Hybrid composite structures for ballistic protection

a composite structure and ballistic protection technology, applied in the direction of protective equipment, weapons, armour, etc., can solve the problems of reducing the mobility and speed of the vehicle, reducing the stiffness of the resulting structure, and the existing type of two-layer composite armor has poor structure integrity and less multi-hit resistance, so as to improve the ability to withstand multiple impacts/hits, improve the structural integrity, and absorb high-impact energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

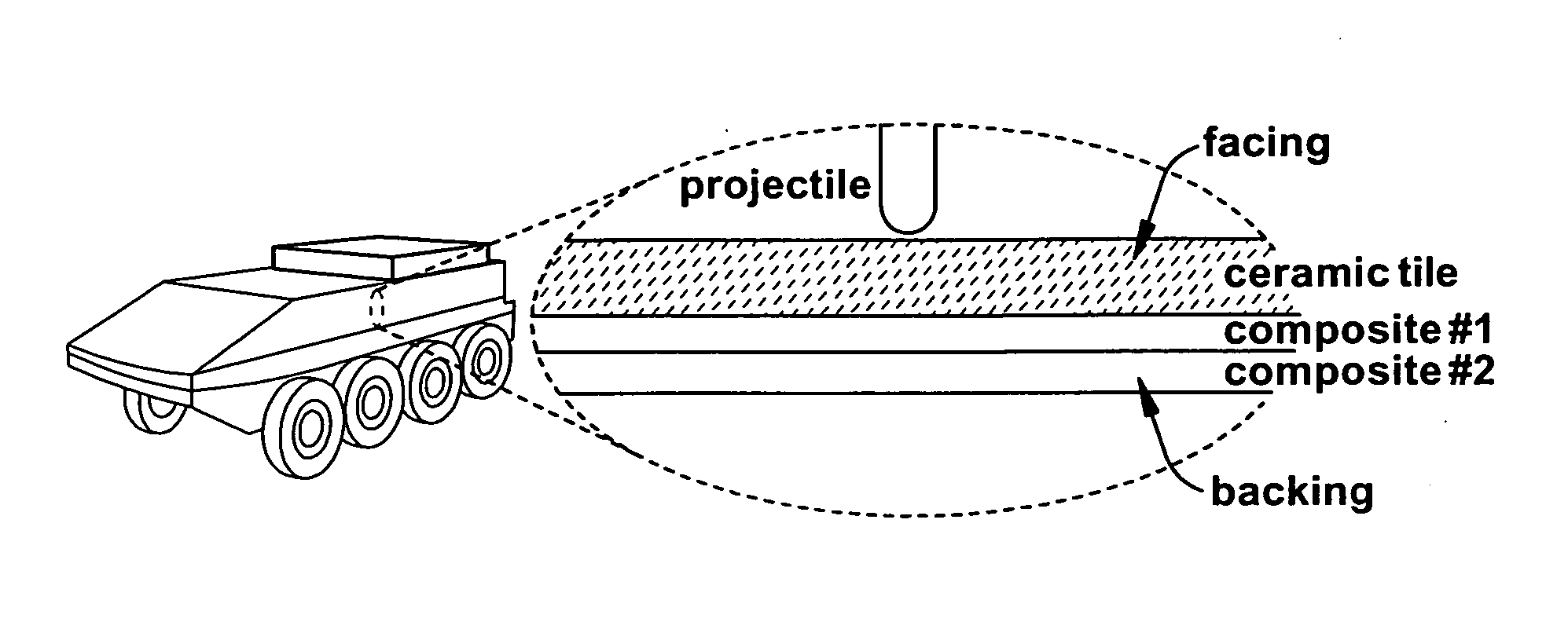

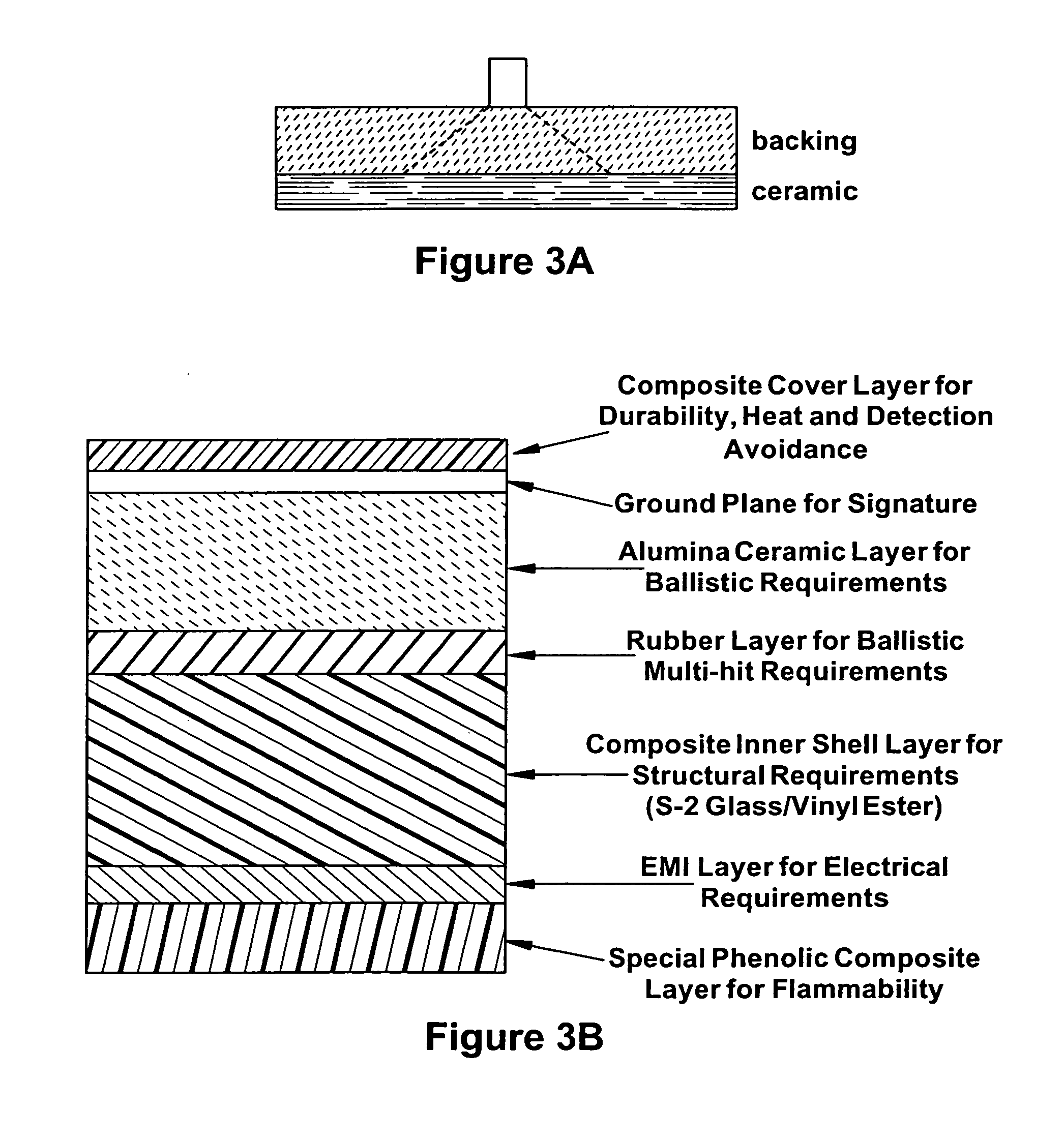

[0021] The present invention relates to hybrid composite structures with improved ballistic protection properties. More specifically, the present invention relates to hybrid composite structures with improved ballistic protection properties that comprise at least three sub-layers.

[0022] In one embodiment, the present invention relates to designs for ballistic protection based on various materials arid fiber architectures, that are achieved using preliminary design analysis and selection of armor composite structure. These armor composite structures achieve performance under ballistic impact as shown using numerical finite element simulation. The result is a hybrid composite structure or structures with improved ballistic protection properties.

[0023] In another embodiment, the present invention relates to hybrid composite armor structures comprising at least three layers. In one embodiment, the three layer hybrid composite armor of the present invention includes at least one cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com