Linear permanent magnet motor system for high-frequency impact

A technology of permanent magnet motor and high-frequency impact, which is applied in the field of oil-assisted percussion drilling and rock breaking, can solve the problems of being unsuitable for high temperature and high pressure working environment, failing to meet the requirements of working conditions, spring coefficient creep, etc., achieving compact structure, The effect of light weight and high natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

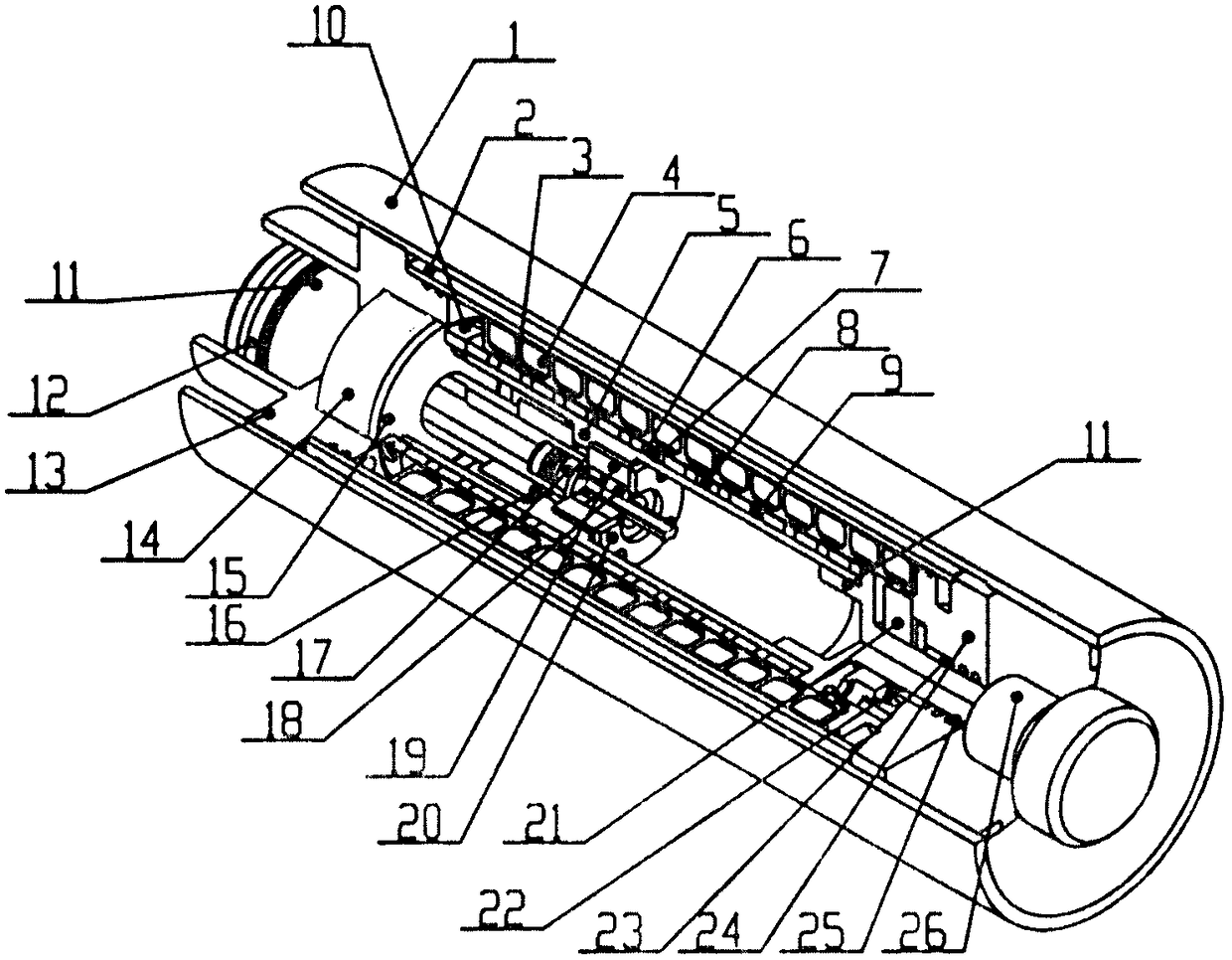

[0015] Such as figure 1As shown, it is mainly composed of stator system, mover system and mechanical system. The stator system includes: outer cylinder 1, inner cylinder 2, stator core 3, winding 4; the mover system includes: mover shaft 5, multiple sets of arranged Permanent magnets, each group of permanent magnets includes N pole 6, magnetic field outward intermediate pole 7, S pole 8, magnetic field inward intermediate pole 9, magnetic steel pressure ring 10, mover upper end 11; mechanical system includes: protector piston 12 , Multifunctional rear support cover 13, return energy storage capsule 14, capsule force cover 15, linear bearing 16, displacement sensor body 17, sensor moving ring 18, moving ring mounting seat 19, moving ring gland 20, anti-collision rubber block 21. Front bearing gland 22, front linear bearing 23, front fixing seat 24, front moving seal 25, impact hammer 26, the upper end of the outer cylinder 1 and the front fixing seat 24 have an interference fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com