Medium-pressure heavy-section outer-cylinder iron casting gating system of steam turbine

A pouring system and large-section technology, which is applied in the directions of casting molds, casting mold components, casting molding equipment, etc., can solve the problems such as the inability to meet the requirements of the filling speed of large-tonnage and large-volume castings, and the inapplicability. Easy to operate, enter the effect of speed buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

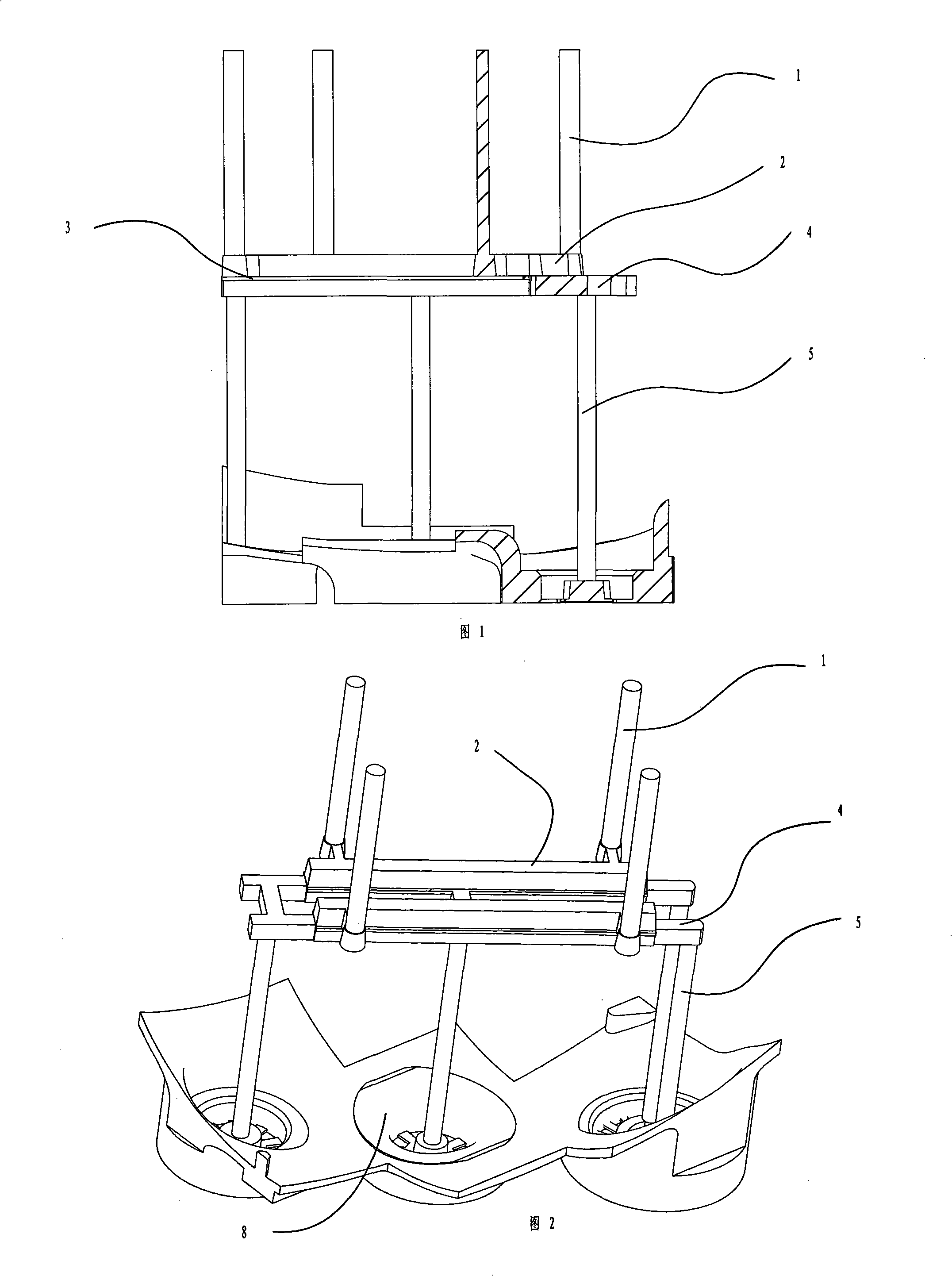

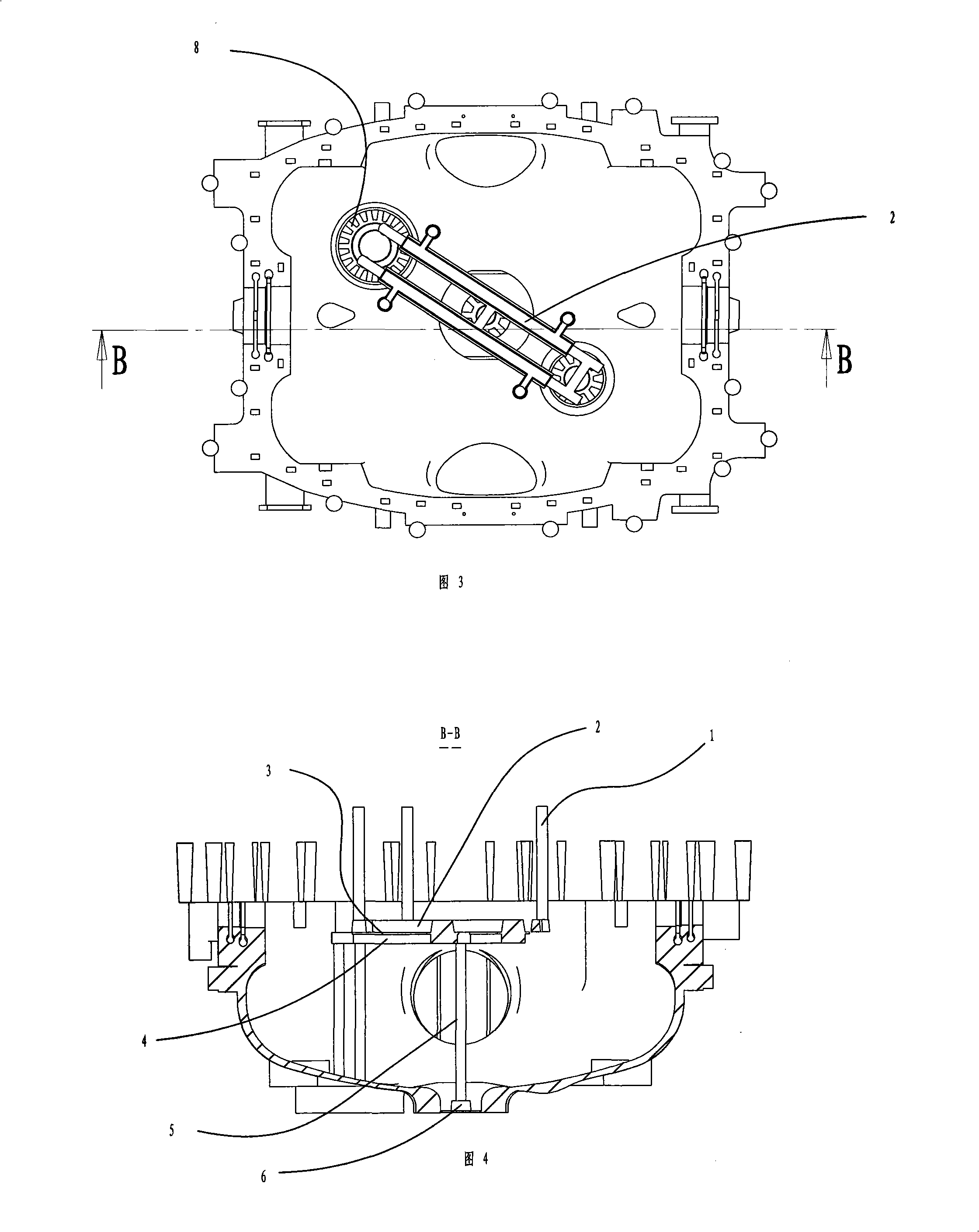

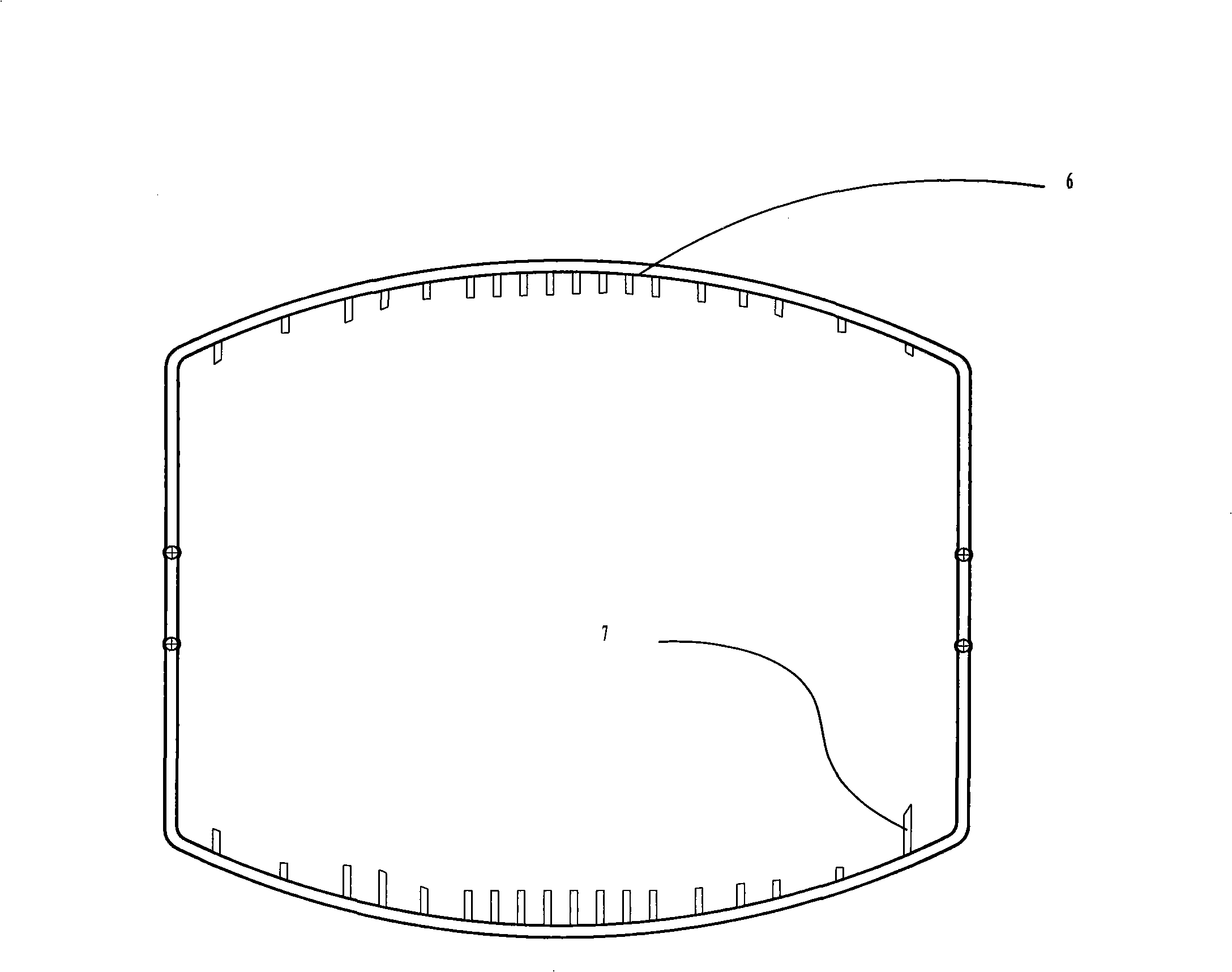

[0017] Since the external structure of the medium-pressure outer cylinder of the casting steam turbine is an irregular hemispherical shape, and there are concave and convex parts such as shaft holes and output holes on the casting body, when designing the pouring system, it is necessary to fully consider the flow rate and flow rate of the molten iron, and prevent the casting from scouring. It can smoothly fill the molten iron in the mold cavity without backflow, and it is beneficial to the slag removal of the molten iron, the solidification and shrinkage of the casting, and the reduction of the shrinkage stress of the casting to improve the internal quality and appearance quality of the casting. Various factors, at the same time, should also take into account the convenience of operation and control during casting. Firstly, determine the space positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com