Mechanical underground vibration-absorption punching drilling tool

A percussion drilling, mechanical technology, which is applied to the driving device for drilling in the borehole, drilling equipment, earthwork drilling and mining, etc., can solve the problems of fracture failure, drill bit tooth wear, etc., and achieve the effect of simple structure and improved rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

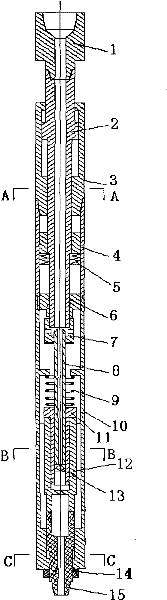

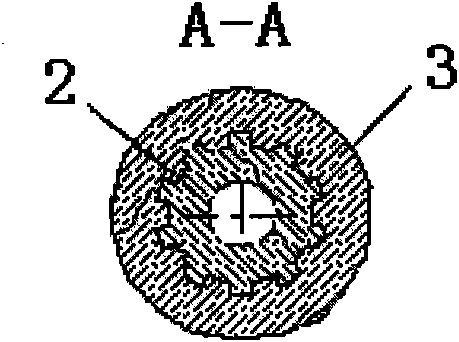

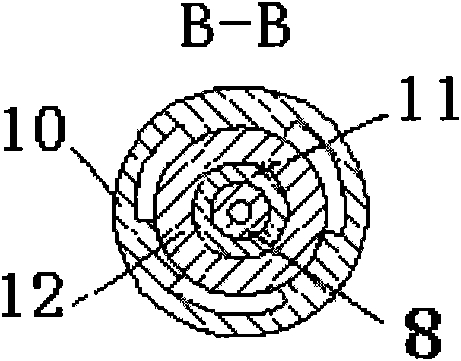

[0011] refer to Figure 1-4 , including a spline mandrel 2, a spline barrel 3, a shock absorbing return spring outer barrel 4, and an impact assembly outer barrel 10. The top end of the spline mandrel 2 is connected with an upper matching joint 1, and the spline barrel 3 and the shock absorbing return spring The outer cylinder 4 and the impact assembly outer cylinder 10 are integrated and can cooperate with the impact structure 12 for transmitting torque and allowing the splined mandrel 2 to reciprocate up and down. The spline mandrel 2 is located inside the spline barrel 3, the outer barrel 4 of the damping return spring and the outer barrel 10 of the impact assembly, and the outer barrel 4 of the damping return spring is provided with a spring limit joint 6 and a return spring 5 for damping. Between the vibration return spring 5 and the shoulder at the lower part of the spline mandrel 2 and the spring limit joint 6, the lower end of the spline mandrel 2 is connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com