.5 times, the friction coefficient is reduced by 40 percent and the Vicat heat-resistance temperature is risen by 5 DEG C, but also sun-proof performance of the pipe is improved and the application range of the power pipe is enlarged.

Owner:ZHEJIANG HUAFENG NEW MATERIAL

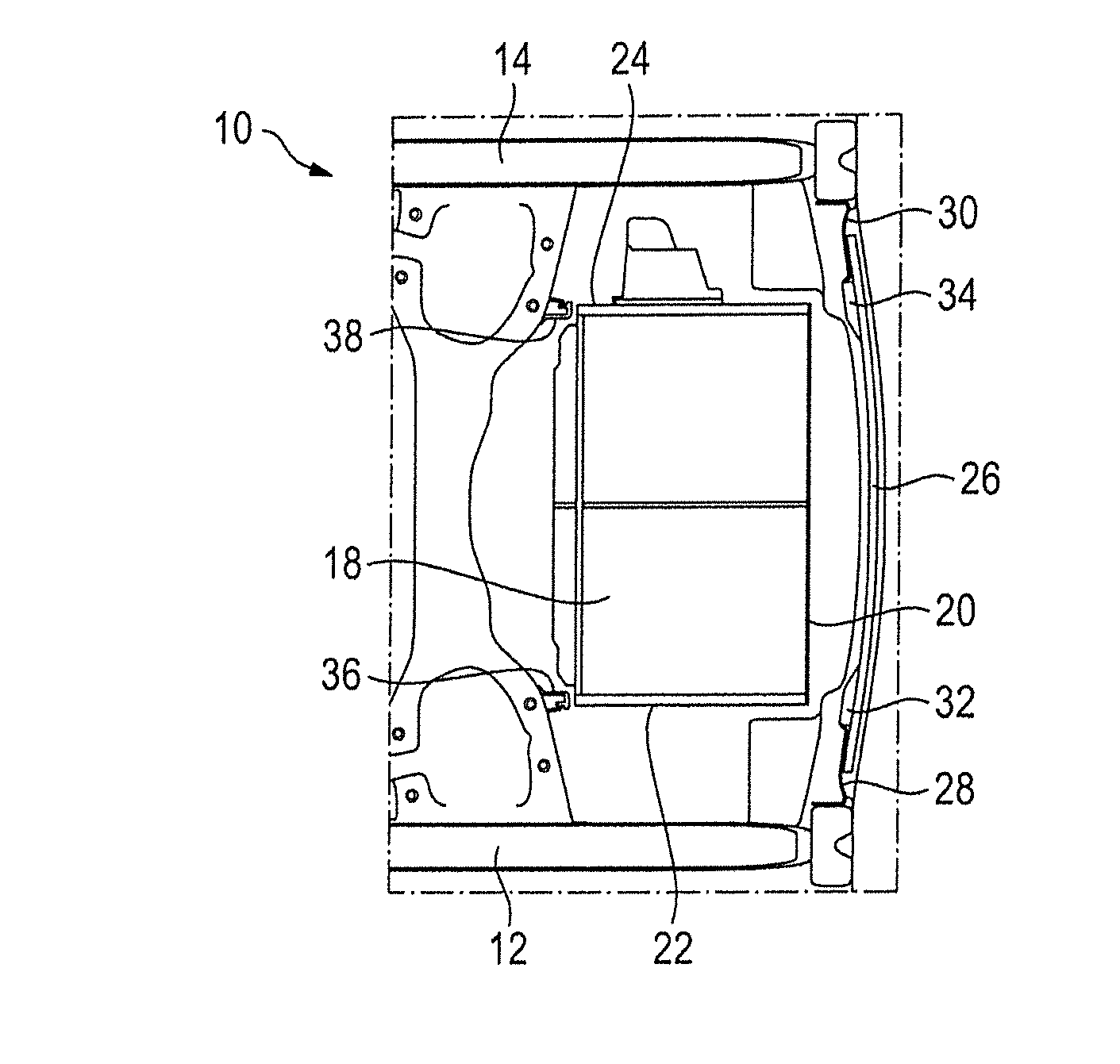

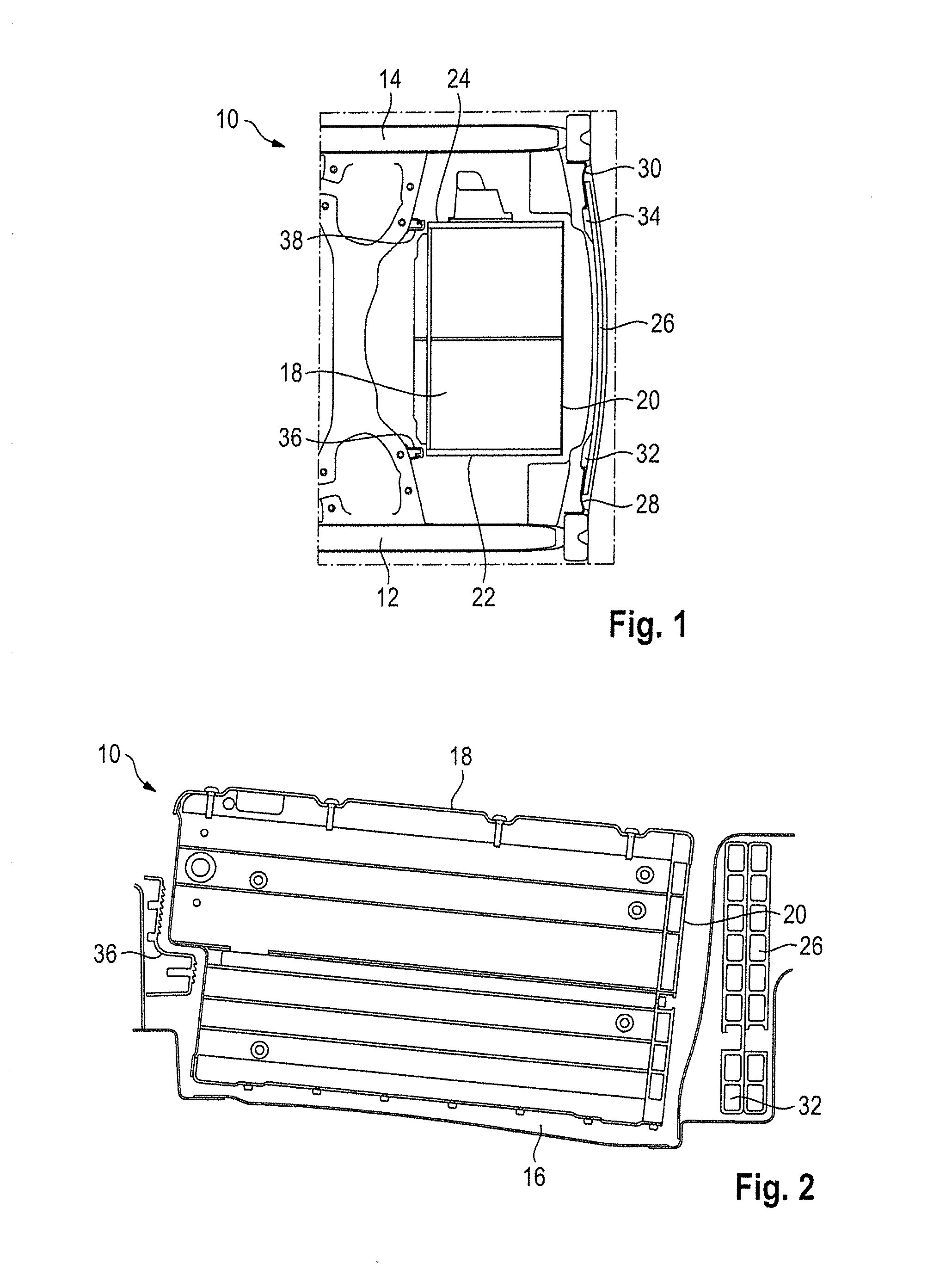

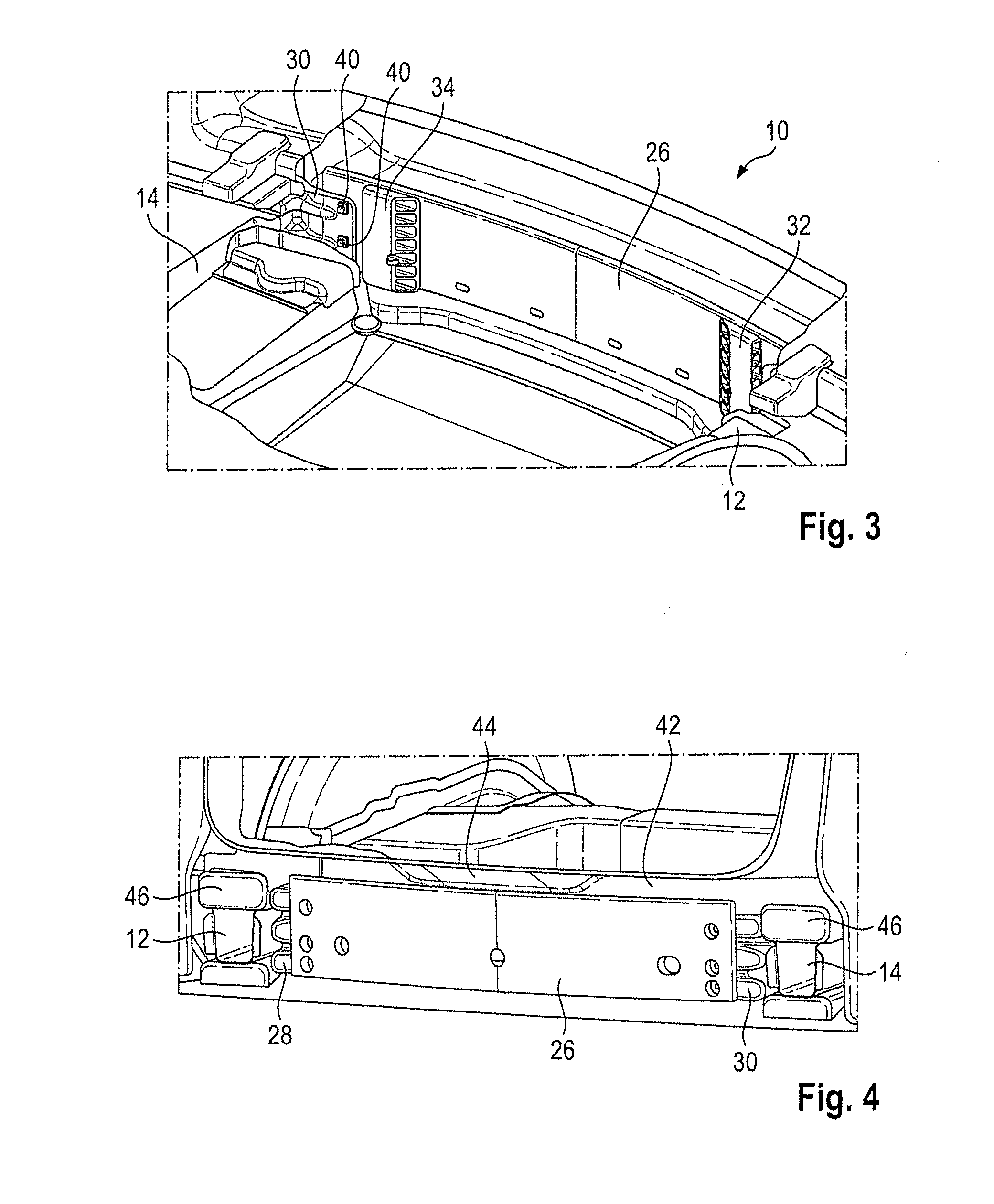

Motor vehicle rear

ActiveUS20150166109A1Dissipate impact energyEasy to bendElectric propulsion mountingVehicle sub-unit featuresMobile vehicleEngineering

A motor vehicle rear (10) has left and right longitudinal members (12) forming a supporting structure of the motor vehicle. A receiving housing (18) is arranged between the longitudinal members (12) for receiving a traction battery. The receiving housing (18) has a left and right side walls (22, 24) running in the forward direction of travel. A back wall (20) is connected to the left and right side walls (22) and running transverse to the forward direction of travel. An impact profile (26) is connected to the left and right longitudinal members (12, 14) and absorbs impact energy in the event of a rear crash. Left and right reinforcing elements (32 34) connect the impact profile (26) to the respective left and right side walls (22, 24) for reinforcing the impact profile (26) and conducting away some of the impact energy into the left and right side walls (22, 24).

