Patents

Literature

89results about How to "Impact speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

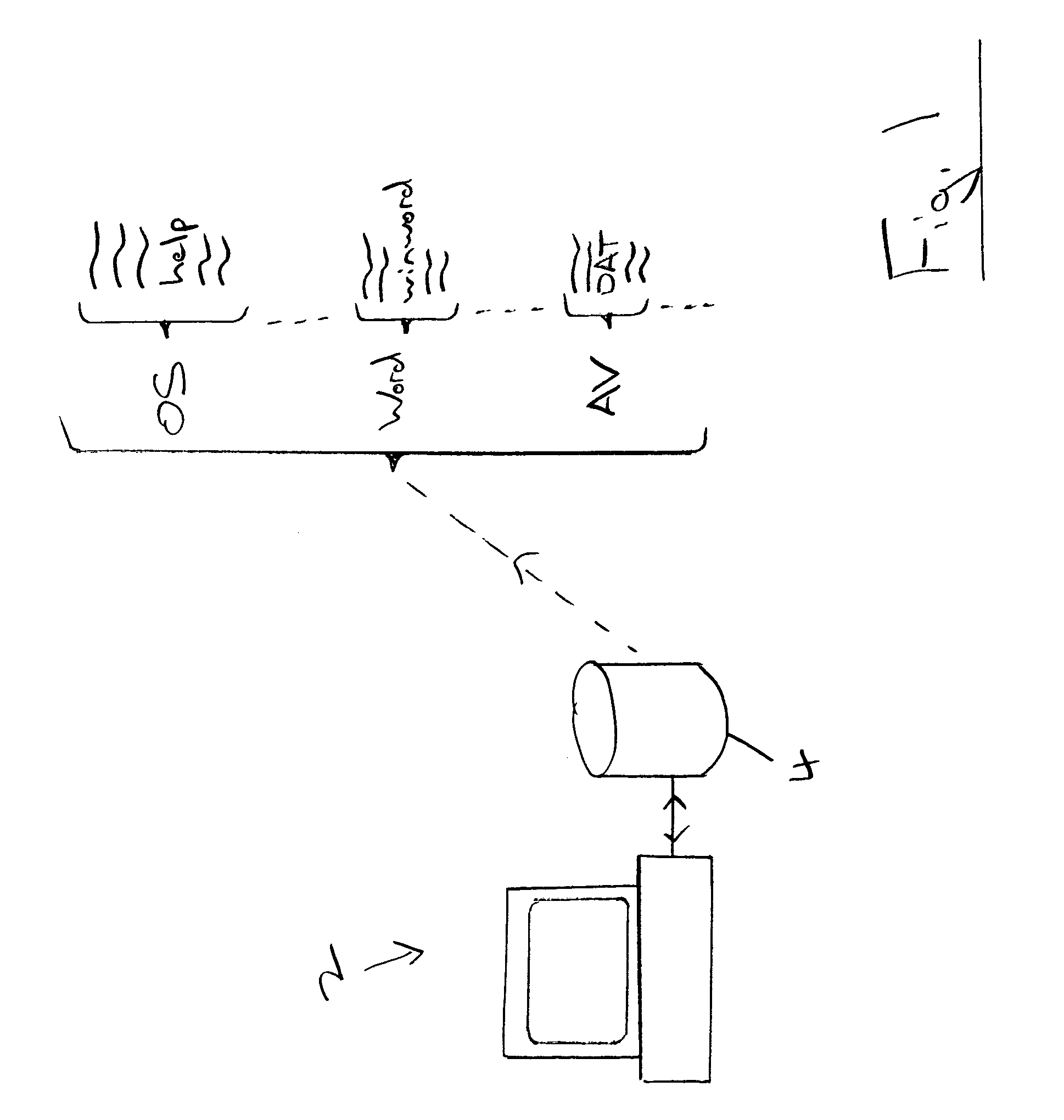

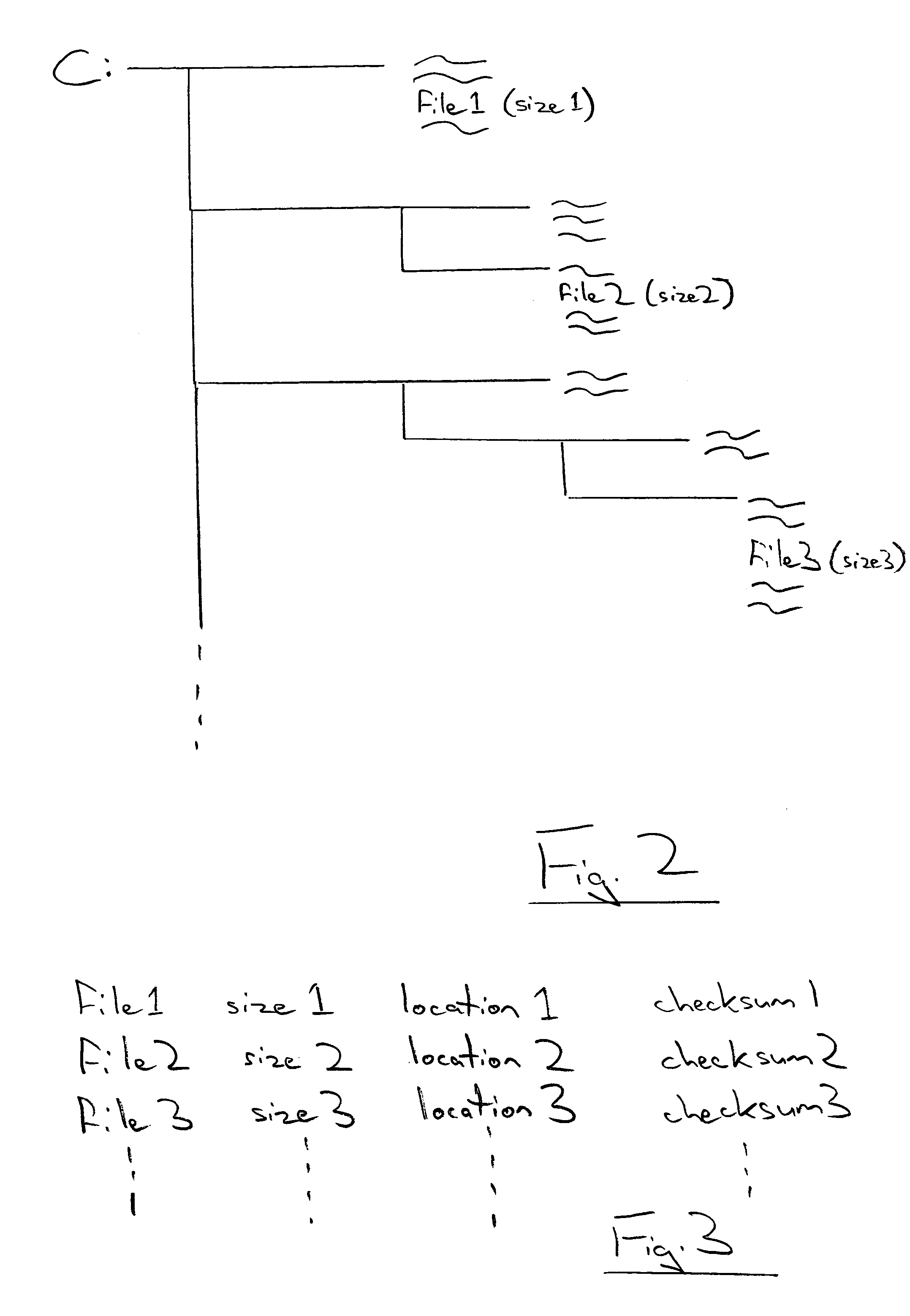

Pre-approval of computer files during a malware detection

InactiveUS20050021994A1Addressing slow performanceEffectively ensureMemory loss protectionDigital data processing detailsChecksumFile size

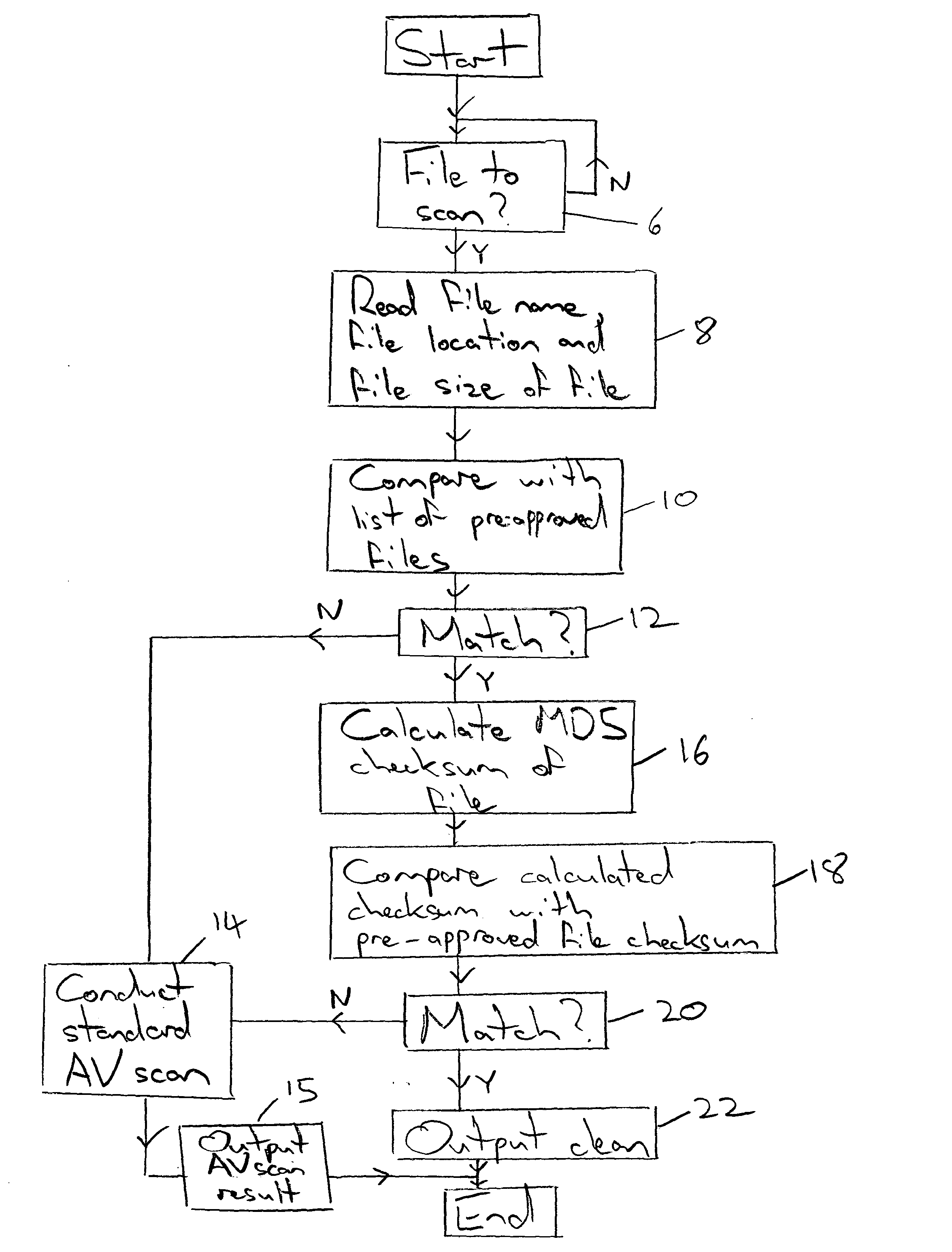

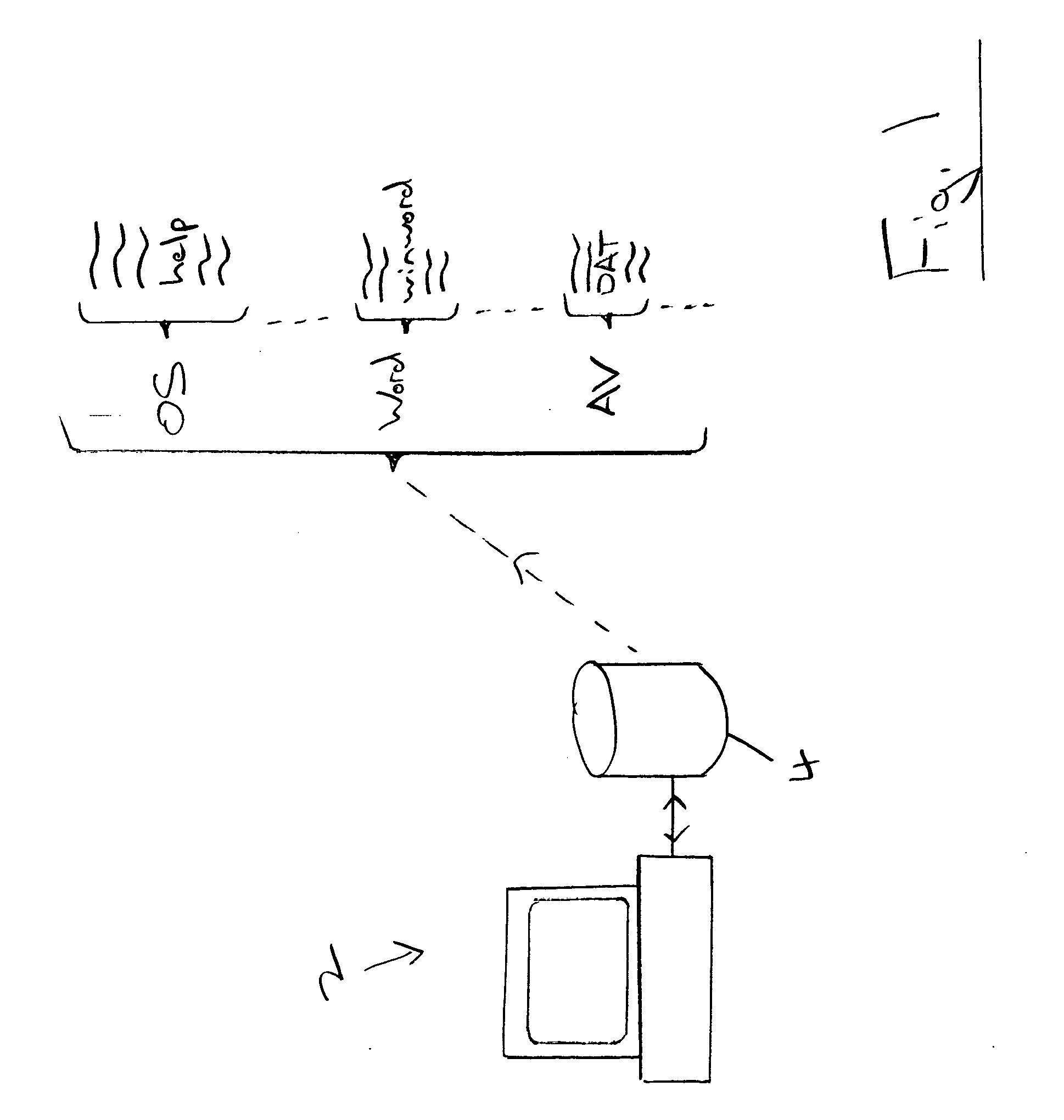

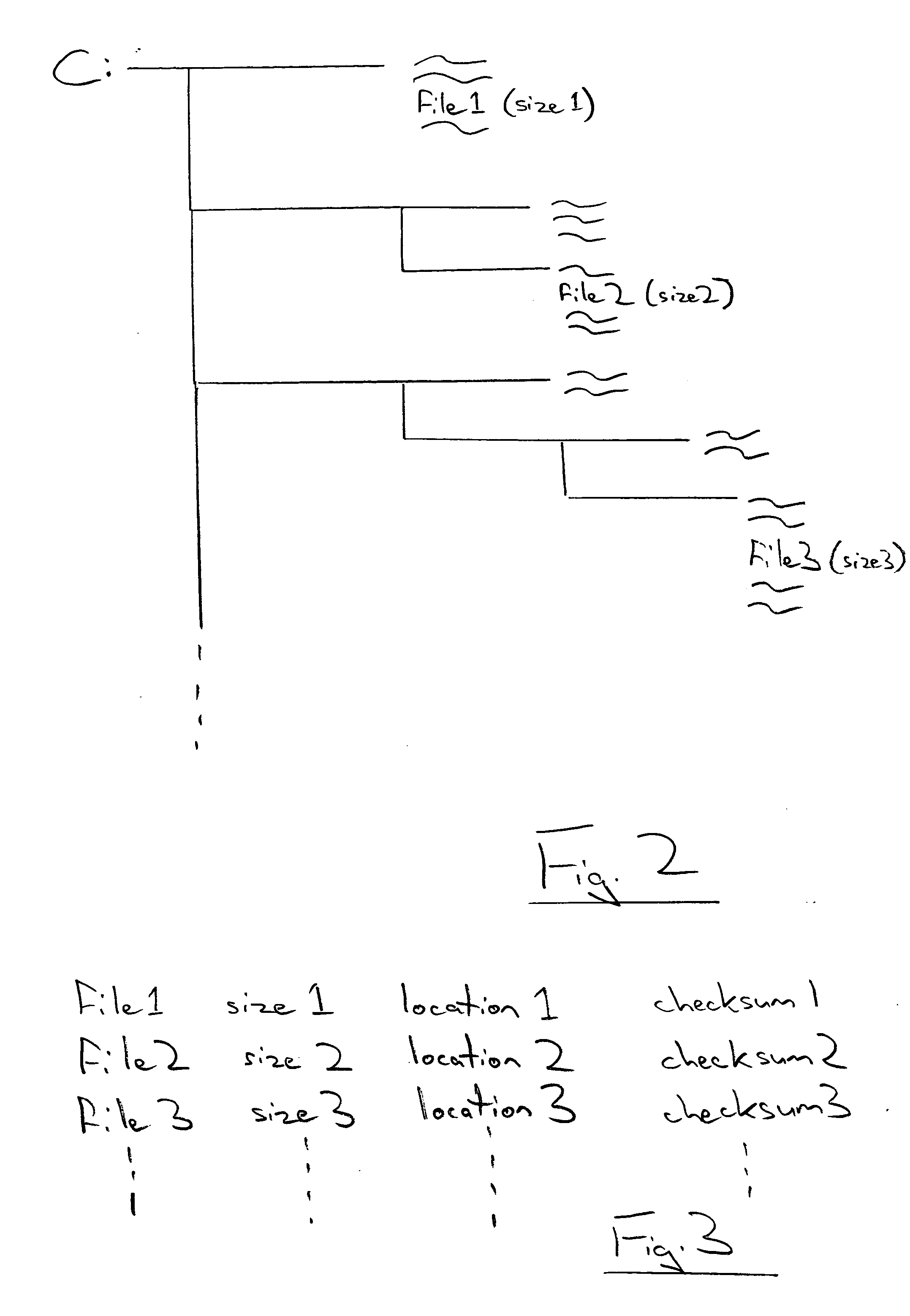

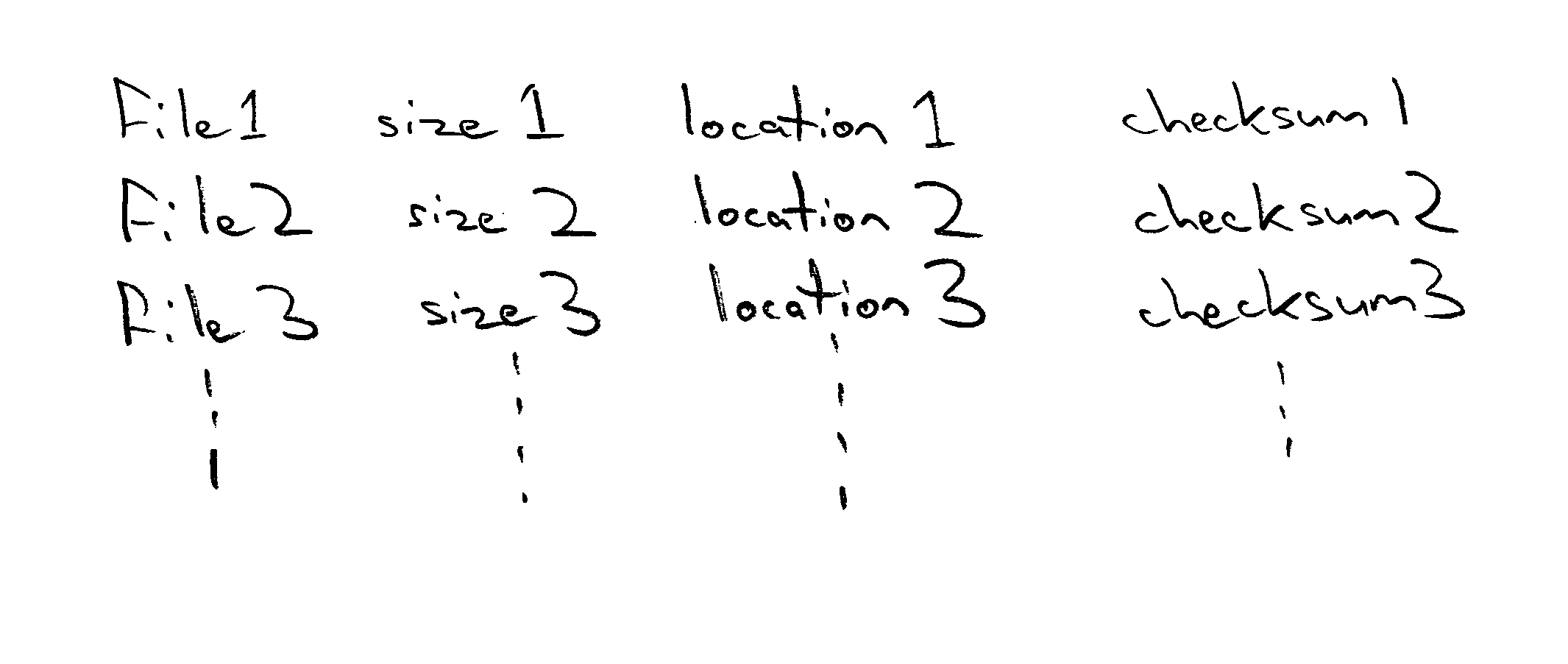

A malware detection system seeking to identify computer viruses, worms, Trojans, banned files and the like acts to determine from the file name, file size and storage location of a computer file being tested, whether that computer file potentially matches a specific known malware free computer file stored within a list of such specific known malware free computer files. If a match occurs indicating that the candidate computer file is potentially the specific known malware free computer file, then this is confirmed by calculating a checksum of the candidate computer file and comparing this against a stored corresponding checksum of the specific known malware free computer file. If these checksums match, then the candidate computer file can be passed as clean without requiring further time consuming malware detection scanning.

Owner:MCAFEE INC

Pre-approval of computer files during a malware detection

InactiveUS7257842B2Abundant resourcesImpact speedMemory loss protectionDigital data processing detailsChecksumMalware

A malware detection system seeking to identify computer viruses, worms, Trojans, banned files and the like acts to determine from the file name, file size and storage location of a computer file being tested, whether that computer file potentially matches a specific known malware free computer file stored within a list of such specific known malware free computer files. If a match occurs indicating that the candidate computer file is potentially the specific known malware free computer file, then this is confirmed by calculating a checksum of the candidate computer file and comparing this against a stored corresponding checksum of the specific known malware free computer file. If these checksums match, then the candidate computer file can be passed as clean without requiring further time consuming malware detection scanning.

Owner:MCAFEE INC

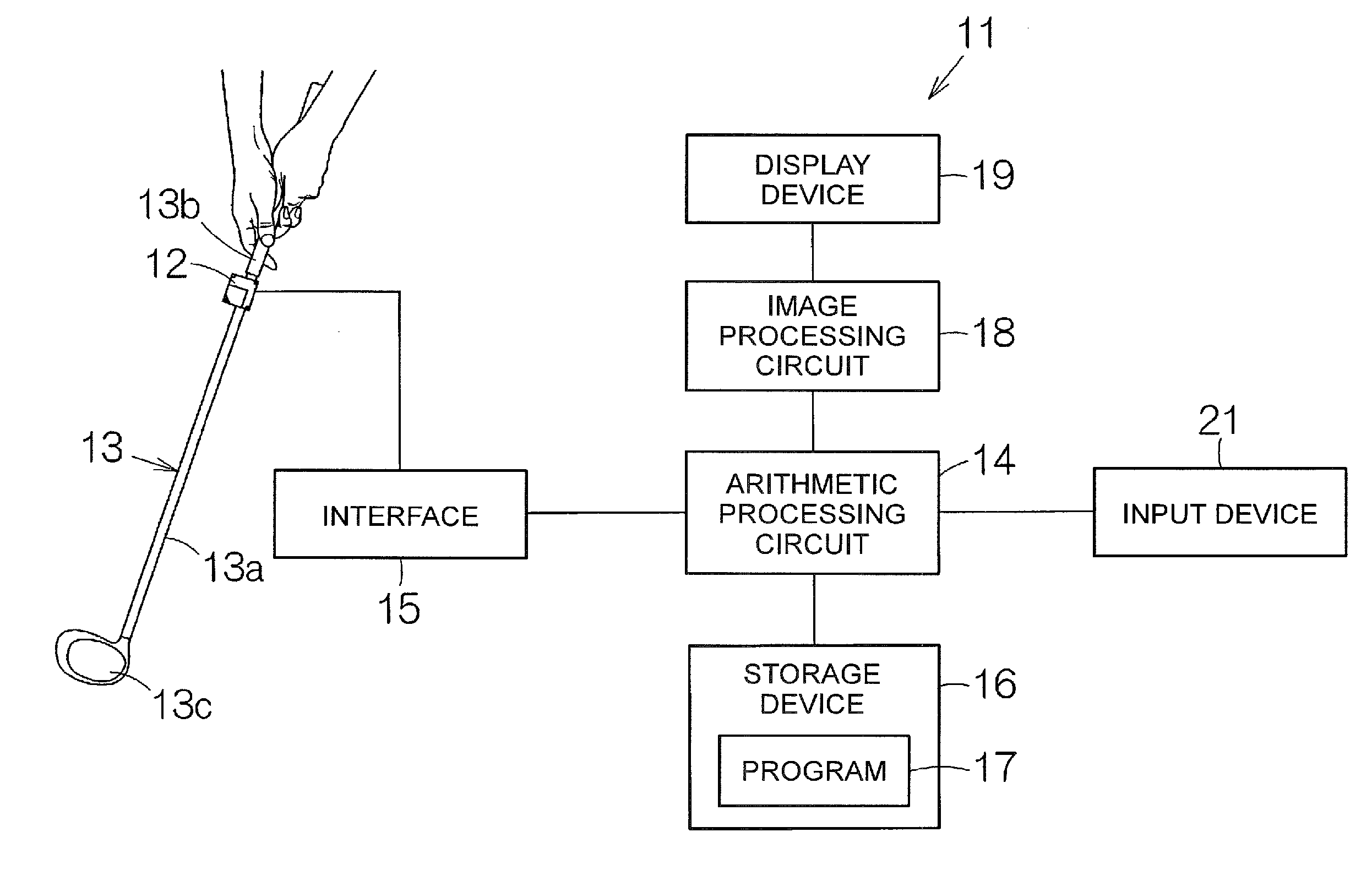

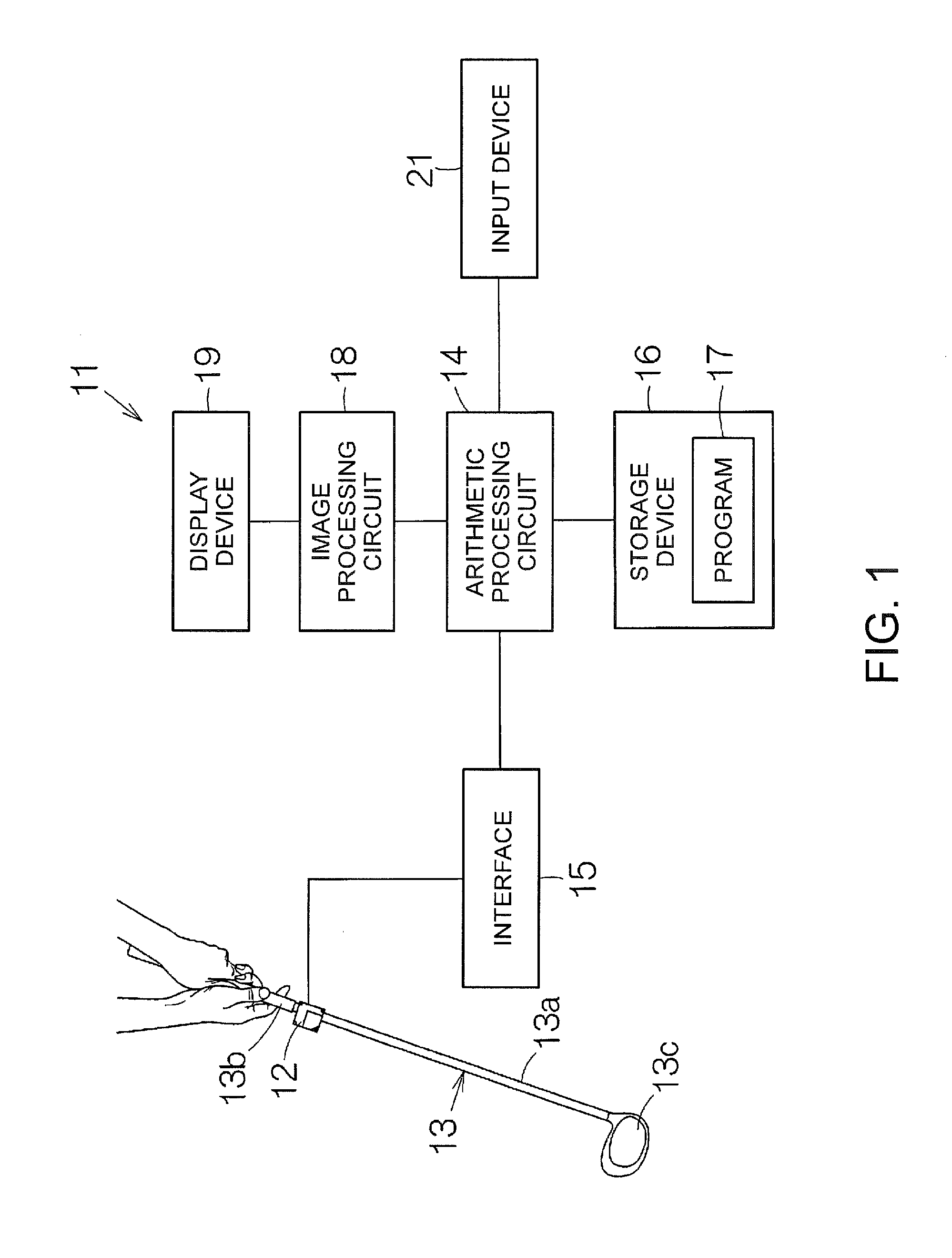

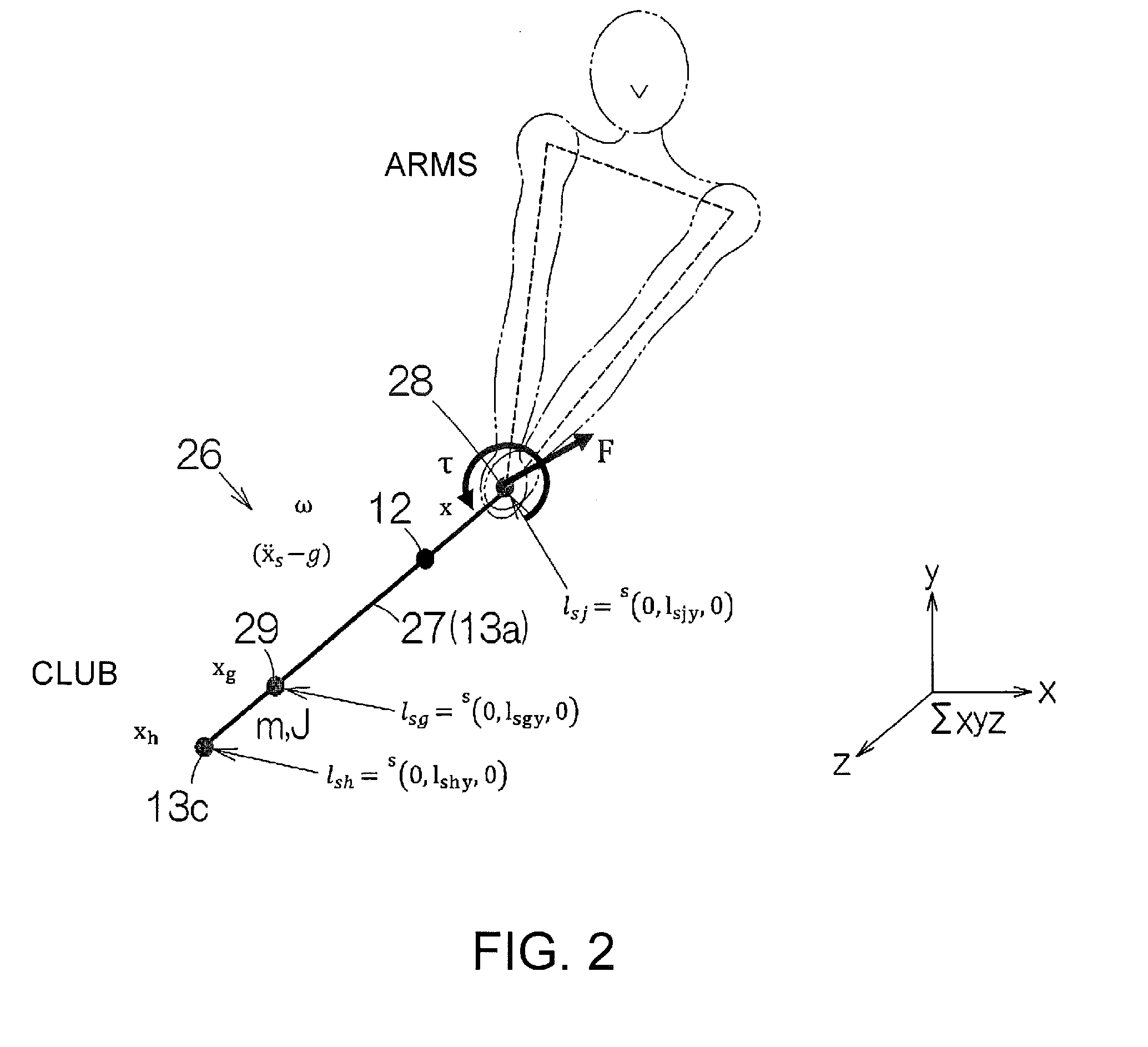

Motion analysis method and motion analysis device

ActiveUS20140379294A1Well formedImpact speedAcceleration measurement using interia forcesSpeed measurement using accelerationEngineeringAnalysis method

A motion analysis method includes calculating a change in an amount of inertia of a region attached with an inertial sensor during a swing using an output of the inertial sensor, and identifying a maximum value of the amount of inertia during the swing to compare the maximum value and the amount of inertia at an impact with each other. A deceleration timing during the swing of the region (the grip of the sporting equipment) attached with the inertial sensor is identified, and the quality of the swing can be evaluated.

