Reciprocating type continuous roller receiving device capable of being used for electrostatic spinning

An electrospinning and receiving device technology, which is applied in the field of reciprocating continuous drum receiving device, can solve the problems of continuous and hanging yarn, high price, poor uniformity, etc., to avoid continuous and hanging yarn, improve efficiency and output , Improve the effect of poor uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

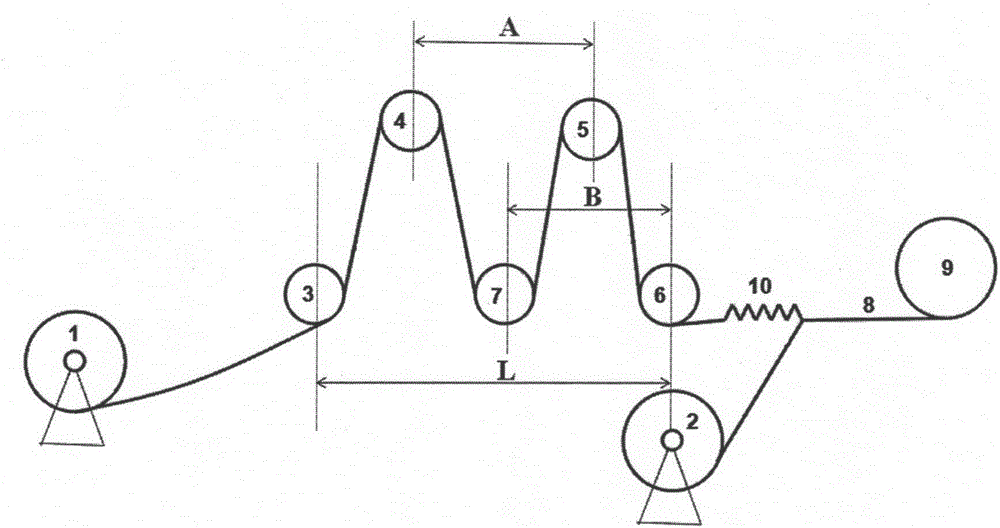

[0022] Before production starts, first press the figure 1 The route shown is to wind the coil material on the nonwoven fabric roll one 1 to the auxiliary drum one 3, the auxiliary drum two 4, the receiving drum 7, the auxiliary drum three 5, the auxiliary drum four 6 and the surface of the spring 10 (the auxiliary drum one 3 , receiving drum 7, auxiliary drum 4 6 are on the relatively lower same horizontal position, auxiliary drum 2 4, auxiliary drum 3 5 are on the relatively higher same horizontal position), spring 10 is in the maximum tension state, wherein auxiliary drum 2.4. The surface of the auxiliary roller 3.5 is covered with smooth fabric. A tension adjustment device is provided between the non-woven fabric roll 1 and the auxiliary drum 4 6; the axis of the receiving drum 7 is connected to the ground wire.

[0023] Turn on the spinning device to make it in the spinning state, open the nonwoven roll one 1, auxiliary roller one 3, auxiliary roller two 4, receiving roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com