Owner:DR ING H C F PORSCHE AG

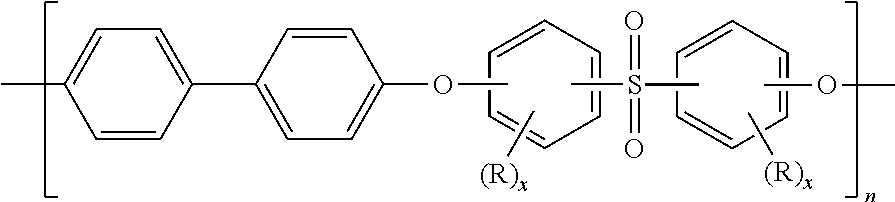

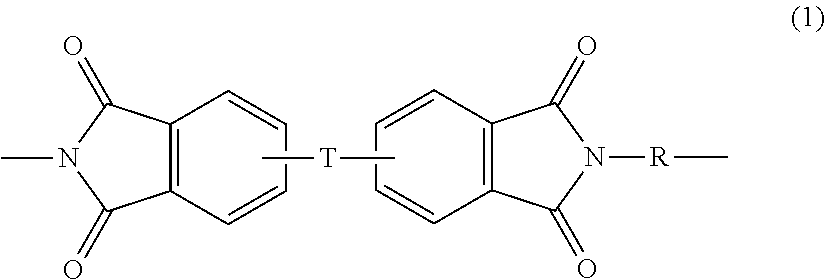

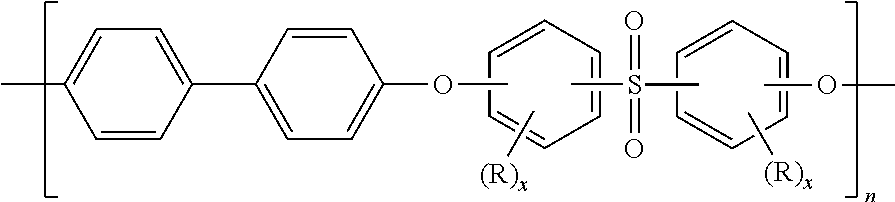

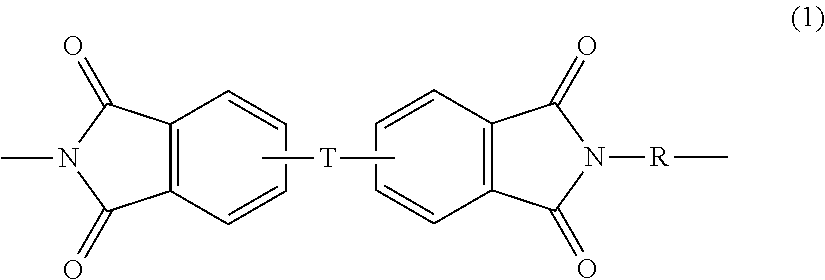

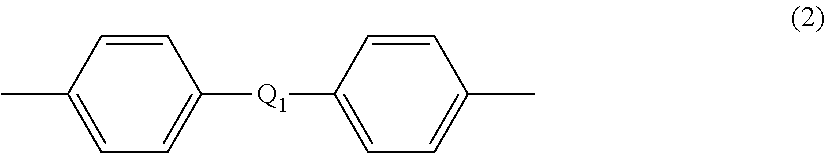

Sterilized polyetherimide /polyphenylene ether sulfone articles

ActiveUS20120308777A1Improve sterilizationIncrease impact energyEnvelopes/bags making machineryAntifouling/underwater paintsImidePolymer science

A sterilized article comprising a hydrogen peroxide plasma or hydrogen peroxide vapor sterilized polymer composition, the polymer composition comprising from 20 to 80 weight % of a polyphenylene ether sulfone; and from 20 to 80 weight % of a polyetherimide. When sterilized with a hydrogen peroxide plasma, or hydrogen peroxide vapor, the articles have surprisingly improved resistance to changes in color and clarity as well as resistance to loss of mechanical properties.

Owner:SHPP GLOBAL TECH BV

Accumulator

ActiveUS9790962B2Improve impact performanceImprove impactMechanical machines/dredgersAccumulator installationsEngineeringMechanical engineering

Owner:ROBSON ANGUS PETER

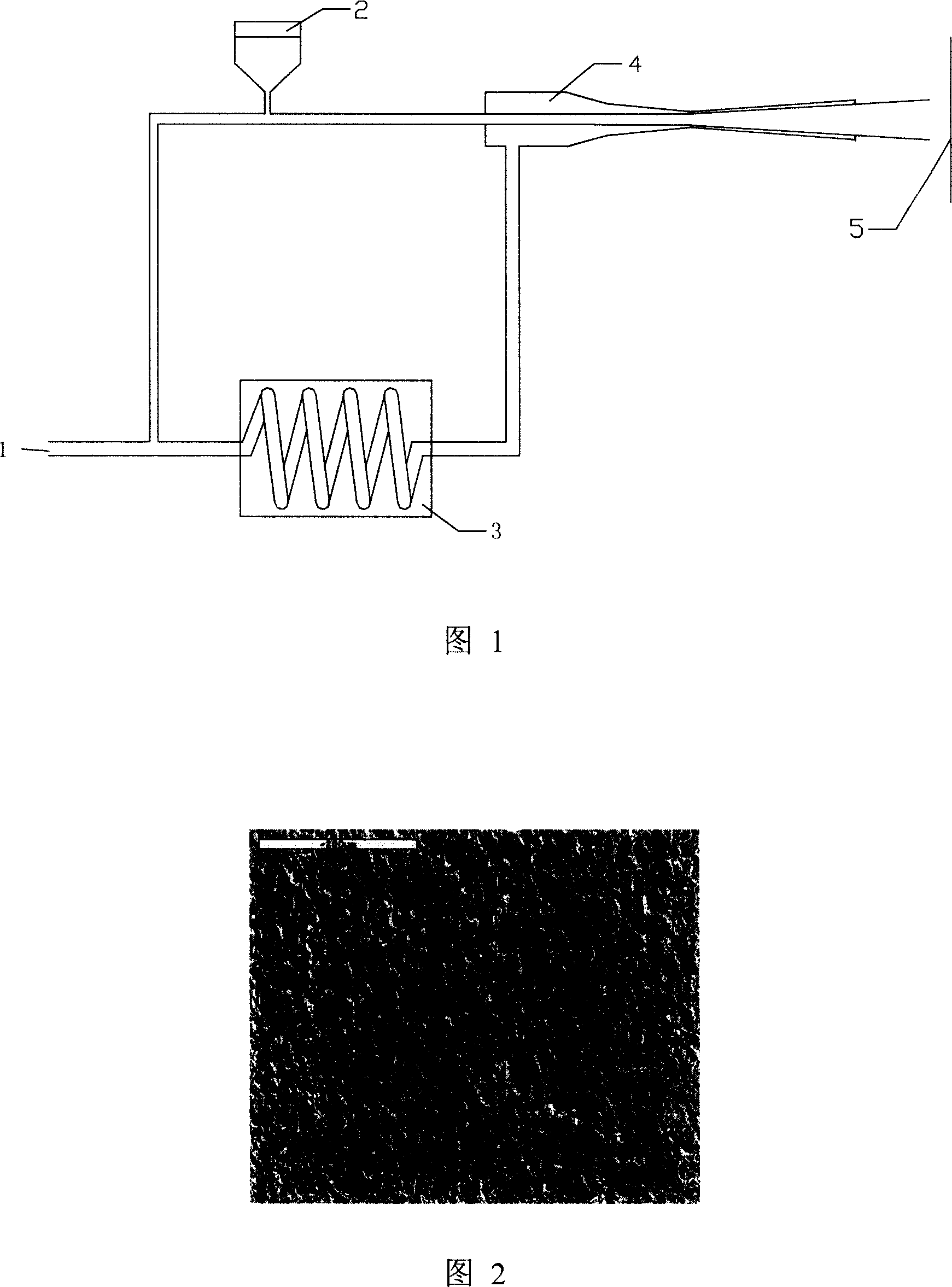

Method for coarsening surface by erosion of hard grains in high speed

InactiveCN101003126ALarge particle sizeSpeed adjustable range is smallAbrasive feedersParticle collisionHigh pressure

A high-speed hard particle collision method for roughening the surface of workpiece features that the superfine hard particles are driven by the compressed air to impact on the surface of workpiece at sonic or supersonic speed to make said surface to be strongly and plastically deformed while the fine metallic particles to be separated from the surface, so roughening it.

Owner:BAOSHAN IRON & STEEL CO LTD

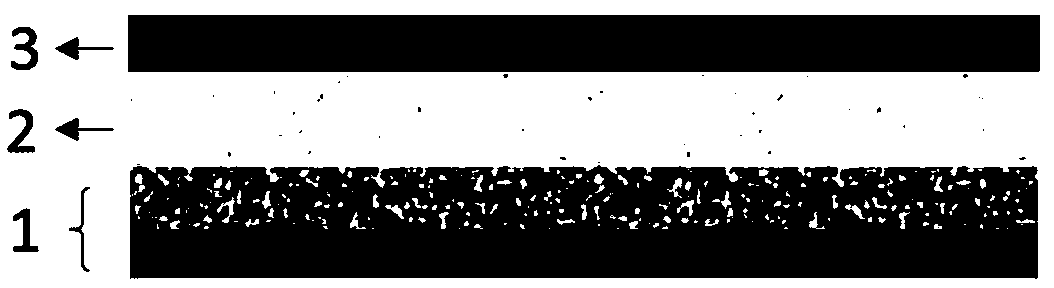

Multilayer bulletproof member and preparation method and application thereof

The invention discloses a multilayer bulletproof member. The bulletproof member comprises a metal / ceramic crack-proof reflecting layer, a fiber / elastomer composite energy absorption layer and a two-dimensional fabric protection blunt injury layer. The three-layer structure is formed by stacking in sequence. By the adoption of the multilayer bulletproof member and the preparation and application ofthe multilayer bulletproof member, the high strength, hardness and good impact toughness of the bulletproof member are ensured through the comprehensive performance of all components.