Owner:SEIKO EPSON CORP

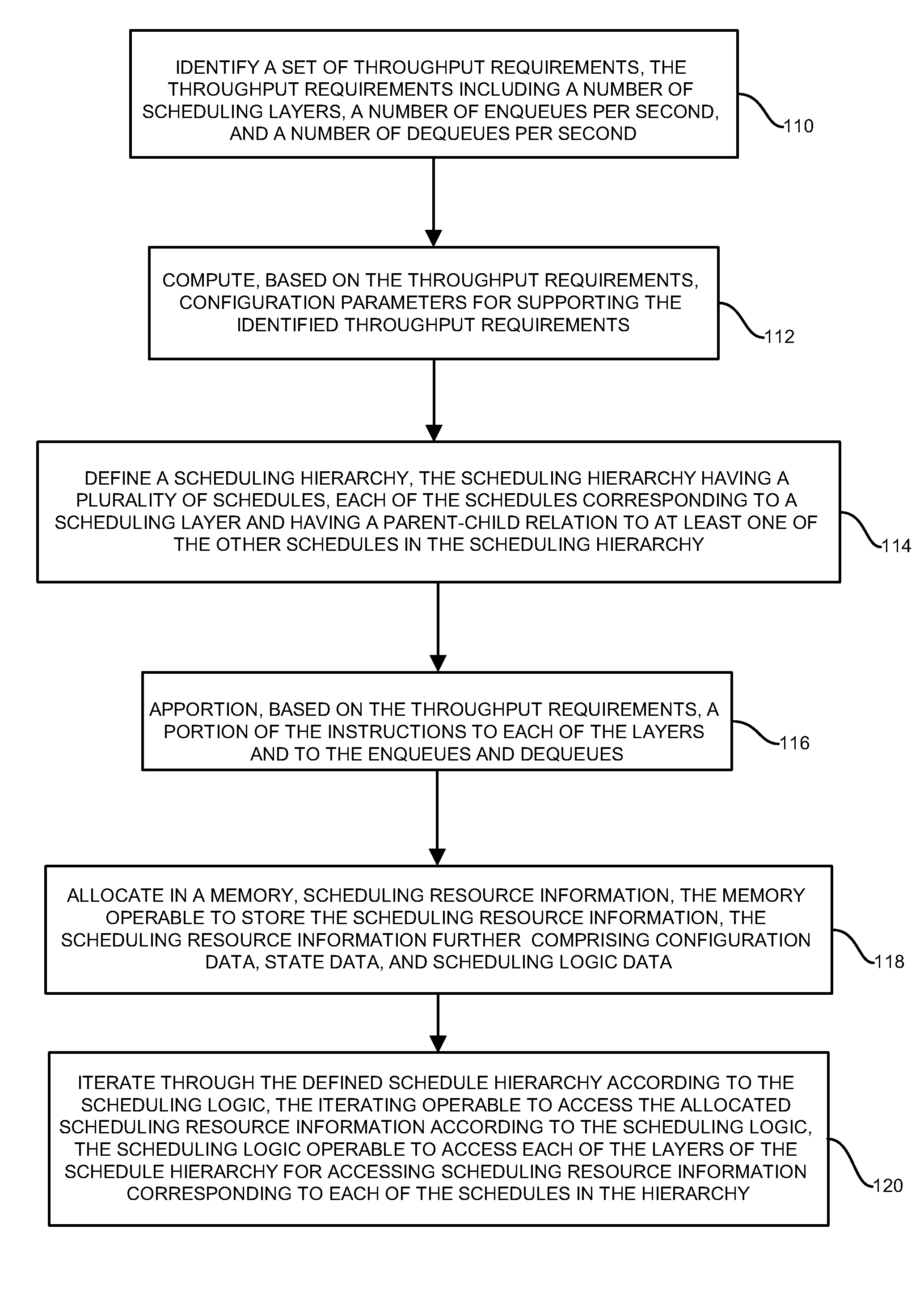

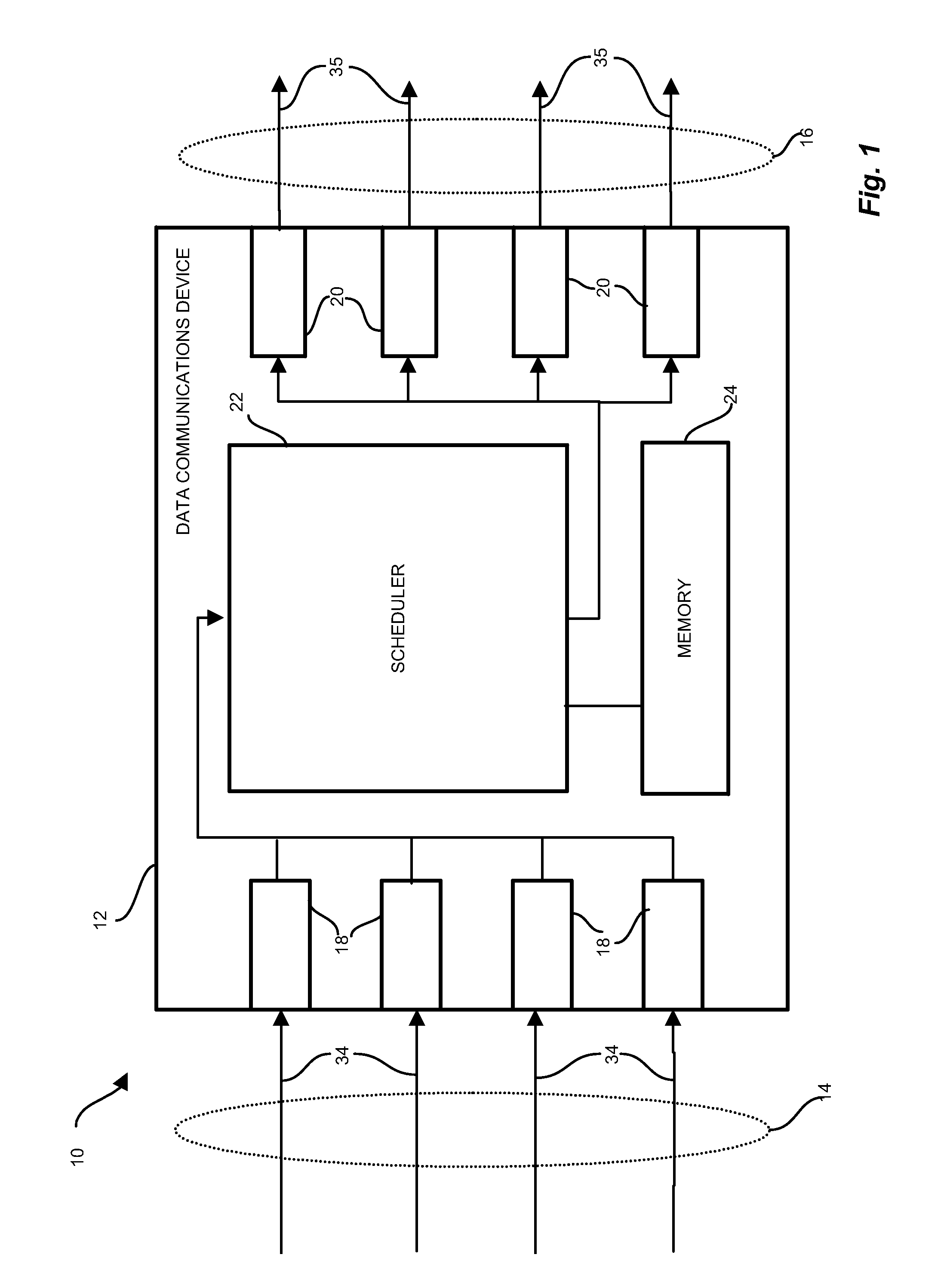

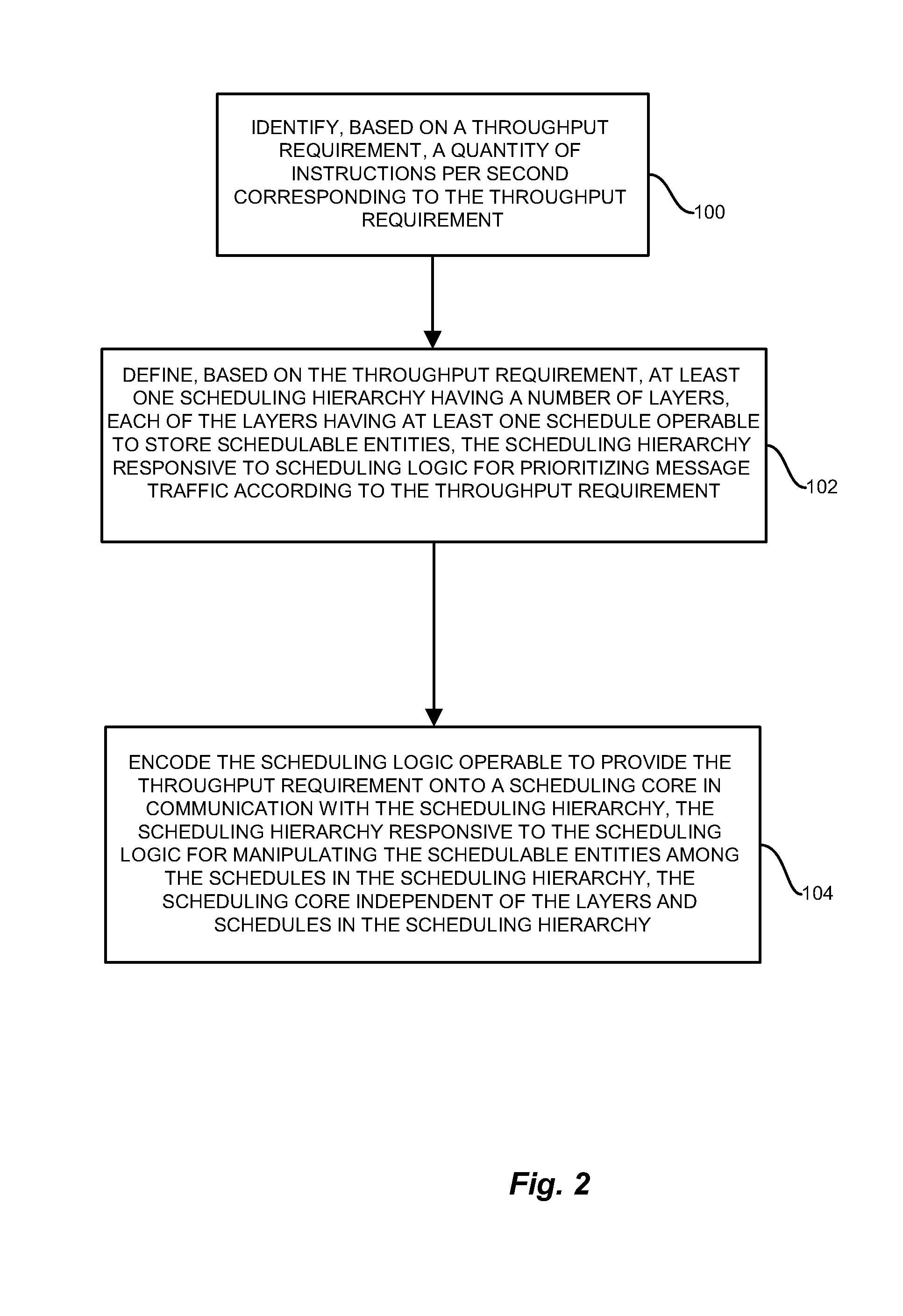

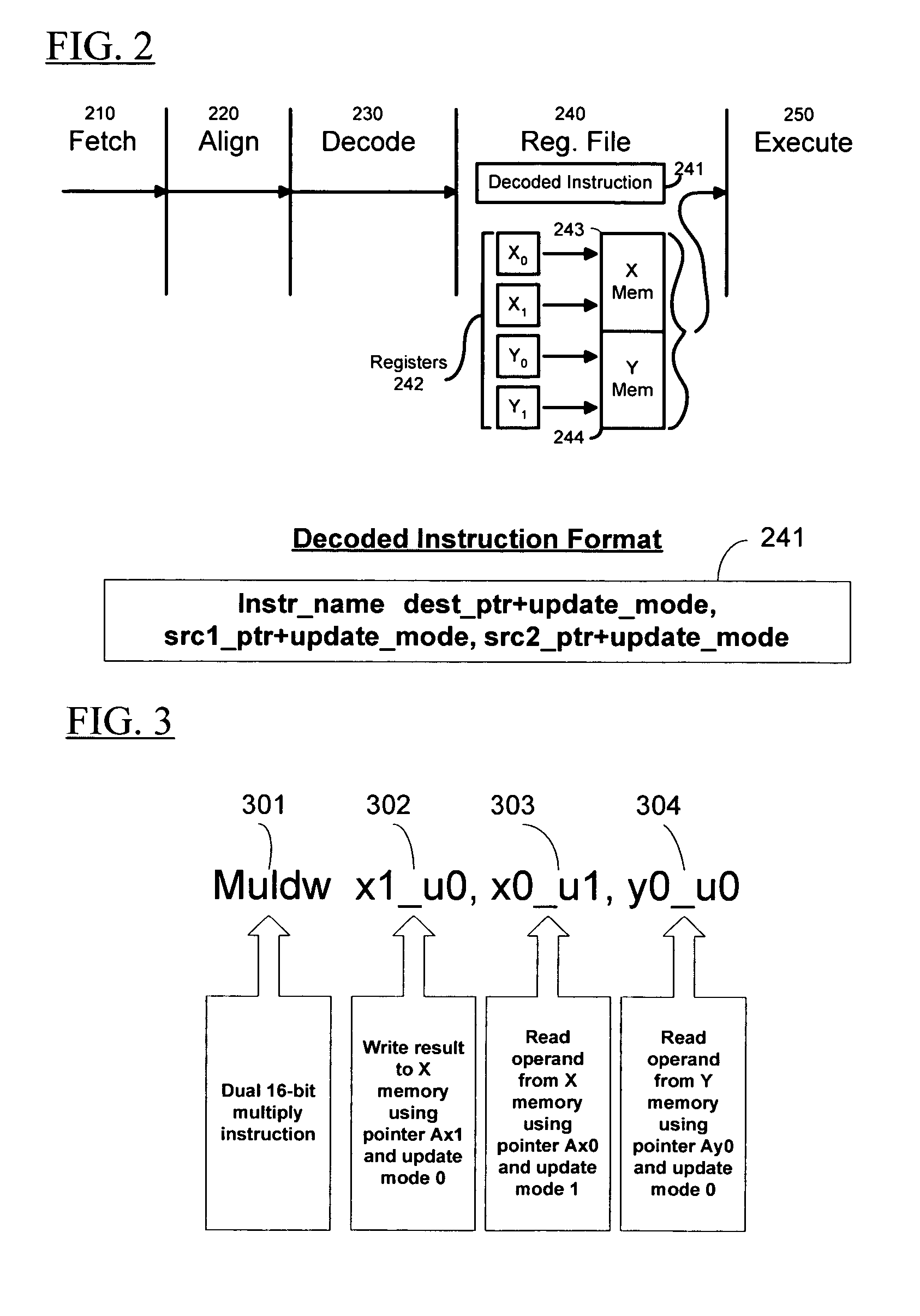

Iterative architecture for hierarchical scheduling

InactiveUS7321940B1Easy to traverseIncrease demandMultiple digital computer combinationsData switching networksGranularityComputer science

Conventional schedulers employ designs allocating specific processor and memory resources, such as memory for configuration data, state data, and scheduling engine processor resources for specific aspects of the scheduler, such as layers of the scheduling hierarchy, each of which consumes dedicated processor and memory resources. A generic, iterative scheduling engine, applicable to an arbitrary scheduling hierarchy structure having a variable number of hierarchy layers, receives a scheduling hierarchy structure having a predetermined number of layers, and allocates scheduling resources such as instructions and memory, according to scheduling logic, in response to design constraints and processing considerations. The resulting scheduling logic processes the scheduling hierarchy in iterative manner which allocates the available resources among the layers of the hierarchy, such that the scheduler achieves throughput requirements corresponding to enqueue and dequeue events with consideration to the number of layers in the scheduling hierarchy and the corresponding granularity of queuing.

Owner:CISCO TECH INC

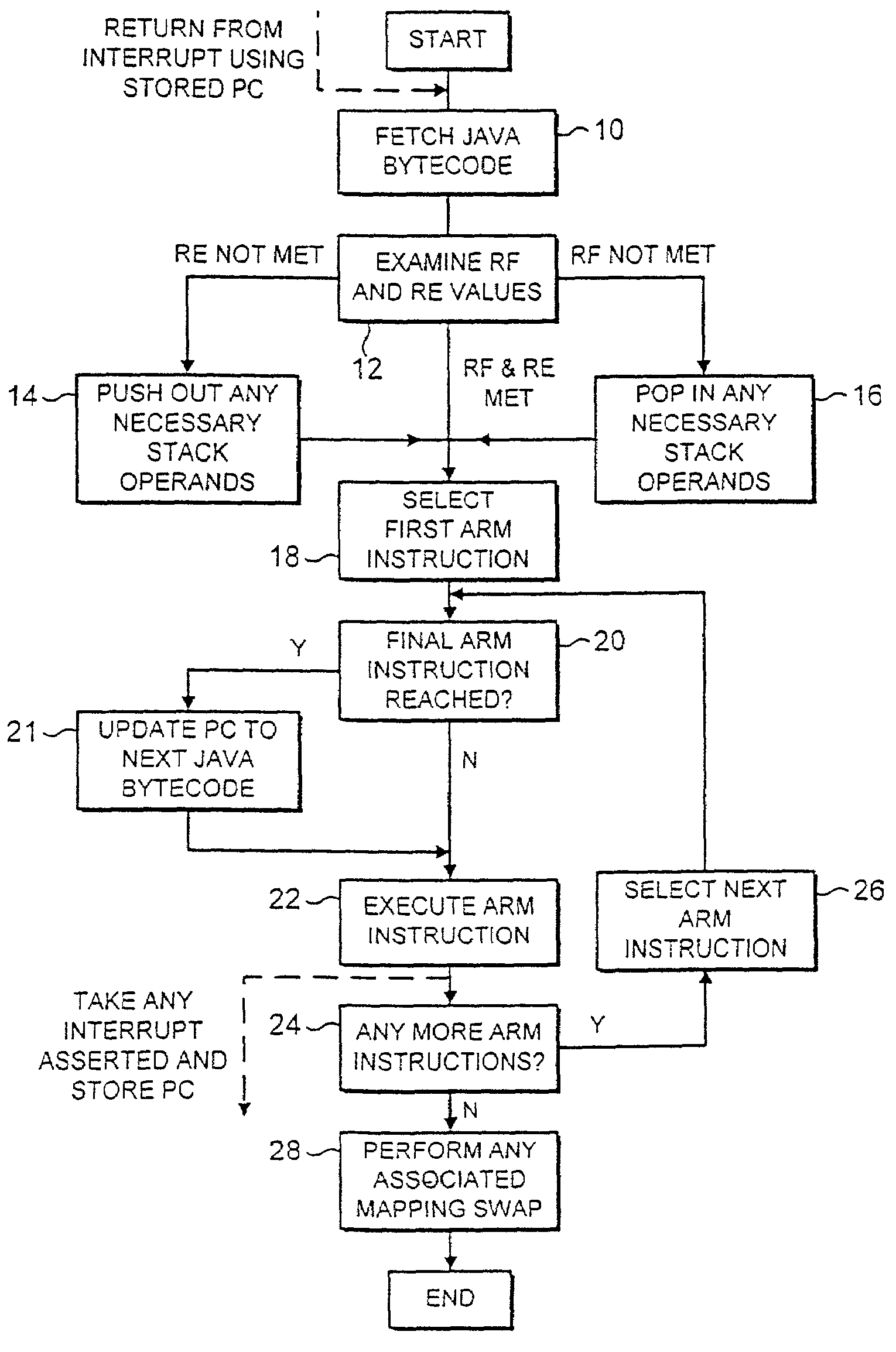

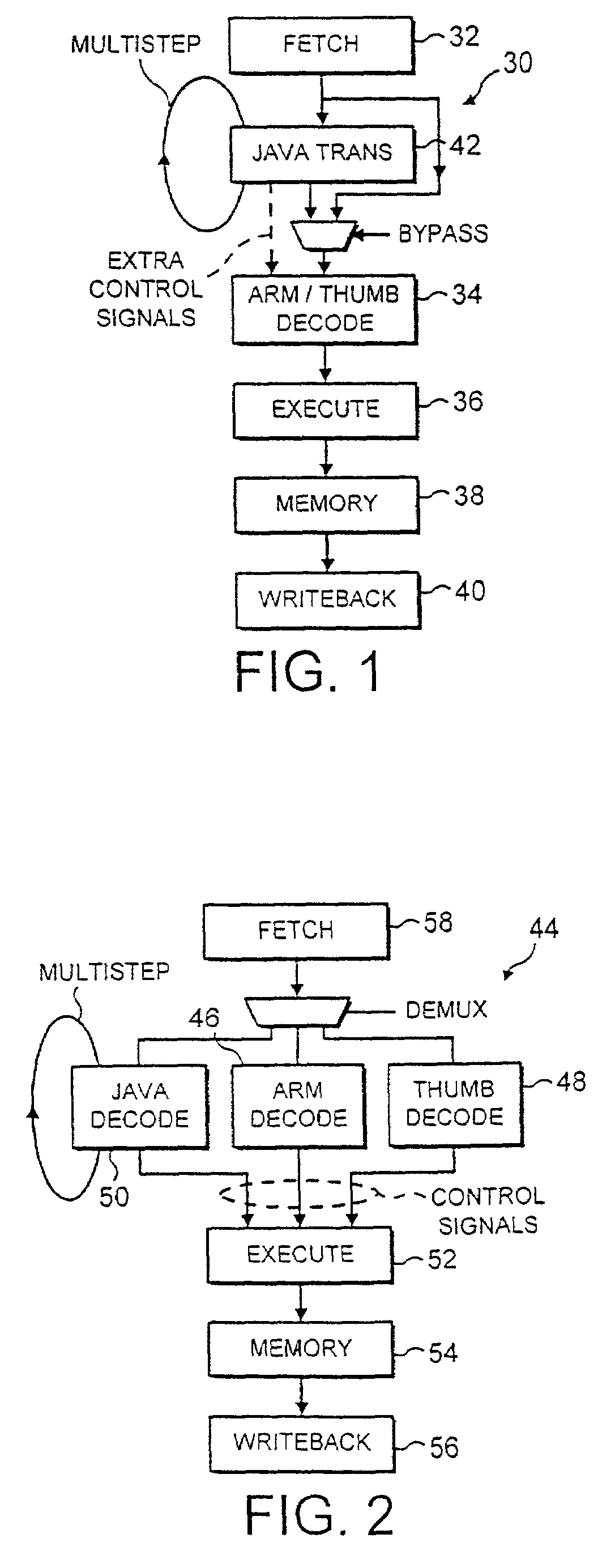

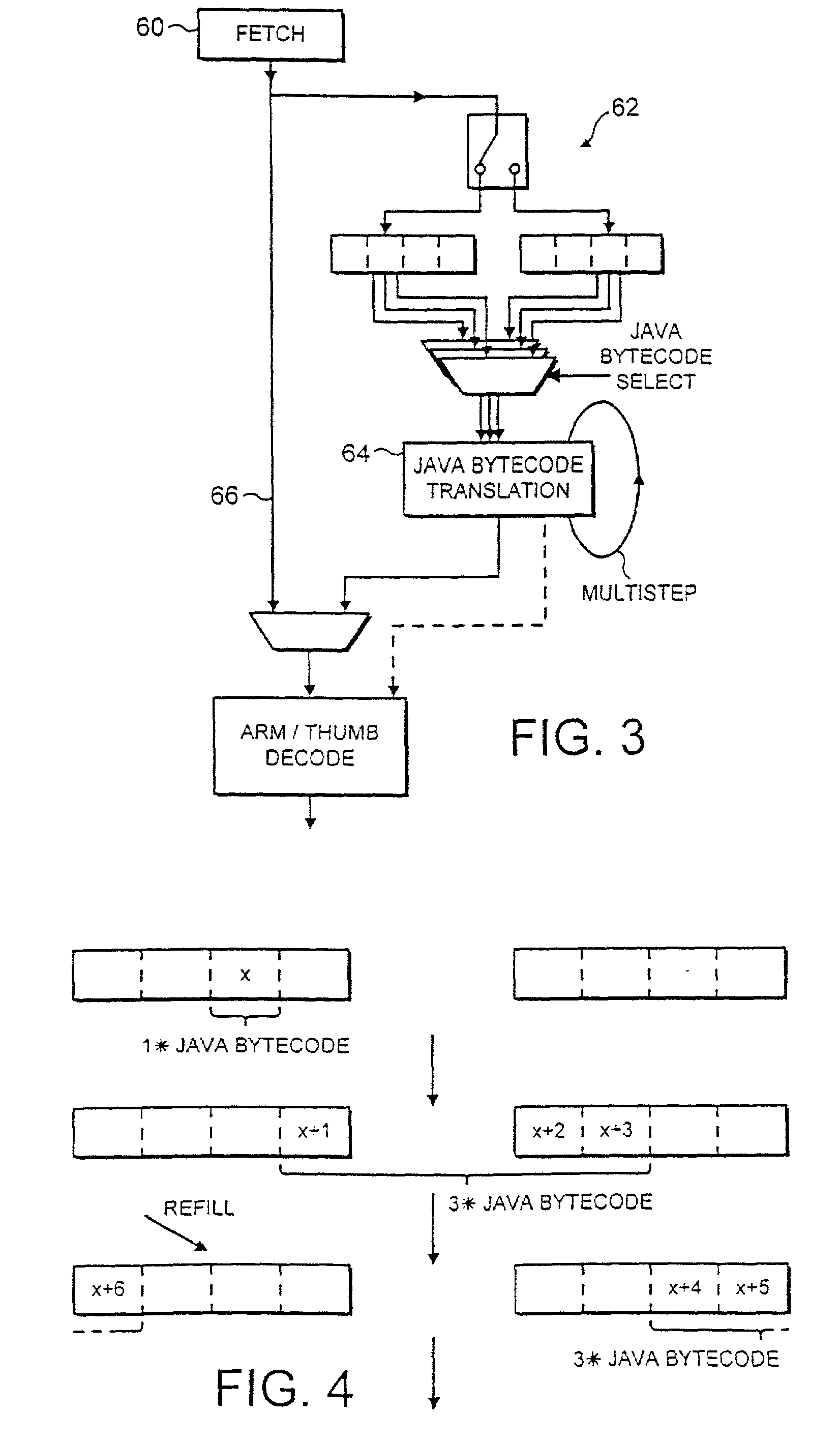

Restarting translated instructions

InactiveUS7003652B2Interrupt latencyImpact on processing speedProgram initiation/switchingInstruction analysisInterrupt handlerInstruction set

A processing system has a processor core executing instructions of a first instruction set and an instruction translator for generating translator output signals corresponding to one or more instructions of the first instruction set so as to emulate instructions of a second instruction set. The instruction translator provides translator output signals specifying operations that are arranged so that the input variables to an instruction of the second instruction set are not changed until the final operation emulating that instruction is executed. An interrupt handler services an interrupt after execution of an operation of the instructions of the first instruction set. Arranging the translated sequences of instructions such that the input state is not altered until the final instruction is executed has the result that processing may be restarted after the interrupt either by rerunning the complete emulation if the final operation had not started when the interrupt occurred, or by running the next instruction from the second instruction set if the final operation had started when the interrupt occurred.

