One-axle multi-cylinder multi-dimensional ball hammer type micro-nano high-energy ball mill

A high-energy ball mill, multi-dimensional technology, applied in grain processing and other directions, can solve the problems of many blind spots that are not accessible to the grinding balls, affecting the ball milling efficiency and powder particle size uniformity, and short motion trajectories. Efficiency and output, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

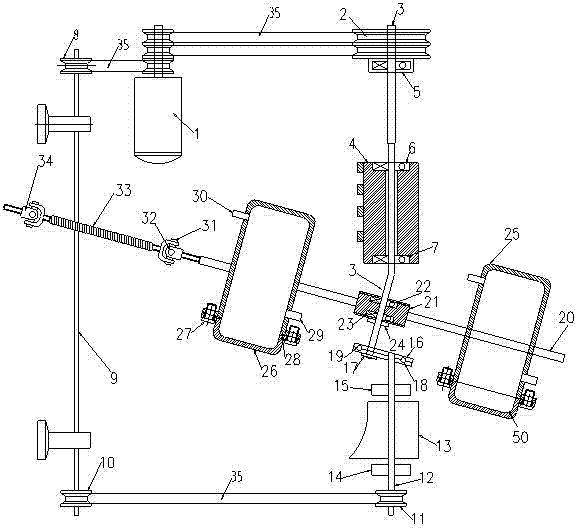

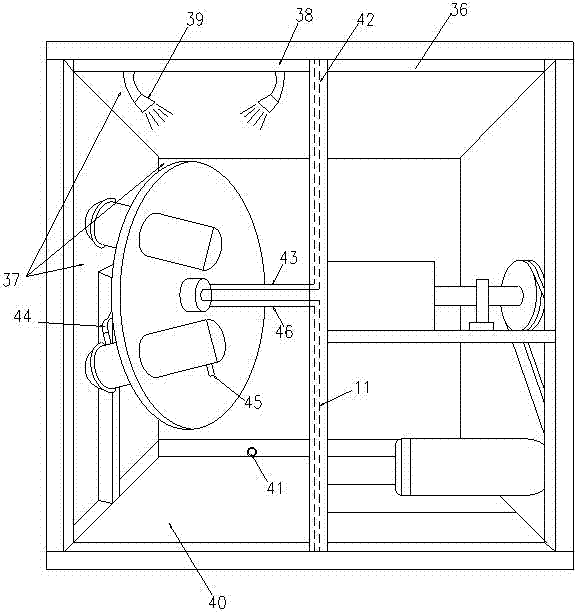

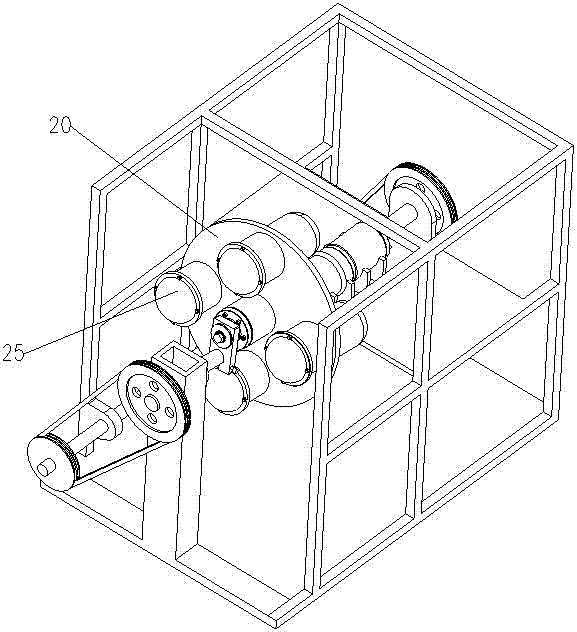

[0027] As shown in the figure, the technical solution provided by the present invention is a one-axis multi-cylinder multi-dimensional ball hammer type micro-nano high-energy ball mill, a frame 36 and an eccentric shaft drive device, an eccentric shaft support device and a rotary disc crushing device installed in the frame, so The eccentric shaft drive device is composed of a frequency converter control motor 1, a pulley 2, an eccentric shaft 3, a bearing seat 4, 5 and a number of bearings 6, 7. One end of the eccentric shaft 3 is installed on the pulley 2, and the other end is connected to the pulley 2. The bearings 6 and 7 installed on the bearing seat are fixedly connected. The pulley 2 is connected to the inverter control motor 1 through the transmission belt 35, and then drives the eccentric shaft 3 to move. The angle of the eccentric shaft 3 is 10-20 degrees. On the contrary, the smaller the machine is, the larger the angle is, that is, when the machine is larger, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com