Owner:JIANGNAN UNIV

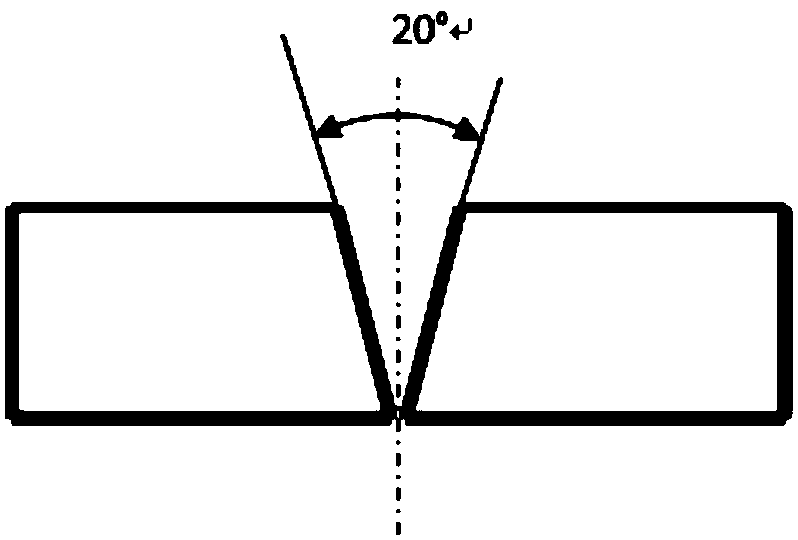

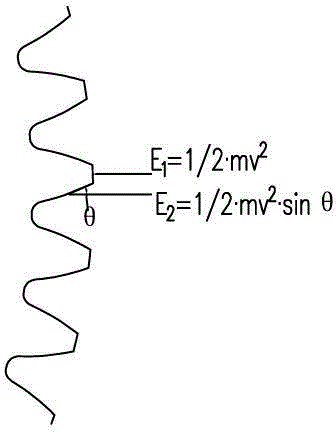

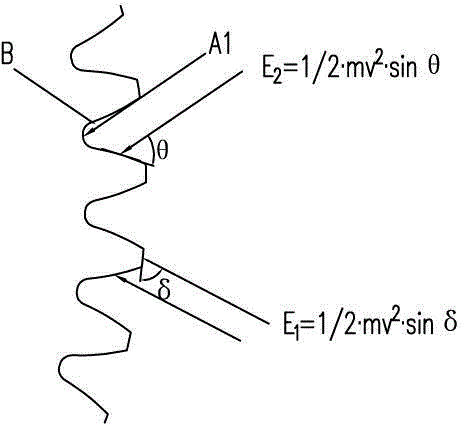

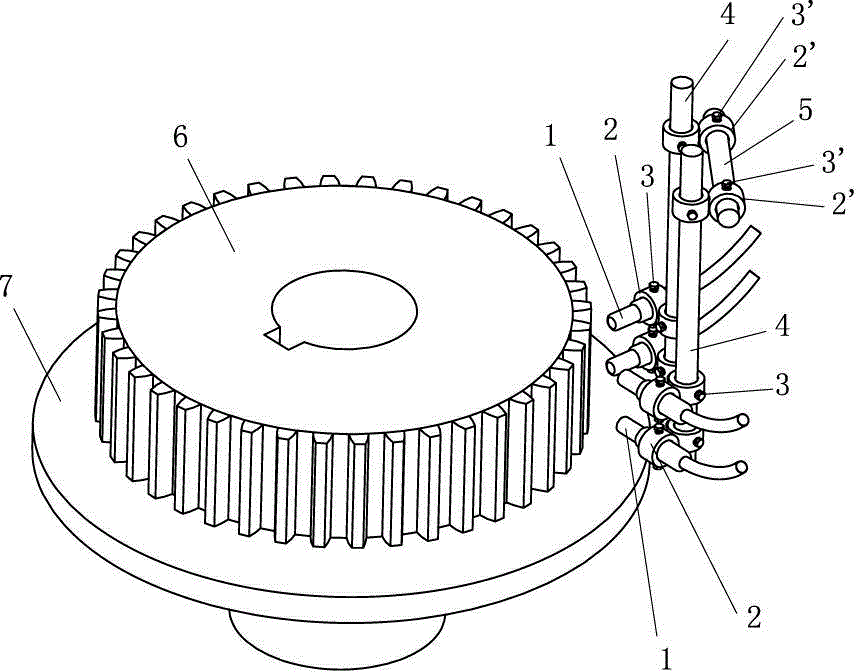

Gear tooth surface shot peening device and method

The invention discloses a gear tooth surface shot peening device and method. The gear tooth surface shot peening device comprises two spraying nozzle fixing rods arranged side by side, each spraying nozzle fixing rod is provided with at least two spraying nozzles, the orientations of the spraying nozzles installed on the two spraying nozzle fixing rods are in an intersecting state, and a spraying nozzle distance adjustment device is arranged between the two spraying nozzle fixing rods. The gear tooth surface shot peening method comprises the steps that two bundles of projectiles are shot to a gear tooth from two sides of the gear tooth of a gear in an intersecting mode, the projectiles are shot at an angle delta relative to the top of the gear, and the angle delta ranges from 20 to 80 degrees. At the time, one bundle of projectiles are shot at an angle theta relative to one side of the gear tooth and the pitch circle position of the gear tooth, and the other bundle of projectiles are shot at an angle theta relative to the other side of the gear tooth and the pitch circle position of the gear tooth. The gear tooth surface shot peening device and method can improve surface residual press stress of the pitch circle position of the gear, shorten shot peening time and prevent micro protrusions from being generated on the outer side of the top of the gear tooth.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Preparation method for metal ceramic composite

A preparation method for a metal ceramic composite comprises the steps of preparation of aluminium oxide ceramic microencapsulated powder, preparation of ceramic particles, preparation of metal ceramic particles and preparation of the metal ceramic composite. The prepared metal ceramic composite is of a structure composed of a ceramic layer, a metal ceramic composite transition layer and a metal layer from inside to outside, an even and compact product with the smooth surface is formed at a high temperature, the composite with the high hardness of ceramics and high toughness and plasticity of metal is formed, and the metal ceramic composite not only has good corrosion resistance and high temperature resistance of the ceramics, but also has the toughness and impact resistance of the metal, and has the characteristics of long service life and low mass.

Owner:洛阳鹏飞耐磨材料股份有限公司

Sterilized polyetherimide/polyphenylene ether sulfone articles

ActiveUS8501291B2Increase impact energyGood color retentionEnvelopes/bags making machineryAntifouling/underwater paintsPolyetherimideEther

A sterilized article comprising a hydrogen peroxide plasma or hydrogen peroxide vapor sterilized polymer composition, the polymer composition comprising from 20 to 80 weight % of a polyphenylene ether sulfone; and from 20 to 80 weight % of a polyetherimide. When sterilized with a hydrogen peroxide plasma, or hydrogen peroxide vapor, the articles have surprisingly improved resistance to changes in color and clarity as well as resistance to loss of mechanical properties.

