Airleg rock drill

A rock drill and air leg technology, which is applied in the field of air leg rock drills, can solve the problems of reduced impact energy, short piston stroke, and poor exhaust in the front chamber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

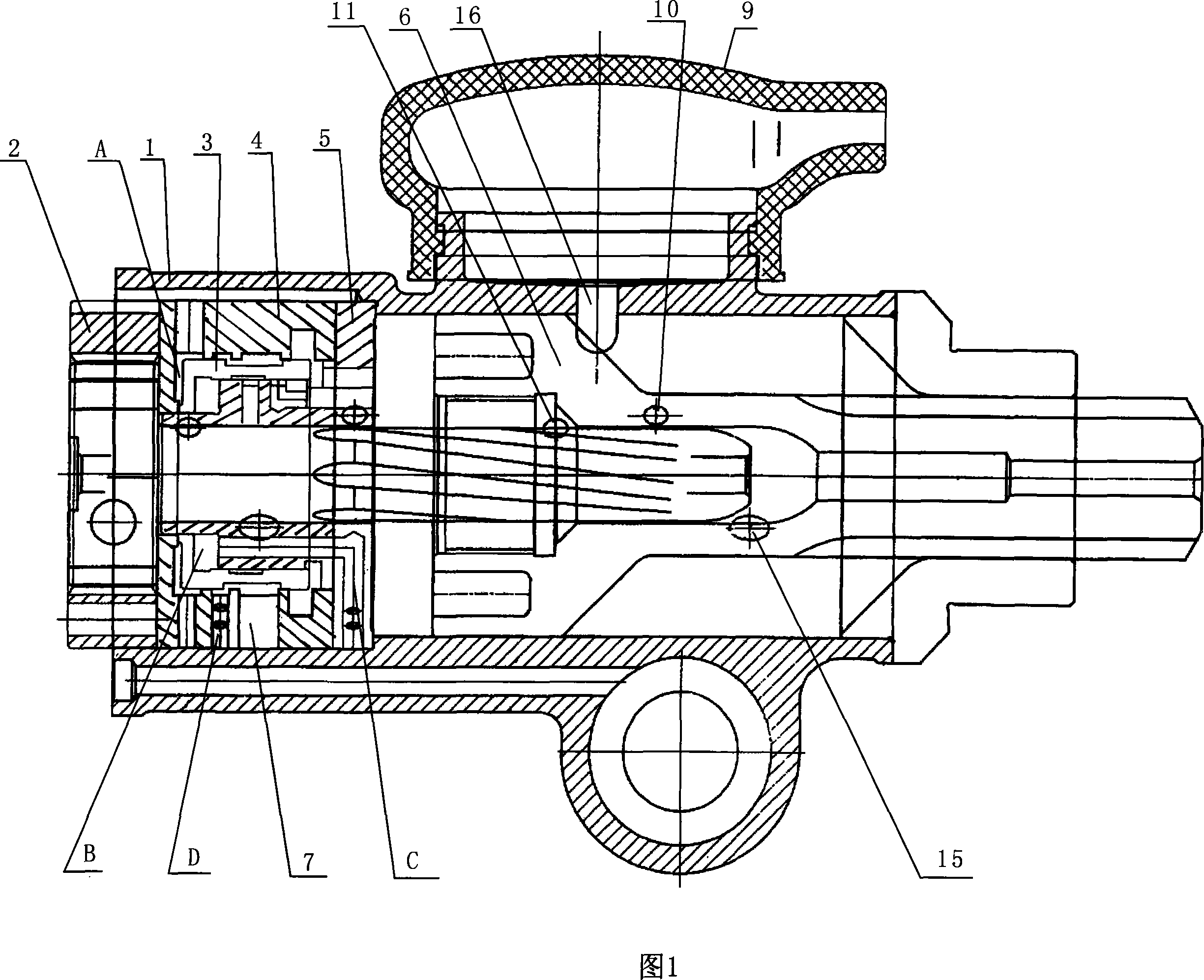

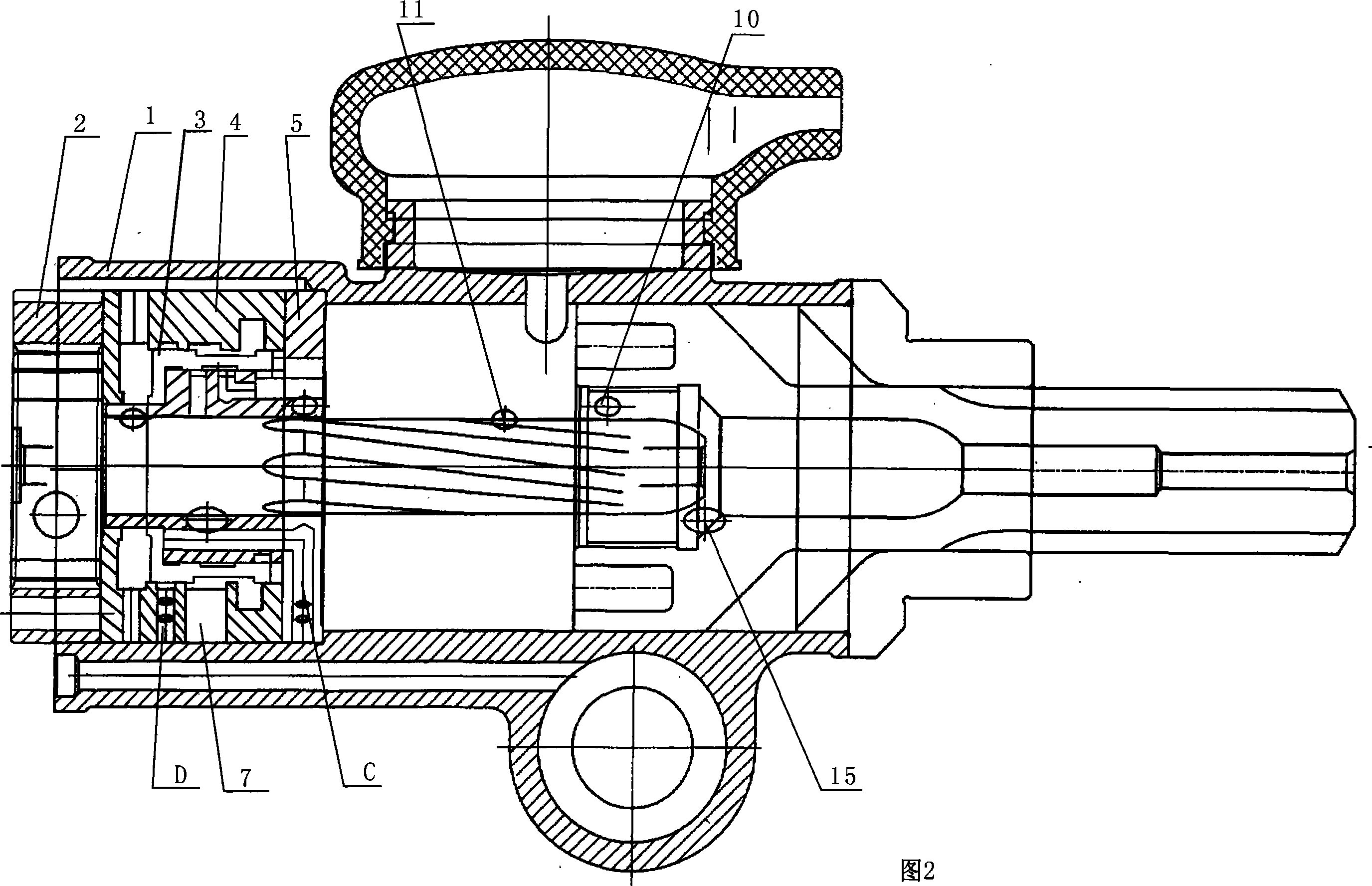

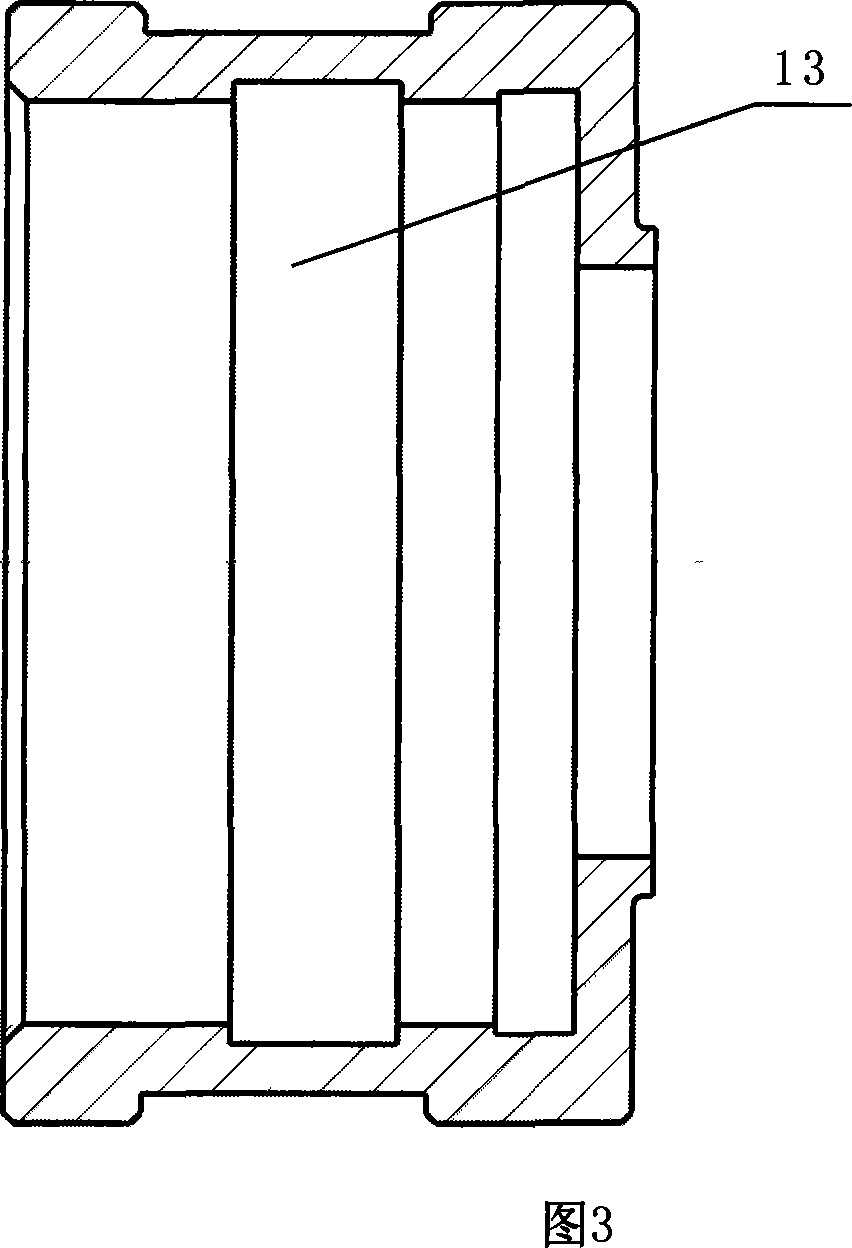

[0026] As shown in Figures 1, 2, 3, 4, 5, and 6: the air leg rock drill includes three parts: a handle body, a cylinder body (1) and a machine head; the cylinder body (1) has a built-in valve body, and the valve body The body consists of a valve cover (5), a reversing valve (3) that can slide left and right on its shaft, and a valve cabinet (4); the D section of the valve cabinet (4) has four vent holes (8a). , newly dug with annular groove (13) on the inner circle of its reversing valve (3). The four newly dug radial holes (14a) in the first annular groove (17) communicate with the newly dug four axial holes (12) on the valve cover (5). The four newly dug radial holes (14b) in the second annular groove (18) communicate with the newly dug four radial exhaust holes (8b) on the side of the valve cover (5). There are 4 axial holes (12) newly excavated on the right end face of its bonnet (5), and 4 exhaust holes (8b) are newly excavated on the side of the bonnet (5); Two annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com