Owner:ARM LTD

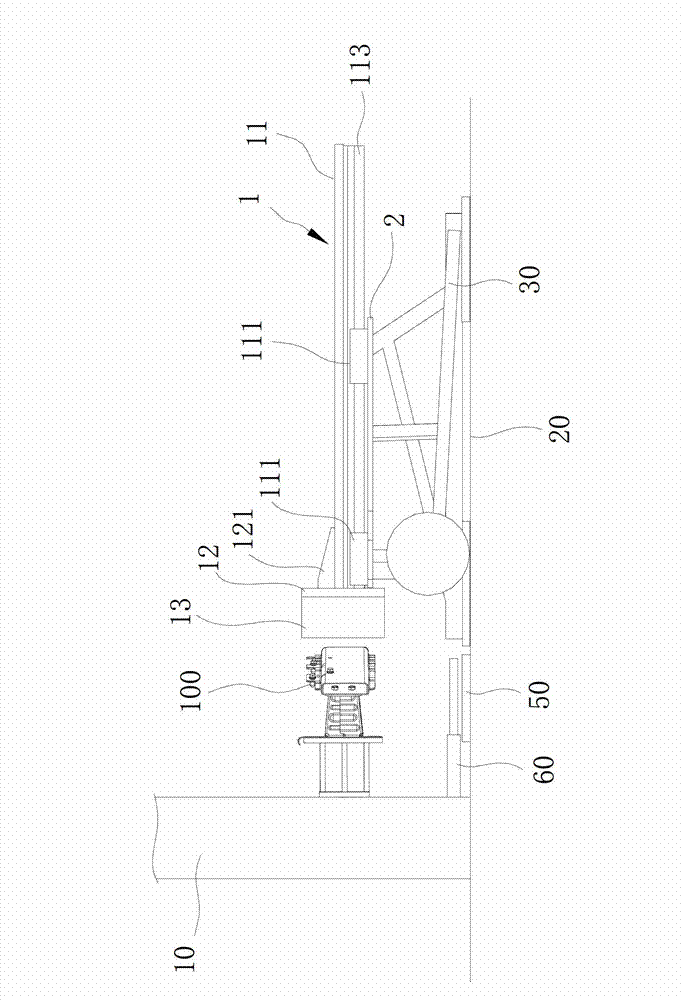

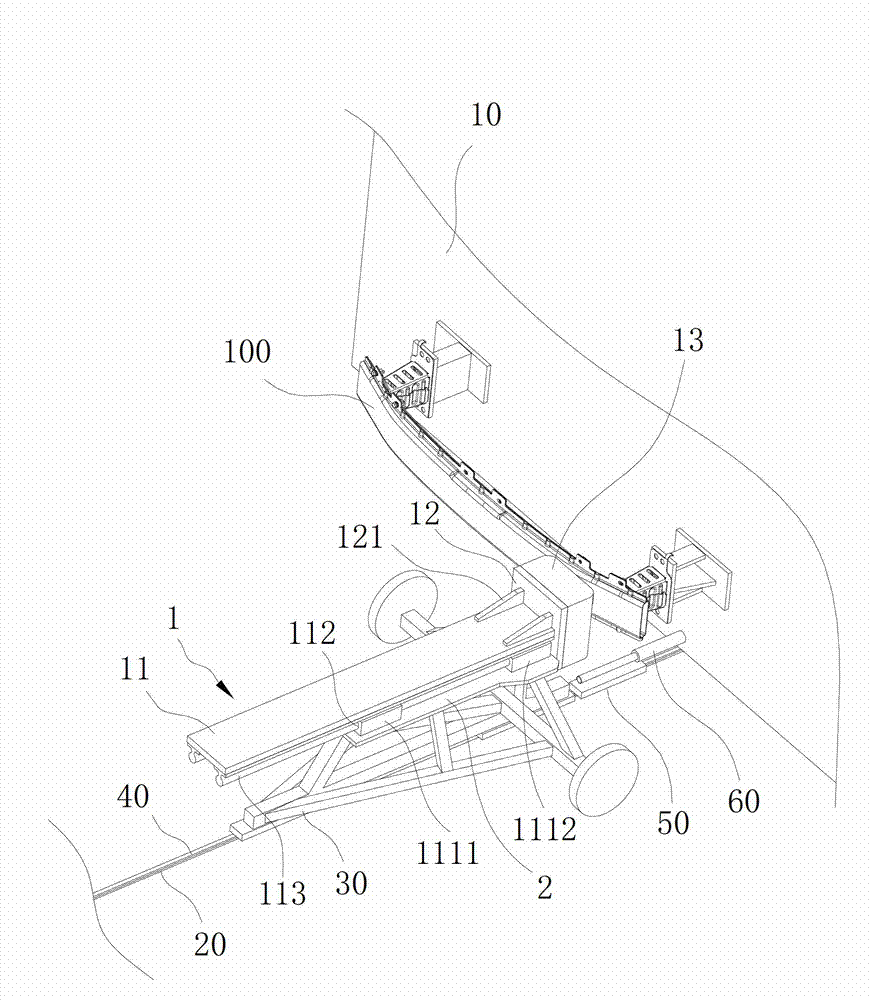

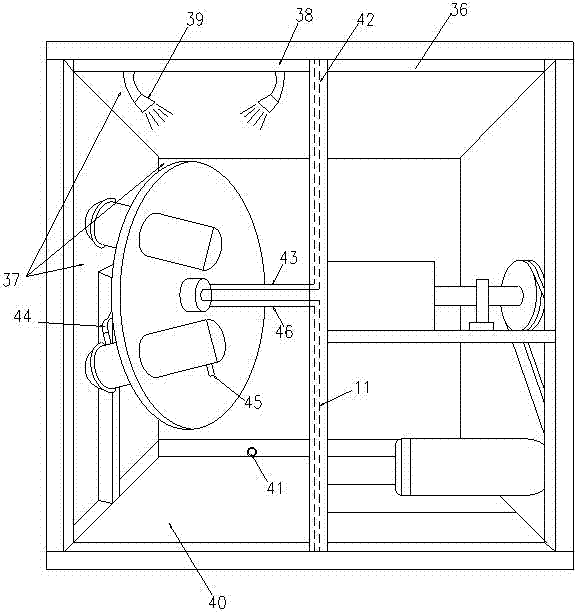

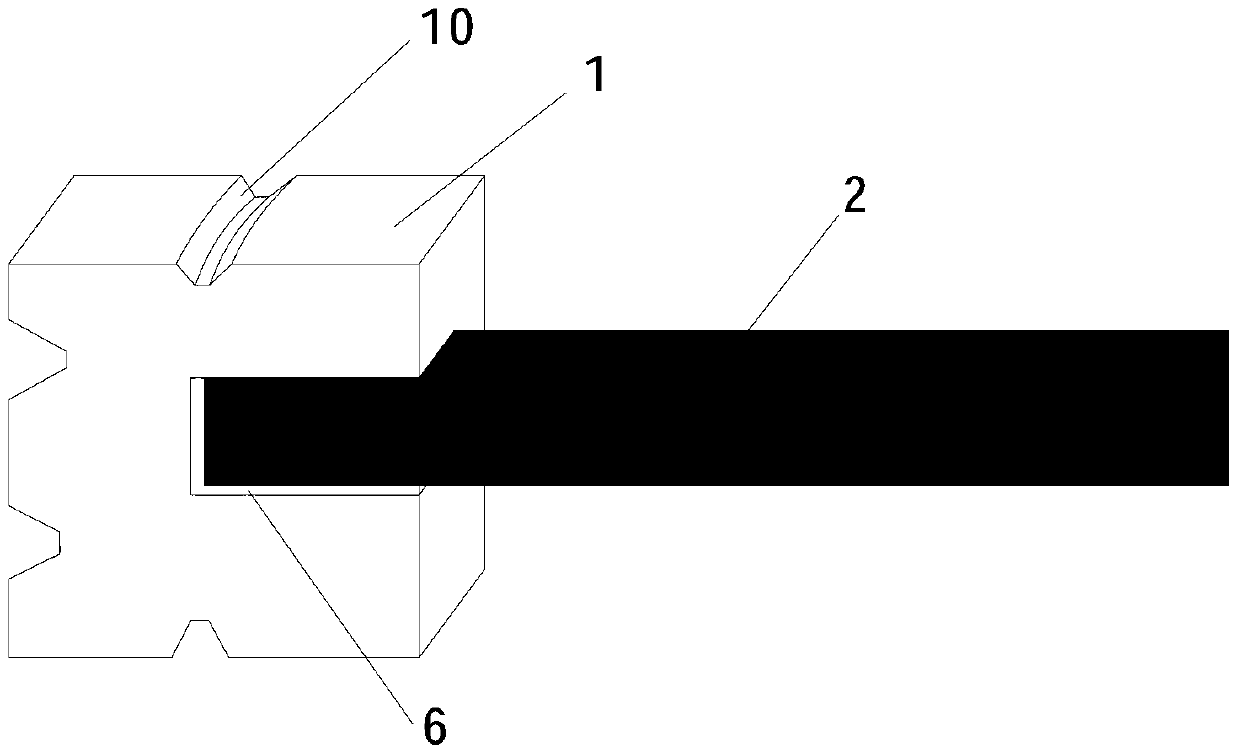

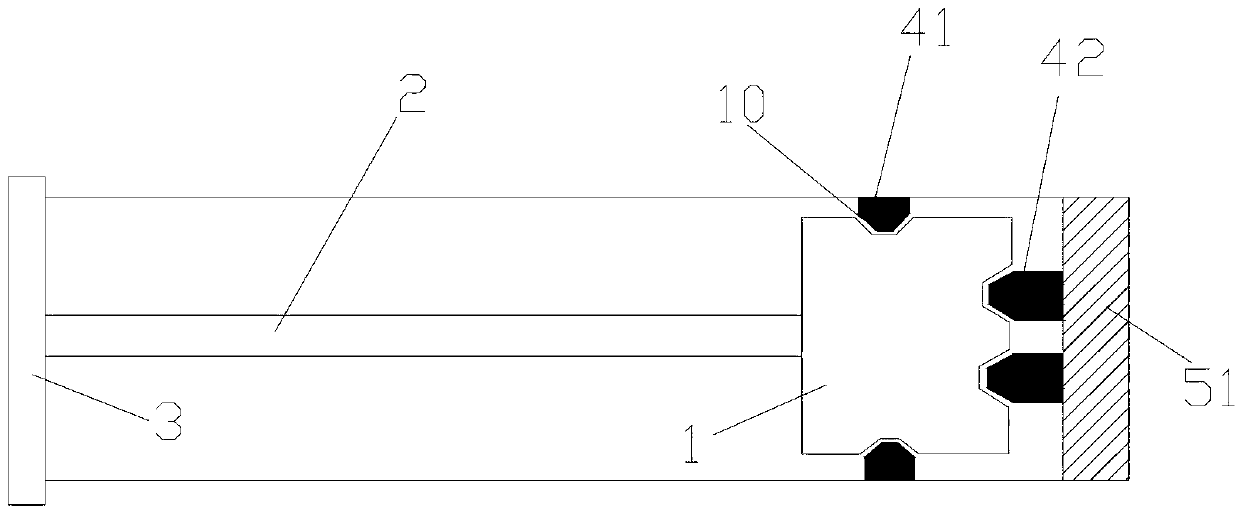

Dynamic impact test equipment

ActiveCN103091064AImpact speedMeet the requirements of high-speed dynamic impact testShock testingTest sampleEngineering

The invention discloses dynamic impact test equipment. The dynamic impact test equipment comprises a ground rail, a counterguard wall surface, a trolley, a traction device, a braking device, a cushioning device and a test recording device, wherein the counterguard wall surface is provided with a test sample piece. The trolley is arranged on the ground rail, can run along the ground rail and is provided with an impact device. The impact device can run together with the trolley, can slide on the trolley under the effect of inertia and then impacts the test sample piece which is installed on the counterguard wall surface. The dynamic impact test equipment can conduct a high speed dynamic impact test of automobile body components and parts and is simple in structure and low in cost.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

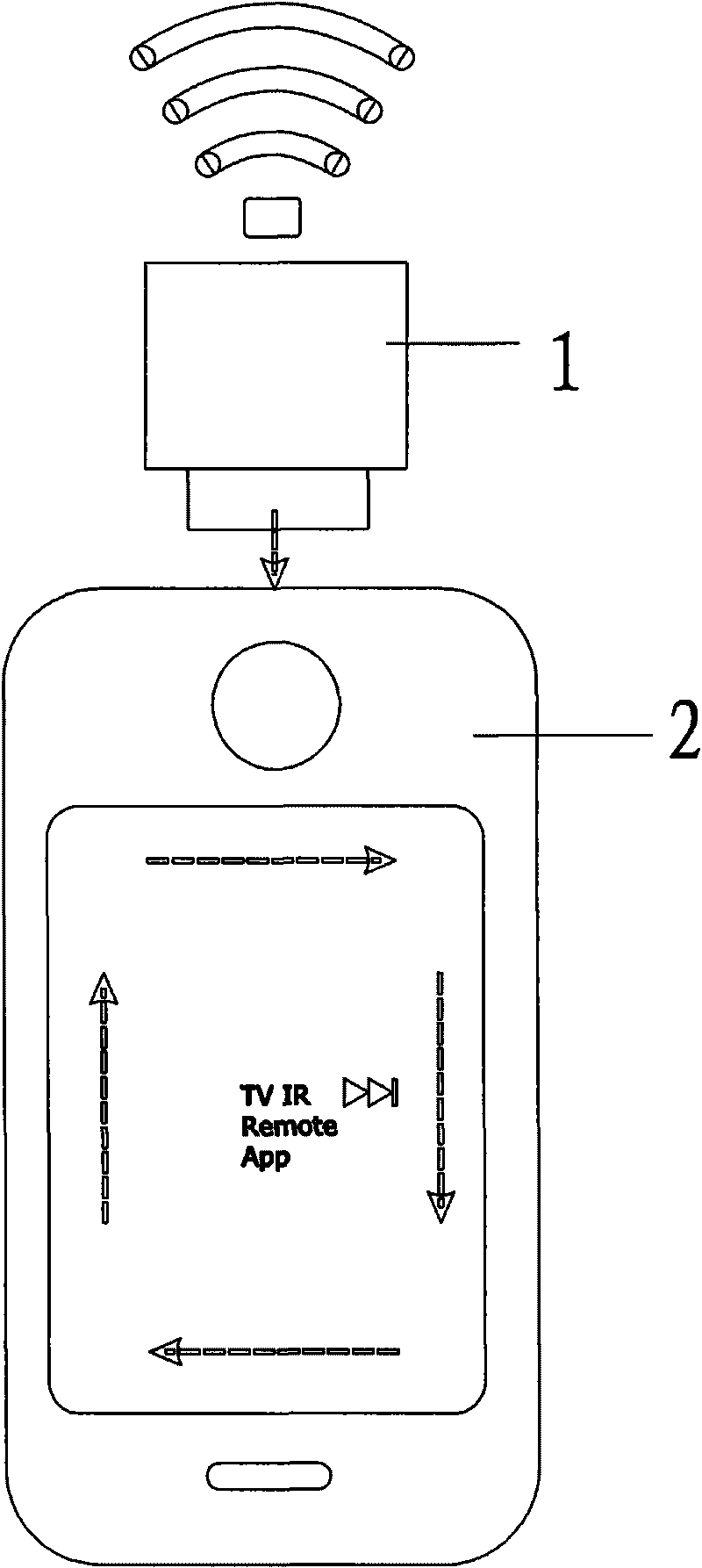

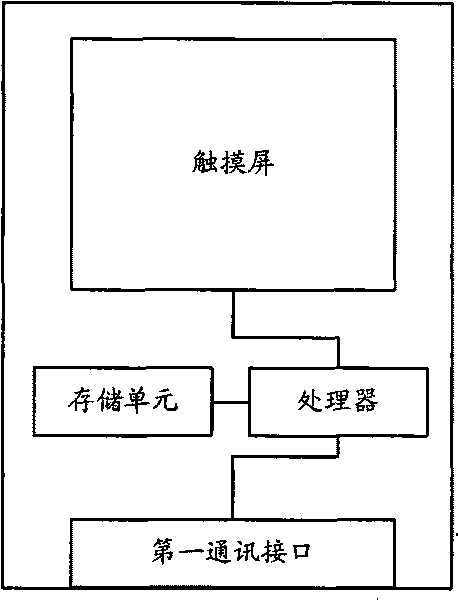

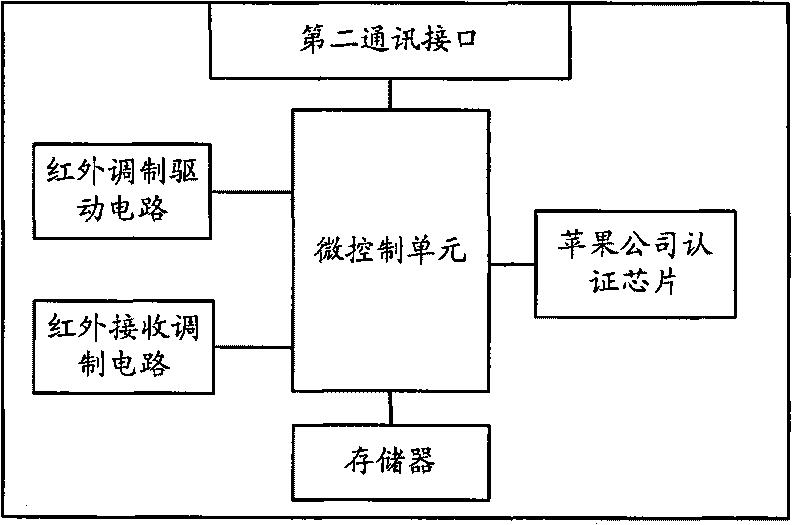

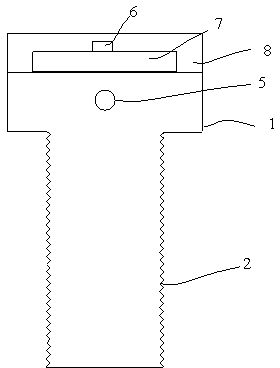

Electronic equipment, mobile communication equipment and remote control device

InactiveCN101707662AEasy remote controlTransmitting power is sufficientTelephonic communicationWireless communicationCommunication interfaceRemote control

The invention discloses electronic equipment, mobile communication equipment and a remote control device. The electronic equipment comprises a mobile communication equipment main body and the remote control device, and the equipment main body comprises a multi-contact touch screen, a first communication interface and a remote control unit, wherein the multi-contact touch screen is used for displaying information and inputting signals including touch signals; the first communication interface is positioned on the lateral surface of the equipment main body, and the first communication interface and the remote control device are connected by insertion; and the remote control unit is connected with a display unit, an input unit and the first communication interface and used for generating or finding remote control coded data corresponding to the input touch signals, sending the remote control coded data to the remote control device through the first communication interface and controlling the remote control device to send remote control coded signals corresponding to the input touch signals to controlled external equipment. The cost can be lower, and the mobile communication equipment can be more conveniently and effectively used for carrying out wireless remote control on the controlled external equipment.

Owner:郭治华

Medium-pressure heavy-section outer-cylinder iron casting gating system of steam turbine

The invention discloses a gating system of a large-section iron casting for an medium pressure external cylinder in a steam turbine; the gating system comprises a weighing ladle, a sprue, a runner and an ingate, the runner consists of an upper runner and a lower runner, a refractory ceramic filter is arranged between the upper runner and the lower runner, the minimum sectional area ratio of the sprue, the runner, a transition sprue, a transition runner and the ingate is 1.2:1.34:1:1.07:1.24; the sprue, the upper runner and the lower runner are arranged at the middle part of the casting, and the ingate of an ingate is arranged at the inner wall of an axle hole of the casting; and the gating system of the structure mainly plays a role in buffering, decompressing and steady entry of melted iron, the molding sand in the scour cast is avoided, the casting is heated evenly, with the advantages of being not easy to be mingled with impurities, carry sand, produce air gaps and cracks.

Owner:RIYUE HEAVY IND

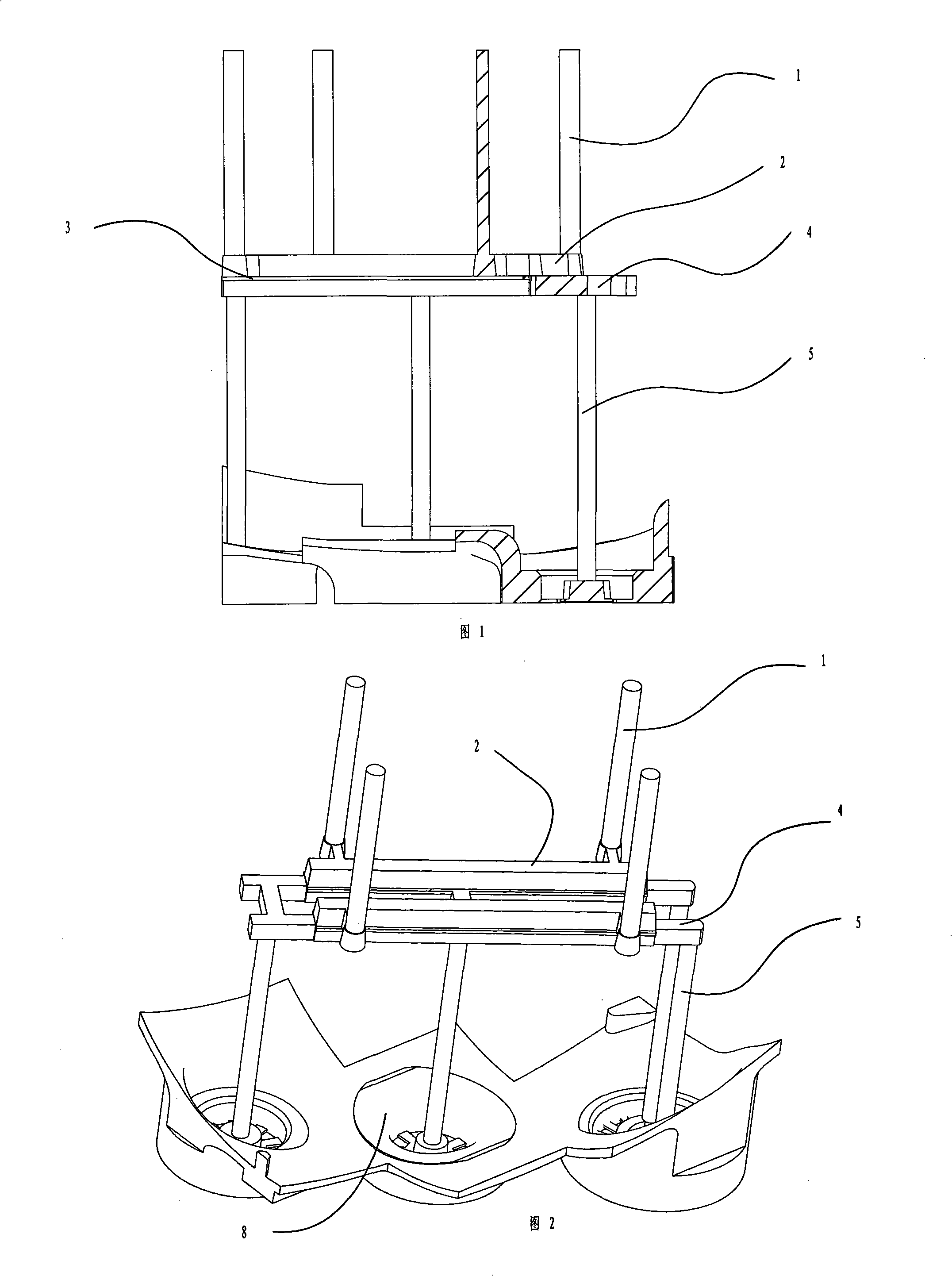

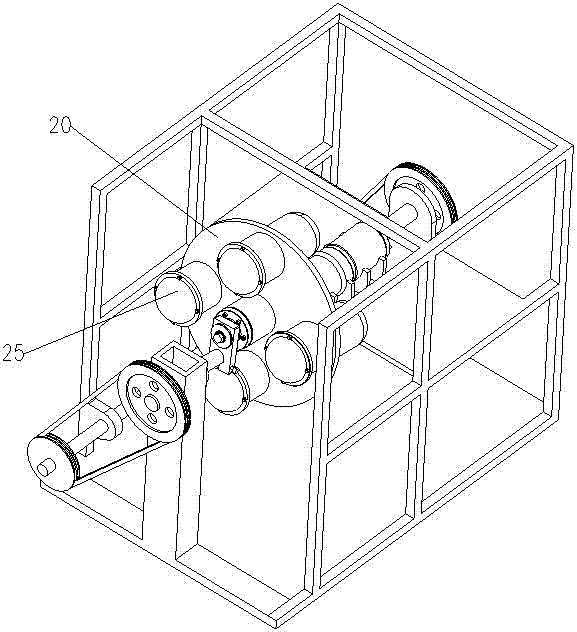

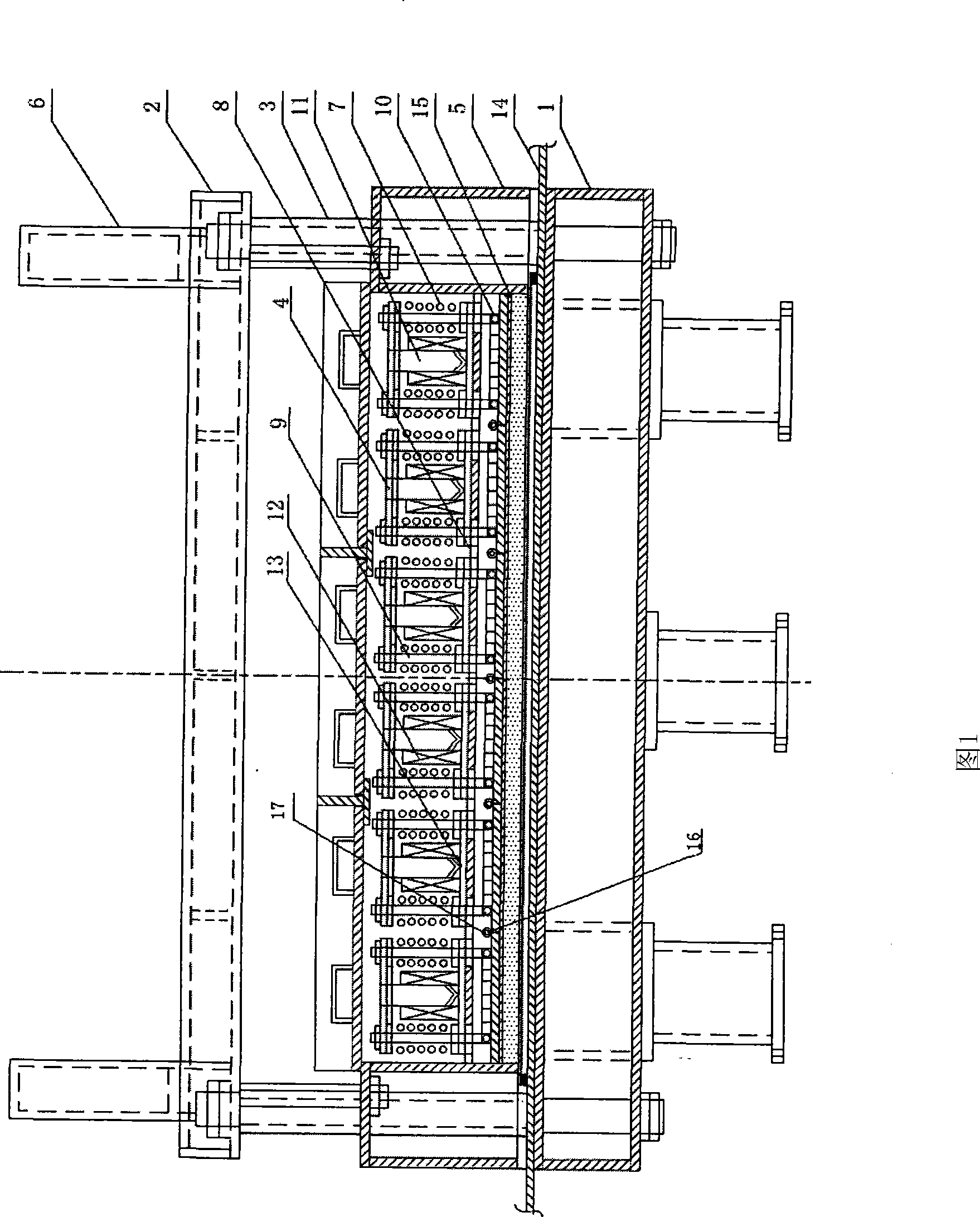

One-axle multi-cylinder multi-dimensional ball hammer type micro-nano high-energy ball mill

InactiveCN104117411AImprove production and efficiencyRun smoothlyGrain treatmentsMicro nanoMultiple dimension

The invention discloses a one-axle multi-cylinder multi-dimensional ball hammer type micro-nano high-energy ball mill. The ball mill is characterized in that a round disk is driven through the rotation of an eccentric shaft driving system and an eccentric shaft support system, a plurality of cylindrical milling tanks are arranged on the round disk, the tank body is driven to regularly swing in a multi-dimension manner up and down, left and right, front and back through the synchronous rotation of the eccentric shaft and the eccentric shaft support system, the ball material in the tank body is thrown up to produce multi-dimensional hammer action, so that fierce impacting, chopping and grinding in multi-dimension can be achieved. Since the multi-dimensional impacting and grinding have no dead angle, the material can be ground into uniform micro-nano powder, the processing efficiency, the yield and the quality of the micro-nano powder are obviously improved; the ball mill has a stable structure, can be easily enlarged to form the scale production, and is suitable for the demand of nanometer application engineering.