Owner:SHPP GLOBAL TECH BV

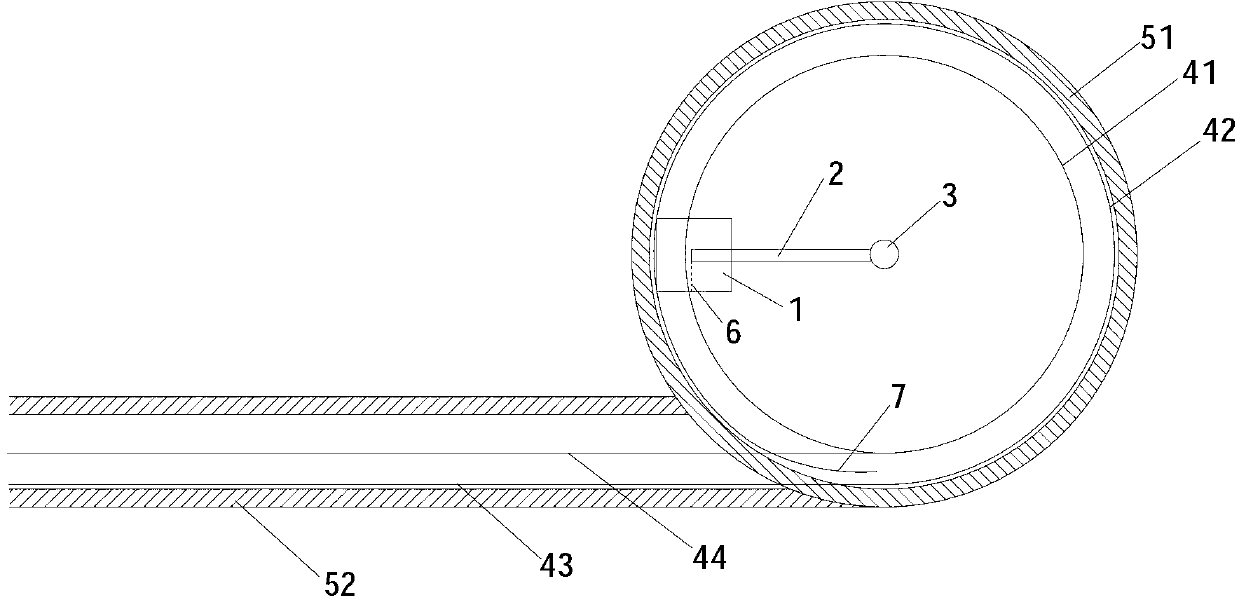

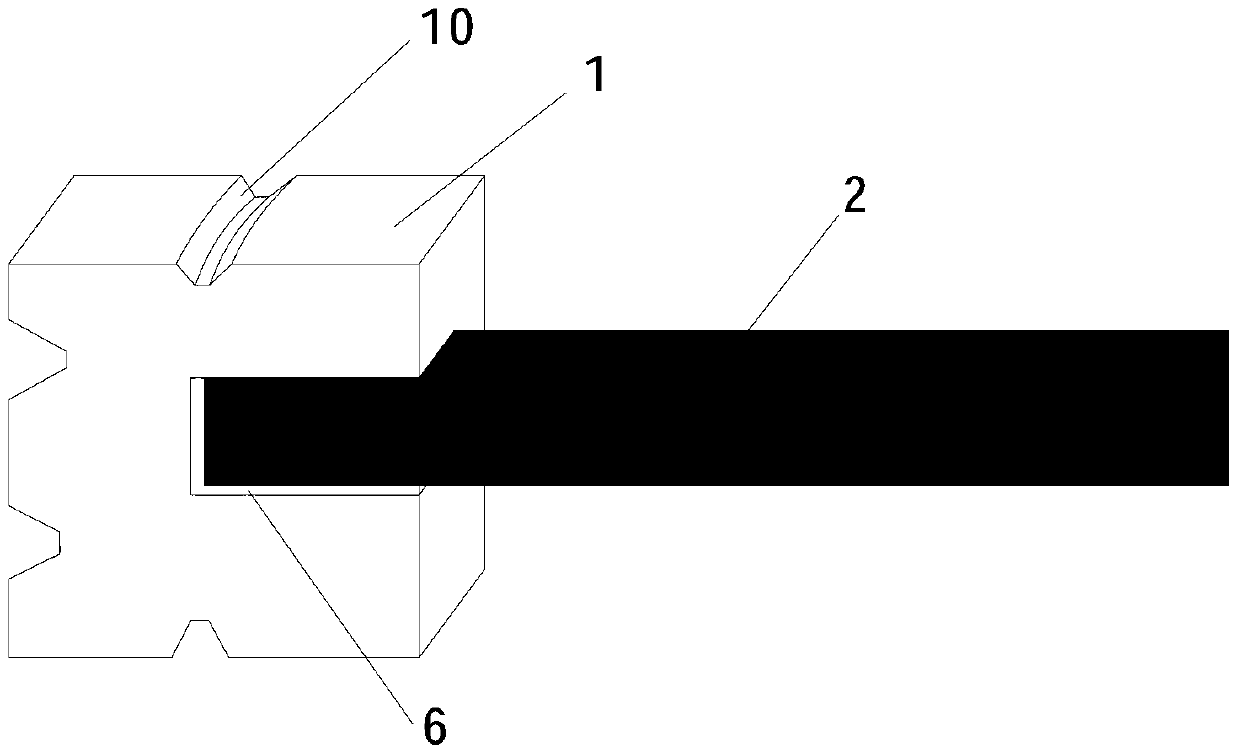

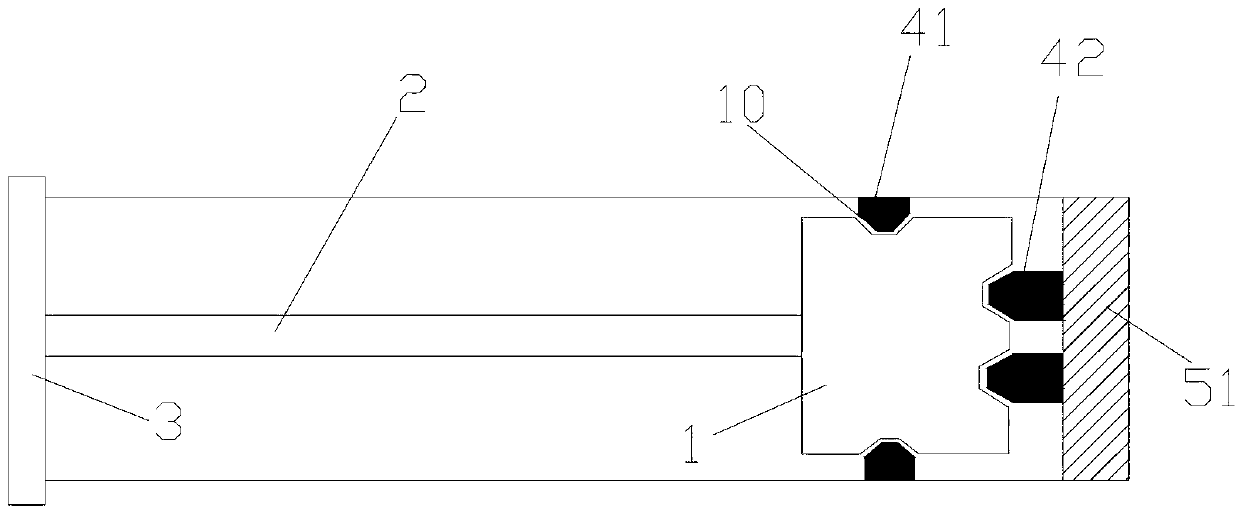

Rotary hammer type impact test device

InactiveCN103134655AImpact speedAvoid secondary impactMaterial strength using single impulsive forceShock testingEngineeringMechanical engineering

