Exchange electrode electroosmotic sludge dewatering system and method based on voltage grading detection

A technology of sludge dehydration and electroosmosis, which is applied in the direction of oxidation treatment sludge, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of inability to improve the serious drying of anode sludge, poor uniformity of mud cake, and inability to dispose of sludge, etc. problems, to achieve the effect of improving the poor uniformity of sludge, improving corrosion problems, and reducing the moisture content of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

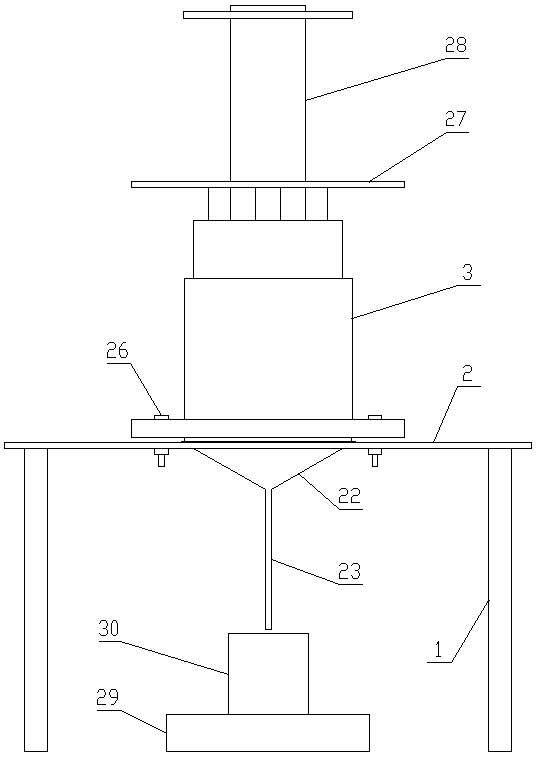

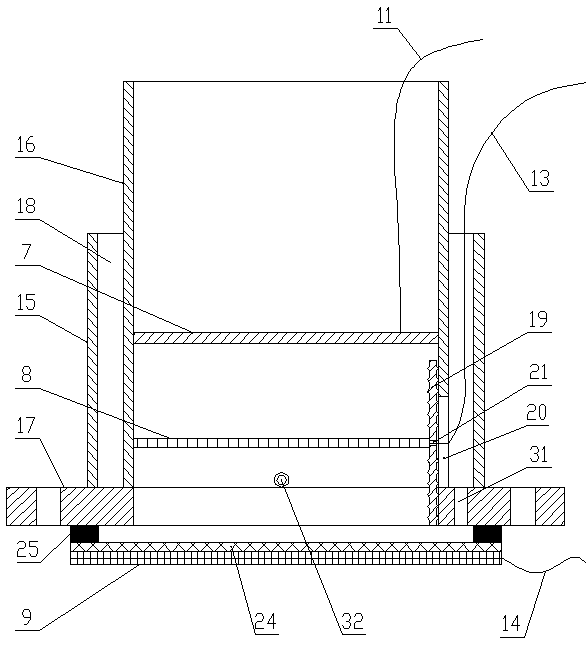

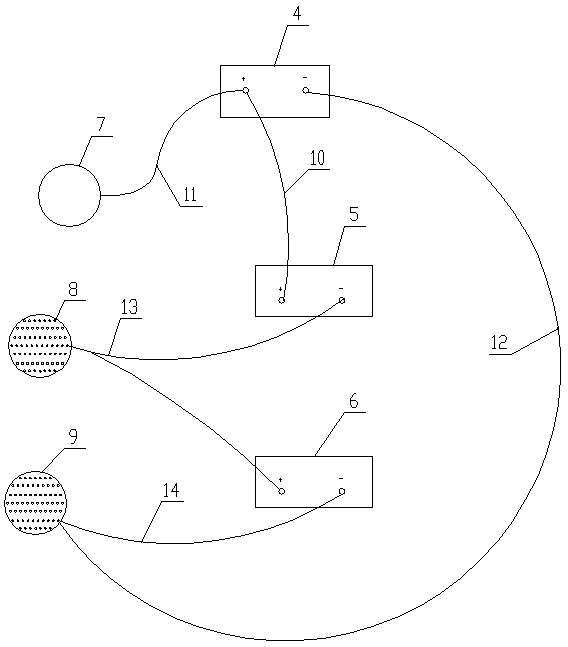

Method used

Image

Examples

Embodiment 1

[0062] An exchange electrode electroosmosis sludge dewatering method based on voltage classification detection. Two sets of experiments were carried out for comparison. The first group used traditional electroosmosis technology, and the second group used exchange electrode electroosmosis technology. The rest of the conditions were the same. The results of the two groups of experiments were Figure 4 shown.

Embodiment 2

[0064] An exchanged electrode electroosmosis sludge dewatering method based on voltage classification detection. Three sets of experiments were carried out for comparison. The first group used traditional electroosmosis technology, and the second group used exchanged electrode electroosmosis technology combined with ammonium persulfate advanced oxidant , the third group used exchanged electrode electroosmosis technology combined with ferrous activation of ammonium persulfate oxidant, and the rest of the conditions were the same. The results of the two groups of experiments were Figure 5 shown.

Embodiment 3

[0066] An exchanged electrode electroosmosis sludge dewatering method based on voltage classification detection. Two sets of experiments were carried out for comparison. The first group used traditional electroosmosis technology, and the second group used exchanged electrode electroosmosis technology combined with ammonium persulfate advanced oxidant And take the voltage classification detection system, the rest of the conditions are the same. The results of the two groups of experiments were Figure 6 shown.

[0067] From the above three examples, it can be clearly concluded that the second group in Example 3 has the best dehydration effect. It also proves the good effect of using exchanged electrode electroosmosis technology combined with ammonium persulfate advanced oxidant and adopting voltage classification for sludge dewatering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com