Evaporation device and control method for driving components thereof

A driving component and evaporation technology, which is applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve problems such as the influence of evaporation film uniformity, and achieve the effect of improving poor uniformity and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

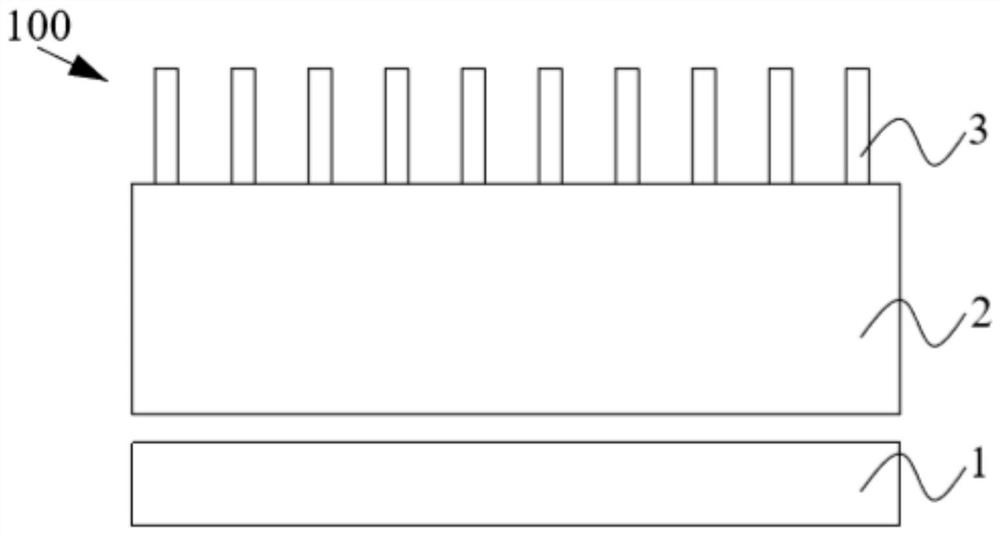

[0043] refer to figure 1 , is a first front view 100 of the evaporation device provided in the embodiment of the present application. It includes: a heating device 1, a crucible 2 and a nozzle 3. The heating device 1 is arranged under the nozzle 3 and the crucible 2, and is used for evaporating and heating the material in the crucible 2; the crucible 2 is a cube or a cylinder, made of organic materials, It is arranged between the heating device 1 and the nozzle 3, and is used to contain evaporation materials; the nozzle 3 is a hollow cylinder, and a plurality of the nozzles 3 are arranged at equal intervals on the crucible 2 away from the The surface of the heating device, and the nozzle 3 is perpendicular to the crucible 2, that is, the preset angle is 90 degrees. When the preset angle is 90 degrees, the uniformity of the vapor-deposited thin film layer of the nozzle is the best when the nozzle is vapor-deposited, and the area covered by the vapor-deposition area is the lar...

Embodiment 2

[0052] refer to Figure 9 , is a second front view 900 of the evaporation device provided in the embodiment of the present application. Including: heating device 1', crucible 2' and nozzle 3'. The heating device 1' is arranged under the nozzle 3' and the crucible 2', and is used for evaporating and heating the material in the crucible 2'; the crucible 2' is a cube or a cylinder. Made of organic materials, set between the heating device 1' and the nozzle 3', used to hold the evaporation material; the nozzle 3' is a hollow cylinder, and a plurality of the nozzles 3' are equally spaced Set on the crucible 2', the difference from the first embodiment is that the preset angle between the nozzle 3' and the crucible 2' can be not only 90 degrees, but also 75 degrees, 80 degrees or 85 degrees. As the preset angle gradually decreases, the area covered by the vapor deposition area also gradually decreases. In combination with the baffle plate or the cover on the nozzle, the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com