The invention provides a rotary hammer type impact test device, and belongs to the field of impact tests. The rotary hammer type impact test device comprises guide rails, a hammer which is arranged on the guide rails and is capable of sliding on the guide rails, and a hammer acceleration device. The guide rails comprise a linear guide rail and a round guide rail and are arranged horizontally, wherein the round guide rail comprises two parts, namely a circular-arc guide rail and a hammer release guide rail, the linear guide rail is tangent to the round guide rail at a connection point, and the hammer release guide rail is movably connected with the round guide rail in the position of the connection point. The hammer acceleration device comprises a driving rod, wherein one end of the driving rod is fixed in the center of the round guide rail in a rotary mode, the other end of the driving rod is connected with a hammer in a releasable mode, and the hammer acceleration device further comprises a power mechanism used for driving the driving rod to rotate. The impact test machine not only better improves the impact energy, but also saves the space, lowers costs, better reduces the influence on surrounding buildings and instrument equipment from impact force.

Owner:浣石

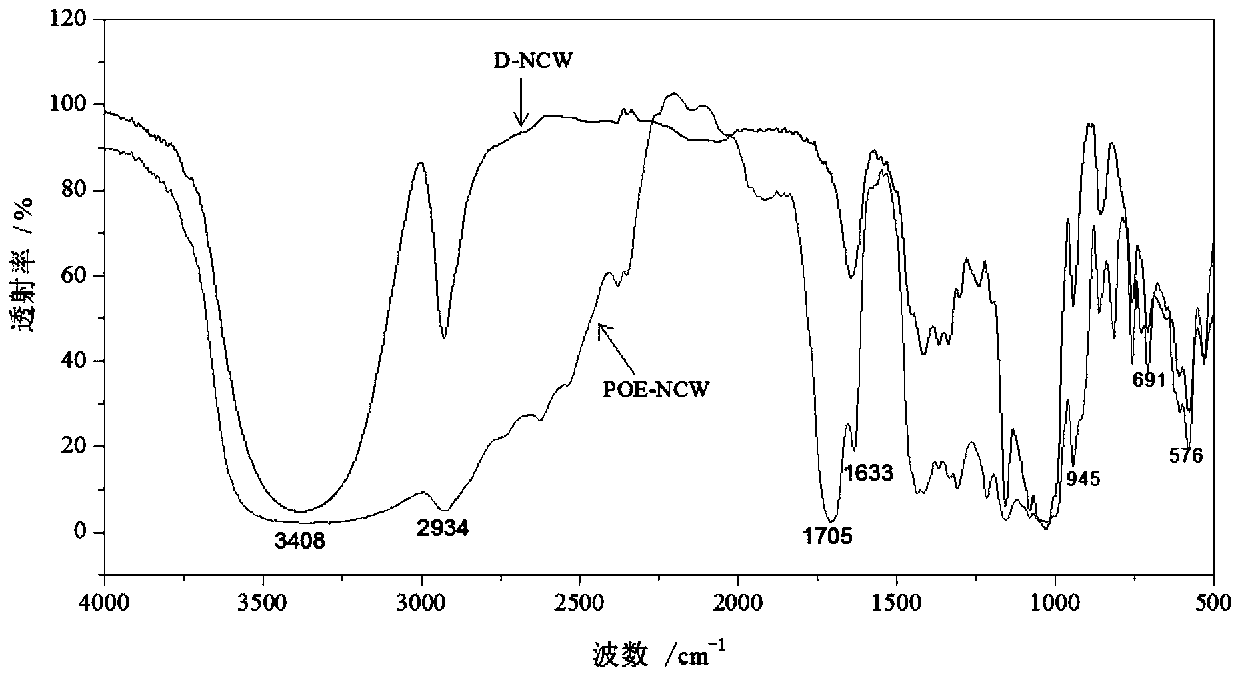

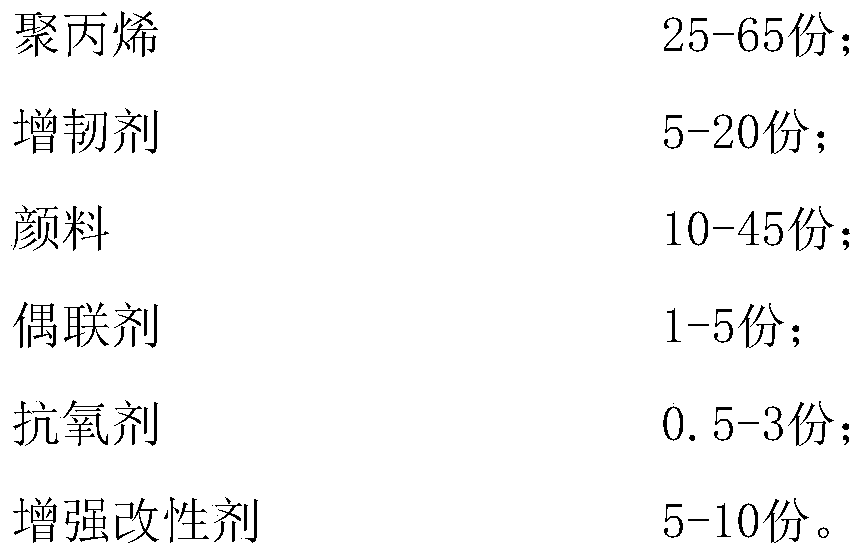

Color master batch for reinforcing and toughening PP (Polypropylene)

The invention belongs to the field of PP (Polypropylene) materials and particularly relates to color master batch for reinforcing and toughening PP (Polypropylene). The color master batch comprises the following components in parts by mass: 25 to 65 parts of polypropylene, 5 to 20 parts of a toughening agent, 10 to 45 parts of a pigment, 1 to 5 parts of a coupling agent, 0.5 to 3 parts of an antioxidant and 5 to 10 parts of a reinforcing modifier. The reinforcing modifier comprises nanocellulose crystal whiskers with POE (Polyolefin Elastomer) grafted surfaces; the nanocellulose crystal whiskers with the POE grafted surfaces are obtained through the following steps: (1) taking carboxylated nanocellulose crystal whiskers and bromoalkane to react, so as to obtain alkylated nanocellulose crystal whiskers; (2) taking the alkylated nanocellulose crystal whiskers and a reaction type elastomer esterifying agent to be subjected to grafting reaction, so as to obtain a dispersion solution of thenanocellulose crystal whiskers with the POE grafted surfaces; and (3) treating the dispersion solution in step (2) by adopting a solution casting method to prepare the nanocellulose crystal whiskerswith the POE grafted surfaces. By adopting the color master batch for reinforcing and toughening the PP, the problem in the prior art that the rigid strength and tough strength of the PP are difficultto improve at the same time is solved and the prepared color master batch has good rigidity and toughness.