Owner:深圳市来源新材料科技有限公司

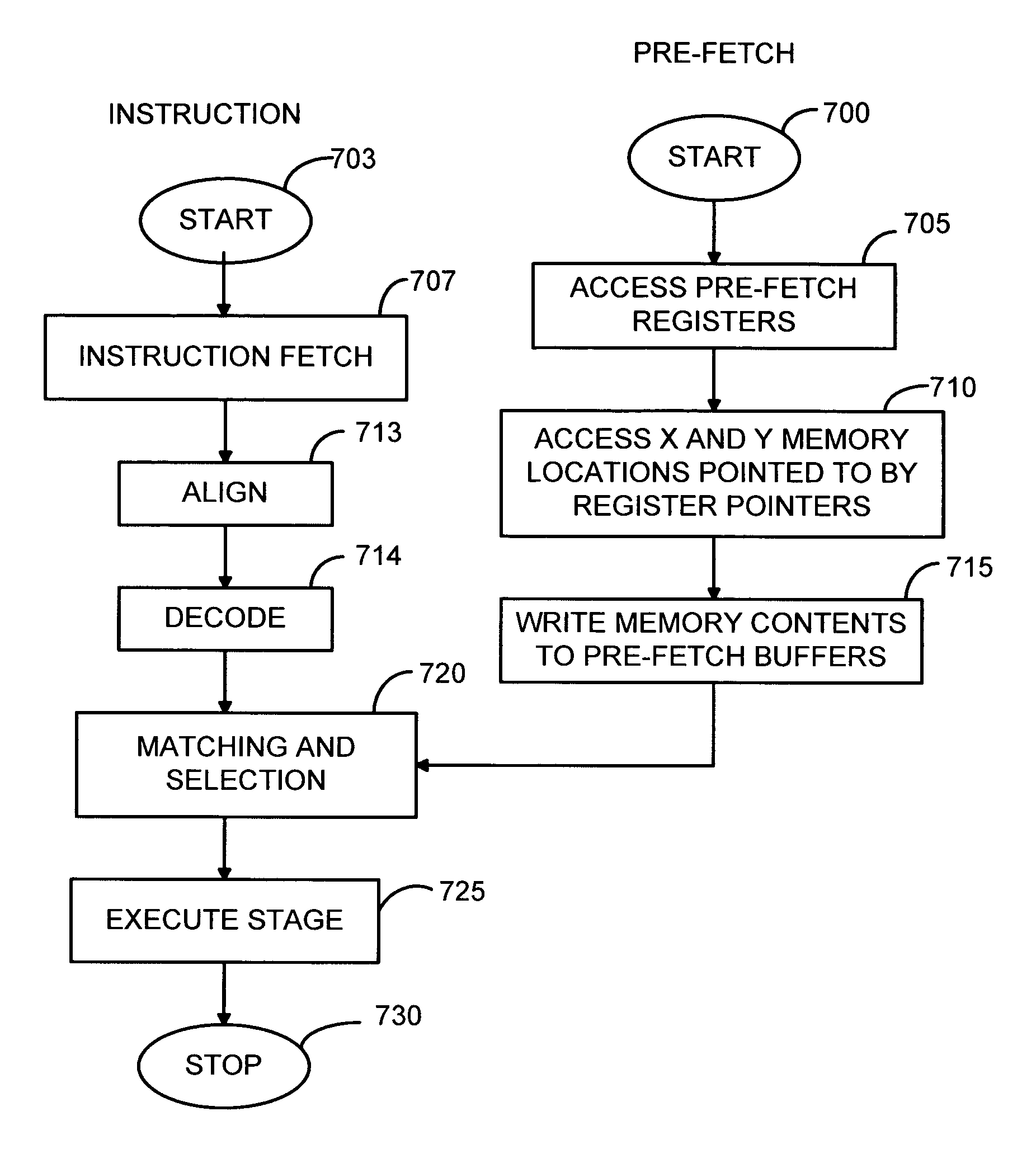

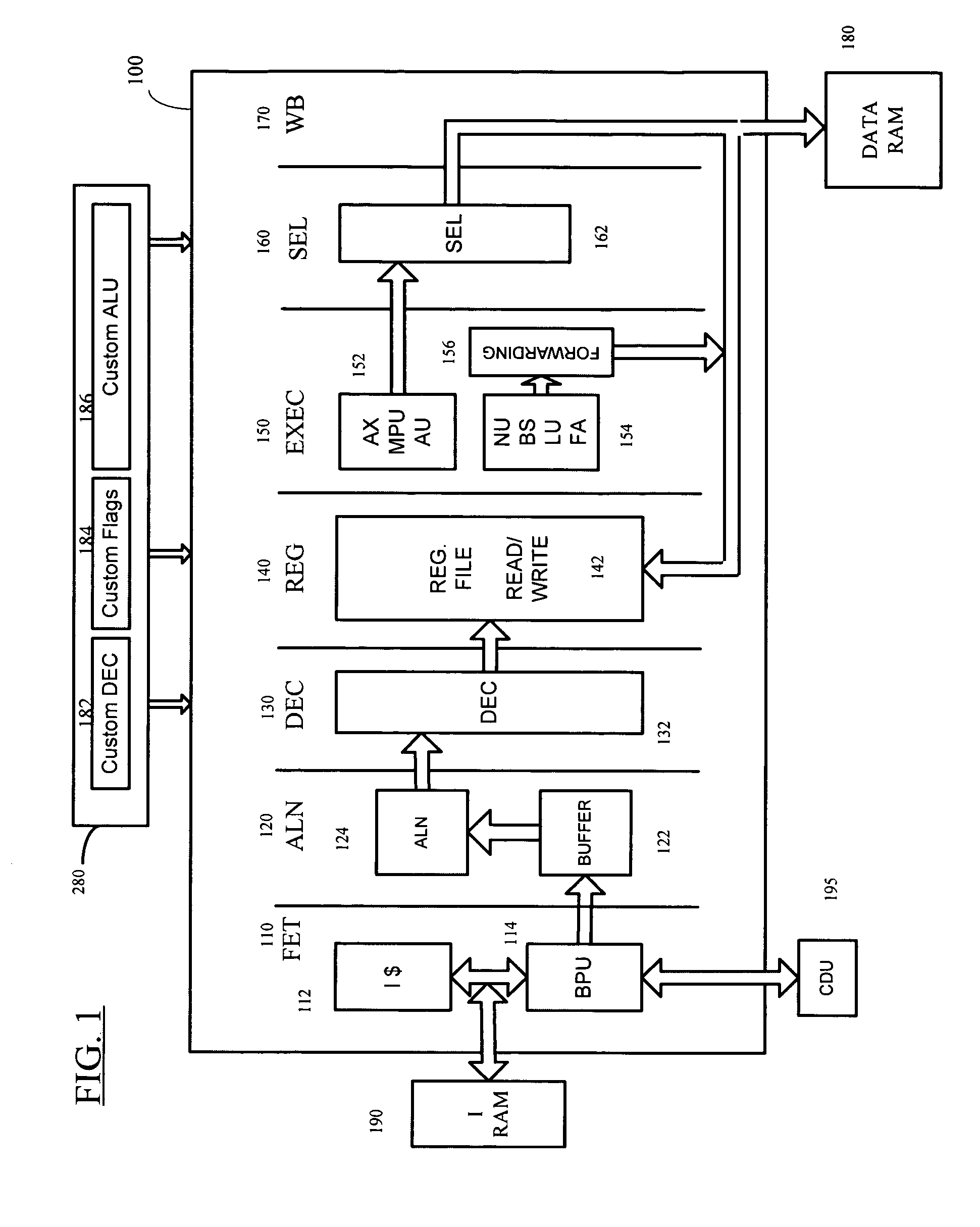

Microprocessor architecture including zero impact predictive data pre-fetch mechanism for pipeline data memory

InactiveUS20050278505A1Impact speedIncrease clock speedEnergy efficient ICTError detection/correctionOperandExecution unit

A microprocessor architecture including a predictive pre-fetch XY memory pipeline in parallel to the processor's pipeline for processing compound instructions with enhanced processor performance through predictive prefetch techniques. Instruction operands are predictively prefetched from X and Y based on the historical use of operands in instructions that target X and Y memory. After the compound instruction is decoded in the pipeline, the pre-fetched operand pointer, address and data is reconciled with the operands contained in the actual instruction. If the actual data has been pre-fetched, it is passed to the appropriate execute unit in the execute stage of the processor pipeline. As a result, if the prediction is correct, the data to use for access can be selected and the data selected fed to the execution stage without any addition processor overhead. This pre-fetch mechanism avoids the need to slow down the clock speed of the processor or insert stalls for each compound instruction when using XY memory.

Owner:ARC INT LTD

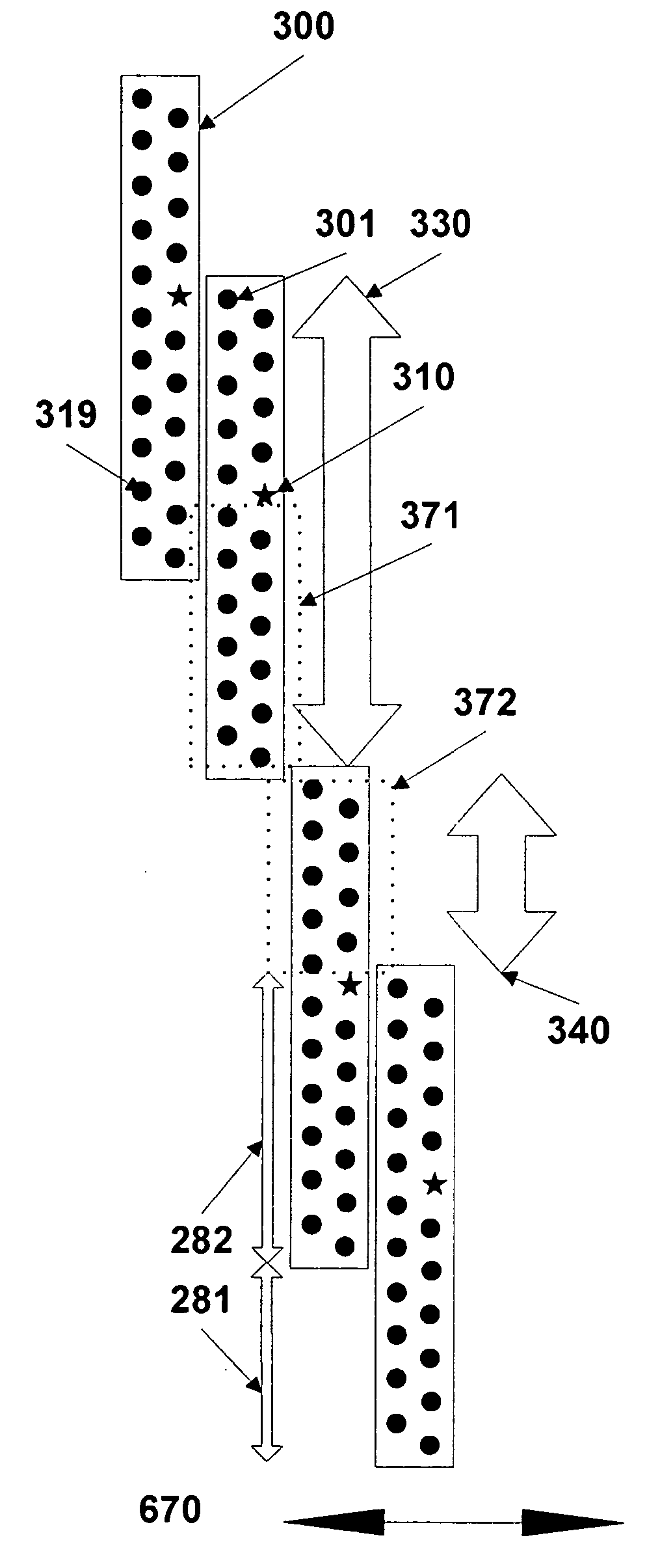

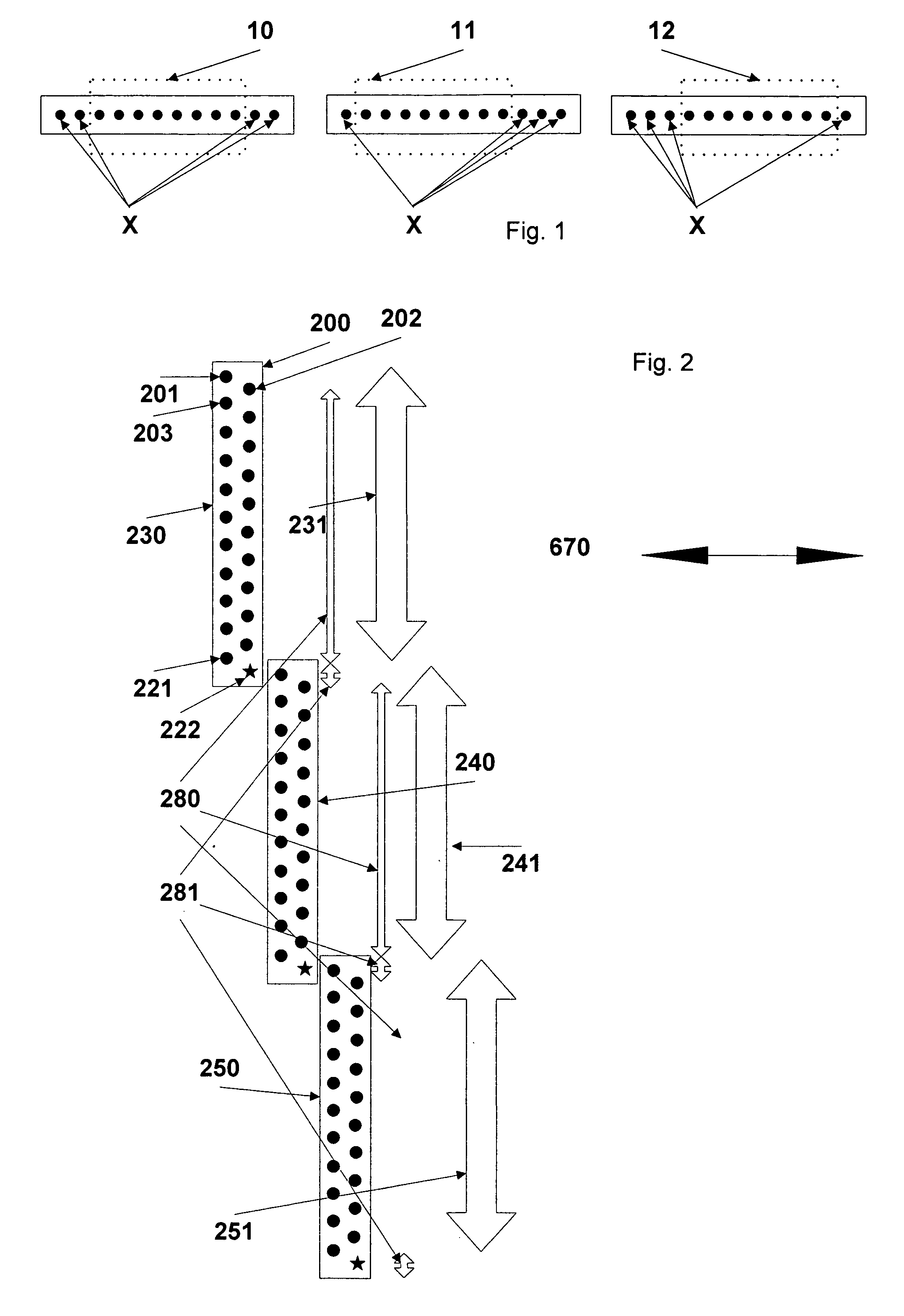

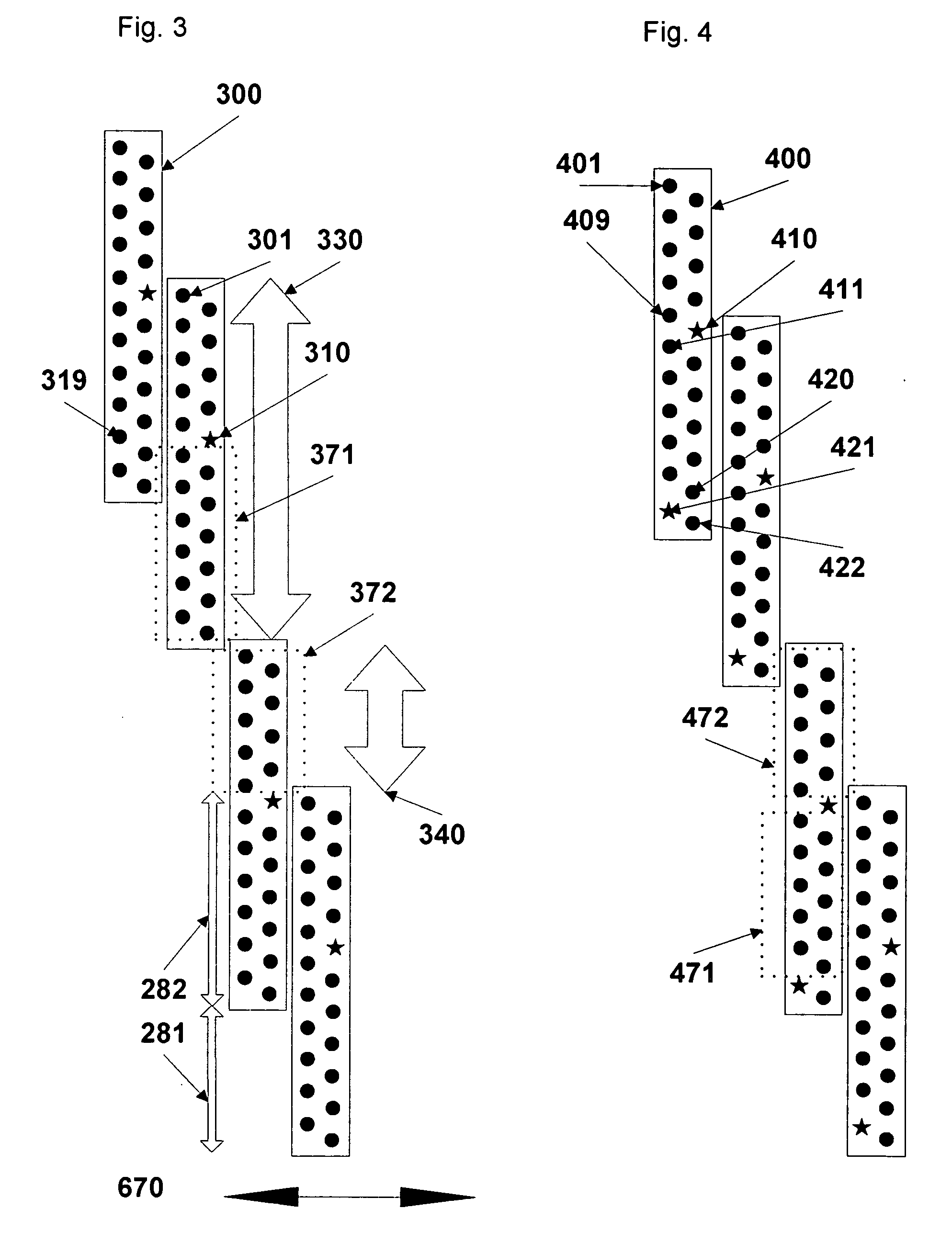

Method of printing on a media

The invention relates to a method of printing on a media comprising: providing a printhead 300 comprising a plurality of nozzles (301, . . . , 310, . . . , 319, . . . ) defining a print zone, at least one 310 of the nozzles of the print zone being faulty, the print head comprising within the print zone one or more healthy zones 371, 372; submitting a first region 281 of the media to N print zone passes; and, submitting a second region 282 of the media to M print zone passes using a healthy zone to overlap a faulty nozzle, at least two of the M passes being separated by an advance of the media relative to the printhead; producing alternate first and second regions when printing on the media; whereby M>N and N>0.

Owner:HEWLETT PACKARD DEV CO LP

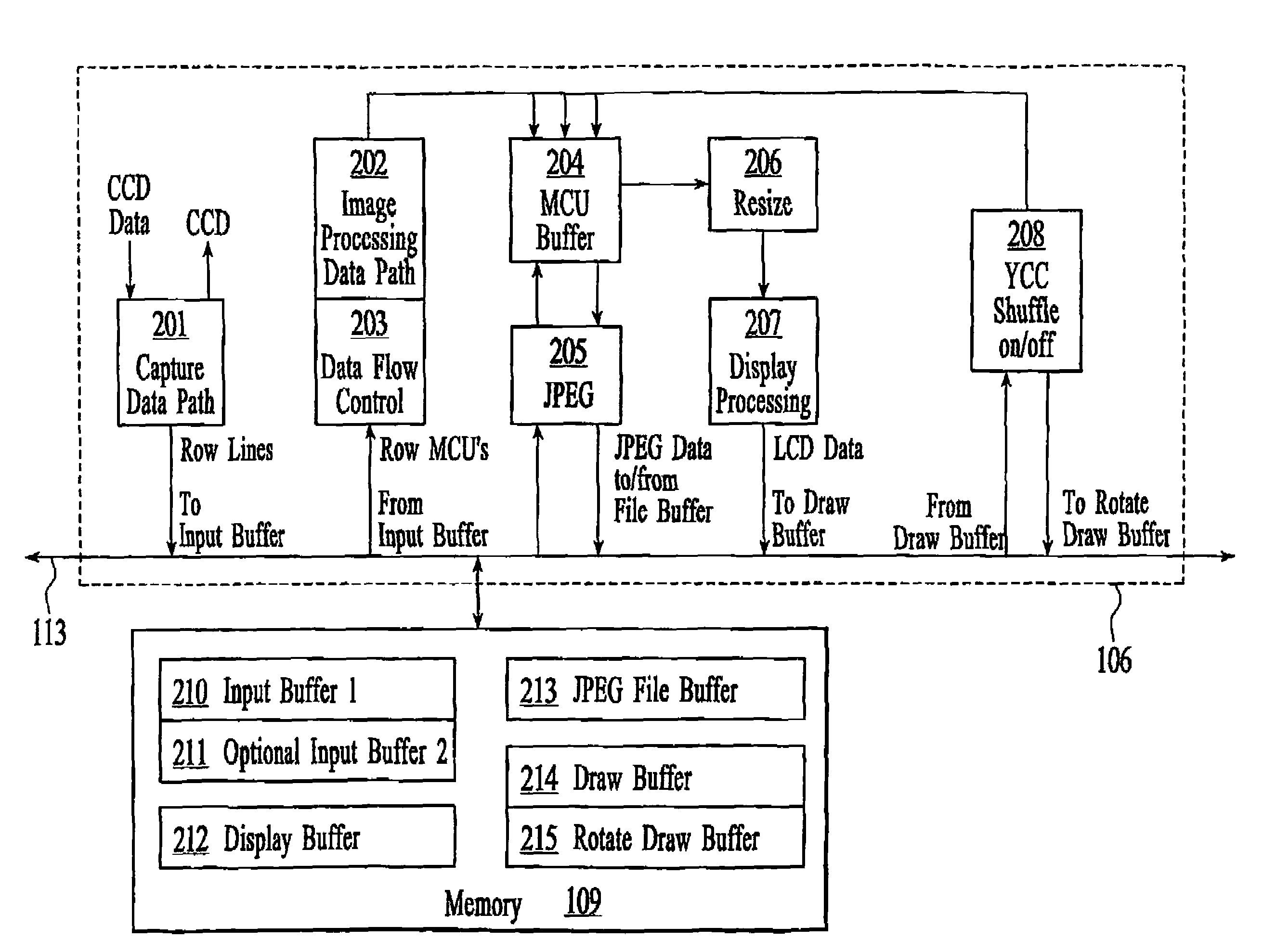

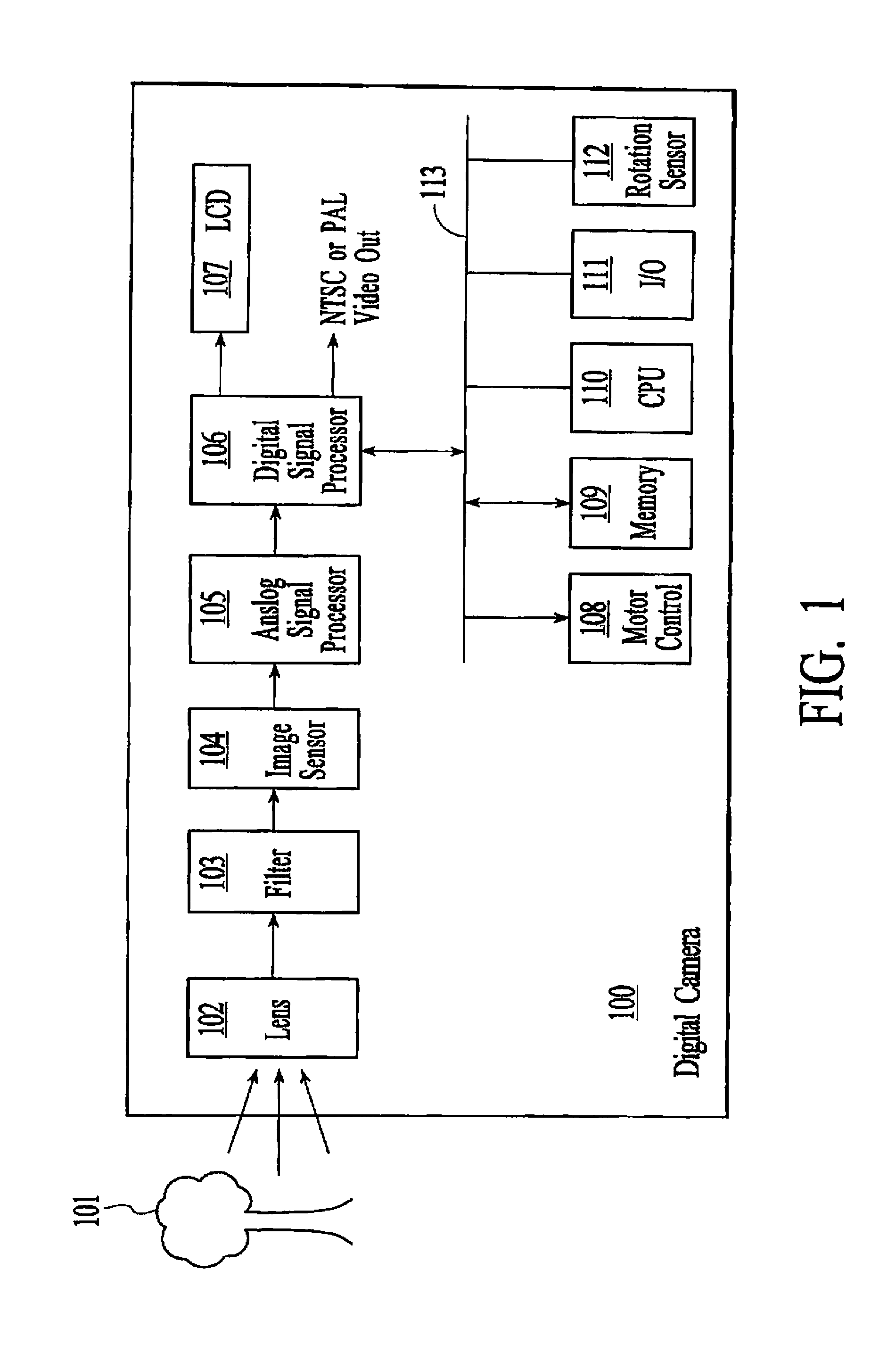

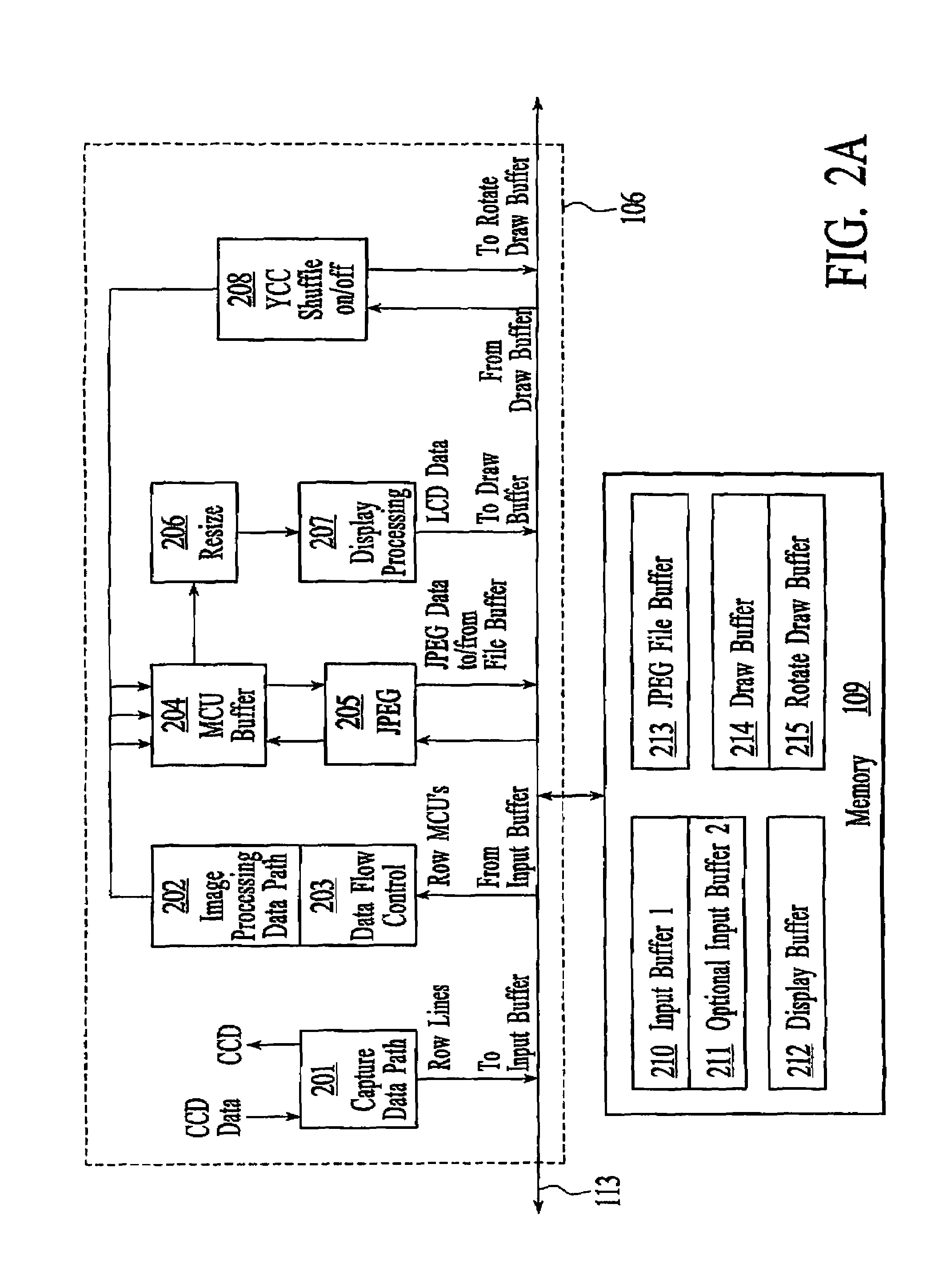

Image processing system for high performance digital imaging devices

InactiveUS7259783B2Fast image processingReduce amountTelevision system detailsColor television detailsDigital signal processingData stream

An image processing system for high performance digital imaging in a digital camera. The reflected light from an image is focused through a lens and optically filtered. A CCD array converts this image into an electrical signal. This electrical signal is processed and then converted into an equivalent digital signal. A digital signal processor is then used to process the raw digital signal. The DSP includes a capture data path, a data flow control, an image processing data path, a compression / decompression engine, a resize circuit, a display processing circuit, and a rotation circuit. Data is routed between the DSP and memory via a bus. By selectively activating and reusing certain parts of the hardware architecture and various data paths, at least four modes of operation can be supported: live view, instant review, and play mode. Furthermore, the correct image is automatically displayed in all four modes, regardless of the orientation of the image or the physical orientation of the camera (both at the time the picture was taken and at the time the picture is being rendered for display).

