Buffer landing leg for planet detector

A technology of detectors and landing legs, which is applied in the direction of extraterrestrial vehicles, etc., can solve problems such as self-repair, heavy weight, and attitude adjustment, and achieve the effects of long service life, good structural rigidity, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

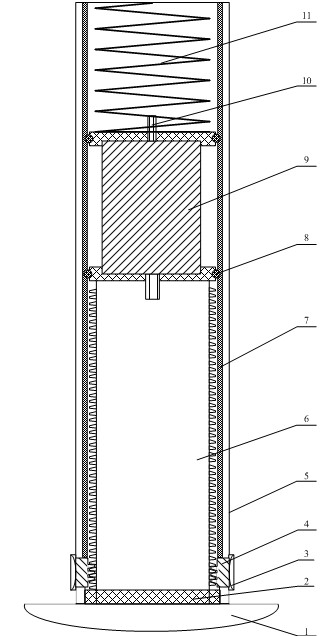

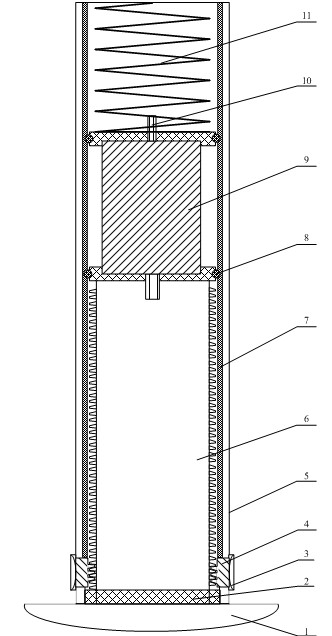

[0014] Such as figure 1 As shown, the buffer landing leg of the planetary probe of the present invention includes an outer cylinder 5, an inner cylinder 6 and a foot pad 1, a guide rail 7 is arranged on the inner wall of the outer cylinder 5, and a rotating motor 9 is arranged on the upper end of the inner cylinder 6. The output rotating shaft 10 of the rotary motor 9 is fixedly connected with the inner cylinder 6, and a compression spring 11 is also arranged on the upper end of the rotary motor, and the upper end of the compression spring 11 contacts with the top of the outer cylinder 5, and the two sides of the rotary motor 9 are also provided with Two sets of 4 pulleys 8; the inner cylinder 6 slides up and down in the outer cylinder 5 through the pulleys 8, the foot pad 1 is arranged at the lower end of the inner cylinder 6, and is connected by a linear bearing 2, and the outer peripheral surface of the inner cylinder 6 is provided with a spiral convex Teeth, on the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com