Brick for building

A technology for building and brick materials, applied in the direction of building materials, etc., can solve the problems of limited exterior decoration style, prolonged construction period, complicated construction process, etc., and achieves good material compatibility and coordination, level and scientific level, and simple and easy process. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

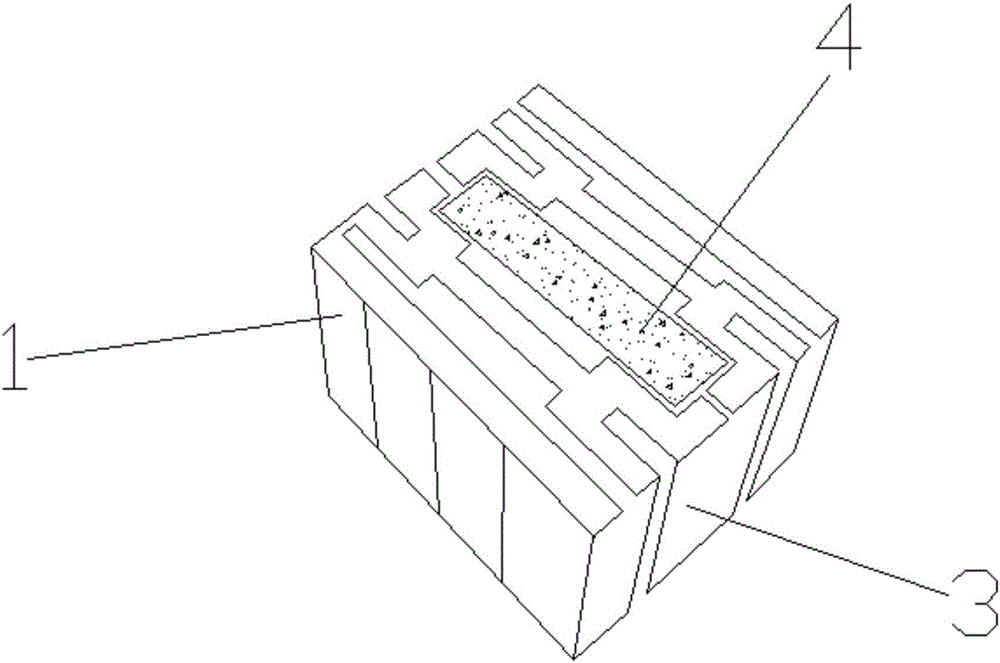

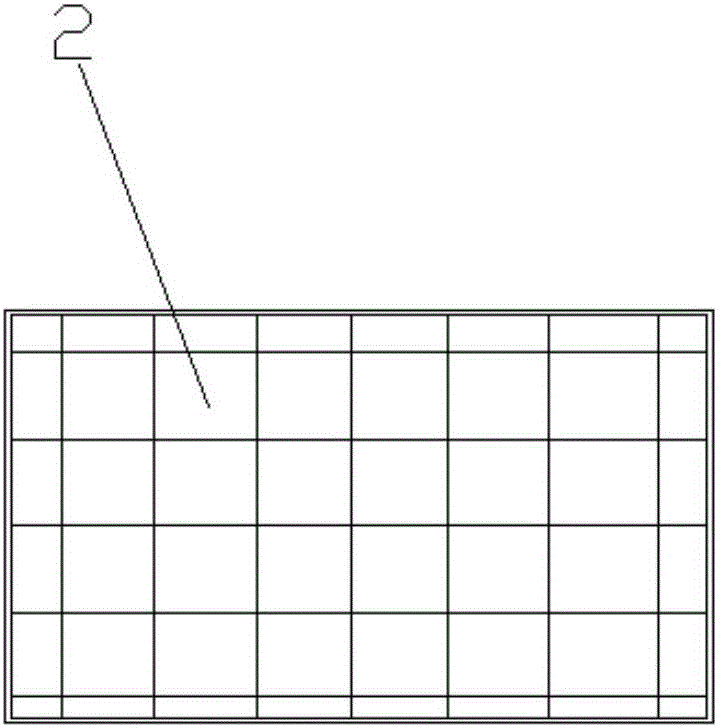

[0016] Such as figure 1 , figure 2 As shown, a building brick in this embodiment includes: a brick body 1, a solar panel 2, rubber benzene particles 3 and an EPS board 4, the brick body 1 has a multi-void structure, and the solar panel 2 Fixedly arranged at the front end of the brick body 1, the solar panel 2 has the same shape as the brick body 1, the brick body 1 is attached with rubber benzene particles 3, the rubber benzene particles 3 are mixed with mortar, and the brick material The surface of the body 1 is embedded with an EPS board 4 .

[0017] Further, the brick body 1 is integrally formed to ensure the quality and stability of the brick.

[0018] Further, the brick body 1 is also provided with a sound insulation layer for sound insulation.

[0019] Further, the EPS board 4 is a polystyrene foam board or a polystyrene extruded board, which has good thermal insulation, shockproof, and moisture-proof properties, and can effectively ensure the indoor temperature.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com