Owner:FLASHPOINT TECH

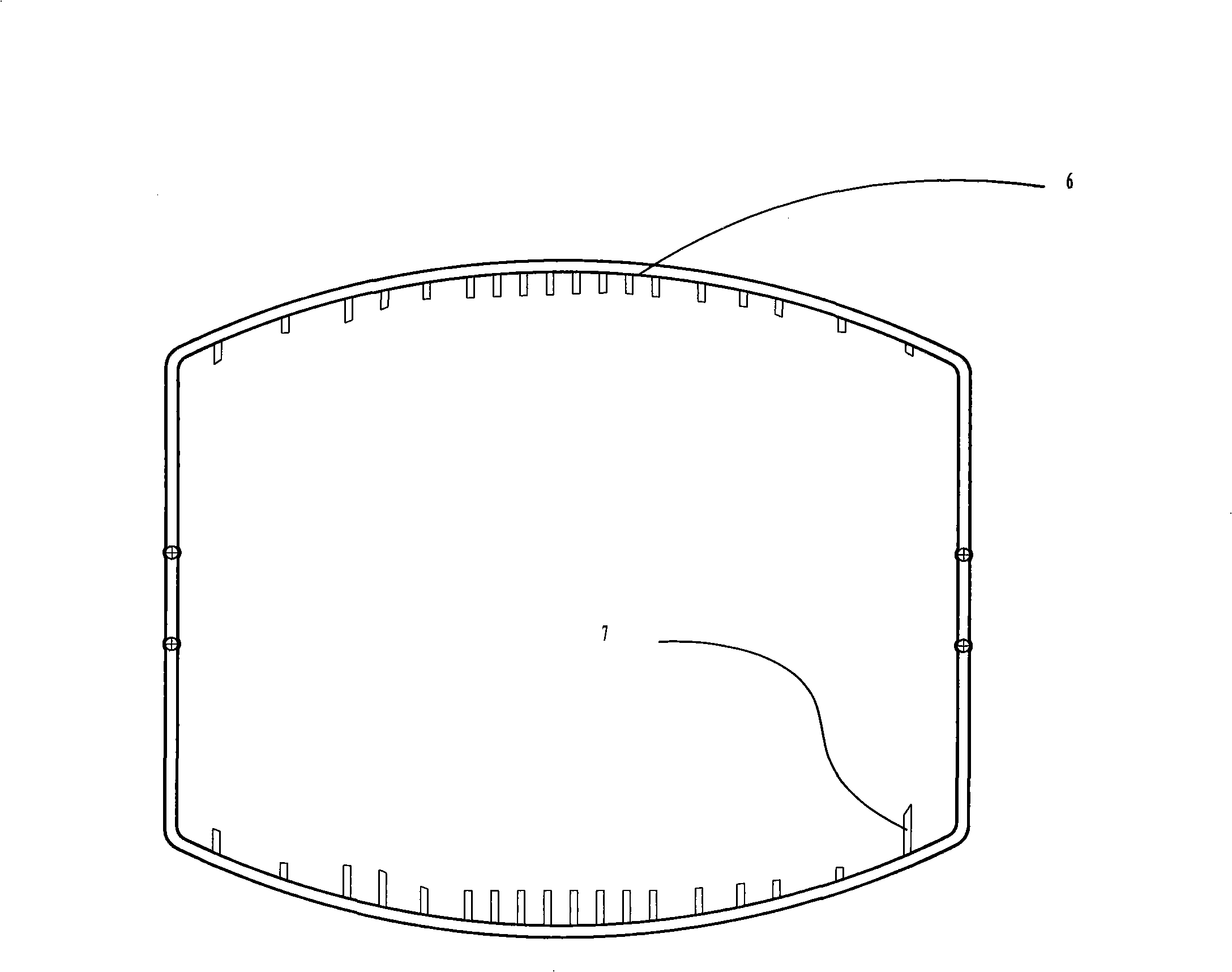

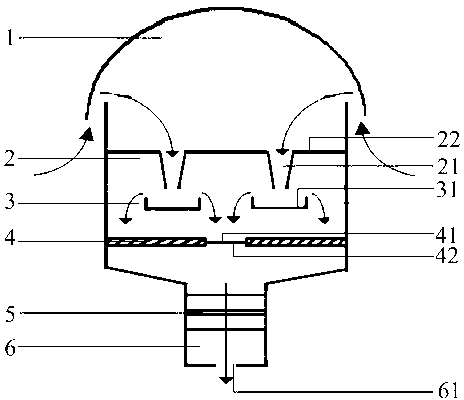

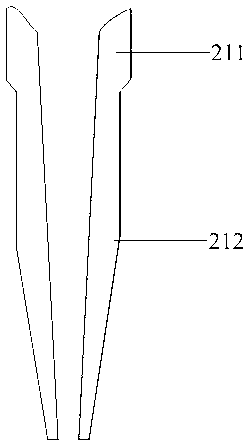

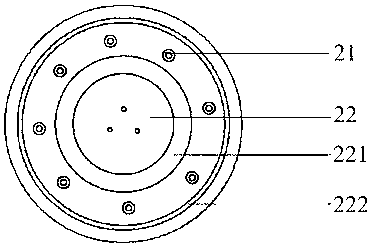

PM2.5 (Particular Matter 2.5) single-grade atmosphere sampling cutter

InactiveCN102798553AMeet sampling needsImpact speedWithdrawing sample devicesParticulatesDesign standard

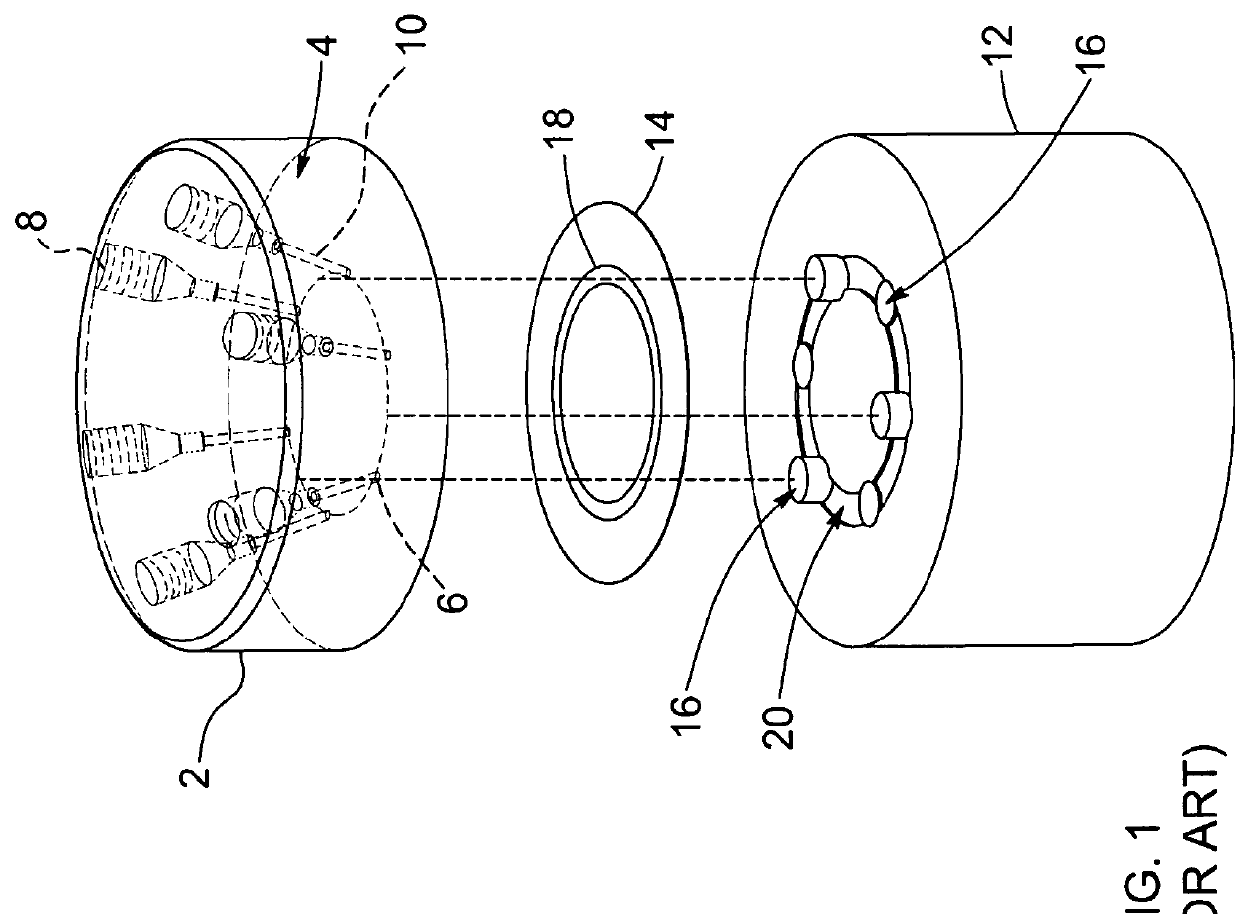

The invention discloses a PM2.5 (Particular Matter 2.5) single-grade atmosphere sampling cutter. The PM2.5 single-grade atmosphere sampling cutter is roughly cylindrical; the PM2.5 single-grade atmosphere sampling cutter comprises a cutting opening cover layer, an impacting nozzle layer, an impacting plate layer, a particular matter collecting layer, a gas organic pollutant collecting layer and a gas discharging layer, wherein the cutting opening cover layer, the impacting nozzle layer, the impacting plate layer, the particular matter collecting layer, the gas POPs (Persistent Organic Pollutants) collecting layer and the gas discharging layer are sequentially sealed and connected in series; the impacting nozzle layer comprises impacting nozzles and an impacting nozzle plate; the impacting nozzles are arrayed at an equal interval and are vertically inserted into the impacting nozzle plate to form an annular ring; the impacting nozzles are internally provided with reversed conical through holes; and the impacting plate layer is provided with an impacting plate and the impacting plate is an annular groove. With the adoption of the PM2.5 single-grade atmosphere sampling cutter disclosed by the invention, the characteristic that a previous air sampling device has middle and small flow is broken through; and a flow design standard of 300 L / min can meet the POPs sampling requirements so that the cutting grain diameter of the cutter is accurate and the target of accurately layering the target particular matters under the cutting of an inertia impacting force can be realized.

Owner:FOSHAN ENVIRONMENTAL PROTECTION TECH & EQUIP RES DEV PROFESSIONAL CENT +1

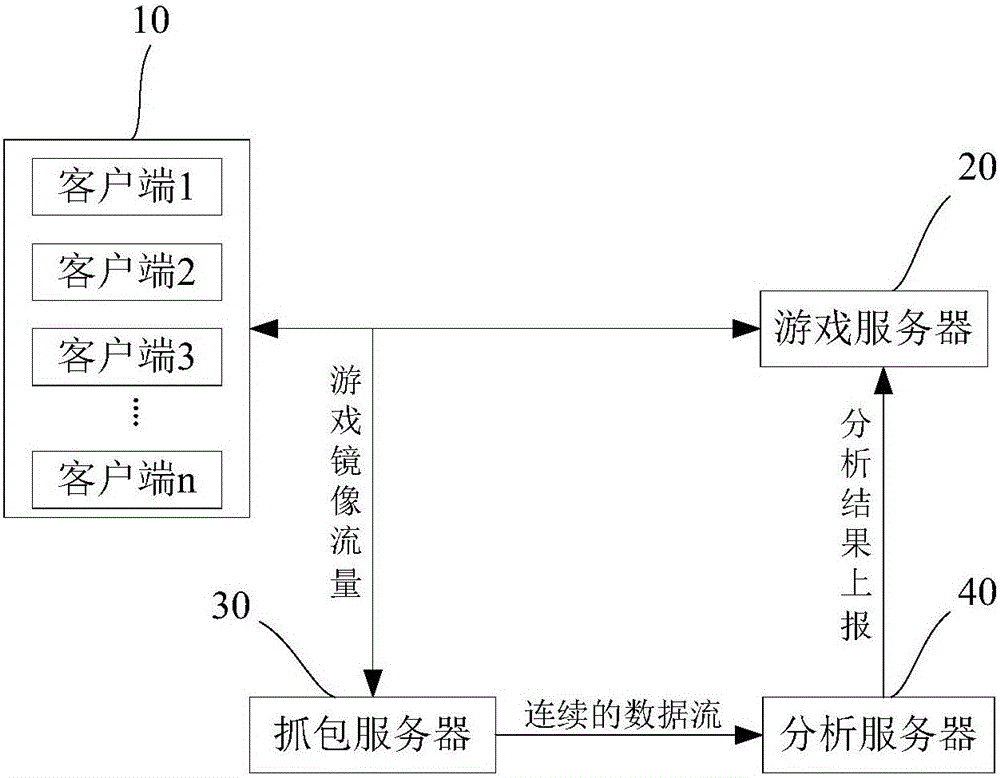

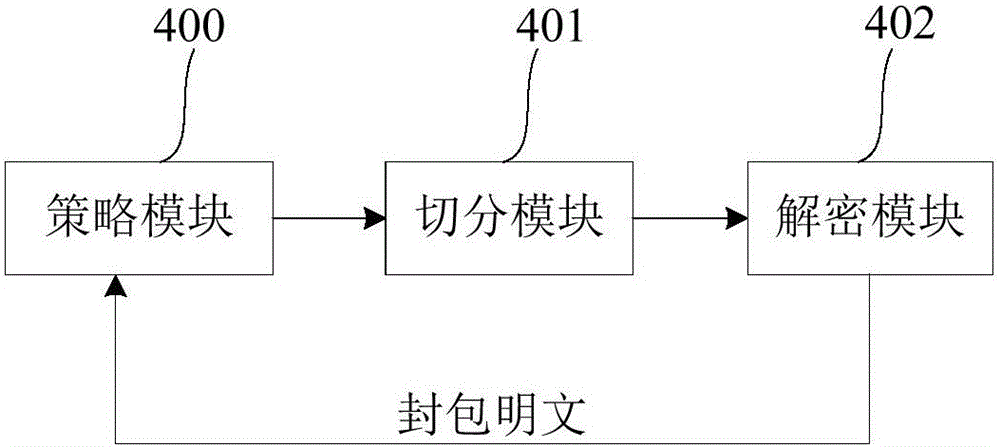

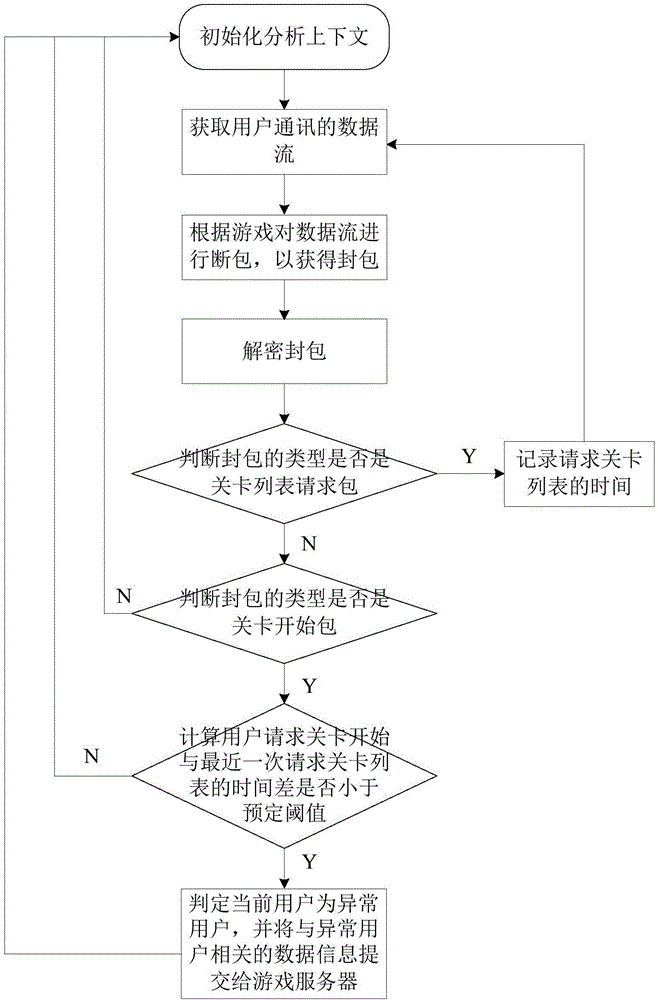

Anti-plug-in online game system

InactiveCN105024885AImpact speedImprove experienceData switching networksClient-sideHuman–computer interaction

The invention provides an anti-plug-in online game system. A package capturing server receives mirror image traffic transmitted by an operation switch after using a switch to perform traffic mirroring copy to network traffic between each client and a game server, and rectifies the mirror image traffic so as to obtain continuous data flow, and an analysis server receives and analyzes the continuous data flow transmitted by the package capturing server so as to determine an abnormal user, and returns the analysis result to the game server. Because the abnormal user is determined by the analysis server which is independent of the game server and the client, the influence to the operating speed of the game server itself is avoided while determining the abnormal user, thereby enhancing the game user experience.

Owner:SHENGQU INFORMATION TECH SHANGHAI

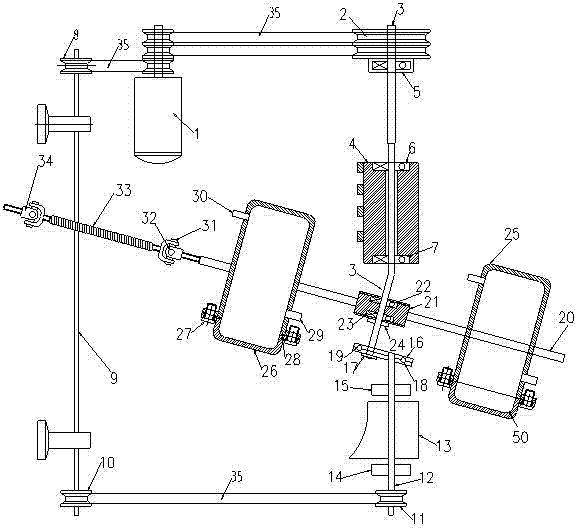

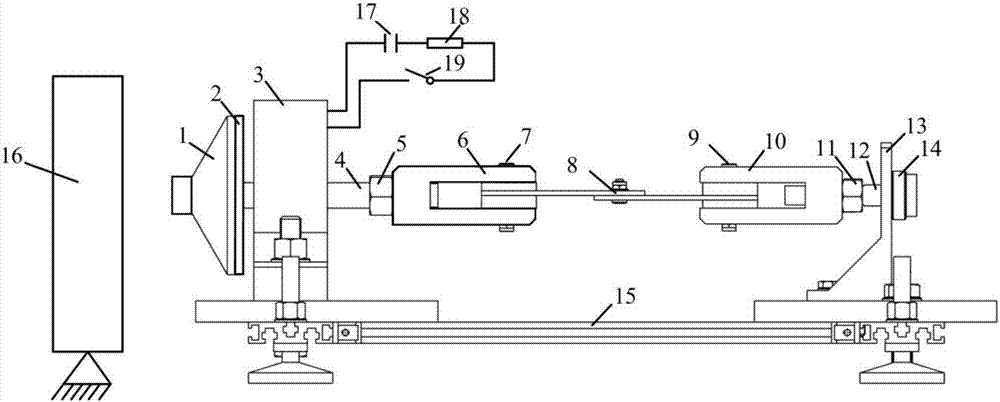

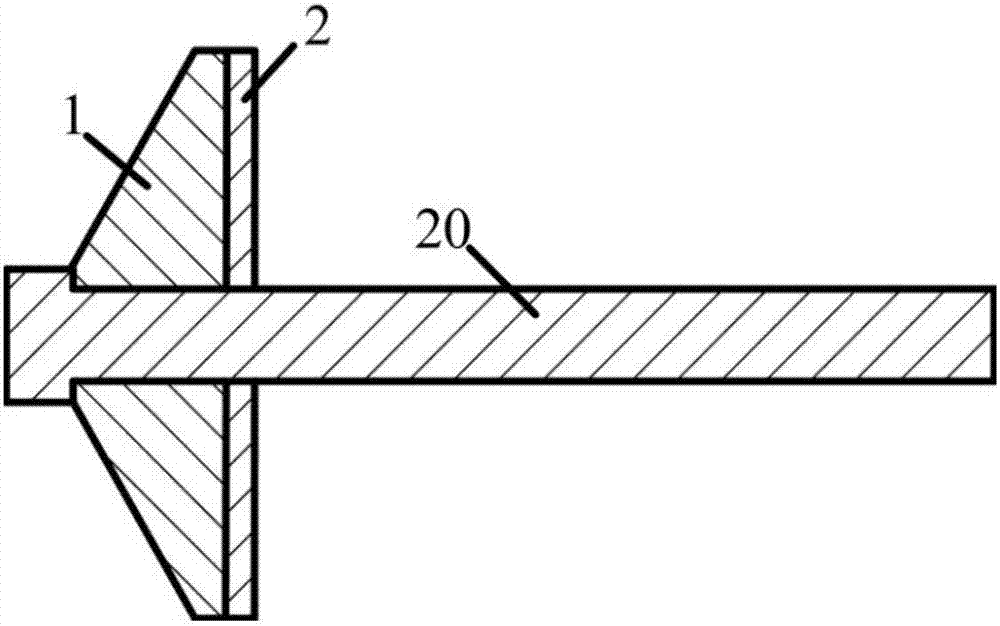

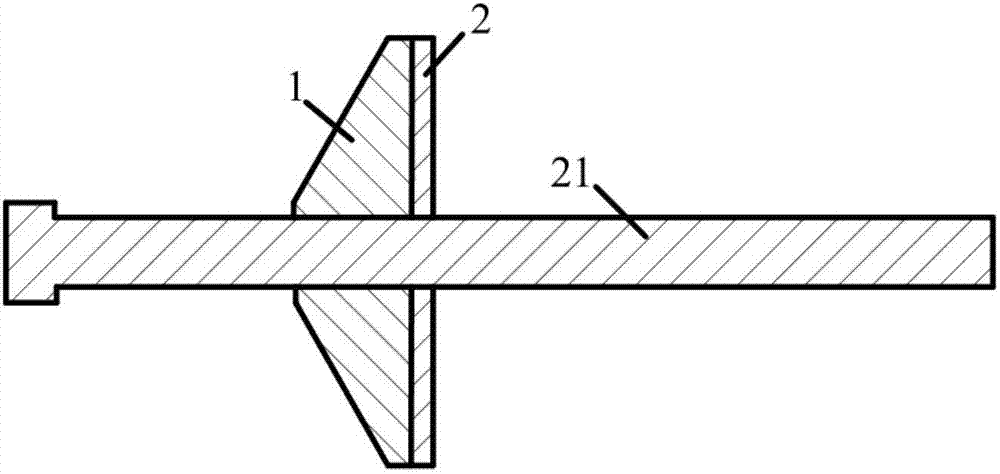

High-speed impact test device for mechanically fastened joint and test method

ActiveCN107063899ARealize integrationImpact speedMaterial strength using steady shearing forcesSoftware engineeringLong pulse

The invention discloses a high-speed impact test device for a mechanically fastened joint and a test method and aims to solve the technical problem of poor practicability of the conventional test device. The technical scheme is that the high-speed impact test device comprises a stress wave amplifier, an induction coil, a discharge coil, a tension bar, a front chuck, a rear chuck, a pressure sensor, a workbench and a buffer board, and integration of an impact shearing device and an extension force test device is realized. The test method comprises a direct loading test method and an impact loading test method. The high-speed impact test device and the test method have the advantages that the impact speed is high, and impact load amplitude and pulse width are controlled precisely, and the practicability is good. Long-pulse and medium-low-velocity impact test loading is realized through direct loading, the impact speed range is 1m.s<-1>-50m.s<-1>, the impact pulse width is 0.5 ms-6.5 ms, narrow-pulse and high-velocity impact test loading is realized through impact loading, and the impact speed range is 1m.s<-1>-300m.s<-1>.

Owner:SHAANXI DAGONG XUHANG ELECTROMAGNETIC TECH CO LTD

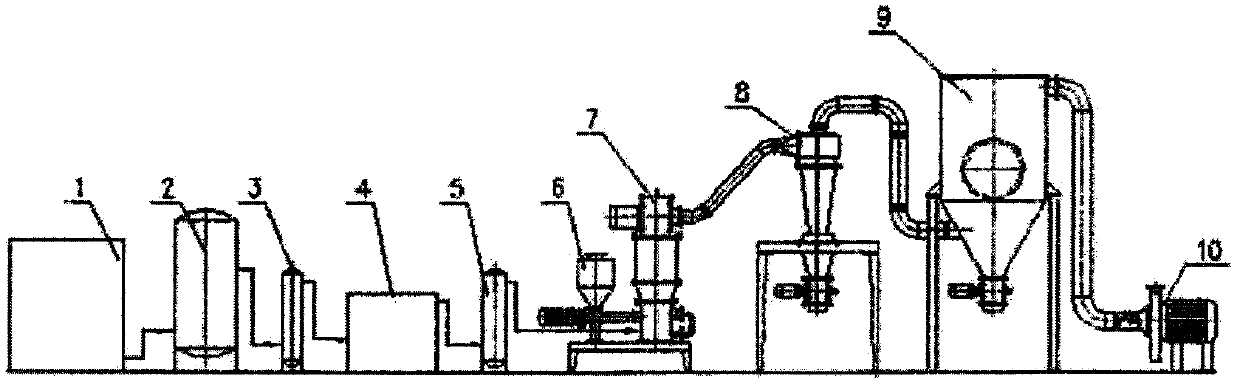

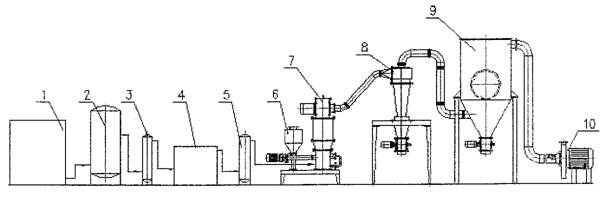

Processing device of ultramicro-tea powder

InactiveCN107912545AOnline work is uniqueFeed size is largePre-extraction tea treatmentCycloneFluidized bed

The invention relates to a processing device for tea powder. A processing device for ultrafine tea powder, which includes sequentially connected compressed air power source and oil-water separator, gas storage tank, primary filter, gas dryer, precision filter and sterilizing filter, material bin, fluidized bed Jet Mill, Cyclone Collector, Bag Collector and High Pressure Induced Fan. The device integrates crushing, grading, mixing and homogenizing, and realizes the unique advantages of on-line operation.

Owner:宁波市纯韩花漫生物科技有限公司

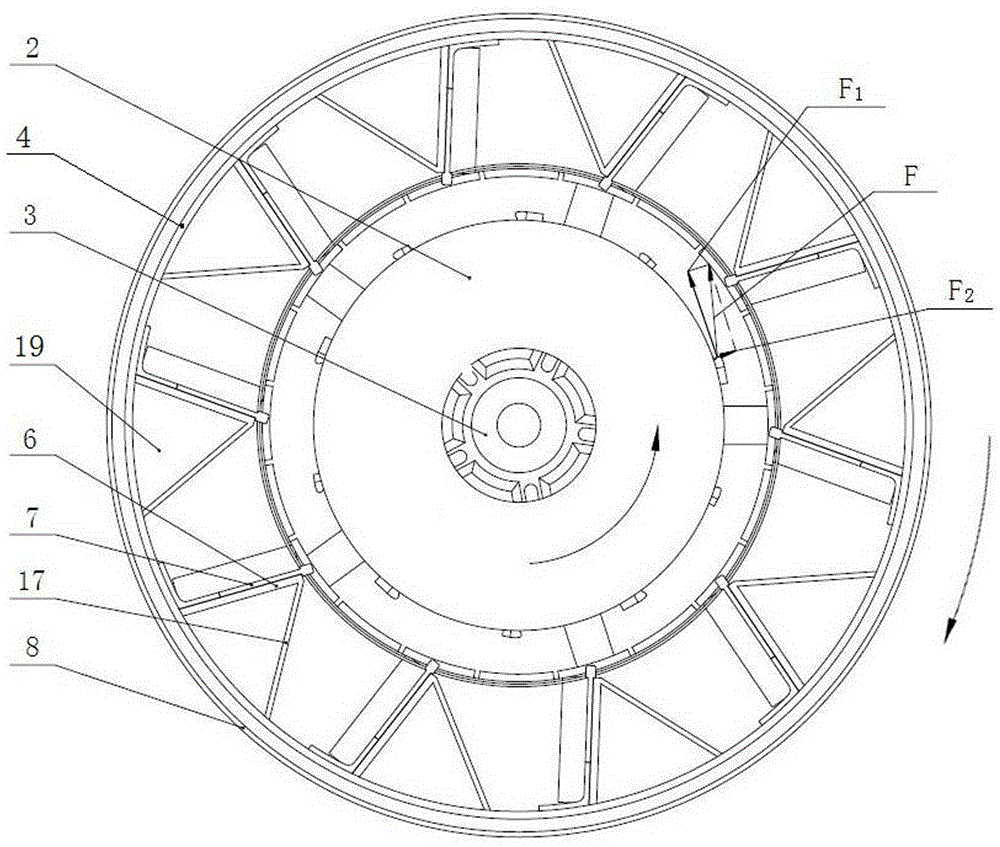

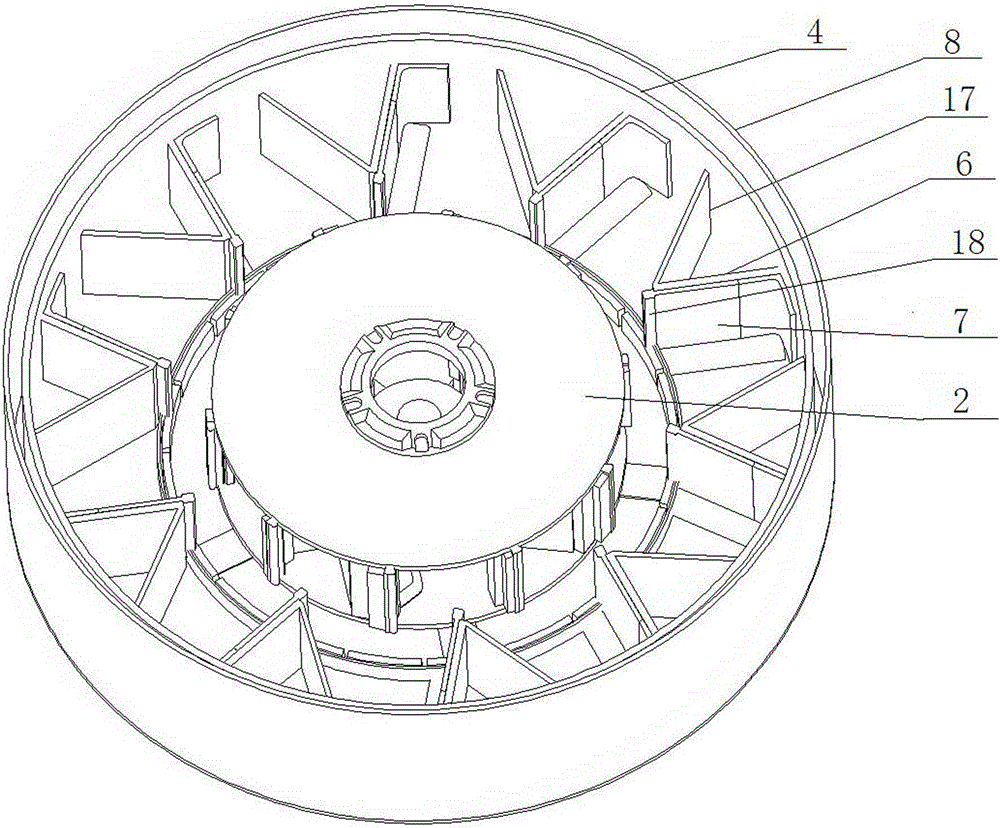

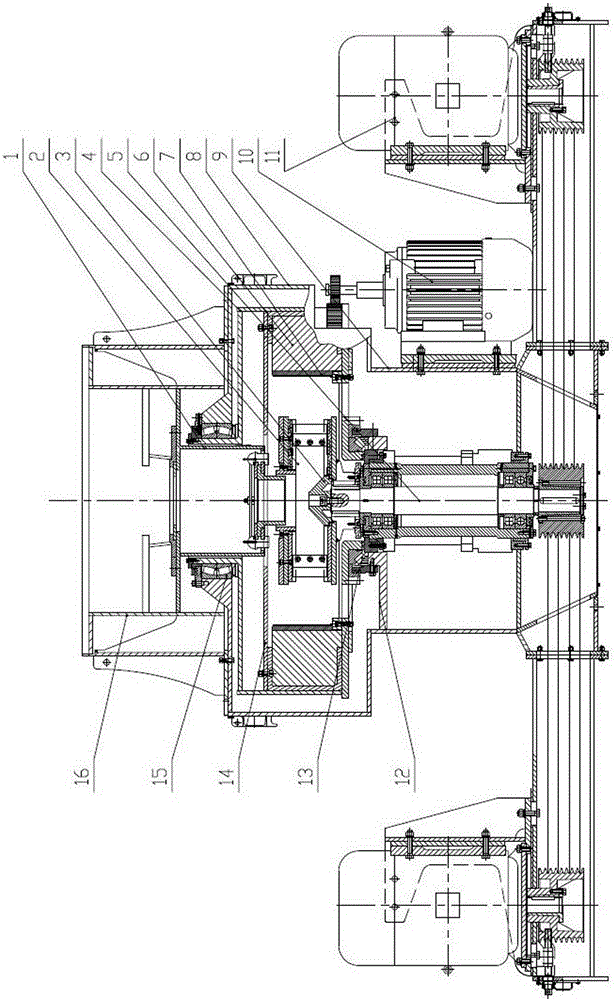

Vertical impact crusher

The invention relates to a crusher, in particular to a vertical impact crusher which comprises a crushing cavity shell, a rotor arranged in the crushing cavity shell and a feeding device used for feeding for the rotor. A crushing cavity is formed by the space between the rotor and the crushing cavity shell. Materials entering the rotor are thrown out from multiple distributing openings formed in the circumferential side wall of the rotor and fly to the crushing cavity shell to be subjected to impact crushing. The crushing cavity shell is rotary, and the rotating direction of the crushing cavity shell is opposite to the rotating direction of the rotor. A plurality of impact plates are arranged in the crushing cavity, rotate along with the crushing cavity shell and impact with the materials thrown out from the rotor. Plate hammers are arranged on the faces, impacting with the materials, of the impact plates, each plate hammer is composed of a wear-resisting plate and a hammer edge arranged at the end, close to the rotor, of the wear-resisting plate, and parts of the hammer edges protrude relative to the faces, impacting with the materials, of the wear-resisting plates. By means of the vertical impact crusher, the impact force and the impact speed of the materials are increased, and the material crushing effect is further improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

