Rotary impact type fining, homogenizing and emulsifying apparatus

An emulsifying device and impact-type technology, applied in the fields of homogenizing, emulsifying device, and rotating impact-type fine-tuning, can solve the problems of impeller speed restriction, etc., and achieve the effects of improving impact speed, novel and unique structure, and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

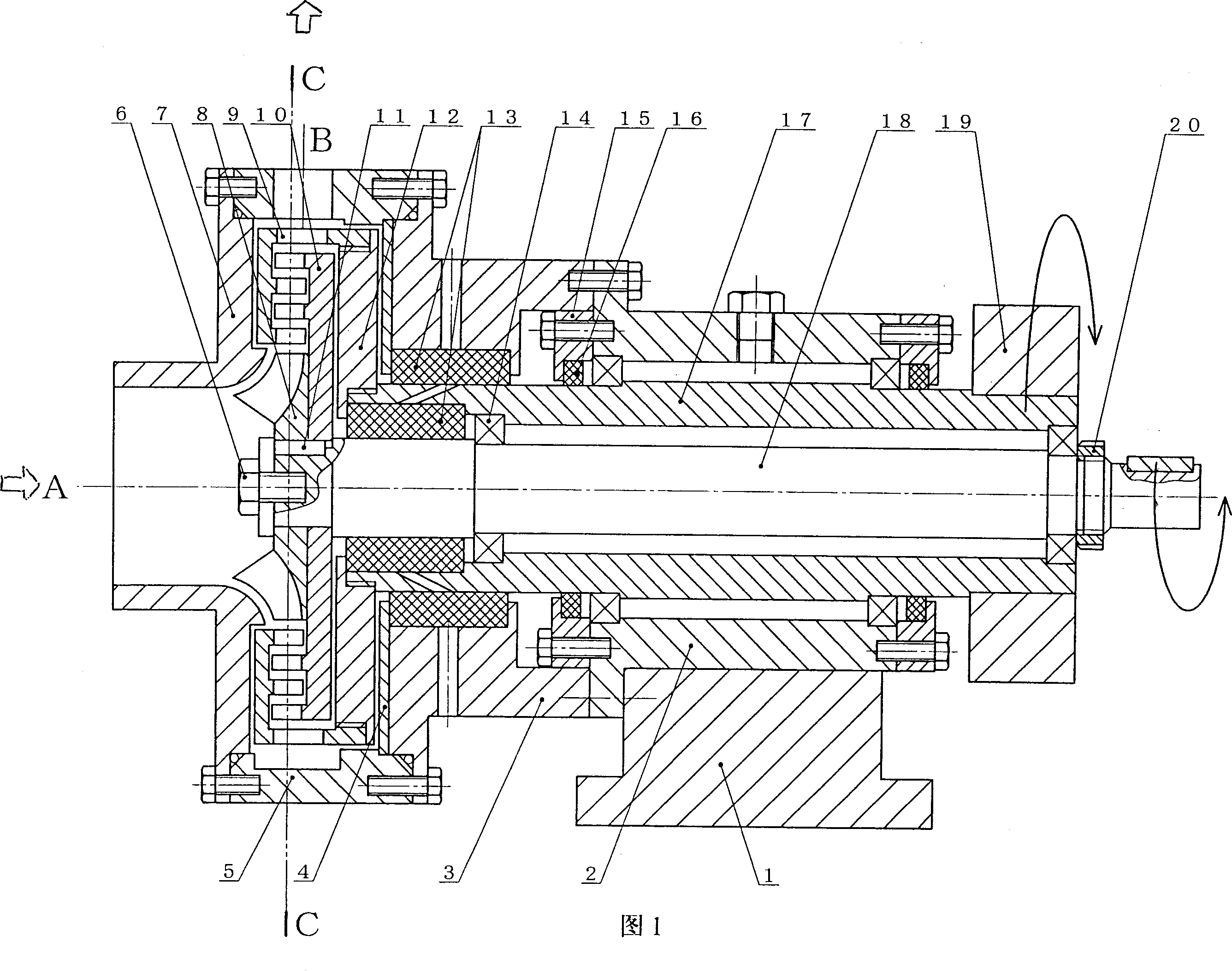

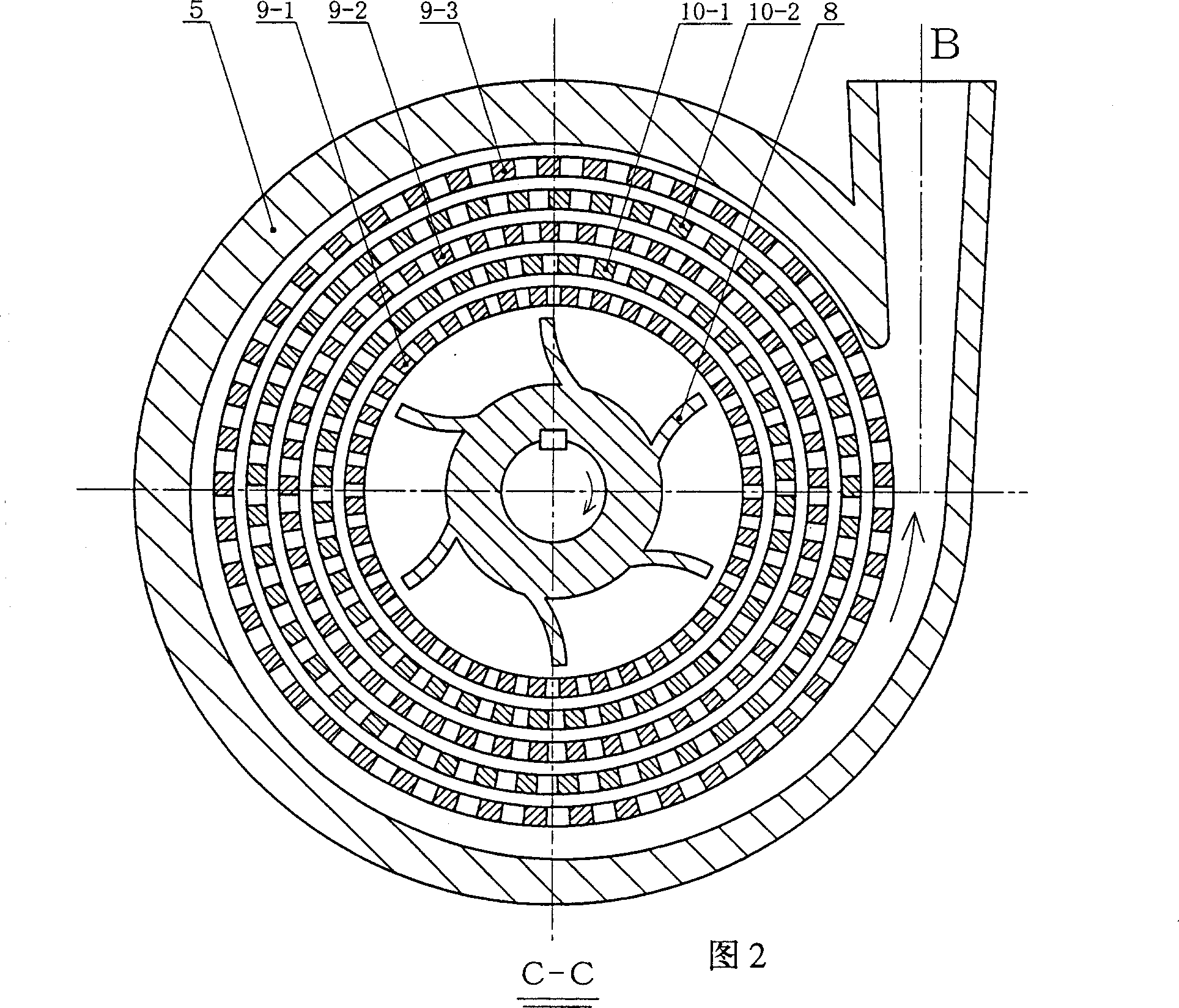

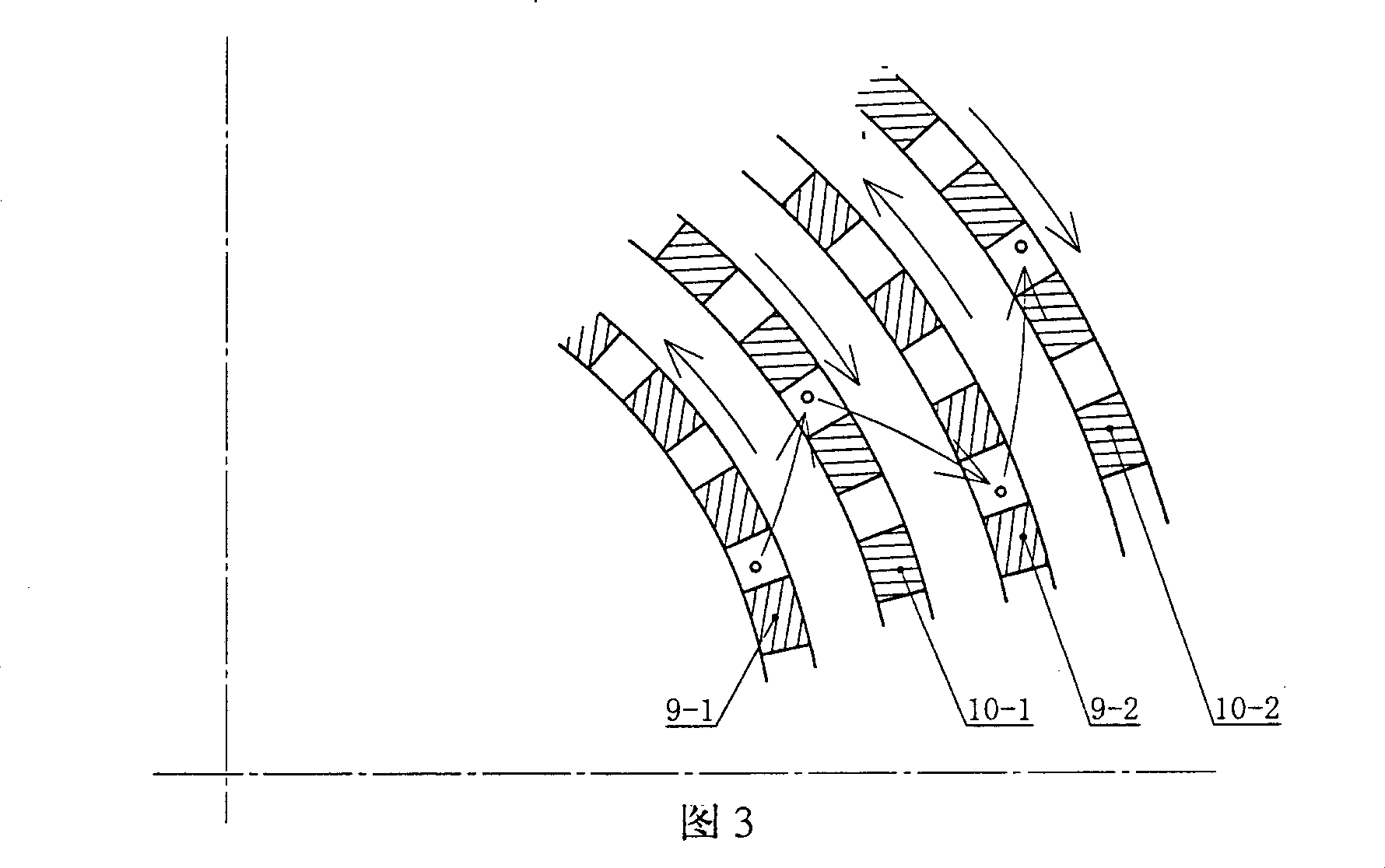

[0012] Fig. 1, 2 has described an embodiment of the present utility model, and it adopts integral structural form respectively for forward-rotating impeller 9, counter-rotating impeller. There is a shell, the shell is installed on the base 1, the shell has a material inlet and a material outlet, the shell is equipped with a power shaft, and the power shaft is equipped with a rotating impeller. The difference between it and the prior art is that : the rotary impeller that power shaft is equipped with comprises forward rotation impeller 9 (Fig. 2, Fig. 3, Figure 4 9-1, 9-2, 9-3, etc.) and reverse impeller 10 (Fig. 2, Fig. 3, Figure 4 10-1, 10-2 etc. in), the power shaft located in the feed inlet is equipped with feed impeller 8. The power shaft equipped with the forward-rotating impeller 9 and the reverse-rotating impeller 10 is composed of a hollow power shaft 17 and a solid power shaft 18 installed in the hollow power shaft 17, and the forward-rotating impeller 9 and the reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com