Vertical impact crusher

A technology of impact crusher and crusher, which is applied in the direction of grain processing, etc., can solve the problems of insufficient impact force and impact speed of materials, and achieve the effect of improving impact force and impact speed, reducing wear and tearing effect, and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

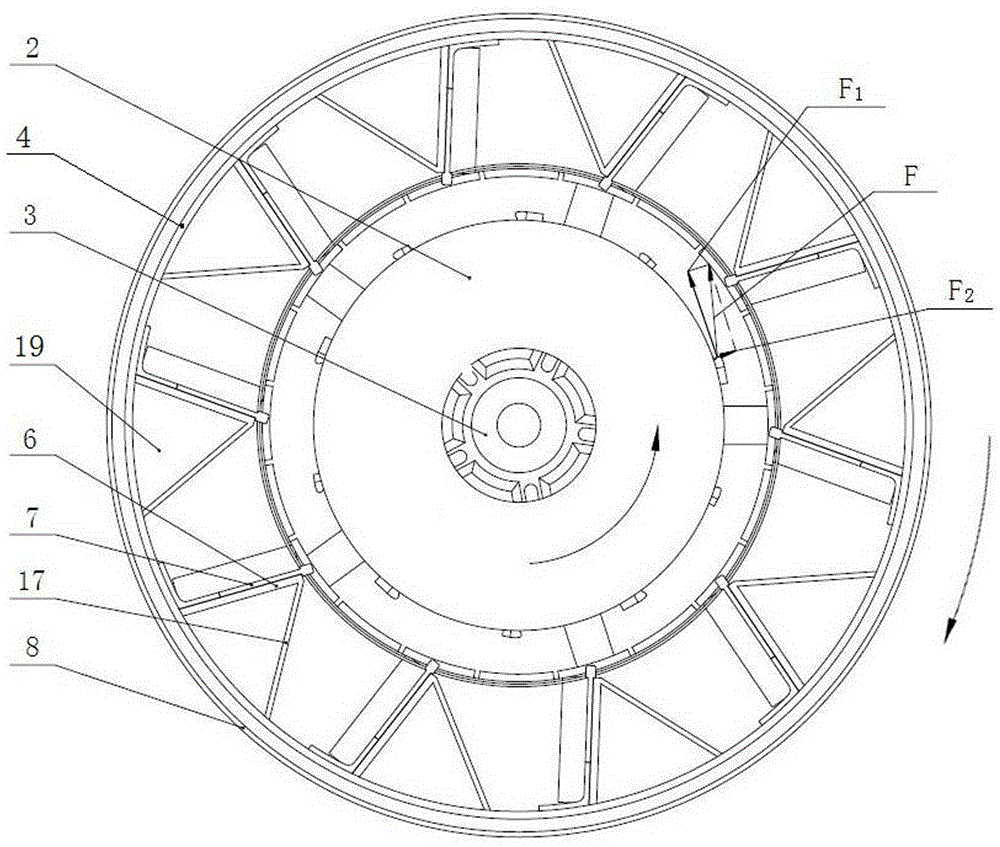

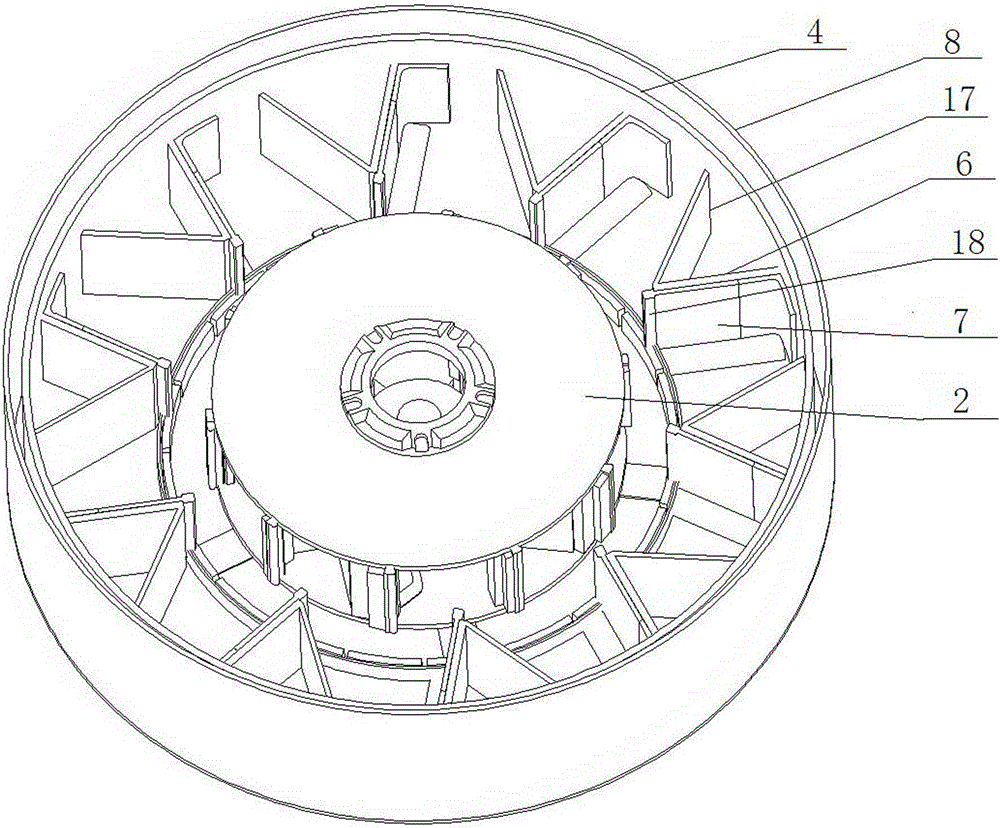

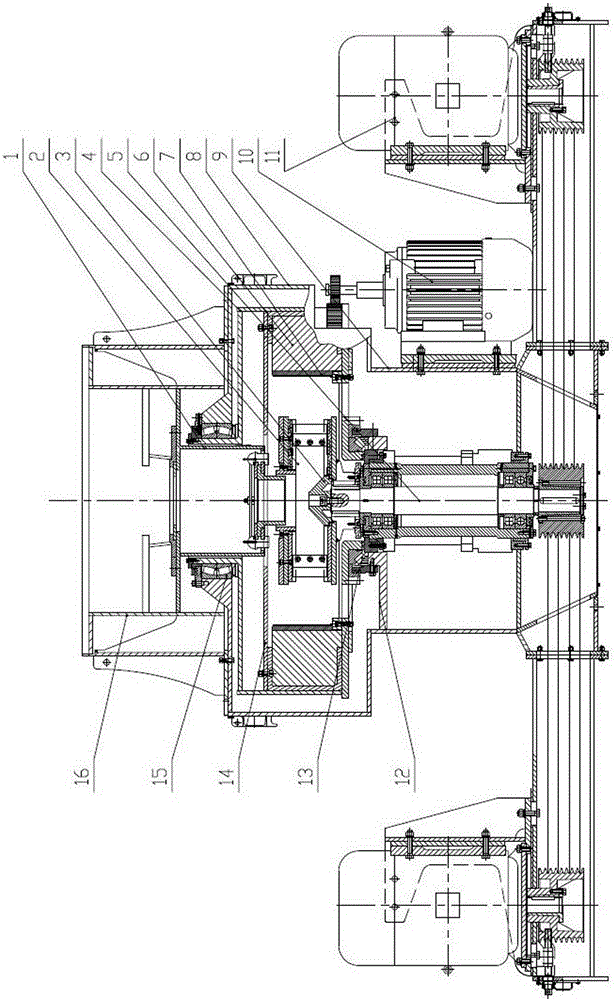

[0024] As shown in the figure, a vertical impact crusher includes a crushing chamber shell 4, a rotor 2 set in the crushing chamber shell 4, and a feeding device 1 for feeding the rotor 2, the rotor 2 and the crushing chamber shell The space between the bodies 4 forms a crushing chamber 19, wherein, in the prior art, the shell of the crushing chamber is directly called a vortex crushing chamber. The feeding device 1 feeds materials into the crusher through the crusher feed port 16, the crusher feed port 16 is fixedly connected with the fixed protective cover 8 provided outside the crushing cavity shell 4, and the fixed protective cover 8 is fixed on the crusher frame 9 Above, the feeding device 1 is fixed in the feed port 16 of the crusher, so that the feed port 16 of the crusher and the feeding device 1 are fixed and do not rotate together with the crushing chamber shell 4, so as to ensure the stability of feeding. The material enters the rotor 2 through the feeding device 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com