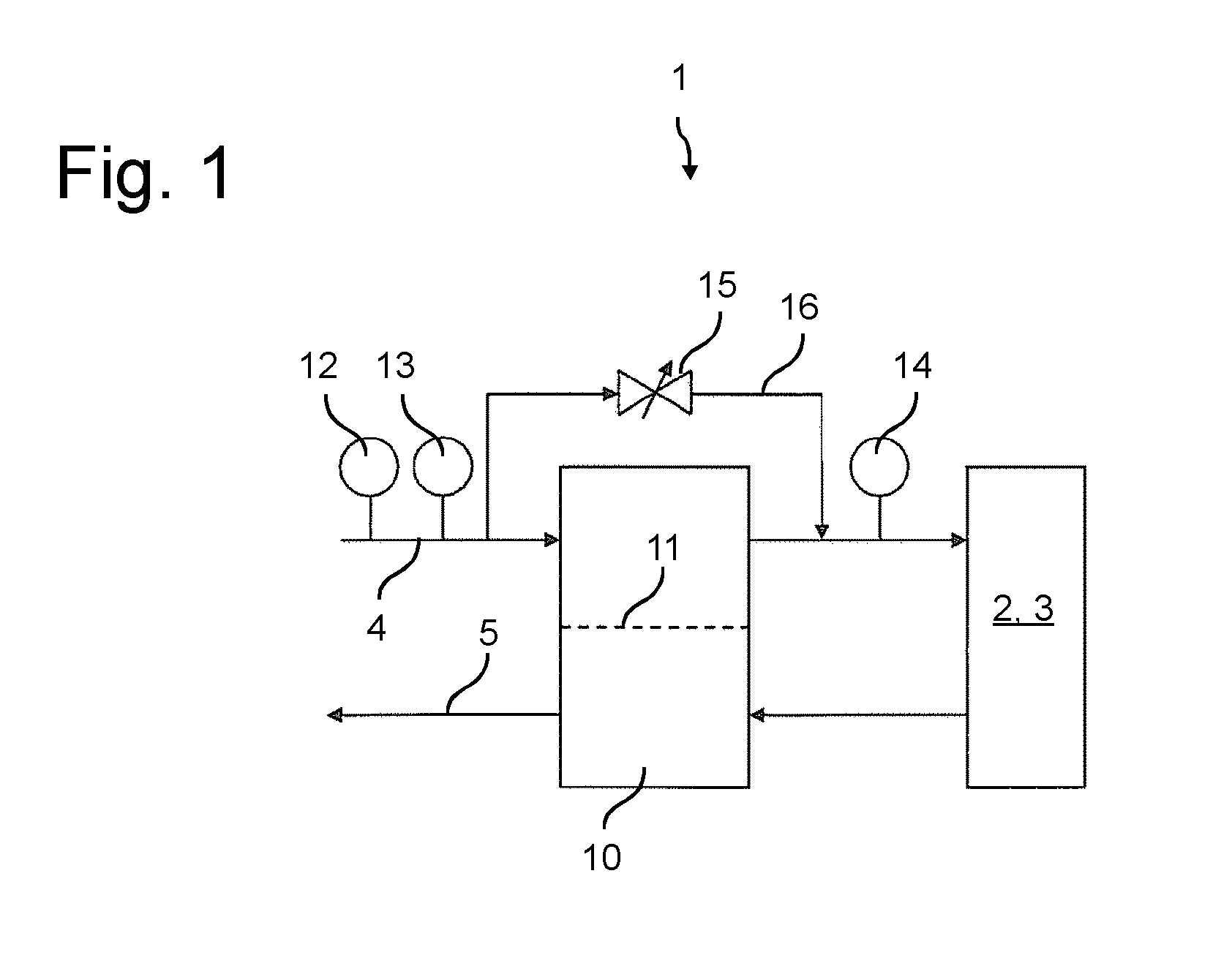

Ascertaining fuel cell inlet humidity by means of pressure sensors, and a mass flow rate-dependent control of the humidifier bypass

ActiveUS20150295258A1Highly susceptible to malfunctioningSimple and robust and cost-effective methodFuel cell auxillariesFuel cellsControl manner

The invention relates to a fuel cell arrangement (1) having at least one fuel cell (2) with a cathode (3) and an anode. The cathode (3) and the anode each have a reactant feed (4) and a reactant discharge (5), a humidifying device (10) and sensors (12, 13, 14) being provided at least at one of the reactant feeds (4). In particular, the sensors (12, 13, 14) are at least one fluid mass sensor (12) and two pressure sensors (13, 14), the fluid mass sensor (12) and one of the pressure sensors (13) being arranged upstream of the humidifying device (10) and one of the pressure sensors (14) being arranged downstream of the humidifying device (10). The humidifying device (10) can be operated in a controlled manner on the basis of the measurements of the sensors (12, 13, 14). The invention further relates to a method for controlling the humidity of a reactant for such a fuel cell arrangement (1).

Owner:ROBERT BOSCH GMBH

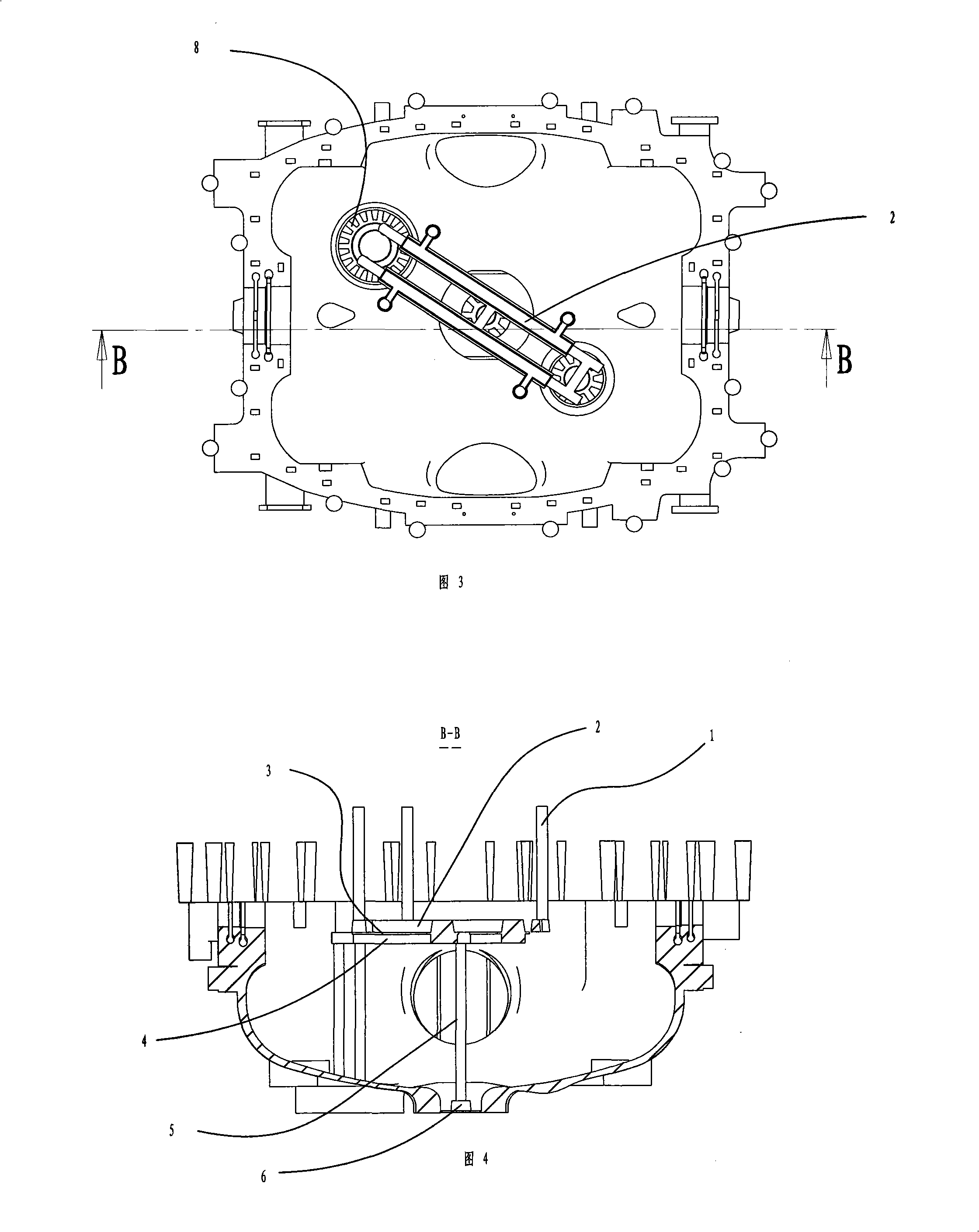

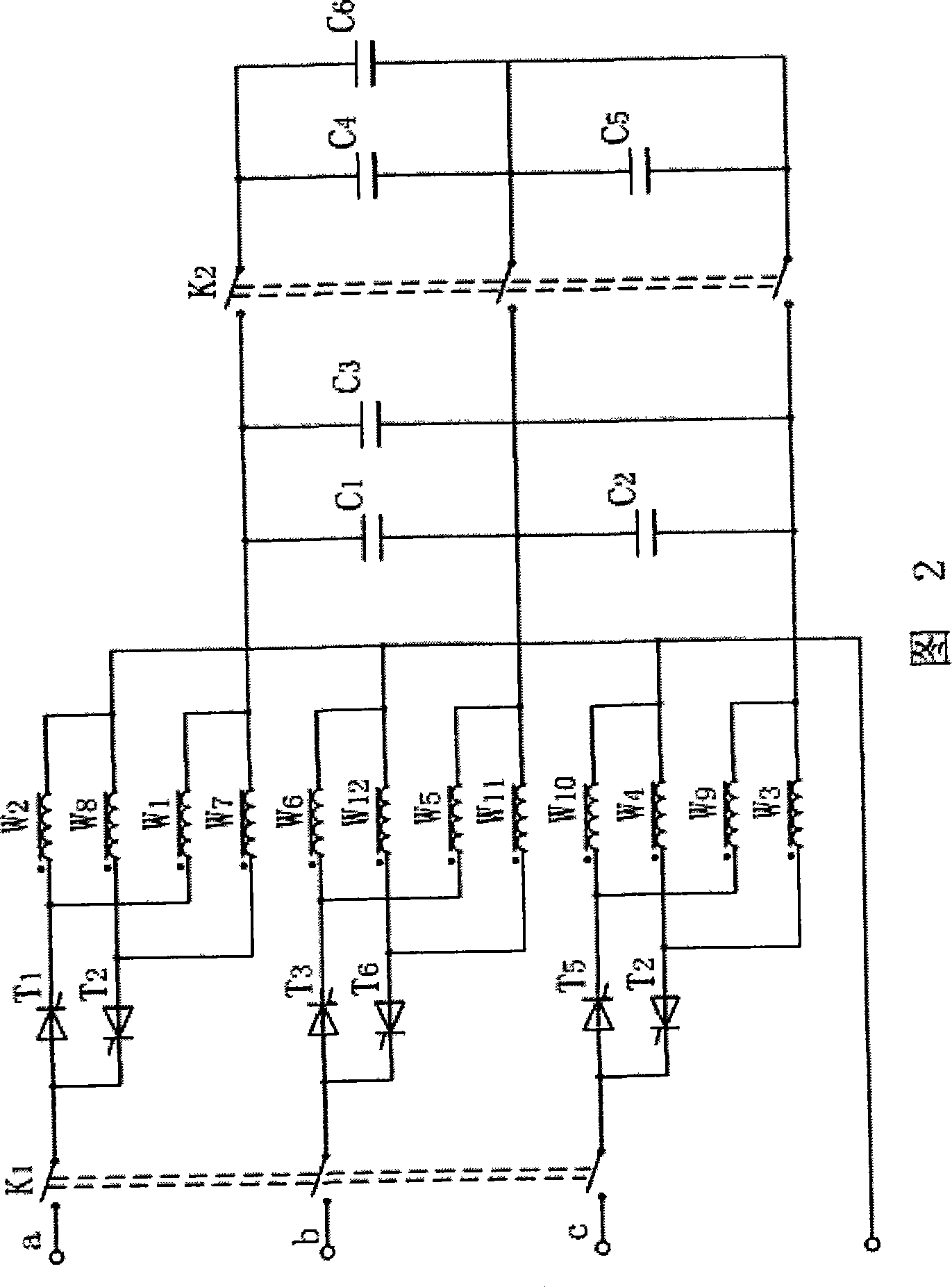

Electromagnetic combined apparatus for synthesizing stone pressure plate

ActiveCN101412245ARealize vibration suppression one by oneSimple structureCeramic shaping apparatusEngineeringQuartz

The invention relates to the field of building material machinery, in particular to an electromagnetic combined synthetic stone pressure plate device. The pressure plate device solves the problem that at present, when the electromagnetic vibration theory is applied to controlling a one-piece pressing tool to achieve integral vibration and pressing, the actual press power applied on part of a material is insufficient, and the pressing requirement on achieving the best compaction effect cannot be satisfied. The device comprises a vacuum cover provided with a supporting plate therein, wherein the supporting plate is provided with electromagnets, and a pressing device is arranged under the supporting plate; the pressing device is provided with a driving rod the end part of which is connected with movable iron cores of the electromagnets through a connecting piece; and a compression spring is arranged between the connecting piece and an electromagnet base. The pressing tool comprises vibrating plates the number of which is in accordance with that of the electromagnets on the supporting plate and which form a rectangular pressing tool through matrix arrangement on the same plane, the vibrating plates are corresponding to the electromagnets on the supporting plate one by one, and each vibrating plate is connected with the movable iron cores of the electromagnets through the driving rod. The pressure plate device has a reasonable and simple structure, good molding effect on pressing artificial quartzes, and high compactness of the finished products.

Owner:STATE GRID CORP OF CHINA +1

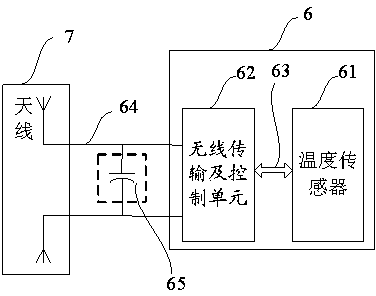

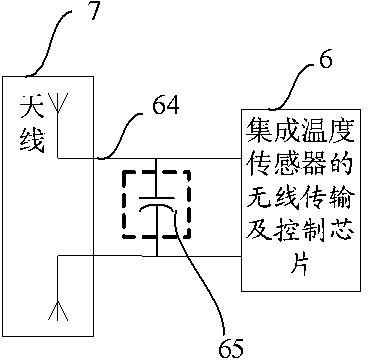

Mounting bolt capable of obtaining temperature of mounted equipment, and train axle thereof

ActiveCN103978992AImpact speedAccurate temperatureRailway auxillary equipmentRailway profile gaugesElectricityEquipment temperature

The invention relates to a mounting bolt capable of obtaining the temperature of mounted equipment. The mounting bolt comprises a bolt body and a wireless temperature measurement module and a wireless transmission antenna which are arranged on the bolt body, wherein a temperature sensor and a wireless transmission and control unit which obtains the numerical value measured by the temperature sensor and converts the numerical value into wireless signals to be sent out are arranged in the wireless temperature measurement module, and the wireless transmission and control unit is electrically connected with the temperature sensor or the temperature sensor is integrated in a wireless transmission and control chip; the antenna is arranged on the outer surface of a bolt head and is connected with a radio frequency port of the wireless temperature measurement module through a cable. The invention also relates to an axle using the bolt. The mounting bolt capable of obtaining the temperature of mounted equipment has the following beneficial effects that the temperature sensor is arranged in a bolt body of the mounting bolt, so the temperature is accurately measured, and can not be affected by the ambient temperature and the operating speed of a train.