Owner:WUHAN KINGBULL ECONOMIC DEV

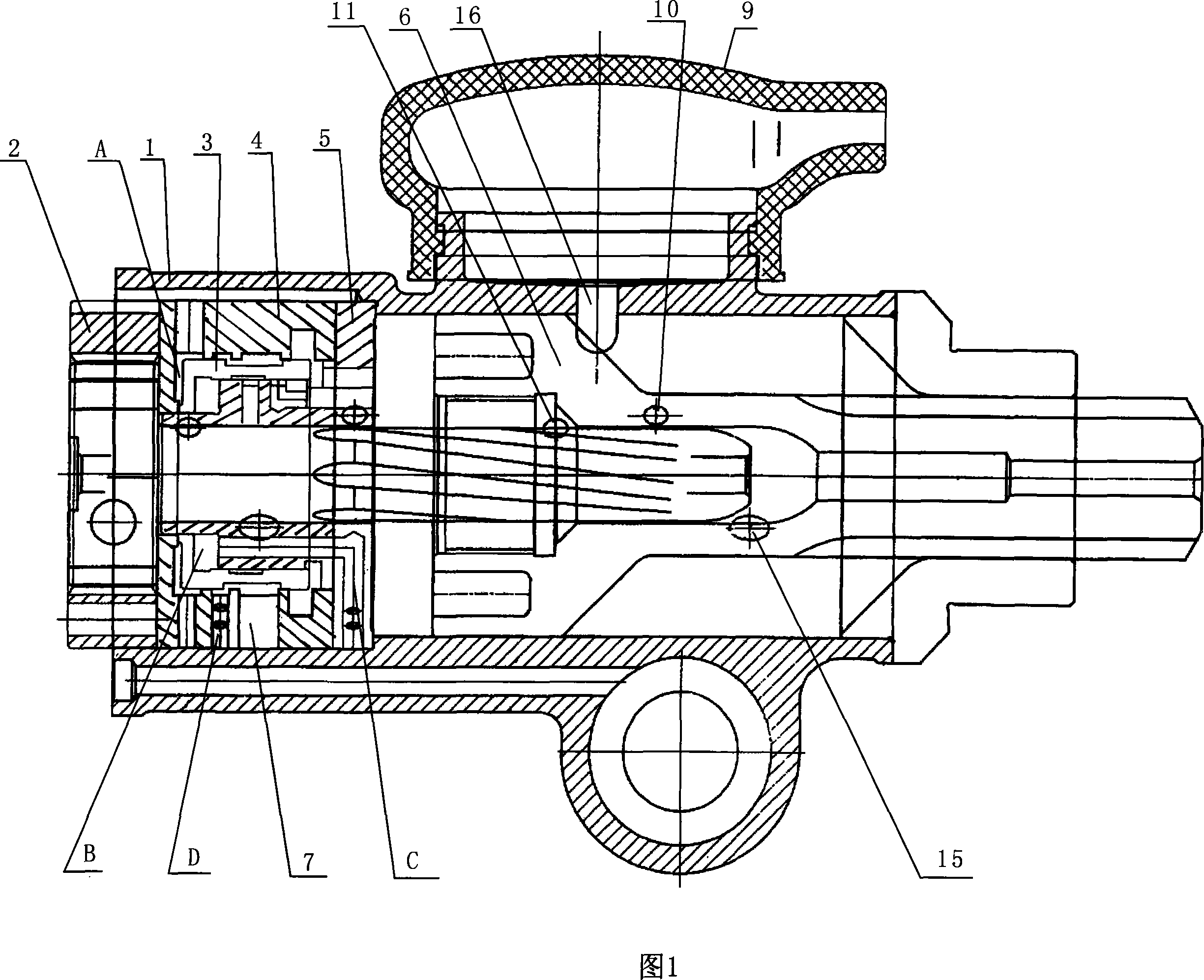

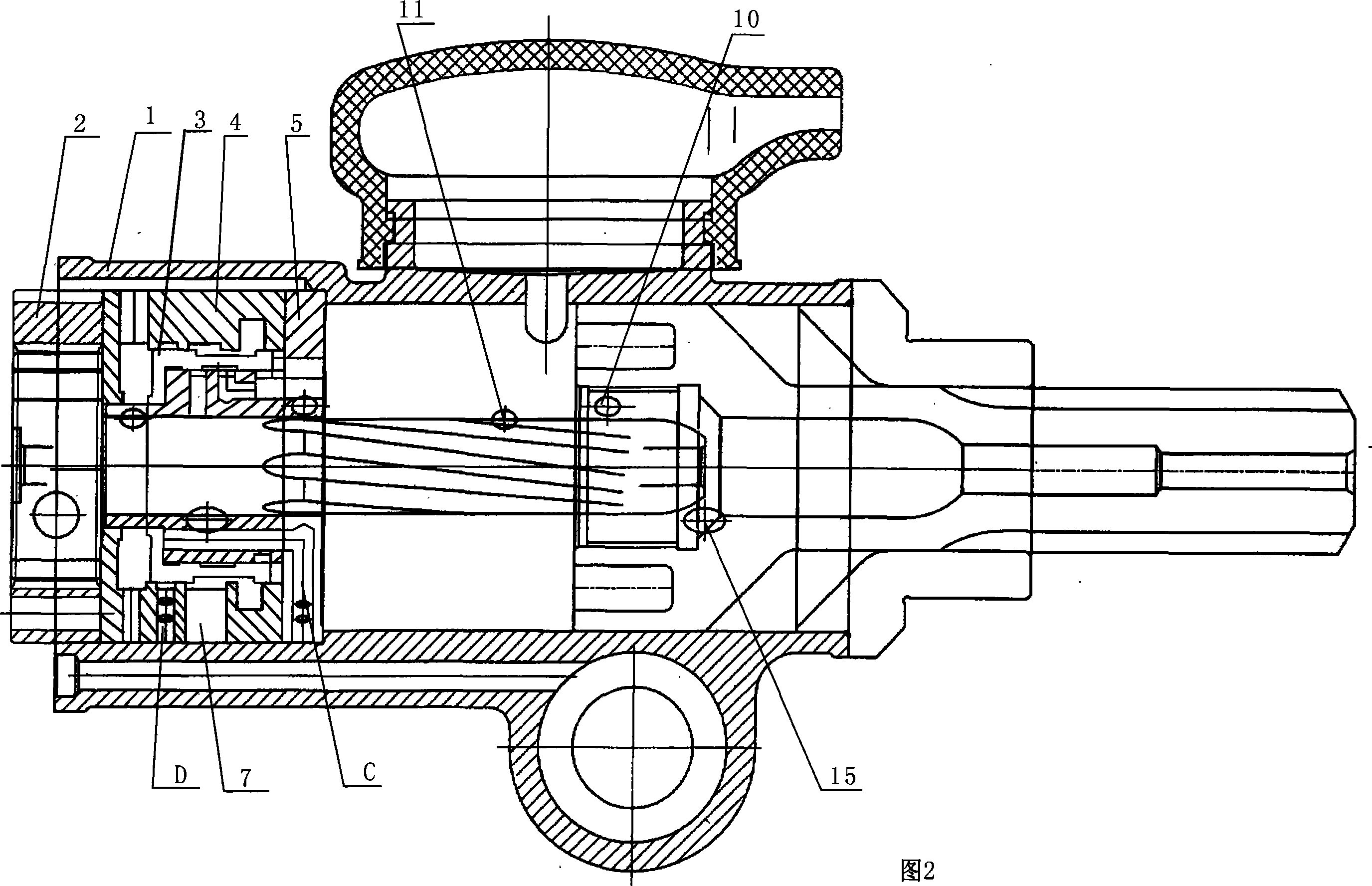

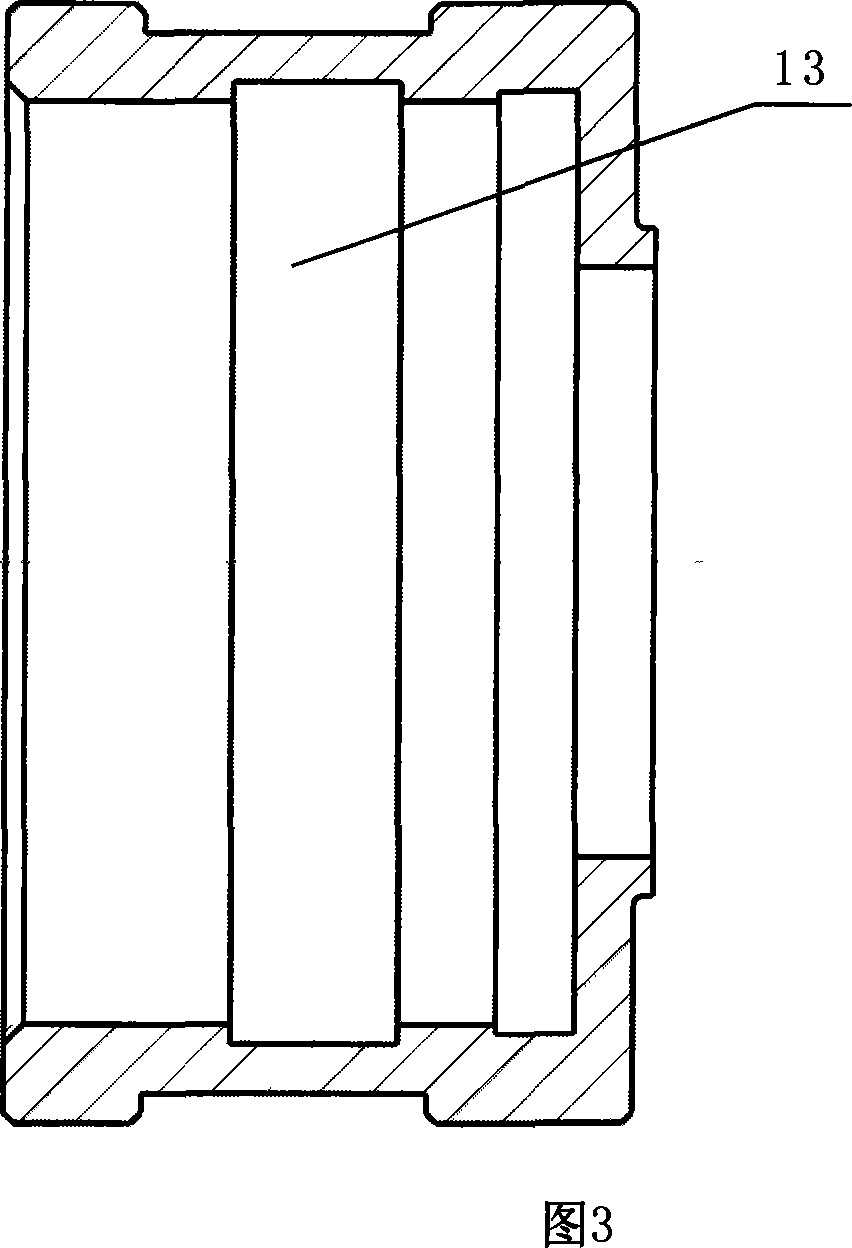

Airleg rock drill

InactiveCN101050688AReduce resistanceIncrease the kinetic energy of impacting the shankConstructionsReciprocating drilling machinesDrillPiston

The present invention relates to an air-feed leg rock drill, belonging to the field of pneumatic machinery technology. It includes three portions of cylinder body, holder body and machine head. In the cylinder body interior a valve body is set, said valve body is formed from valve cover, reversal valve which can be leftwards and rightwards slided on its shaft and valve chest. On D section of its valve chest four exhaust outlets are cut, on the internal circumferential surface of its reversal valve a circular groove is cut, on the right end face of its valve cover several axial holes are set, four radial holes cut in first circular groove are communicated with four axial holes cut on the valve cover and four radial holes cut in second circular groove are communicated with four axial holes set on the side surface of valve cover. Said invention can increase stroke of piston and can raise impact energy.

Owner:王光临

Medium chromium alloy wear-resisting steel ball and preparation method thereof

InactiveCN107739985AHigh hardnessImprove toughnessFurnace typesHeat treatment furnacesSteel ballWear resistance

The invention discloses a medium chromium alloy wear-resisting steel ball and a preparation method thereof and relates to the technical field of wear-resisting materials. The chemical components of the medium chromium alloy wear-resisting steel ball comprise, by weight, 1.5-1.9% of C, 0.9-1.2% of Si, 0.7-1.0% of Mn, 5.5-7.0% of Cr, 0.3-0.5% of Mo, 0.08-0.20% of Ti, 0.1-0.2% of Cu, 0.02-0.05% of Nb, 0.06-0.08% of Al, 0.02-0.05% of Hf, 0.05-0.1% of B, 0-0.05% of P, 0-0.04% of S, and the balance Fe and inevitable impurities. The chemical components and contents thereof of the medium chromium alloy wear-resisting