Gas shielded arc welding method for high intensity bridge heavy plate K type joint

A welding method and high-strength technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problem that the impact energy of deposited metal and the actual joint toughness cannot meet the welding technical requirements, the impact energy cannot meet the requirements, and the toughness index is too different To solve problems such as distance, achieve the effect of excellent welding process performance, high impact toughness reserve and safety margin, and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for gas-shielded welding of K-type joints of high-strength bridge steel plates, the steps of which are as follows:

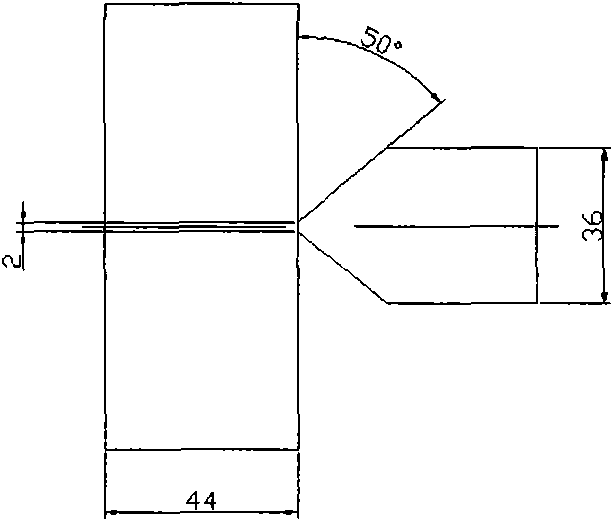

[0022] (1) Substrate: WNQ570, that is, the tensile strength is 575MPa, and after TMCP+tempering, the thick plate combination is 44mm+36mm; the size of the test plate is 600mm×400mm×44(36)mm; its yield strength R eL : 465MPa, elongation: A18%, impact energy -40℃CA KV : 250J bridge steel, a combination of thickness 36 and 44mm; matching welding wire tensile strength greater than 600MPa, welding wire diameter Φ1.2mm;

[0023] (2) The gas shielded welding groove adopts double-sided K-type symmetrical groove, the groove angle is 50°, and the blunt edge is 2mm;

[0024] (3) Welding current 250A, welding voltage 22V, welding speed 20cm / min, welding line energy 17kJ / cm, the volume percentage is 20% CO 2 Add 80% Ar-rich argon as shielding gas and control its flow rate at 18L / min for continuous welding until the weld seam is filled, and the interlayer te...

Embodiment 2

[0028] A method for gas-shielded welding of K-type joints of high-strength bridge steel plates, the steps of which are as follows:

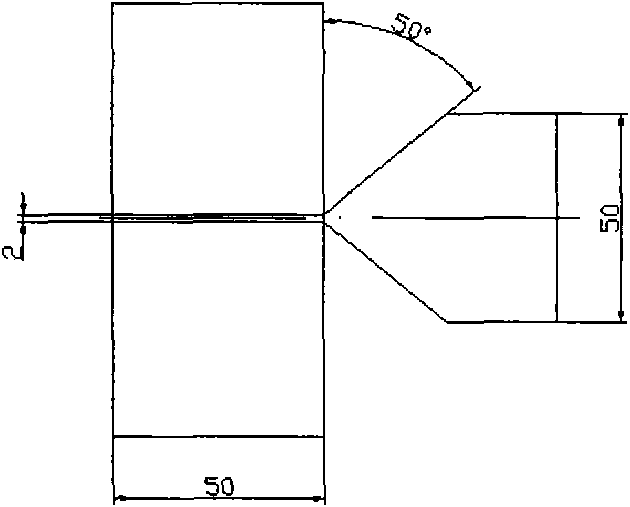

[0029] (1) Substrate: WNQ570, that is, the tensile strength is 650MPa, and after TMCP+tempering, the thick plate combination is 50mm+50mm; the size of the test plate is 600mm×400mm×50mm; its yield strength R eL : 525MPa, Elongation: A22%, Impact Energy -40℃CA KV : 240J bridge steel, a combination of thickness 50 and 50mm; matching welding wire tensile strength greater than 600MPa, welding wire diameter Φ1.2mm;

[0030] (2) The gas shielded welding groove adopts double-sided K-type symmetrical groove, the groove angle is 50°, and the blunt edge is 2mm;

[0031] (3) The welding current is 260A, the welding voltage is 23V, the welding speed is 29cm / min, the welding line energy is 12kJ / cm, and the volume percentage is 20% CO 2 Add 80% Ar-rich argon as shielding gas and control its flow rate at 20L / min for continuous welding until the weld seam is f...

Embodiment 3

[0035] A method for gas-shielded welding of K-type joints of high-strength bridge steel plates, the steps of which are as follows:

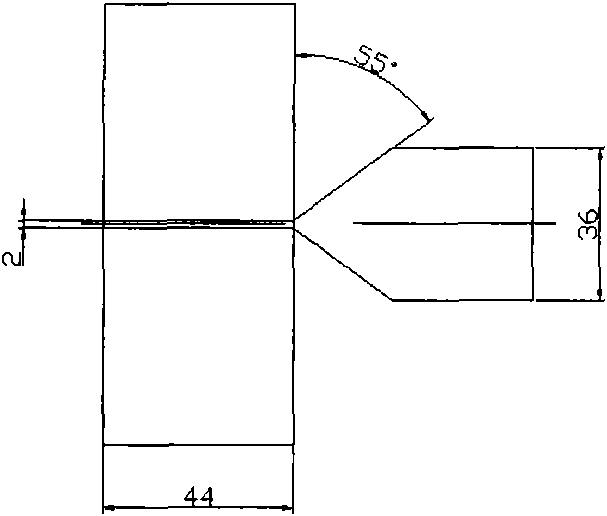

[0036](1) Substrate: WNQ570, that is, the tensile strength is 620MPa, and after TMCP+tempering, the thick plate combination is 44mm+36mm; the size of the test plate is 600mm×400mm×44(36)mm; its yield strength R eL : 510MPa, elongation: A21%, impact energy -40℃CA KV : 270J bridge steel, a combination of thickness 44 and 36mm; matching welding wire tensile strength greater than 600MPa, welding wire diameter Φ1.2mm;

[0037] (2) The gas shielded welding groove adopts double-sided K-type symmetrical groove, the groove angle is 55°, and the blunt edge is 2mm;

[0038] (3) The welding current is 255A, the welding voltage is 23V, the welding speed is 24cm / min, the welding line energy is 15kJ / cm, and the volume percentage is 20% CO 2 Add 80% Ar-rich argon as shielding gas and control its flow rate at 19L / min for continuous welding until the weld seam i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com