Owner:INVENGO INFORMATION TECH

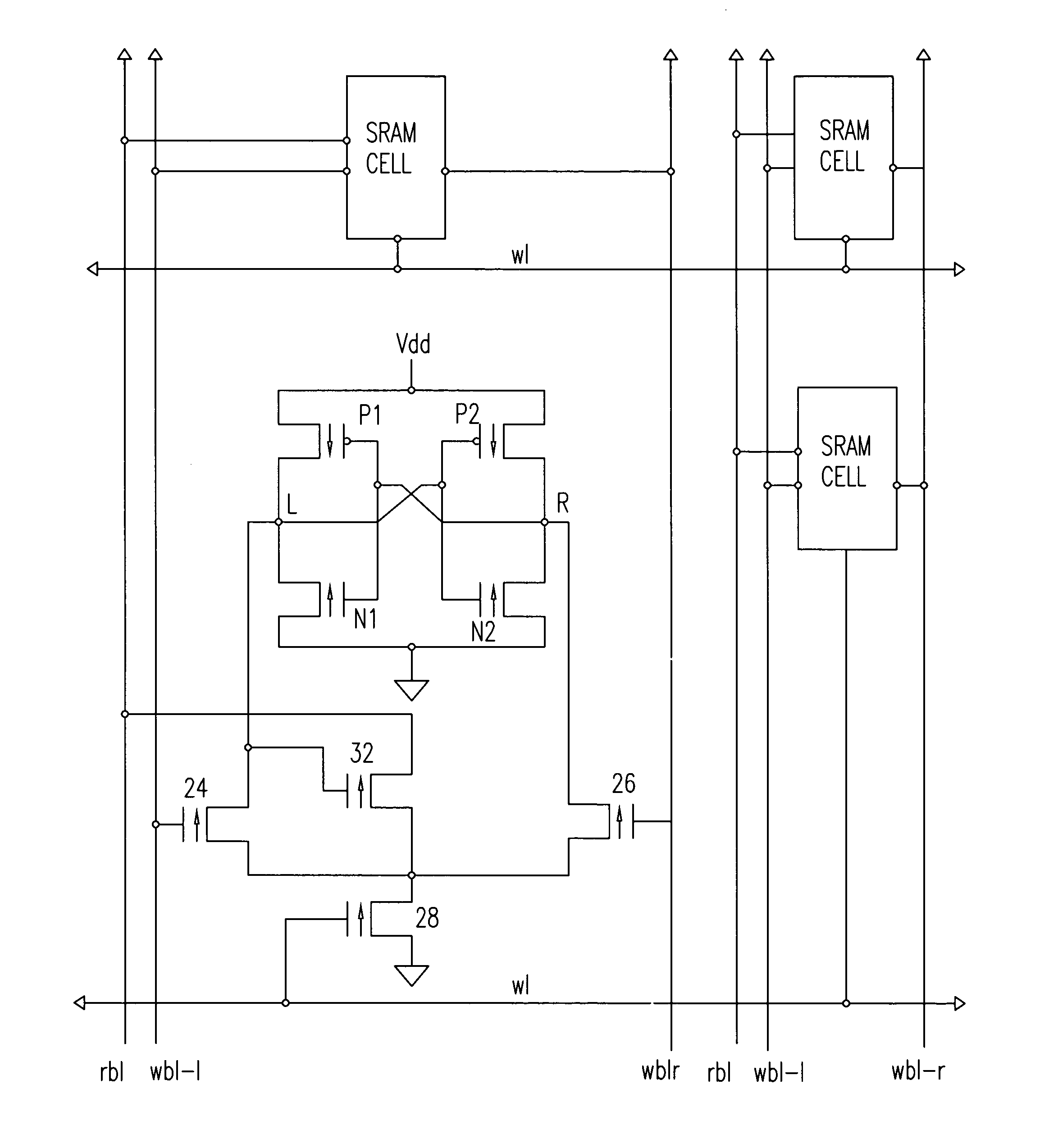

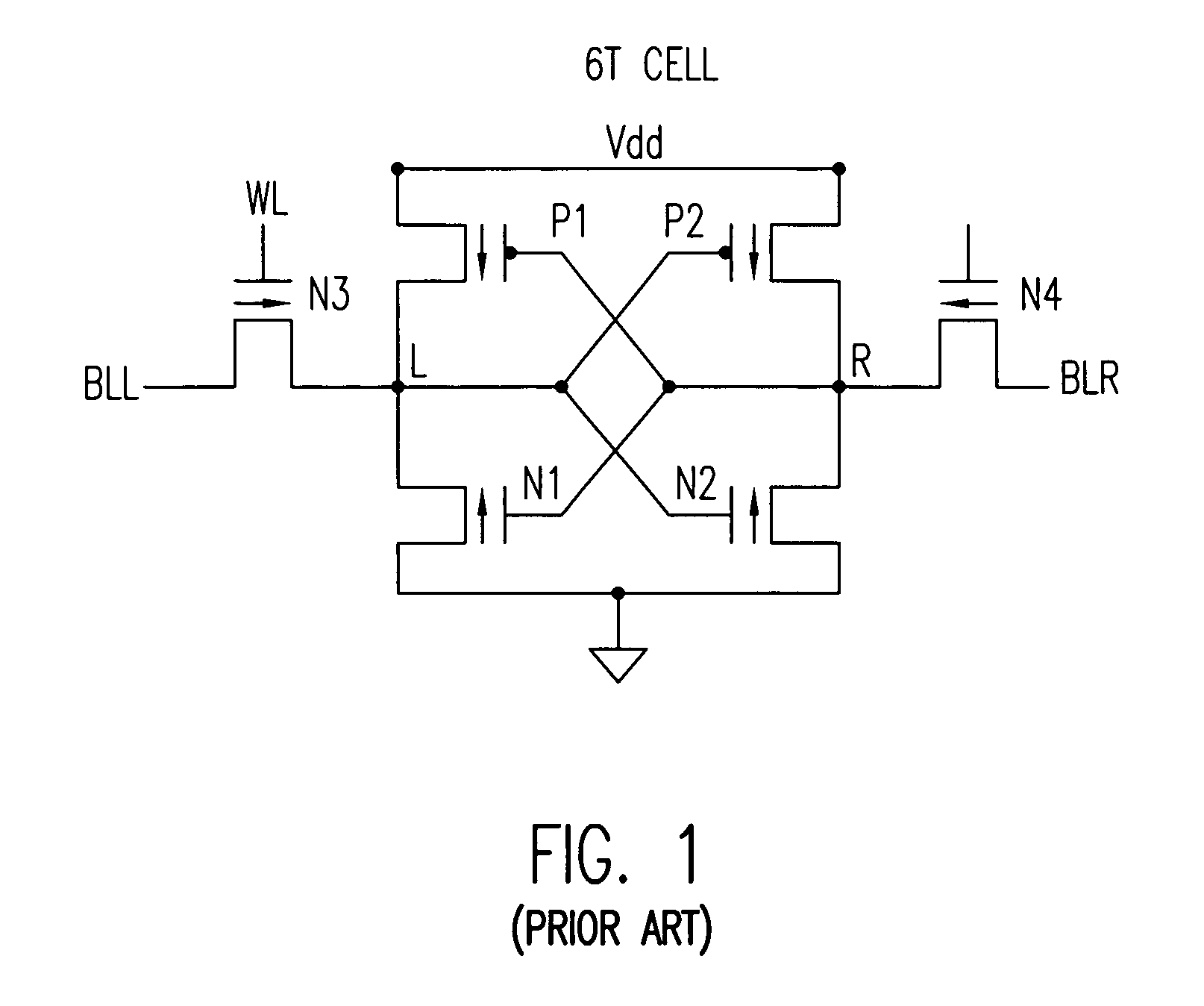

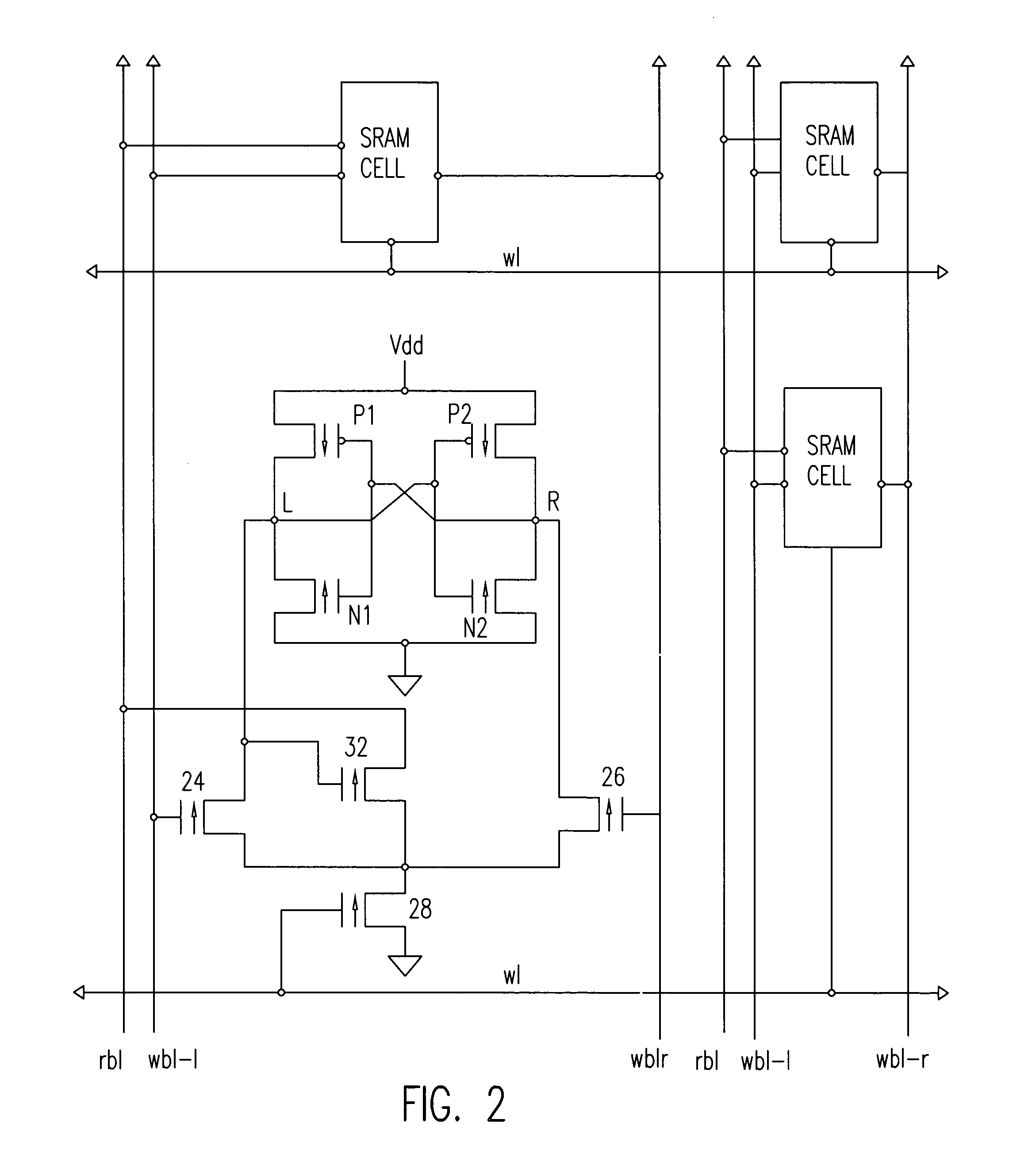

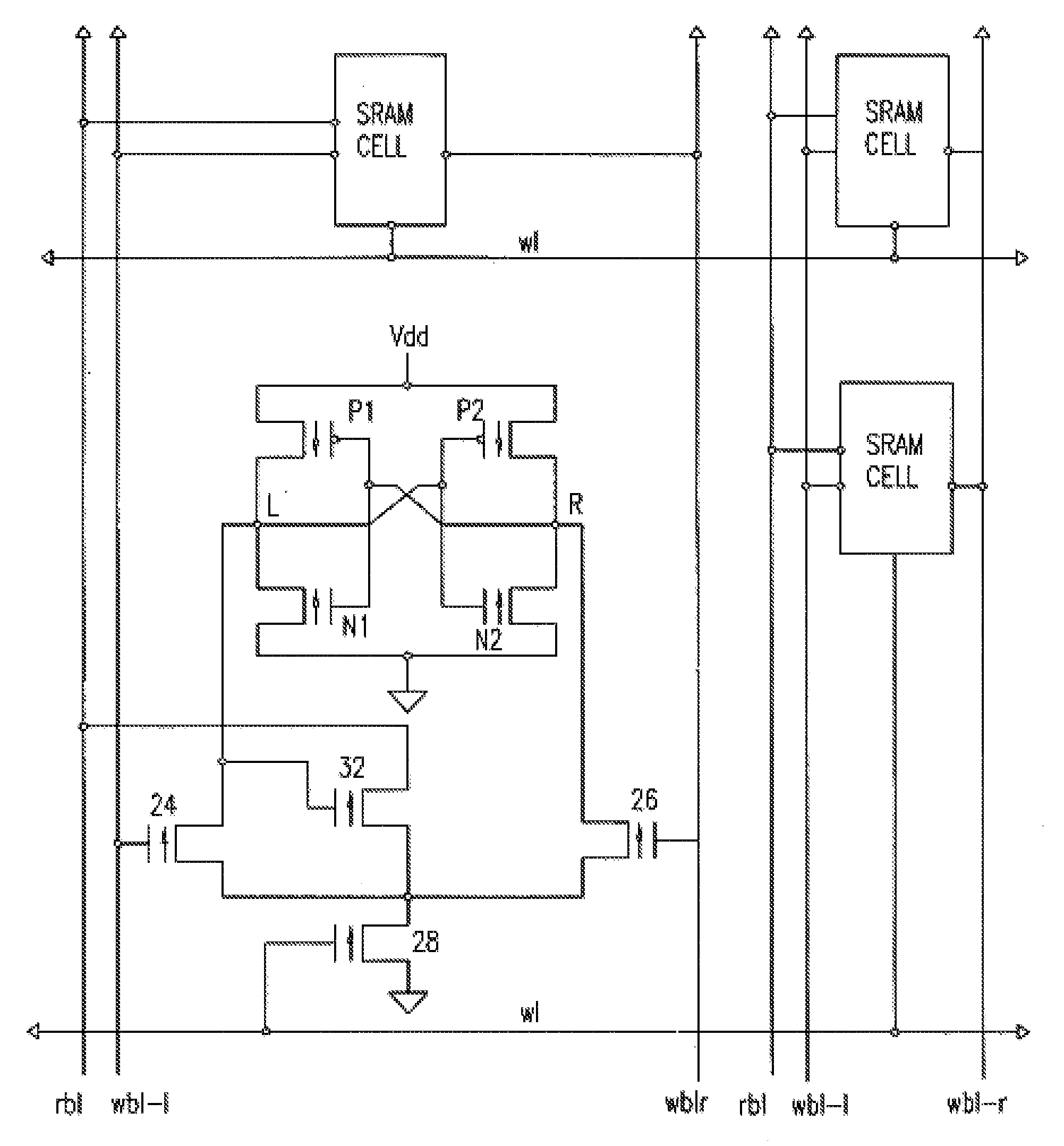

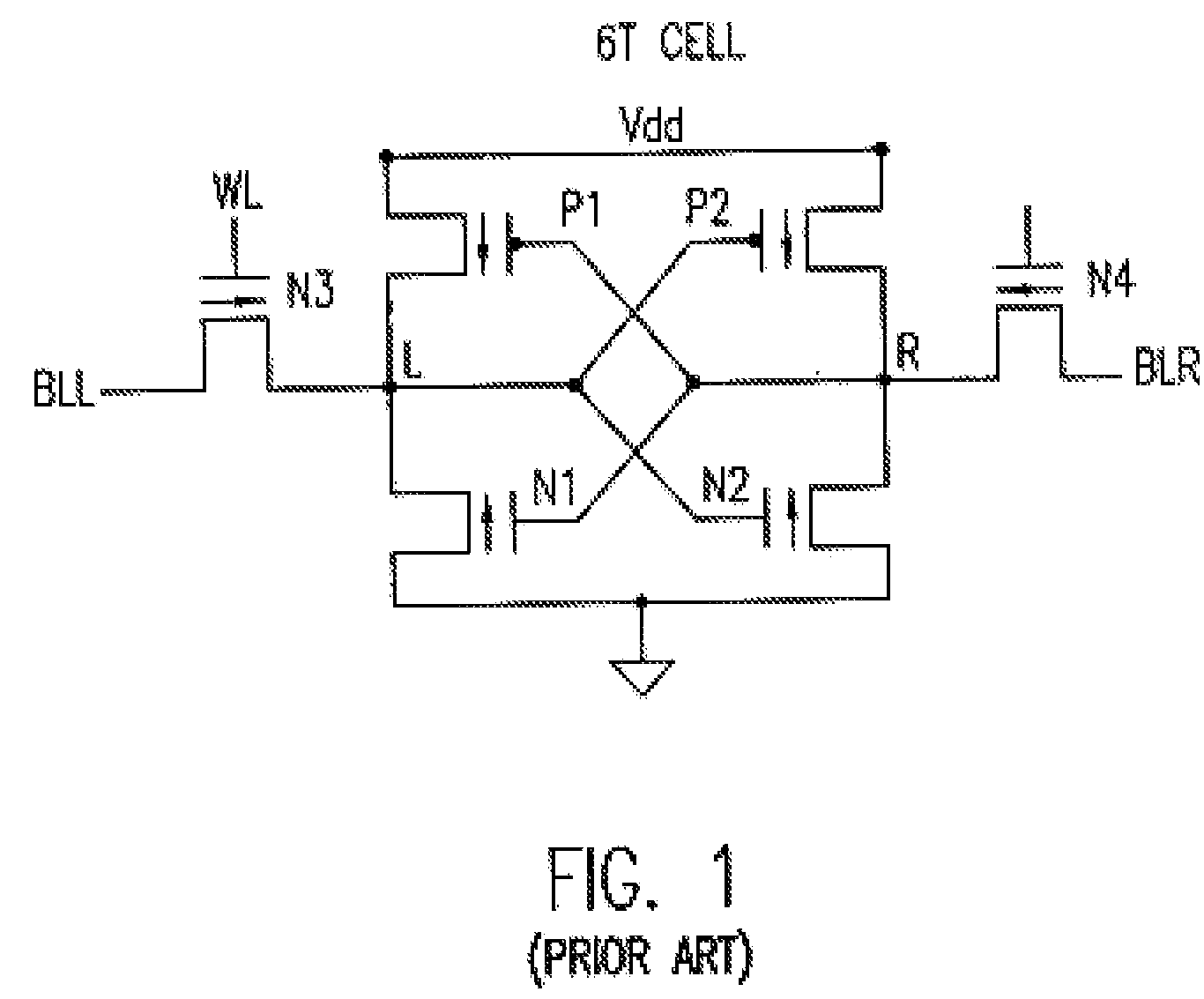

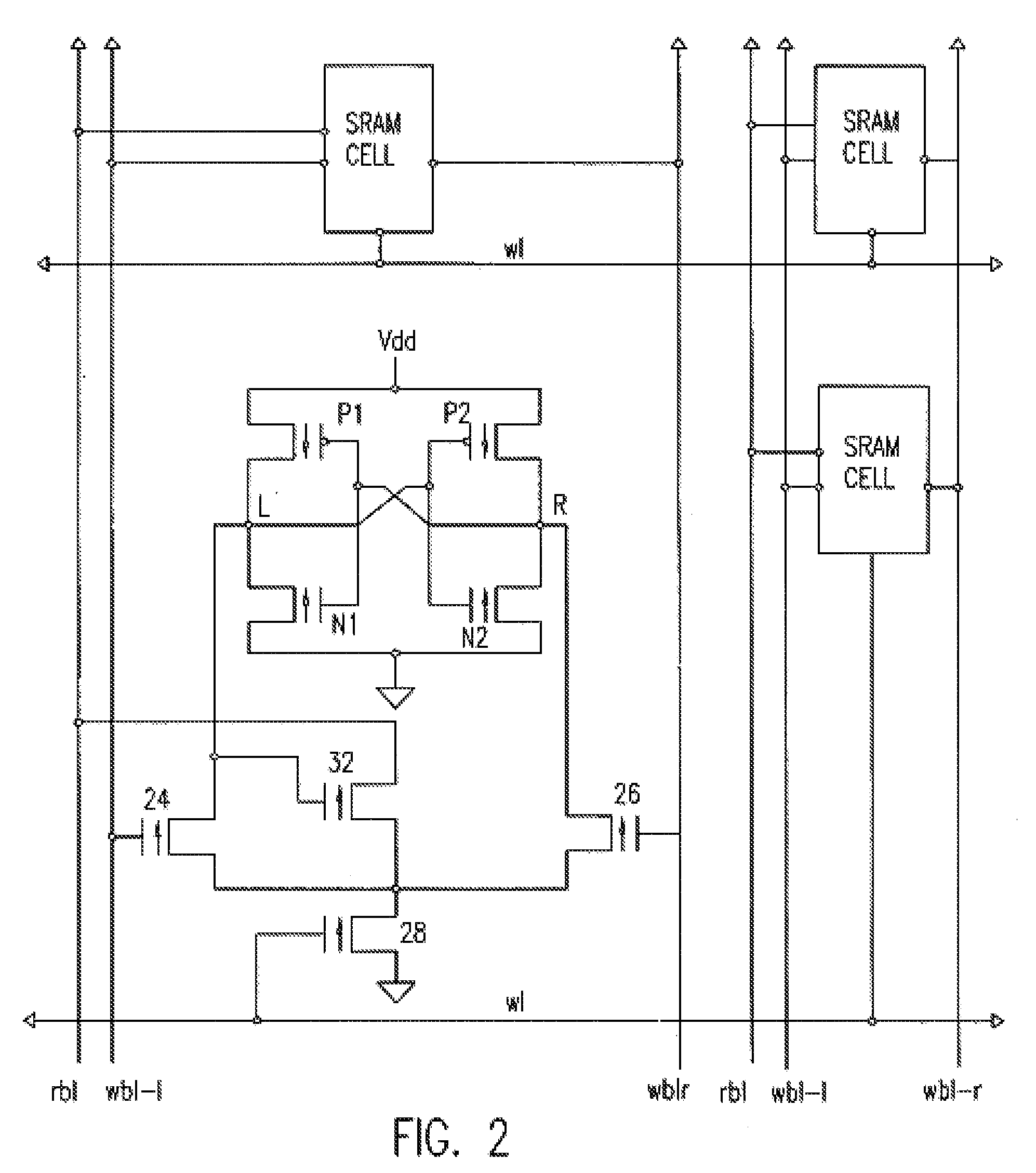

Eight transistor SRAM cell with improved stability requiring only one word line

An SRAM cell that is accessed by a single word line and separate access transistors for read and write operations. A pair of write bit line transfer devices provide respectively access to the right and left sides of cross coupled pull-up, pull-down transistor pairs for a write operation, and a single read bit line transistor in series with the word line transistor, when selected, reads the content of the cell.

Owner:GLOBALFOUNDRIES INC

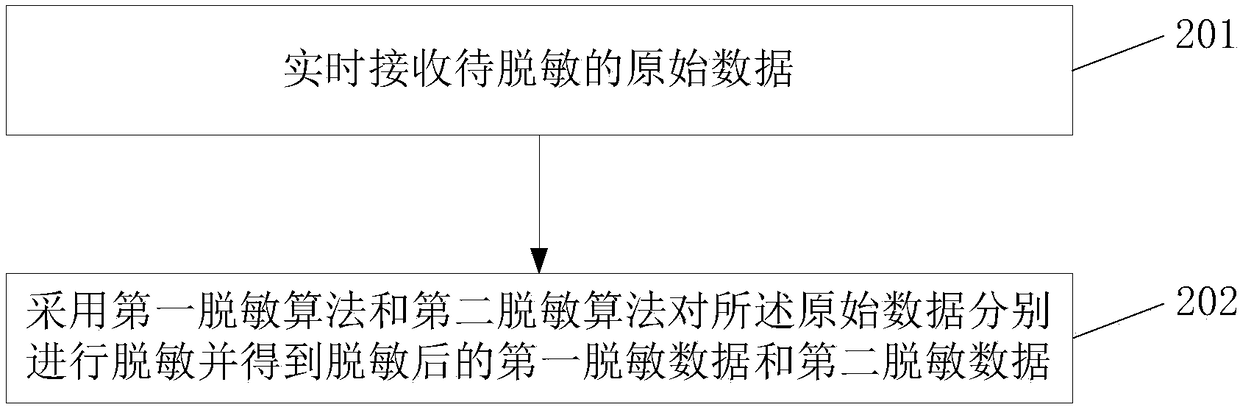

Data desensitization method and device

ActiveCN108549824AGuaranteed relevanceReduce data volumeDigital data protectionOriginal dataData mining

The invention provides a data desensitization method and device. The method comprises the following steps of: receiving to-be-desensitized original data in real time; respectively desensitizing the original data by adoption of a first desensitization algorithm and a second desensitization algorithm so as to obtain first desensitized data and second desensitized data, and obtaining the first desensitized data and the second desensitized data in to-be-analyzed data; and if second encrypted data of the second desensitized data is same as preset second encrypted data, analyzing the second desensitized data and returning an analysis result, wherein the analysis result is the original data.

Owner:杭州橙鹰数据技术有限公司

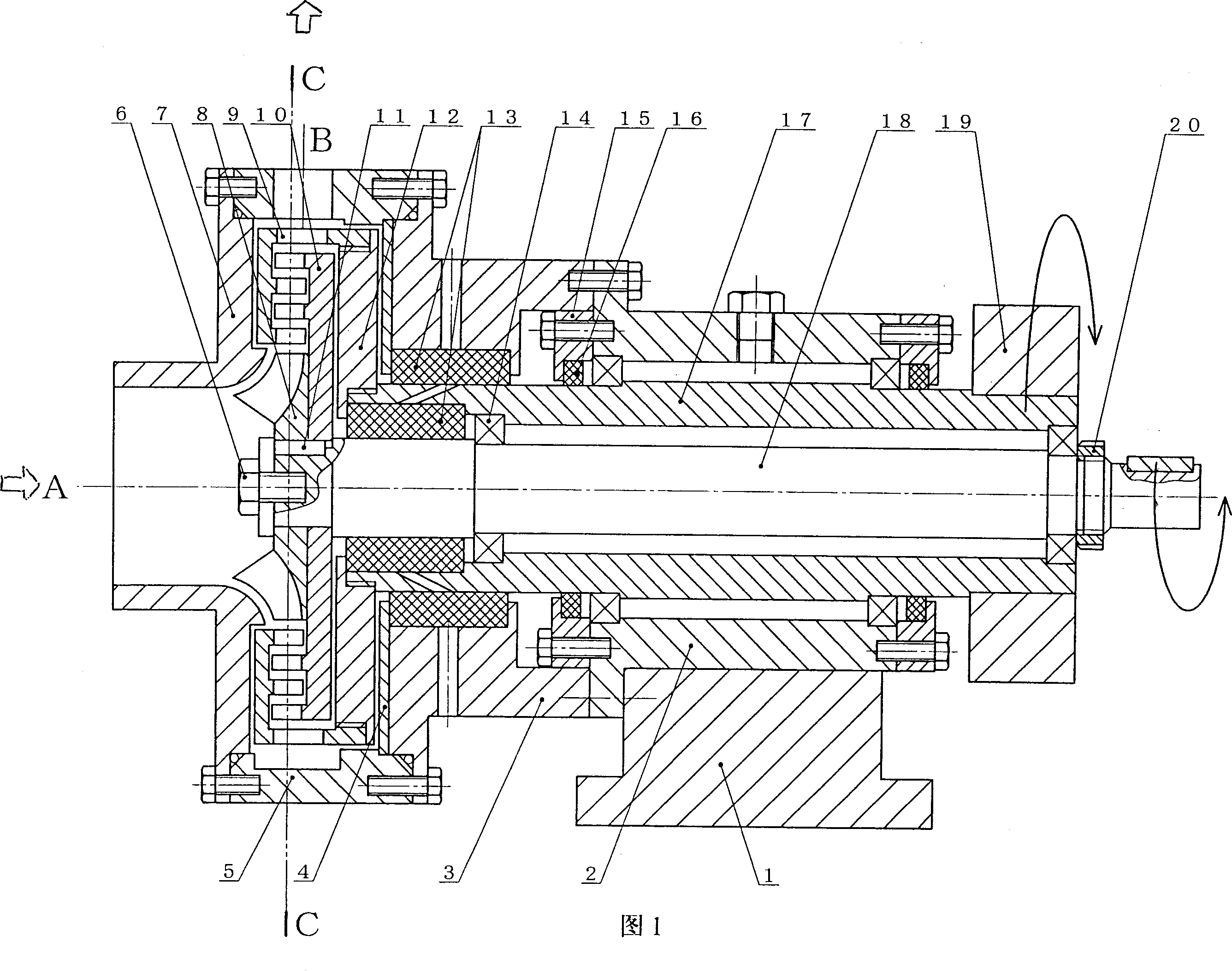

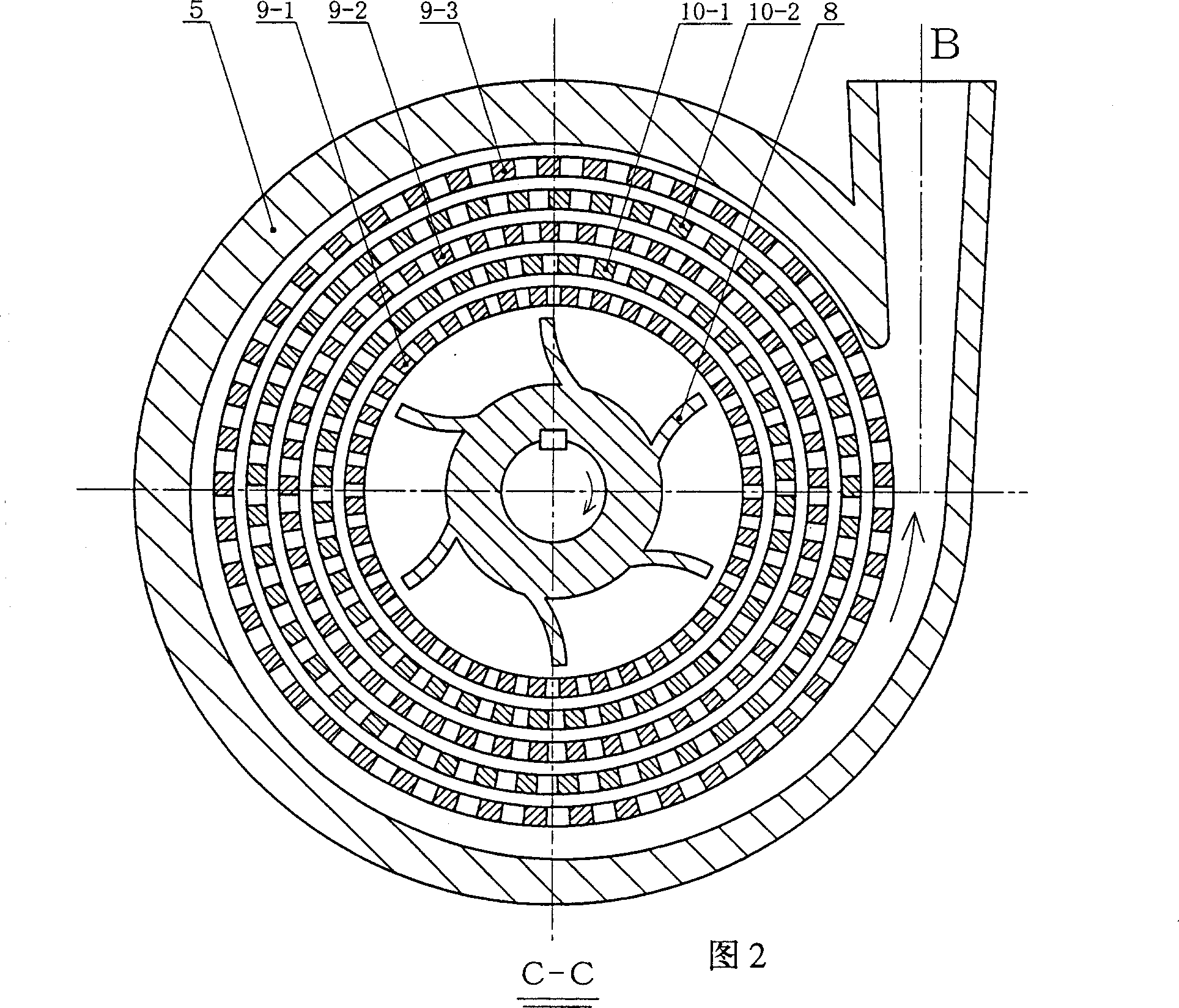

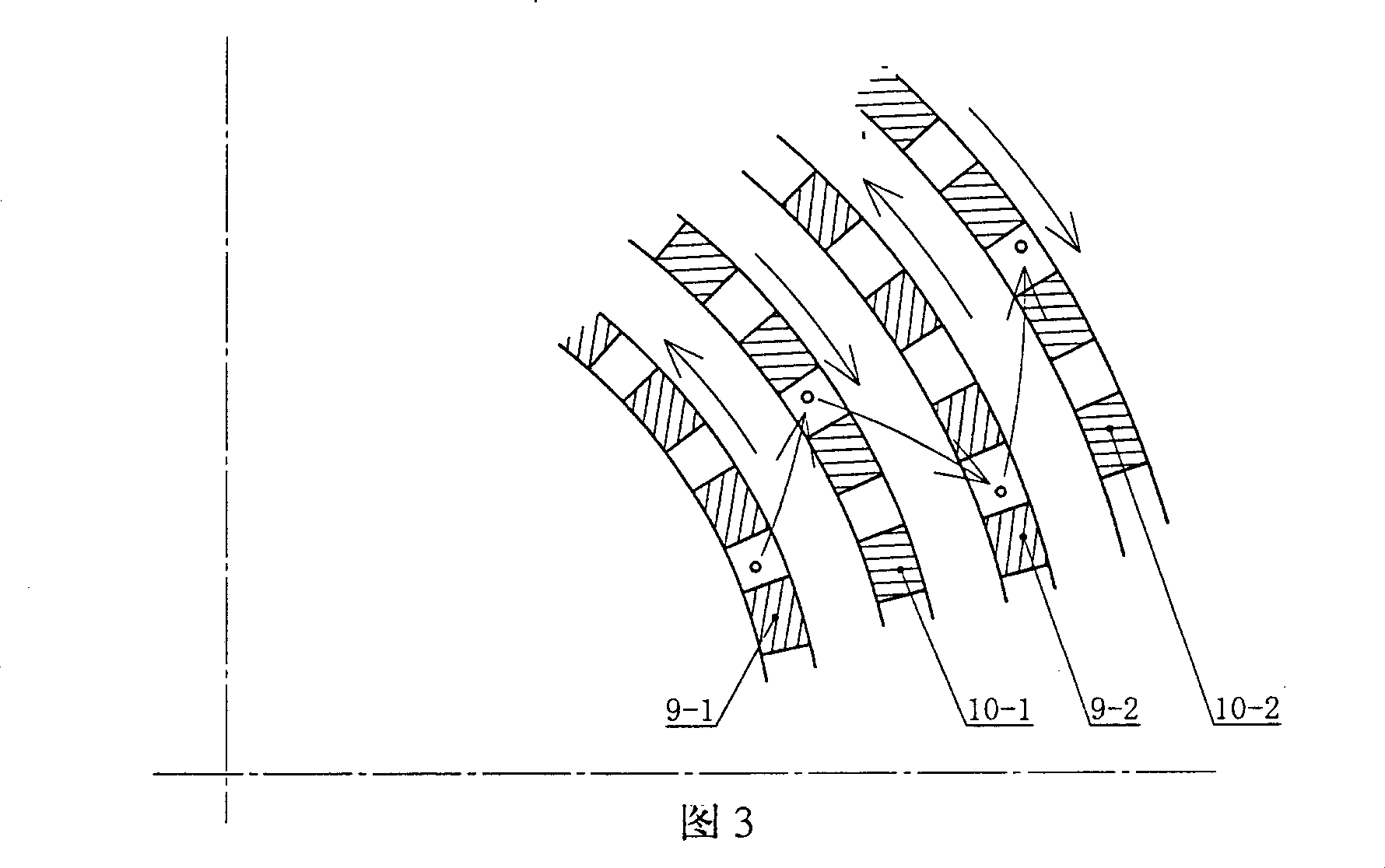

Rotary impact type fining, homogenizing and emulsifying apparatus

A rotation impact type fining, homogenizing and emulsifying apparatus is composed of a base, a casing, a power shaft and blade wheels on the power shaft, and is characterized by that said blade wheels include forward rotating one, backward rotating one and feeding one. Its advantages are unique structure and high performance.

Owner:丁楠

Processing device for superfine tea powder

InactiveCN102613325AOnline work is uniqueFeed size is largePre-extraction tea treatmentCycloneFluidized bed

The invention relates to a processing device for superfine tea powder, which comprises a compression air power source, an oil-water separation device, a gas storage tank, a primary filter, a gas drying machine, a precise filter, a sterilization filter, a material cabin, a fluidized bed jet mill, a cyclone collector, a bag-type collector and a high pressure draught fan which are sequentially connected. The device integrates crushing, gradation, mixing and homogenization into a whole and achieves a unique advantage of on-line operation.

