High-speed impact test device for mechanically fastened joint and test method

A technology of high-speed impact and mechanical connection, applied in the direction of measuring devices, using stable shear force to test the strength of materials, instruments, etc., can solve the problems of poor practicability and achieve good practicability, precise control of amplitude and pulse width, The effect of high impact speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

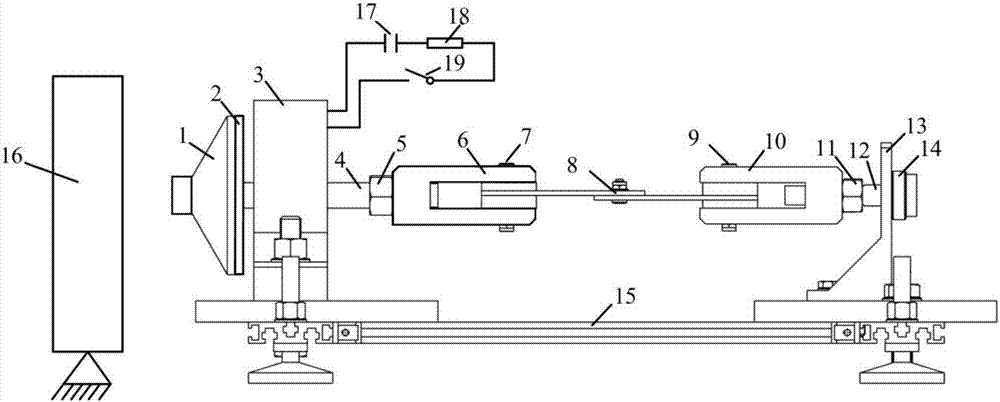

[0055] The following examples refer to figure 1 -8.

[0056] Device example:

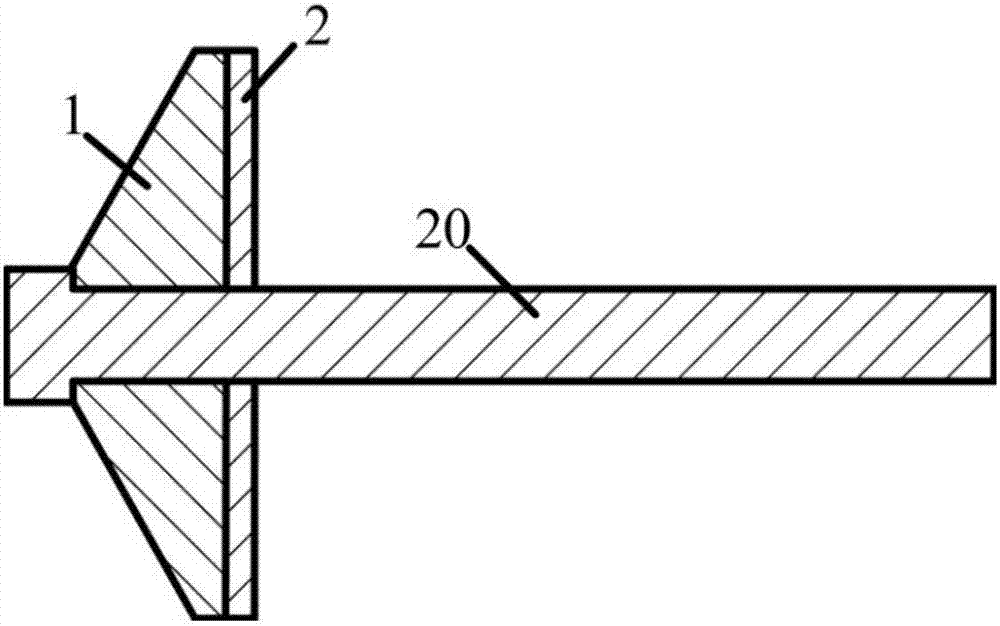

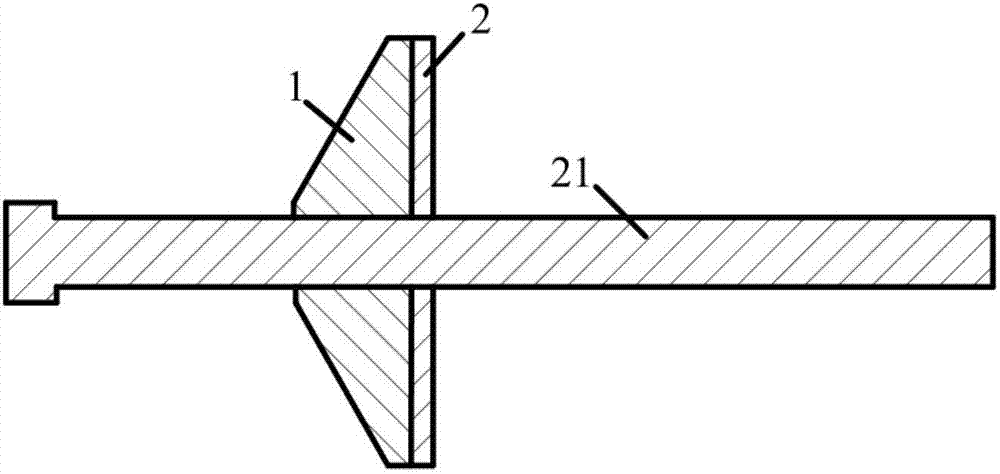

[0057] The present invention is based on electromagnetic riveting technology, and uses electromagnetic force to implement impact loading on mechanically connected joints. The device includes a stress wave amplifier 1, an induction coil 2, a discharge coil 3, a stretching rod 4, a front chuck 6, a rear chuck 10, Pressure sensor 14, workbench 15 and buffer plate 16. The stress wave amplifier 1 is a conical structure with a hole in the center to amplify the electromagnetic force stress wave. The induction coil 2 is a round cake copper plate with a central hole, which is connected to the stress wave amplifier by bolts; the discharge coil 3 is a central The pie-shaped coil with through holes is fixed on the workbench 15 by bolts to provide a strong magnetic field; the stretching rod 4 includes a short stretching rod 20 and a long stretching rod 21, and the short stretching rod 20 is used for long pulse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com