Piston tail pipe type impacter of valveless single-cylinder type downhole

A down-the-hole impactor and piston technology, applied in the field of pneumatic impact drilling equipment, can solve the problems of shortening the working life of the impactor, reducing the reliability of the impactor, and machine parts being damaged and scrapped, so as to achieve a simple and smooth gas distribution channel and improve reliability Sexuality and the effect of prolonging the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

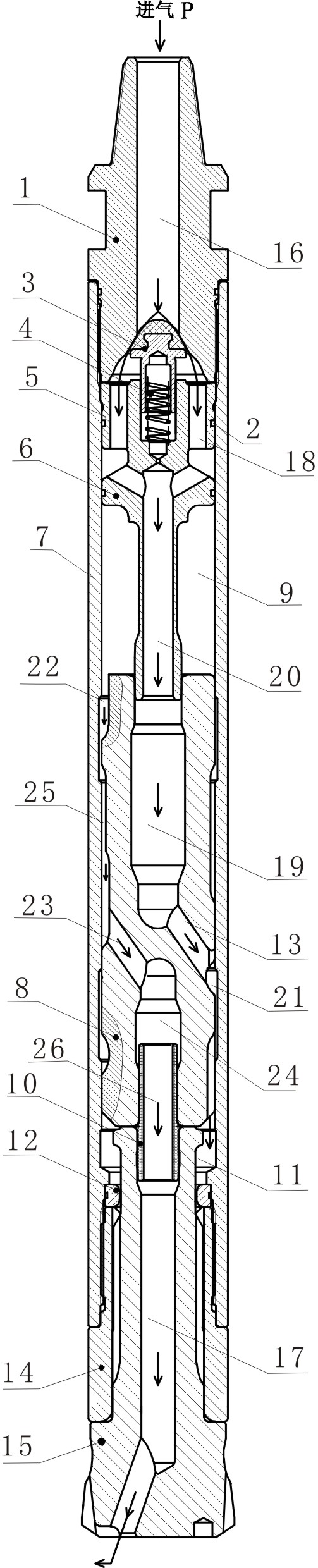

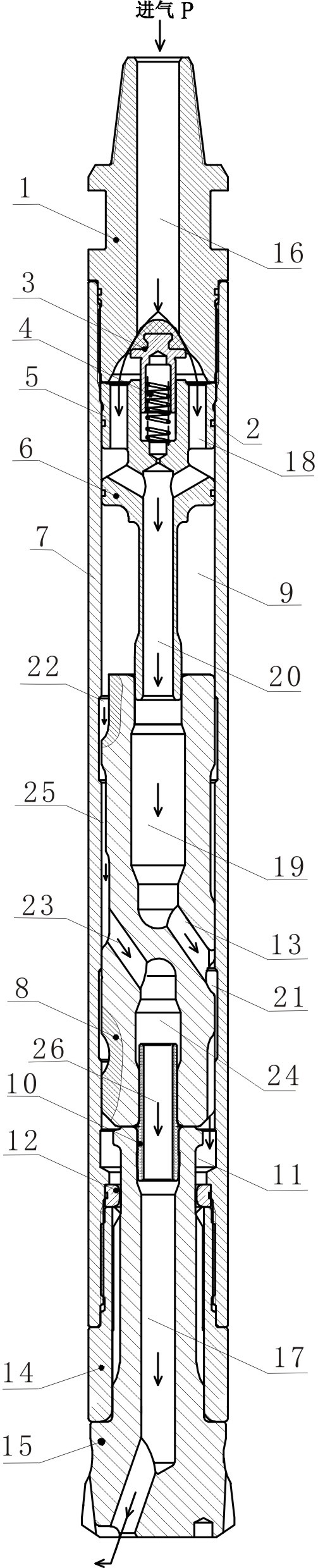

[0022] Such as figure 1 As shown, the present invention comprises the cylinder body 7 that inner wall is provided with annular groove, and one end of cylinder body 7 is fixedly installed with rear joint 1, and rear joint 1 offers hollow channel 16, and the other end of cylinder body 7 is fixedly installed with front joint 14, and front joint 14 The drill bit 15 connected by the feather key is provided with an internal channel 17 up to the end face of the drill bit, and the air distribution seat 5 with an axial air distribution seat channel 18 is sealed and installed in the cylinder body 7, and a check valve is installed on the air distribution seat 5 3. The gas distribution rod 6 provided with the gas distribution rod ventilation channel 20 is provided with the large end of the gas distribution rod and the small end of the gas distribution rod. The gas distribution rod 6 is integrated with the check valve seat. The small end of the piston and the small end of the air distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com