Multilayer bulletproof member and preparation method and application thereof

A multi-level, component technology, applied in the direction of protective equipment, offensive equipment, armor plate structure, etc., can solve the problems of low performance, high quality, weak design, etc., to avoid human injury, reduce damage, and facilitate the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

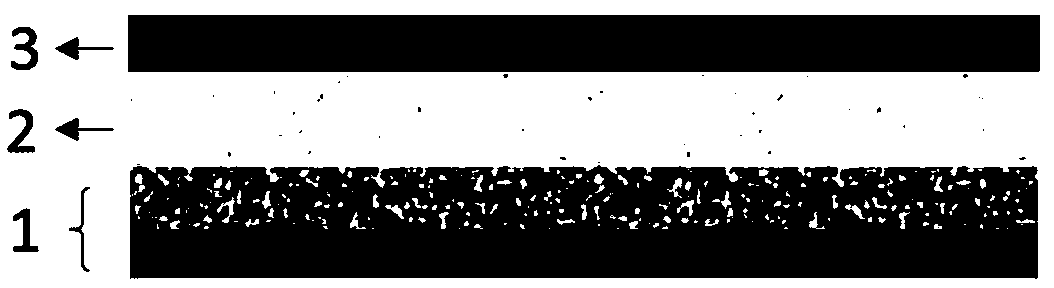

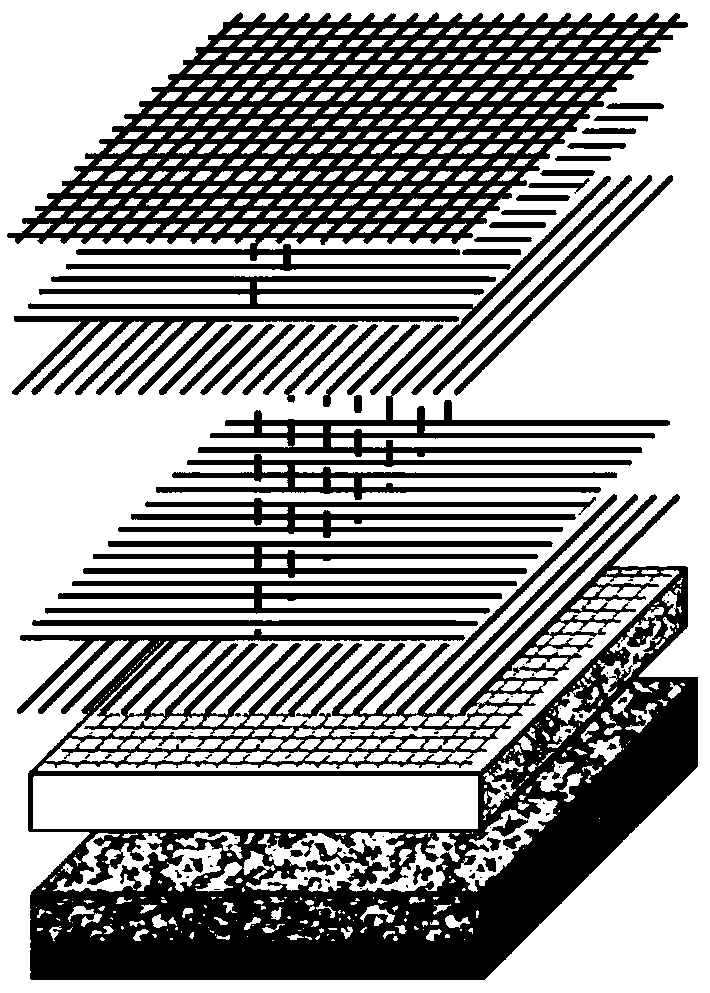

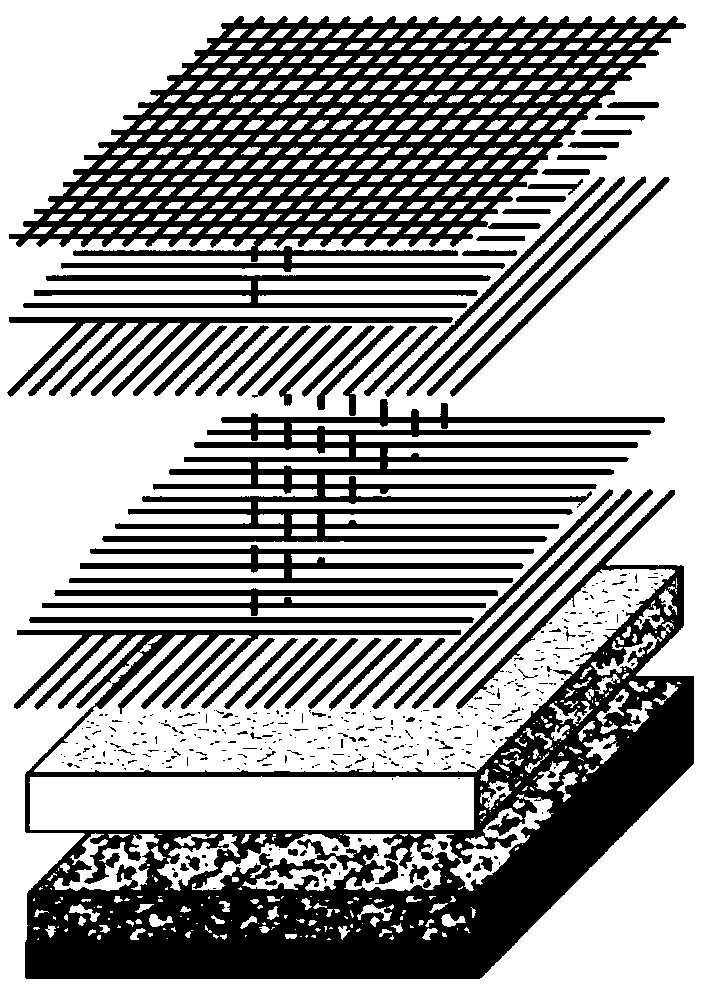

[0029] A multi-layer bulletproof component, the bulletproof component includes a metal / ceramic anti-crack reflective layer, a fiber / elastomer composite energy-absorbing layer and a two-dimensional fabric protection blunt injury layer; the three-layer structure is stacked in sequence; the bulletproof component The preparation method comprises the steps:

[0030] (1) prepare metal / ceramic anti-crack reflection layer;

[0031] The metal / ceramic anti-crack reflective layer is made of 2024 series aluminum alloy and boron carbide ceramic material with a particle size of 30 μm, which is prepared by impregnating the metal solution of the ceramic preform, in which the content of aluminum alloy and ceramic is 1:1, and the preheating temperature of the preform is 300°C , the casting temperature is 800°C, the osmotic pressure is 3.5MPa, and the density of the prepared composite material is about 2.8g / cm 3 , the thickness is 9mm;

[0032] (2) Preparation of fiber / elastomer composite ener...

Embodiment 2

[0040] A multi-layer bulletproof component, the bulletproof component includes a metal / ceramic anti-crack reflective layer, a fiber / elastomer composite energy-absorbing layer and a two-dimensional fabric protection blunt injury layer; the three-layer structure is stacked in sequence; the bulletproof component The preparation method comprises the steps:

[0041] (1) prepare metal / ceramic anti-crack reflection layer;

[0042] The metal / ceramic anti-crack reflective layer is made of 7000 series aluminum alloy and silicon carbide ceramic material with a particle size of 25 μm, which is prepared by the metal solution impregnation method of the ceramic preform, in which the content of aluminum alloy and ceramic is 1:1, and the preheating temperature of the preform is 500°C , the casting temperature is 900°C, the osmotic pressure is 2MPa, and the density of the prepared composite material is about 3.0g / cm 3 , the thickness is 7mm;

[0043] (2) Preparation of fiber / elastomer composi...

Embodiment 3

[0051] A multi-layer bulletproof component, the bulletproof component includes a metal / ceramic anti-crack reflective layer, a fiber / elastomer composite energy-absorbing layer and a two-dimensional fabric protection blunt injury layer; the three-layer structure is stacked in sequence; the bulletproof component The preparation method comprises the steps:

[0052] (1) prepare metal / ceramic anti-crack reflection layer;

[0053] The metal / ceramic anti-crack reflective layer is prepared from 5000 series aluminum alloy and boron nitride ceramic material with a particle size of ceramic preform metal solution impregnation method, in which the content of aluminum alloy and ceramic is 1:1, and the preheating temperature of the preform is 400°C. The casting temperature is 700°C, the osmotic pressure is 5MPa, and the density of the composite material prepared is about 3.0g / cm 3 , the thickness is 8mm;

[0054] (2) Preparation of fiber / elastomer composite energy-absorbing layer;

[0055]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com