Owner:ZHEJIANG DEQING AOCUI BIOLOGICAL TECH

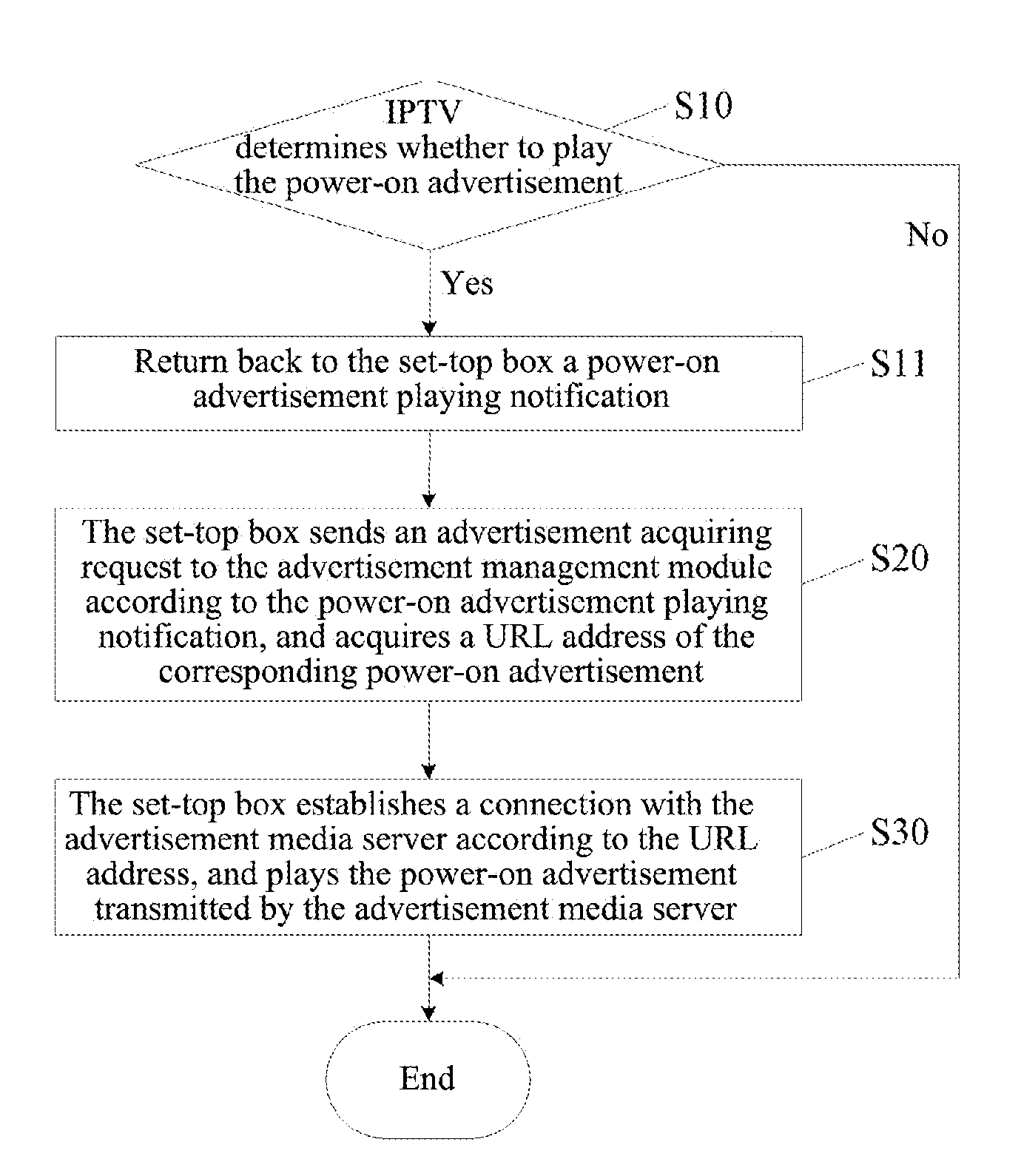

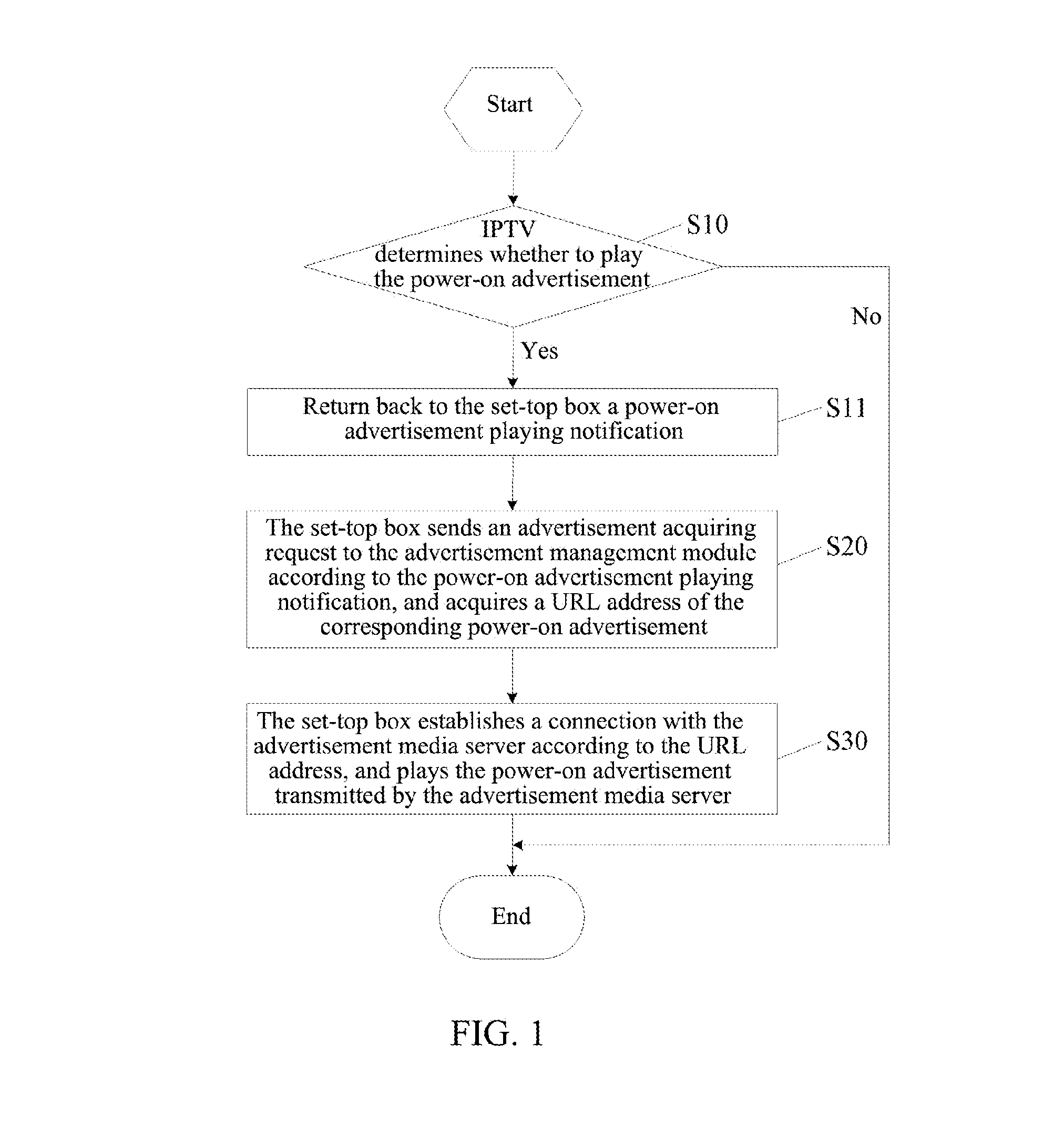

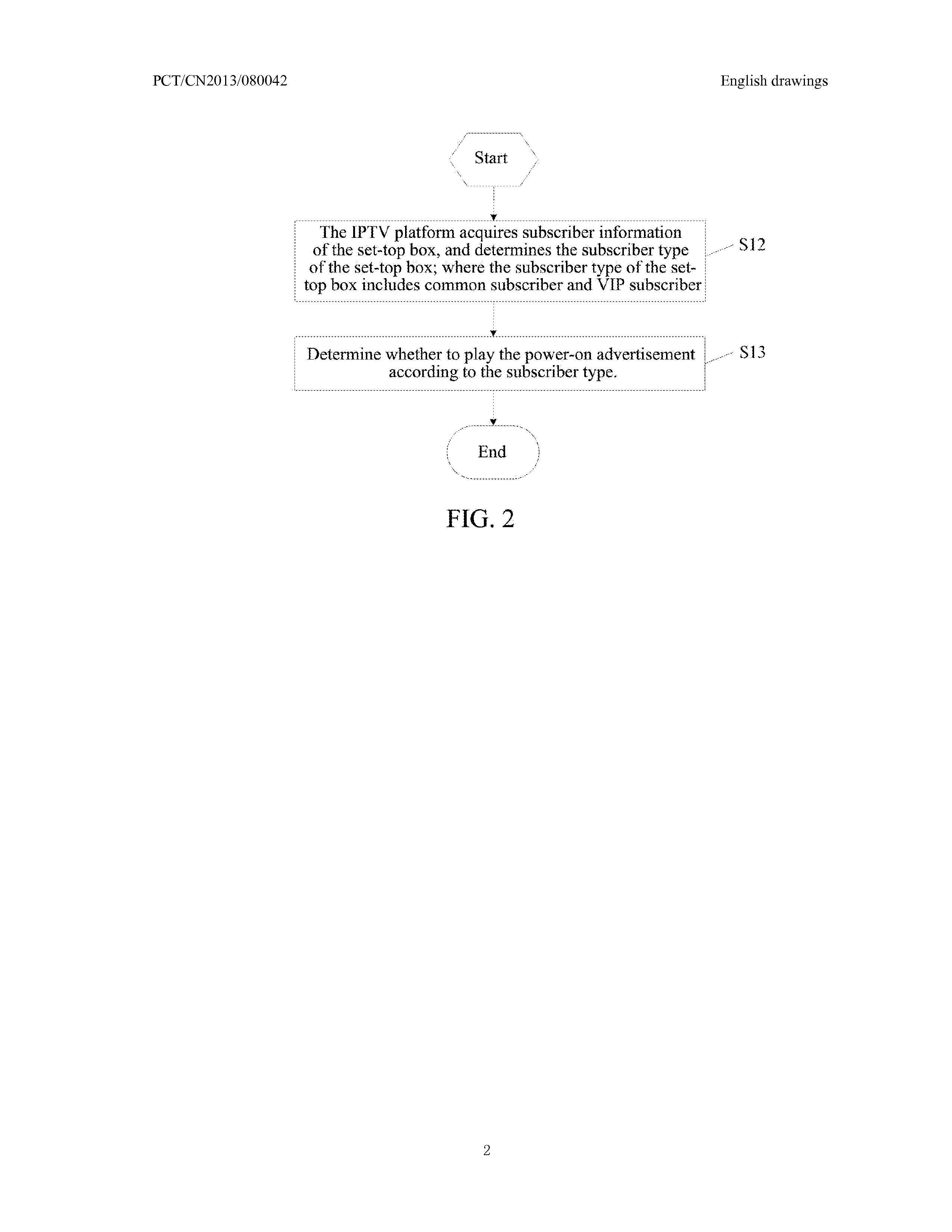

Method And System For Playing Set-Top Box Startup Advertisement, And Set-Top Box

ActiveUS20150264449A1Increase experienceImpact speedSelective content distributionMedia serverWorld Wide Web

The present document discloses a method and a system for playing a set-top box power-on advertisement and a set-top box, the method includes: according to the power-on advertisement playing notification returned by the IPTV platform, the set-top box acquiring from the advertisement management module the URL address corresponding to a content of the power-on advertisement in which a subscriber is interested and analyzed according to a hotness value of the subscriber watching TV programs / videos on demand, wherein the hotness value is analyzed by the advertisement management module according to a watching record of the subscriber of the set-top box by means of cloud statistical analysis; the set-top box establishing a connection with an advertisement media server according to the URL address, and playing the power-on advertisement.

Owner:ZTE CORP

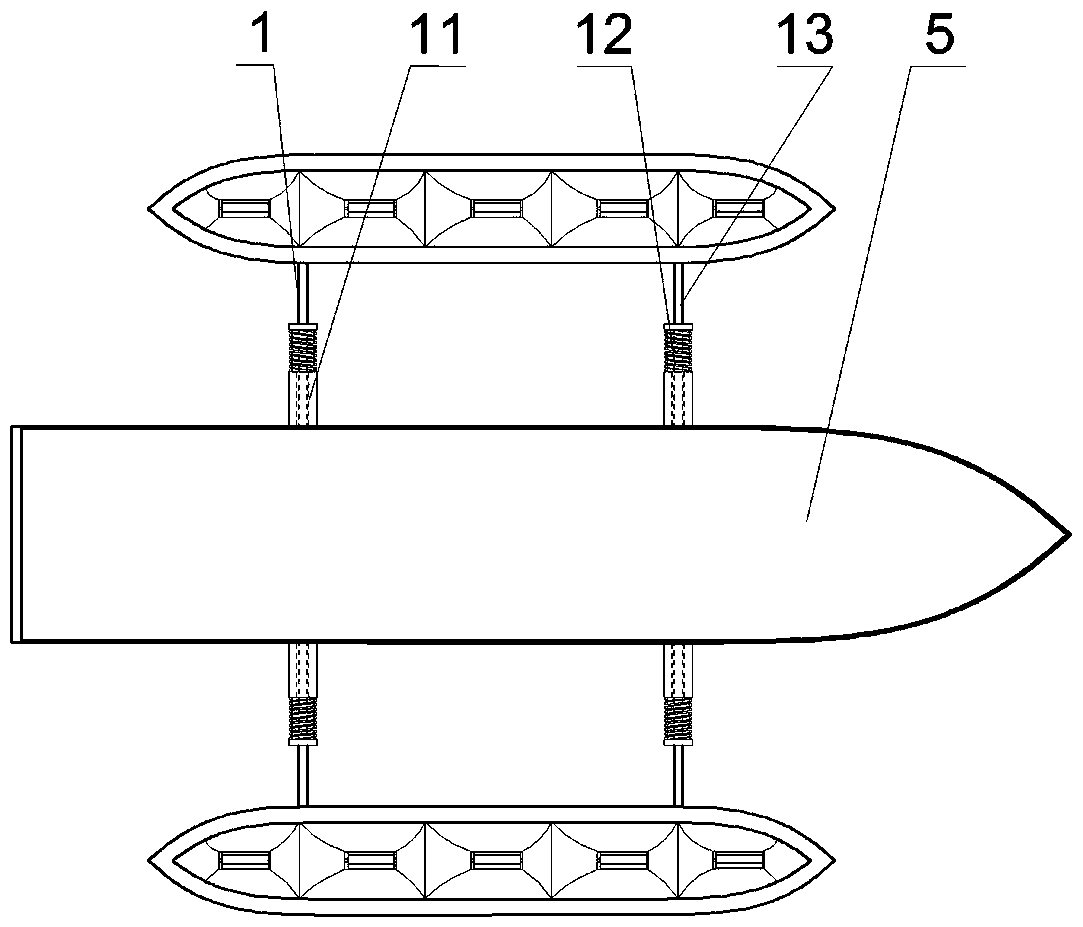

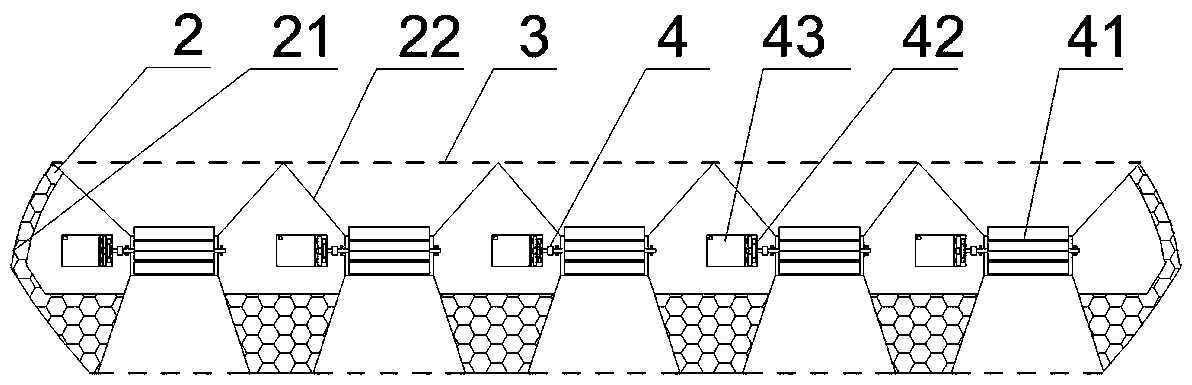

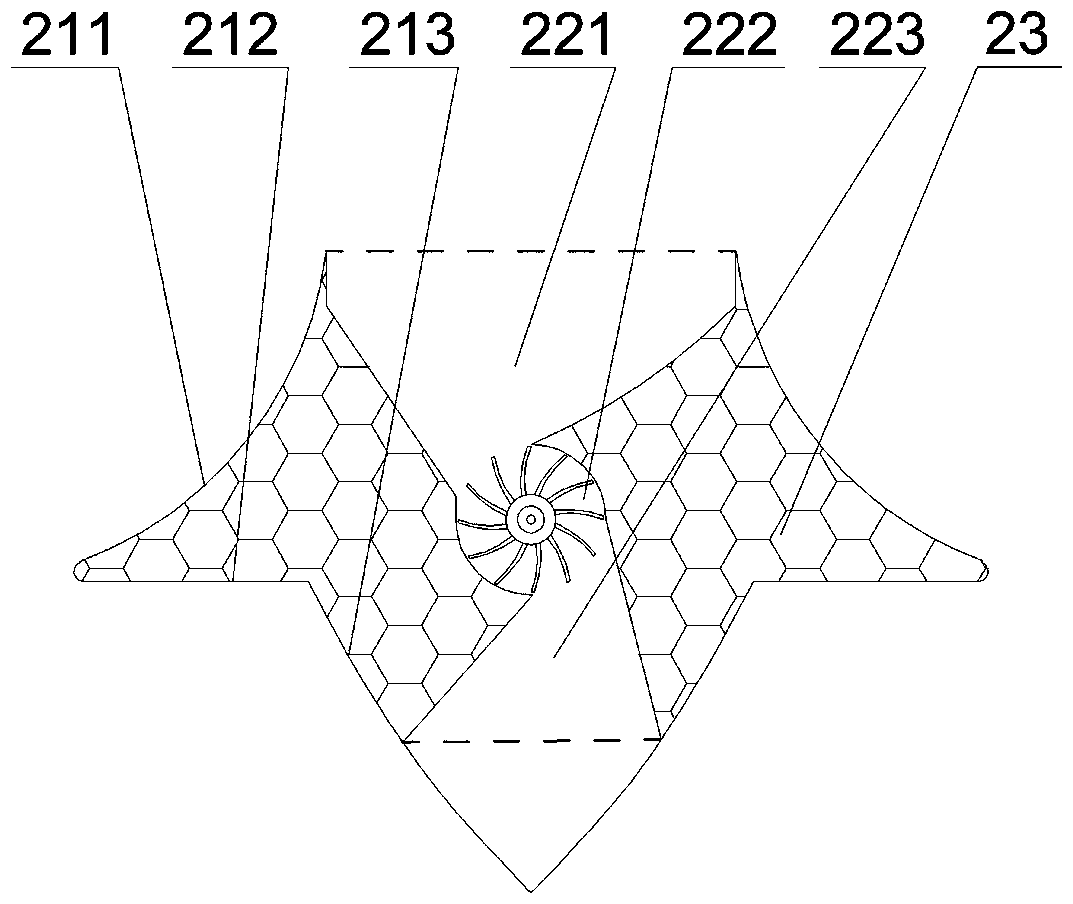

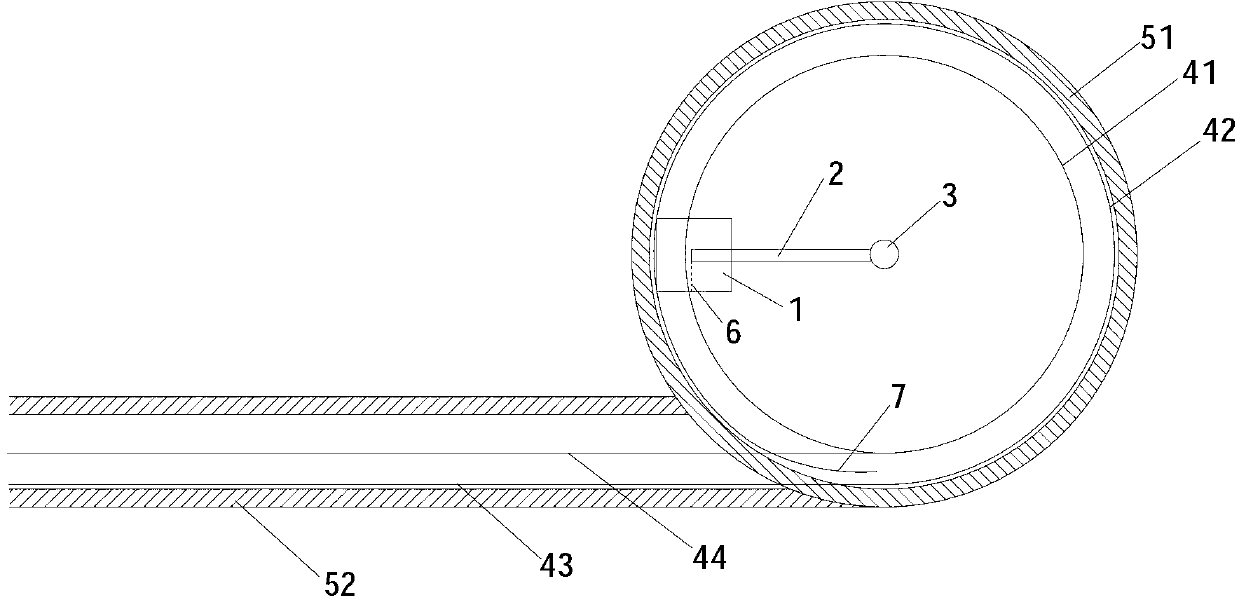

Wave-energy energy-collecting power generation device for ships

PendingCN108252851AReduce the cost of going to seaIncrease the voyageVessel cleaningHullsWater turbineWater flow

The invention discloses a wave-energy energy-collecting power generation device for ships. The wave-energy energy-collecting power generation device comprises two balanced drainage energy-collecting mechanisms, connecting components, protection components and a power generation system, wherein the two balanced drainage energy-collecting mechanisms are symmetrically arranged on the two sides of a ship body and are connected with the ship body through the connecting components; the protection components are mounted at the top end and on the bottom part of each of the balanced drainage energy-collecting mechanisms; and the power generation system is mounted in the balanced drainage energy-collecting mechanisms. According to the wave-energy energy-collecting power generation device for the ships disclosed by the invention, power is generated by adopting marine-renewable wave energy instead of fossil energy such as gasoline or diesel, so that the sailing cost of the ships is reduced, voyages of the ships can be increased, and pollution to a marine environment is reduced. By adopting the balanced drainage energy-collecting mechanisms, wave is converged and accelerated, so that water flowing kinetic energy can be effectively improved, and the power generation efficiency is promoted; and meanwhile, a water turbine is driven by bidirectionally utilizing wave energy so as to generate thepower, so that the adaptability of the power generation device on complicated and changeable marine conditions also can be improved.

Owner:长沙紫宸科技开发有限公司

Rotary hammer type impact test device

InactiveCN103134655AImpact speedAvoid secondary impactMaterial strength using single impulsive forceShock testingEngineeringMechanical engineering

The invention provides a rotary hammer type impact test device, and belongs to the field of impact tests. The rotary hammer type impact test device comprises guide rails, a hammer which is arranged on the guide rails and is capable of sliding on the guide rails, and a hammer acceleration device. The guide rails comprise a linear guide rail and a round guide rail and are arranged horizontally, wherein the round guide rail comprises two parts, namely a circular-arc guide rail and a hammer release guide rail, the linear guide rail is tangent to the round guide rail at a connection point, and the hammer release guide rail is movably connected with the round guide rail in the position of the connection point. The hammer acceleration device comprises a driving rod, wherein one end of the driving rod is fixed in the center of the round guide rail in a rotary mode, the other end of the driving rod is connected with a hammer in a releasable mode, and the hammer acceleration device further comprises a power mechanism used for driving the driving rod to rotate. The impact test machine not only better improves the impact energy, but also saves the space, lowers costs, better reduces the influence on surrounding buildings and instrument equipment from impact force.

Owner:浣石

Eight Transistor SRAM Cell with Improved Stability Requiring Only One Word Line

An SRAM cell that is accessed by a single word line and separate access transistors for read and write operations. A pair of write bit line transfer devices provide respectively access to the right and left sides of cross coupled pull-up, pull-down transistor pairs for a write operation, and a single read bit line transistor in series with the word line transistor, when selected, reads the content of the cell.

Owner:GLOBALFOUNDRIES INC

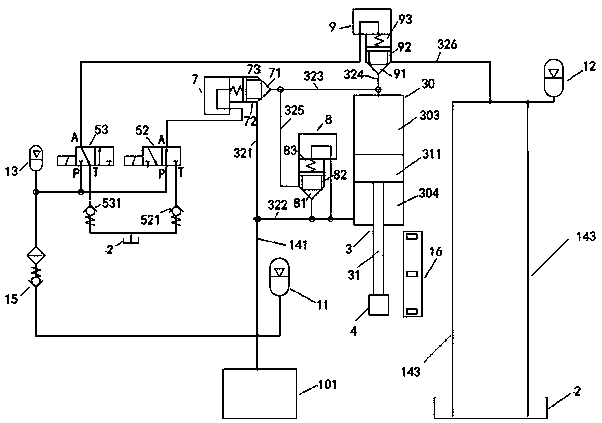

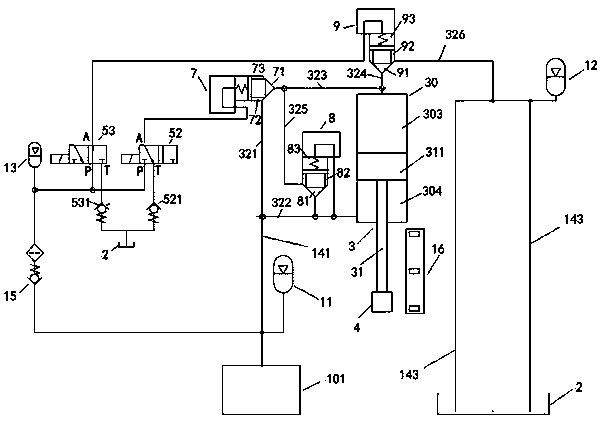

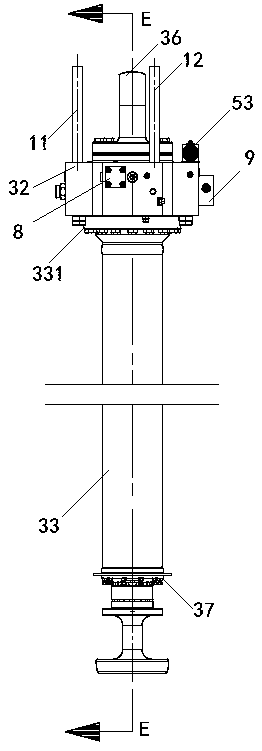

Hydraulic system for hydraulic hammer

PendingCN110985483ASpeed up the flowImprove high-speed reciprocating motion requirementsServomotor componentsFluid-pressure actuator componentsCheck valveImpact hammer

The invention discloses a hydraulic system for a hydraulic hammer. The hydraulic system comprises a power source, an oil tank, a lifting oil cylinder, an impact hammer core, a second electromagnetic reversing valve, a third electromagnetic reversing valve, a second plug-in valve, a third plug-in valve, a one-way plug-in valve, a second energy accumulator, a third energy accumulator, a fourth energy accumulator, a second check valve, a third check valve, a fourth check valve, a high-pressure pipeline, a low-pressure pipeline, a travel switch and a control unit, wherein the lifting oil cylinderis positioned in the central pit of a valve block through the inner cylinder barrel and the outer cylinder barrel of the lifting oil cylinder and is fastened with a cylindrical boss; the bottom of theinner cylinder barrel is provided with a plurality of oil holes for communicating a lower hydraulic cavity communicates with an annular oil channel; an upper hydraulic cavity and the lower hydrauliccavity communicate through switching on the one-way plug-in valve; and the second plug-in valve, the third plug-in valve and the one-way plug-in valve are independently installed on installation positions between a first oil channel and a third oil channel, between a fourth oil channel and a sixth oil channel as well as between a second oil channel and a fifth oil channel on the valve block. The hydraulic system has the characteristics of large blow energy, small hydraulic oil reversing pressure fluctuation, a low hydraulic element damage rate, small hydraulic pipeline vibration, high piling efficiency and the like, and is suitable for the high-speed flowing and the timely reversing of hydraulic oil.

Owner:上海工程机械厂有限公司 +1

Diaphragm-sealed valve with improved actuator design

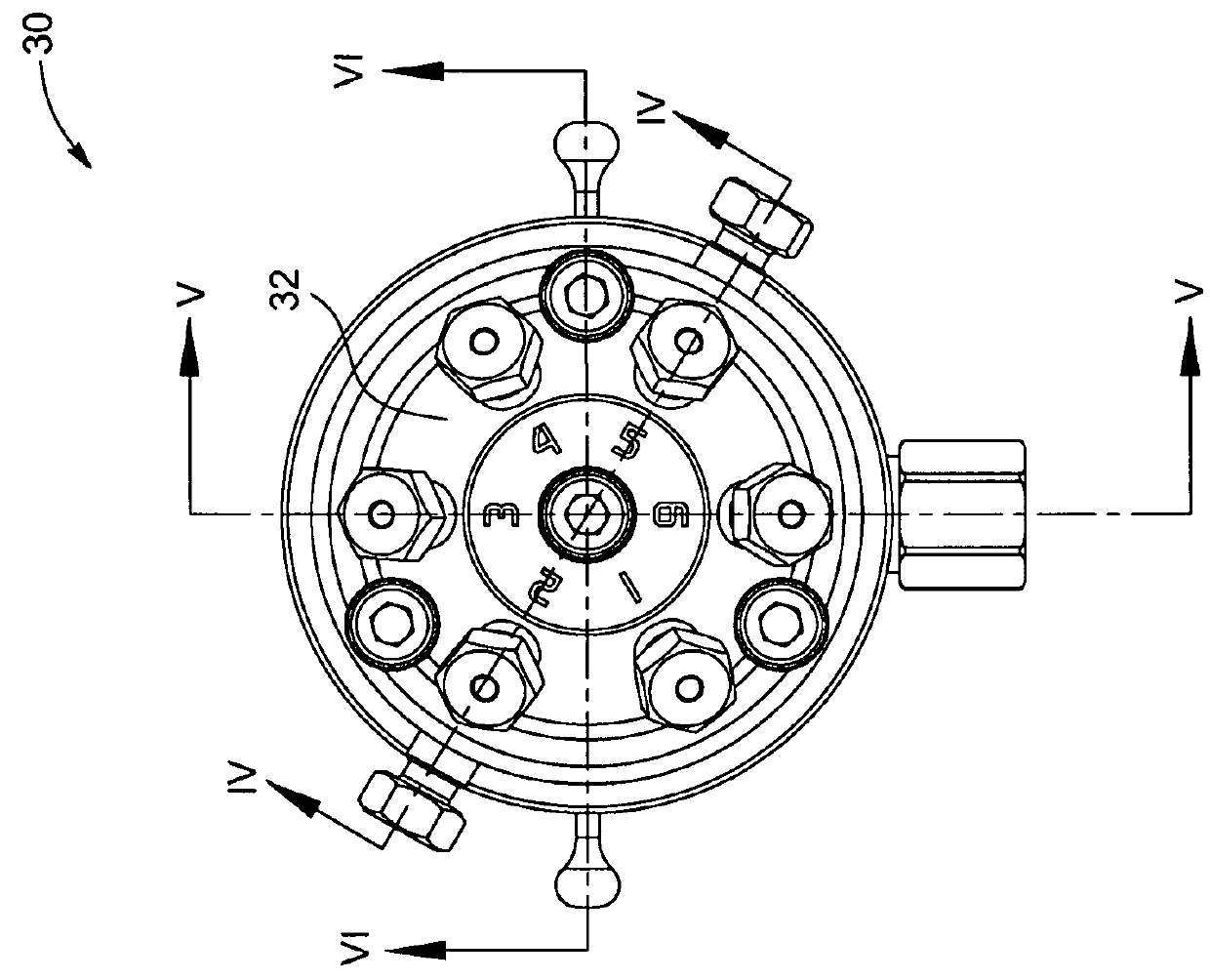

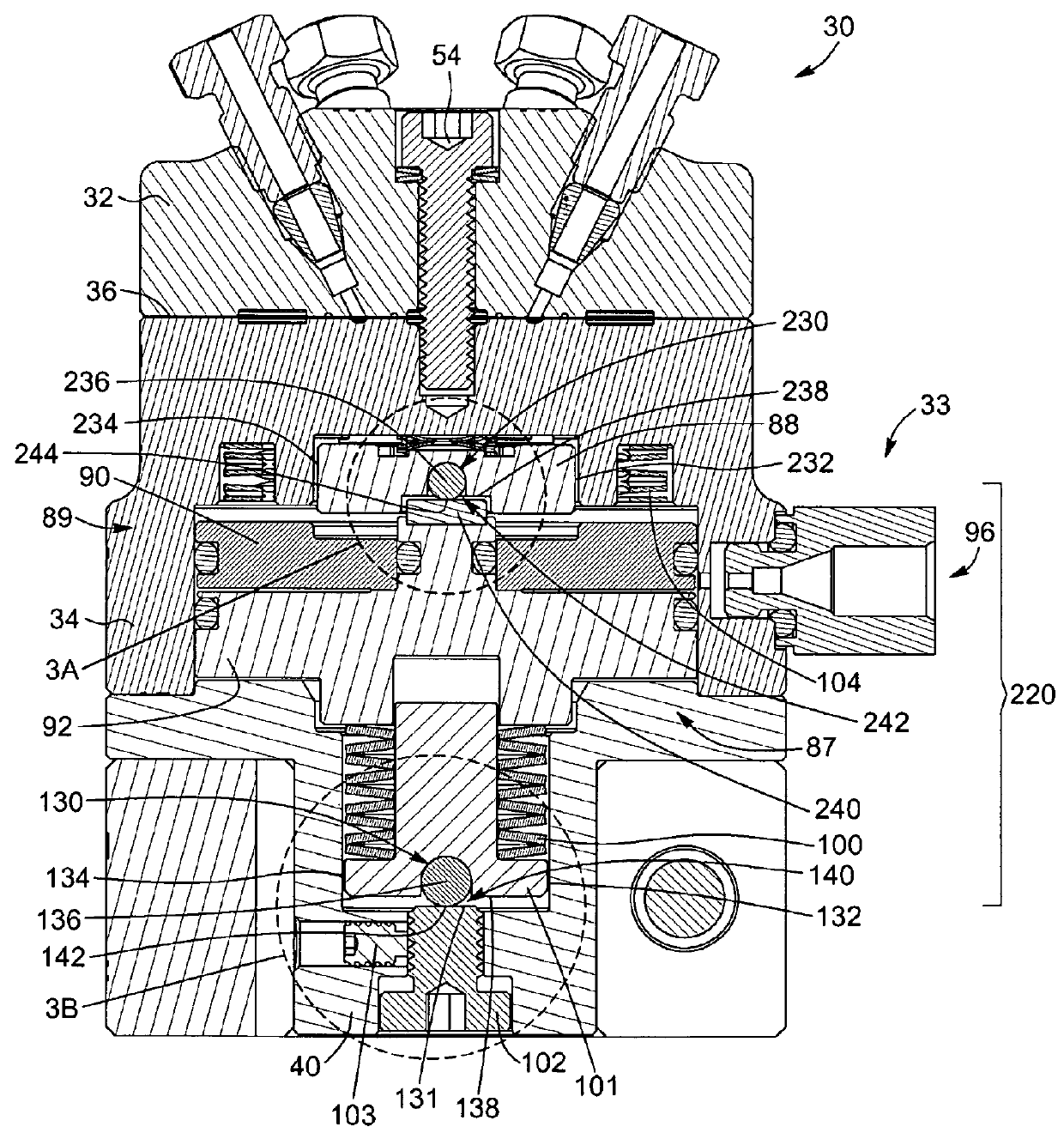

ActiveUS9377444B2Less mechanical toleranceShort assembly timeDiaphragm valvesOperating means/releasing devices for valvesTangential contactDiaphragm seal

A valve includes a valve cap, a valve body and a diaphragm positioned between the valve cap and the valve body. The valve further includes a plurality of plungers movable, by an actuation system, between a closed position where the plunger engages the diaphragm, and an open position where the plunger is disengaged from the diaphragm. Each plunger includes a base section connected to the actuation system and a head projecting away therefrom, a top section extending between the base section and the diaphragm, wherein the top section includes a foot in contact with the head of the base section, and a biasing mechanism biasing the top section away from the diaphragm when the plunger is in the open position. Tangential contact points may also be provided between components of the actuation and the biasing mechanism for preventing a misalignment of the actuation system within the valve body.

Owner:APN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com