Electromagnetic combined apparatus for synthesizing stone pressure plate

A combination type and synthetic stone technology, which is applied in the field of building materials machinery, can solve the problems of insufficient pressing force and impact speed of the material body, and can not meet the pressing requirements, and achieve good forming effect, easy increase of frequency, and simplified equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

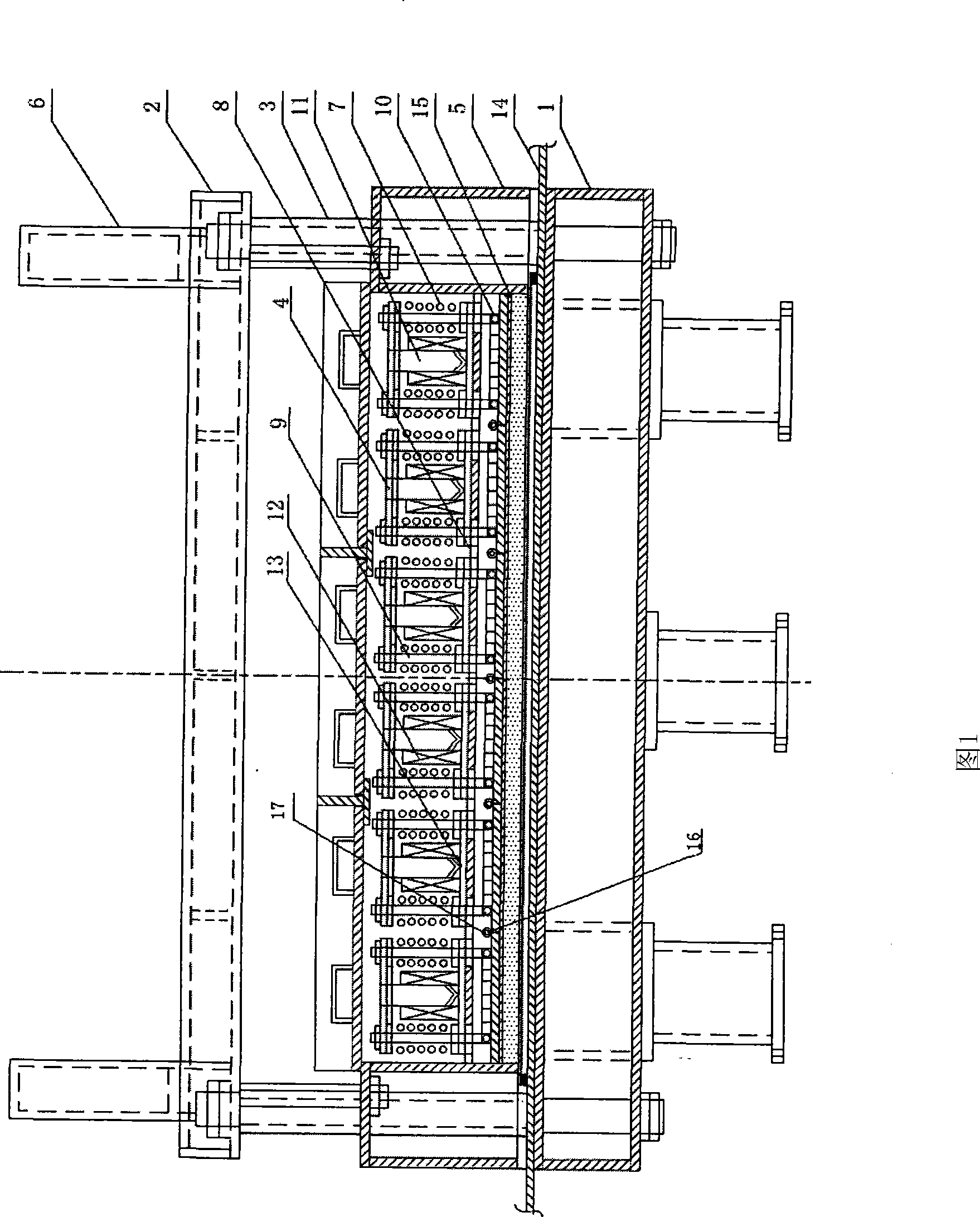

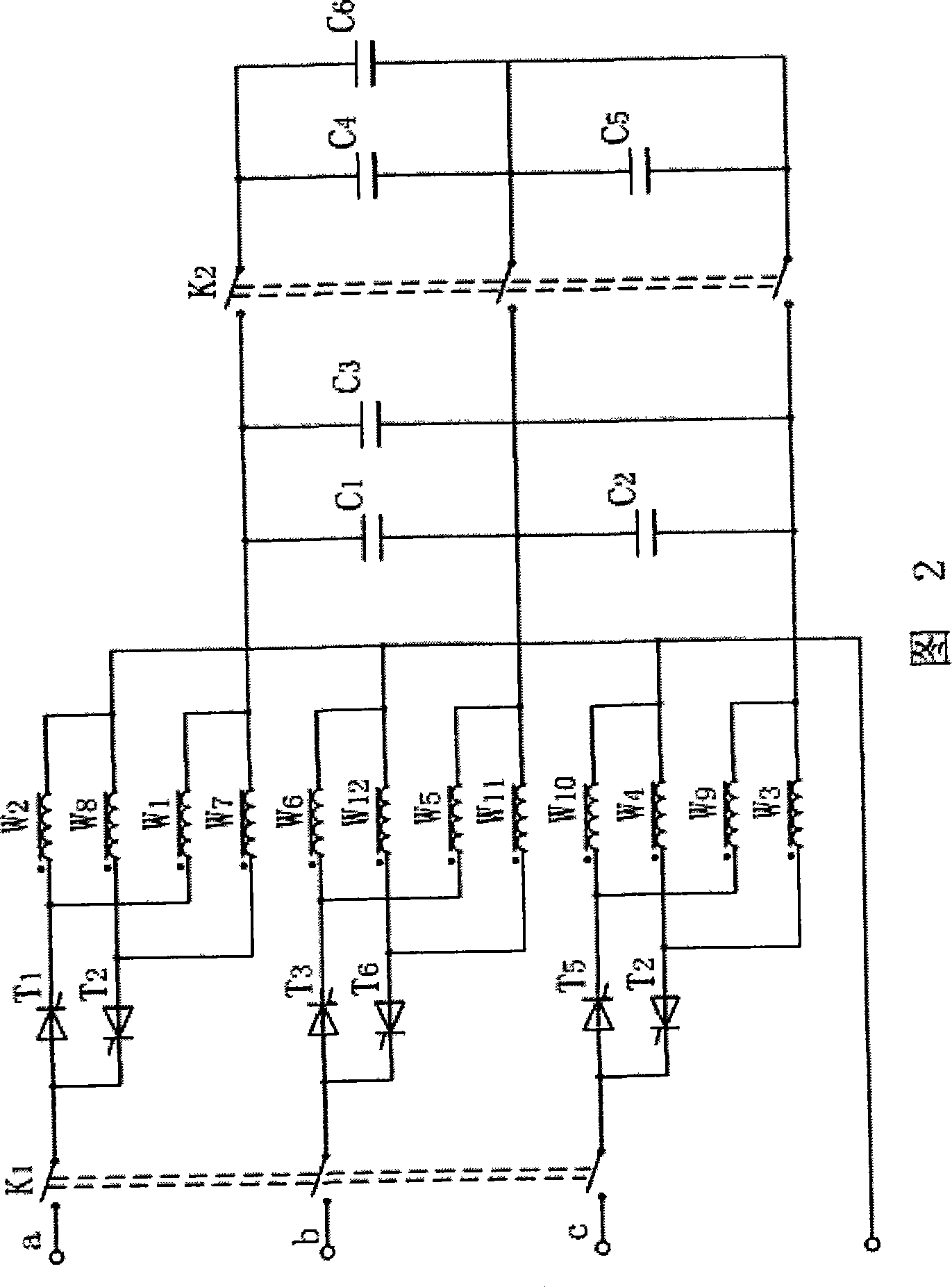

[0014] The electromagnetic combination type synthetic stone pressing plate device includes a base 1, an upper frame 2 fixed above the base 1 through columns 3, a vacuum cover 5 with a built-in supporting plate 8 placed above the base 1, and the upper frame 2 is set There is an oil cylinder 6 for controlling the lifting of the vacuum cover 5, a group of electromagnets 4 are arranged on the supporting plate 8 in the vacuum cover 5, a presser is arranged under the supporting plate 8, and a transmission rod passing through the supporting plate 8 is vertically arranged on the pressing tool 9. There is a copper sleeve on the supporting plate 8 and the transmission rod 9, and the end of the transmission rod 9 is connected with the moving iron core 11 of the electromagnet 4 through a connecting piece, and a matching electromagnet is arranged between the connecting piece and the base of the electromagnet 4 4. The compression spring 7 that works to make the transmission rod 9 reciprocate...

Embodiment 2

[0019] The electromagnetic combination type synthetic stone pressing plate device includes a base 1, an upper frame 2 fixed above the base 1 through columns 3, a vacuum cover 5 with a built-in supporting plate 8 placed above the base 1, and the upper frame 2 is set There is an oil cylinder 6 for controlling the lifting of the vacuum cover 5, a group of electromagnets 4 are arranged on the supporting plate 8 in the vacuum cover 5, a presser is arranged under the supporting plate 8, and a transmission rod passing through the supporting plate 8 is vertically arranged on the pressing tool 9. There is a copper sleeve on the supporting plate 8 and the transmission rod 9, and the end of the transmission rod 9 is connected with the moving iron core 11 of the electromagnet 4 through a connecting piece, and a matching electromagnet is arranged between the connecting piece and the base of the electromagnet 4 4. The compression spring 7 that works to make the transmission rod 9 reciprocate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com