Sun-proof composite modified polypropylene pipe for power cable protection

A polypropylene pipe, composite modification technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor vertical rigidity and toughness of polypropylene, affecting the service life of pipes, and long placement time of pipes, etc., to improve the light resistance performance. , the effect of improving market competitiveness and improving impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

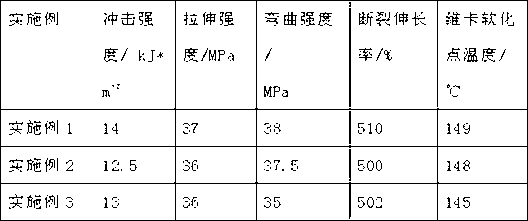

Examples

Embodiment 1

[0030] A light-resistant composite modified polypropylene pipe material for power cable protection, comprising the following components by weight percentage:

[0031] PP 78%

[0032] POE 10%

[0033] Nano calcium carbonate 4.8%

[0034] Nucleating agent 0.3%

[0035] Coupling agent 0.2%

[0036] Sun-resistant and lubricating composite functional masterbatch 0.5%

[0037] In terms of weight percentage, it also contains 3.8% metal wire and 3.3% modified capsaicin, and the modified capsaicin is a kind of capsaicin wrapped with organic substances.

[0038] The sun-resistant and lubricating composite functional masterbatch includes a light stabilizer, a composite heat stabilizer, a free radical quenching agent, and a dispersant.

[0039] The selected nucleating agent model is XL-NA2002; the coupling agent is γ-(methacryloyloxy)propyltrimethoxysilane; the POE model is 8198, produced by DOW Company of the United States; the PP model is PP1300, Yanshan Petrochemical Production. ...

Embodiment 2

[0044] A light-resistant composite modified polypropylene pipe material for power cable protection, comprising the following components by weight percentage:

[0045] PP 73%

[0046] POE 15%

[0047] Nano calcium carbonate 5.2%

[0048] Nucleating agent 0.4%

[0049] Coupling agent 0.25%

[0050] Light-resistant and lubricating composite functional masterbatch 1%

[0051] In terms of weight percentage, it also contains 3% metal wire and 3% modified capsaicin, which is a kind of capsaicin wrapped with organic substances.

[0052] The sun-resistant and lubricating composite functional masterbatch includes a light stabilizer, a composite heat stabilizer, a free radical quenching agent, and a dispersant.

[0053] The selected nucleating agent model is ZC-3; the coupling agent is vinyl tris (b-methoxyethoxy) silane; the POE model is 8198, produced by DOW Company of the United States; the PP model is PP1300, produced by Yanshan Petrochemical .

[0054] The preparation method ...

Embodiment 3

[0058] A light-resistant composite modified polypropylene pipe material for power cable protection, comprising the following components by weight percentage:

[0059] PP 75.6%

[0060] POE 12%

[0061] Nano calcium carbonate 5%

[0062] Nucleating agent 0.35%

[0063] Coupling agent 0.22%

[0064] Sun-resistant and lubricating composite functional masterbatch 0.8%

[0065] In terms of weight percentage, it also contains 3% metal wire and 3% modified capsaicin, which is a kind of capsaicin wrapped with organic substances.

[0066] The sun-resistant and lubricating composite functional masterbatch includes a light stabilizer, a composite heat stabilizer, a free radical quenching agent, and a dispersant.

[0067] The selected nucleating agent model is CaV102; the coupling agent is γ-aminopropyltriethoxysilane; the POE model is 8198, produced by DOW Company of the United States; the PP model is PP1300, produced by Yanshan Petrochemical.

[0068] The preparation method of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com