steel ball are reasonably optimized, the synergy is enhanced, the strength, hardness and toughness of the medium chromium alloy are improved remarkably, the prepared wear-resisting steel ball is excellent in comprehensive mechanical performance, the good impact energy is achieved while the effect that the high hardness HRC is greater than or equal to 61 is ensured, and wear resistance and corrosion resistance are good.

Owner:TONGLING MINGCHENG FOUNDRY

Erosion-resistant fluorine rubber nanometer composite material with graphene and method for preparing erosion-resistant fluorine rubber nanometer composite material

The invention belongs to the technical field of graphene / rubber nanometer composite materials, and relates to an erosion-resistant fluorine rubber nanometer composite material with graphene and a method for preparing the erosion-resistant fluorine rubber nanometer composite material. The erosion-resistant fluorine rubber nanometer composite material comprises, by weight, 100 parts of fluorine rubber, 0.1-15 parts of graphene, 0.5-20 parts of carbon black, 0.5-20 parts of carbon fibers, 3-7 parts of oxide or hydroxide acid acceptors, 2-5 parts of peroxide or bisphenol vulcanizing agents, 0.2-7parts of assistant cross-linking agents and 0.5-5 parts of silane coupling agents. The erosion-resistant fluorine rubber nanometer composite material and the method have the advantages that pre-dispersion treatment is carried out on the graphene by the aid of ball milling processes, accordingly, the dispersibility of the graphene in the fluorine rubber can be improved, the erosion resistance of the fluorine rubber can be effectively improved, erosion loss can be reduced by 62% as compared with fluorine rubber without graphene, the erosion loss further can be reduced by 43% as compared with fluorine rubber which is not subjected to pre-dispersion treatment and is directly additionally provided with graphene, and the erosion resistance can be obviously improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com