Color master batch for reinforcing and toughening PP (Polypropylene)

A technology of strengthening and toughening, color masterbatch, applied in the field of color masterbatch, can solve the problem of PP rigid strength and toughness strength being difficult to improve at the same time, and achieve the effect of improved impact strength, simple operation process and large adsorption free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

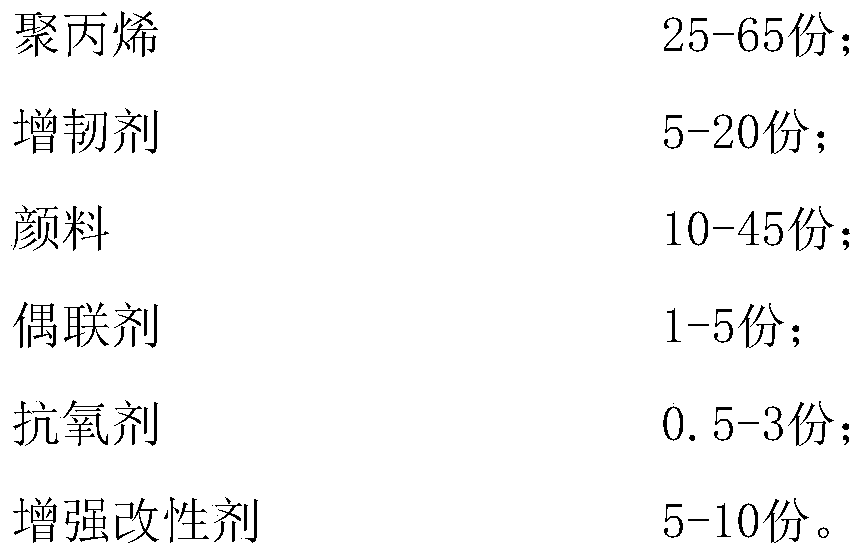

[0025] A color masterbatch for PP reinforcement and toughening, comprising the following components in parts by mass:

[0026]

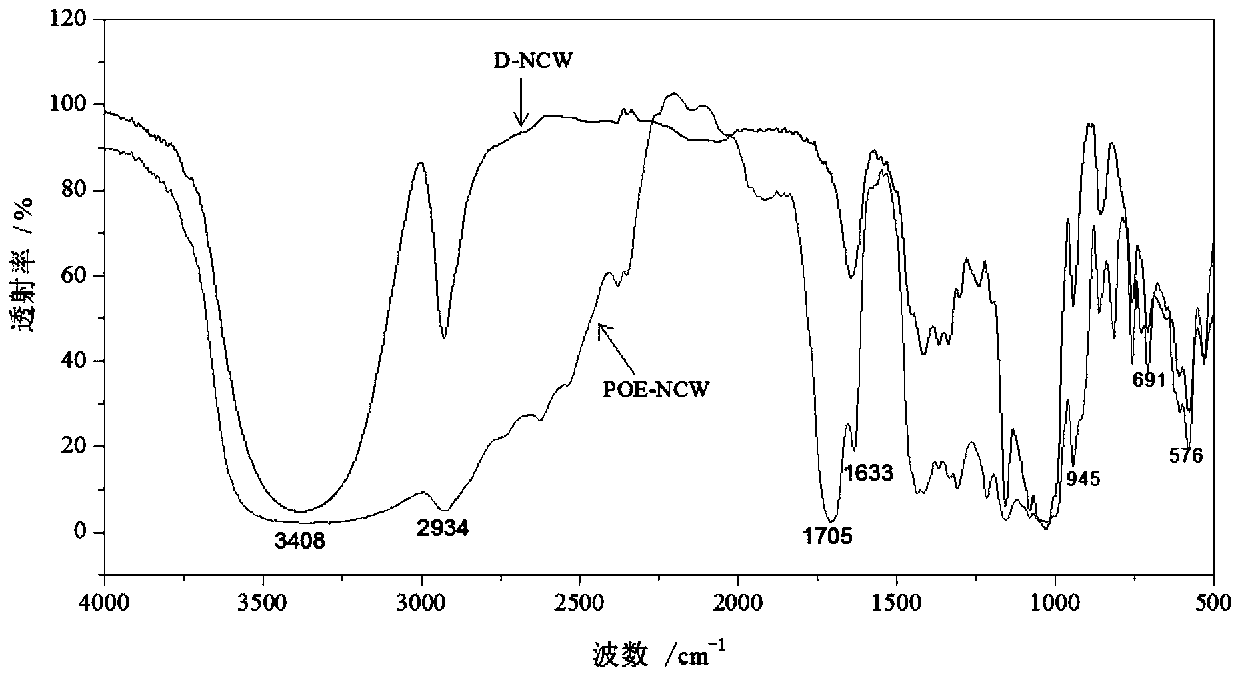

[0027] The reinforcing modifier includes surface POE-grafted nanocellulose whiskers, and the surface POE-grafted nanocellulose whiskers are prepared by the following method:

[0028] (1) obtain alkylated nanocellulose whiskers by reacting carboxylated nanocellulose whiskers with alkyl bromide;

[0029] Dissolve the carboxylated nanocellulose whiskers (NCW) in tetrahydrofuran, and the solution is warmed up to 80°C, adding bromododecane CH3 (CH2) The mass fraction of 11Br is 60% of the nanocellulose whiskers, under sealed conditions Stirring and reacting for 4h, filtering the reacted suspension to obtain flocs, that is, obtaining alkylated nanocellulose whiskers (D-NCW); the carboxylated nanocellulose whiskers are wood pulp carboxylated nanocellulose whiskers , with an average length of 200-300nm and an average diameter of 15-30nm;

[0030] (2) gr...

Embodiment 2

[0047] The difference with Embodiment 1 is:

[0048] A color masterbatch for PP reinforcement and toughening, comprising the following components in parts by mass:

[0049]

Embodiment 3

[0051] The difference with Embodiment 1 is:

[0052] A color masterbatch for PP reinforcement and toughening, comprising the following components in parts by mass:

[0053]

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com