Method for coarsening surface by erosion of hard grains in high speed

A hard particle and texturing technology, applied in the direction of abrasive feeding device, abrasive, metal processing equipment, etc., can solve the problem of low processing efficiency, achieve good effect, improve strength and hardness, uniform and irregular shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

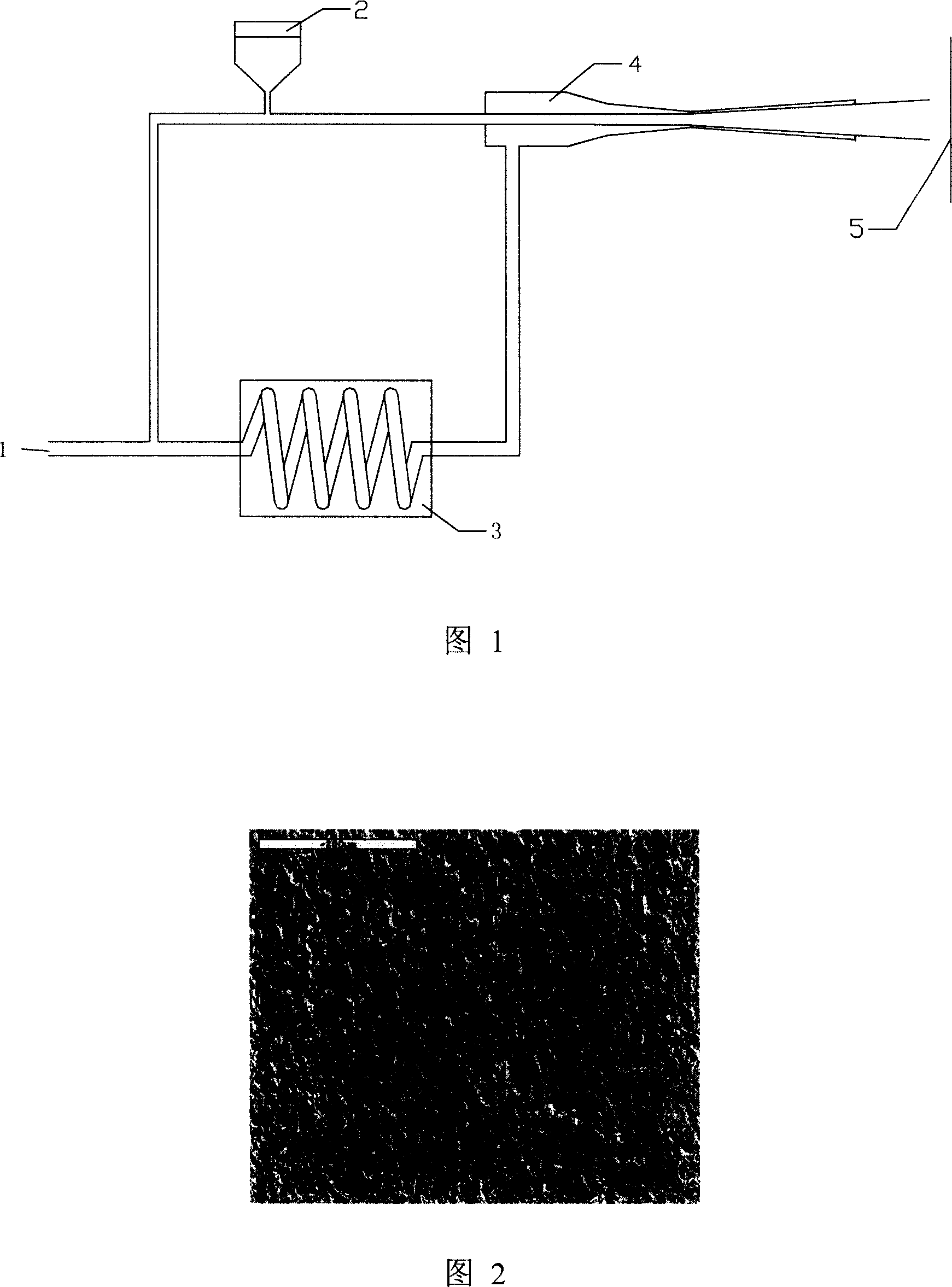

Method used

Image

Examples

Embodiment 1

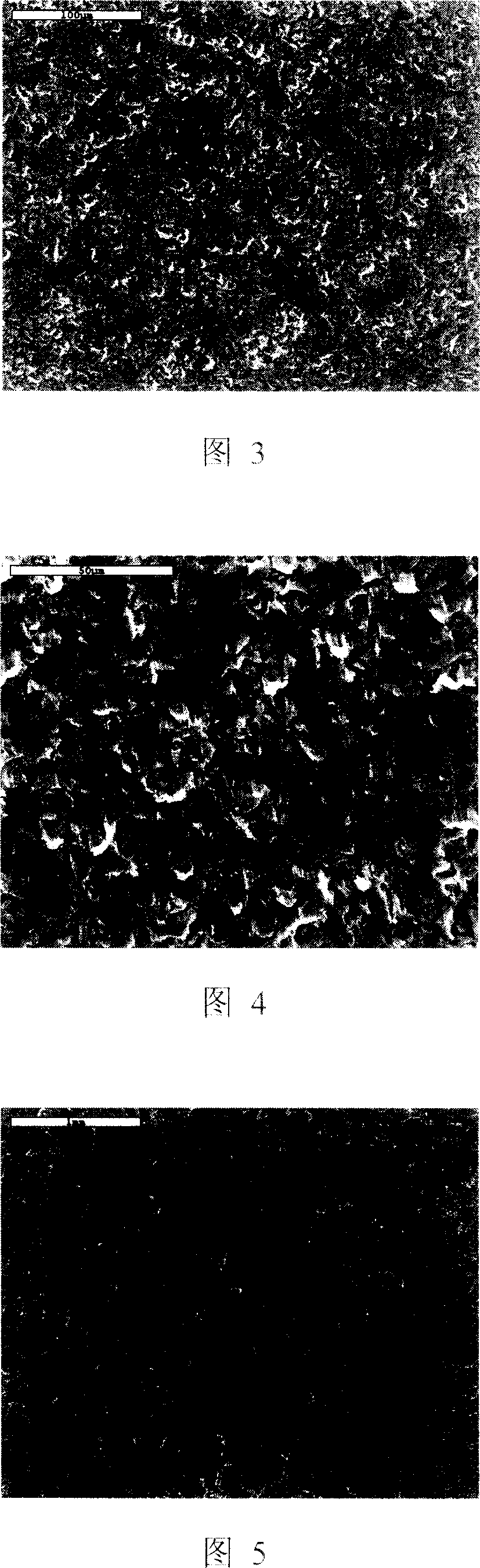

[0034] The selected hard particles are alumina ceramics (α-Al 2 o 3), the particle diameter is: 10-20μm, and the substrate is Cr5 steel plate. The high pressure compressed gas is air. Texturing process: gas pressure 1.0MPa, gas flow rate 20g / s, powder feeding density 100 pieces / mm 2 , The distance between the nozzle and the workpiece surface is 25mm. The textured surface morphology is shown in Figure 2. It can be seen that the surface morphology of the material after texturing technology is characterized by: uniform and irregular morphology, roughness (Ra) value of 0.1 μm-1 μm, large Pc value, Ra and Pc The value correlation is not strong, and there are interconnected channels between the bumps or pits.

Embodiment 2

[0036] The selected hard particle material is glass powder, the diameter of the particles is 20-30 μm, and the matrix is GCr15 roller. The high-pressure compressed gas is a mixture of nitrogen and helium. Texturing process: gas pressure 2.5MPa, gas flow 30g / s. The textured appearance of the forming roller surface is shown in Figure 3. It can be seen that the surface appearance of the material after the texturing technology is characterized by uniform and irregular appearance, the roughness (Ra) value is 1 μm-2 μm, and the correlation between Ra and Pc values is not significant. Strong, there are interconnected channels between the protrusions or pits.

Embodiment 3

[0038] The selected hard particles are cemented carbide, NiCrCo alloy, and the diameter of the particles is 30-60 μm. The substrate is a leveling roll. The high-pressure compressed gas is a mixture of nitrogen and helium. Texturing parameters: gas pressure 3.5MPa. The flow rate is 35g / s, and the textured appearance of the formed roller surface is shown in Figure 4. It can be seen that the surface appearance of the material after the texturing technology is characterized by: uniform and irregular appearance, and a roughness (Ra) value of 3 μm-5 μm; Ra and The correlation of Pc value is not strong; there are interconnected channels between the protrusions or pits.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com