Valveless single cylinder blind hole channel down-hole hammer

A down-the-hole impactor and single-cylinder technology, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes, etc., can solve the problems of shortening the working life of impactors, affecting the sealing status of check valves, and scrapping machine parts due to damage To achieve the effect of ensuring high efficiency and stability, simple and unobstructed airway, and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

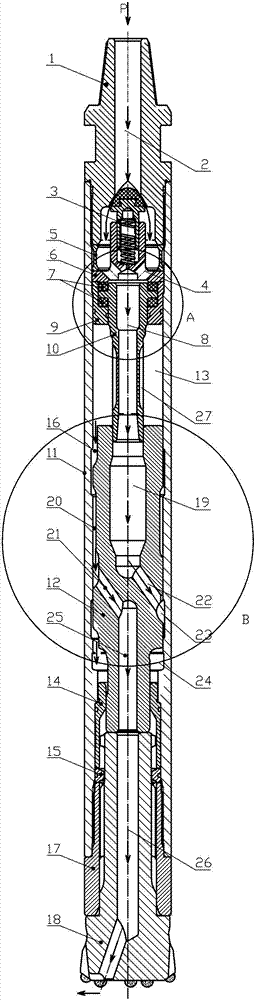

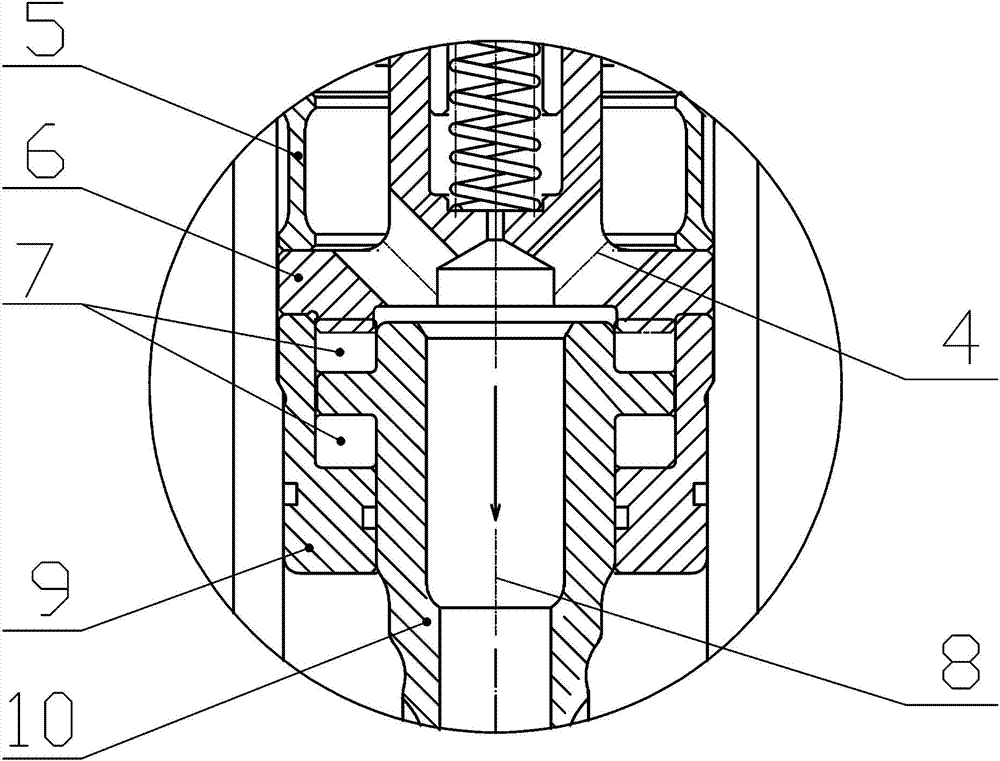

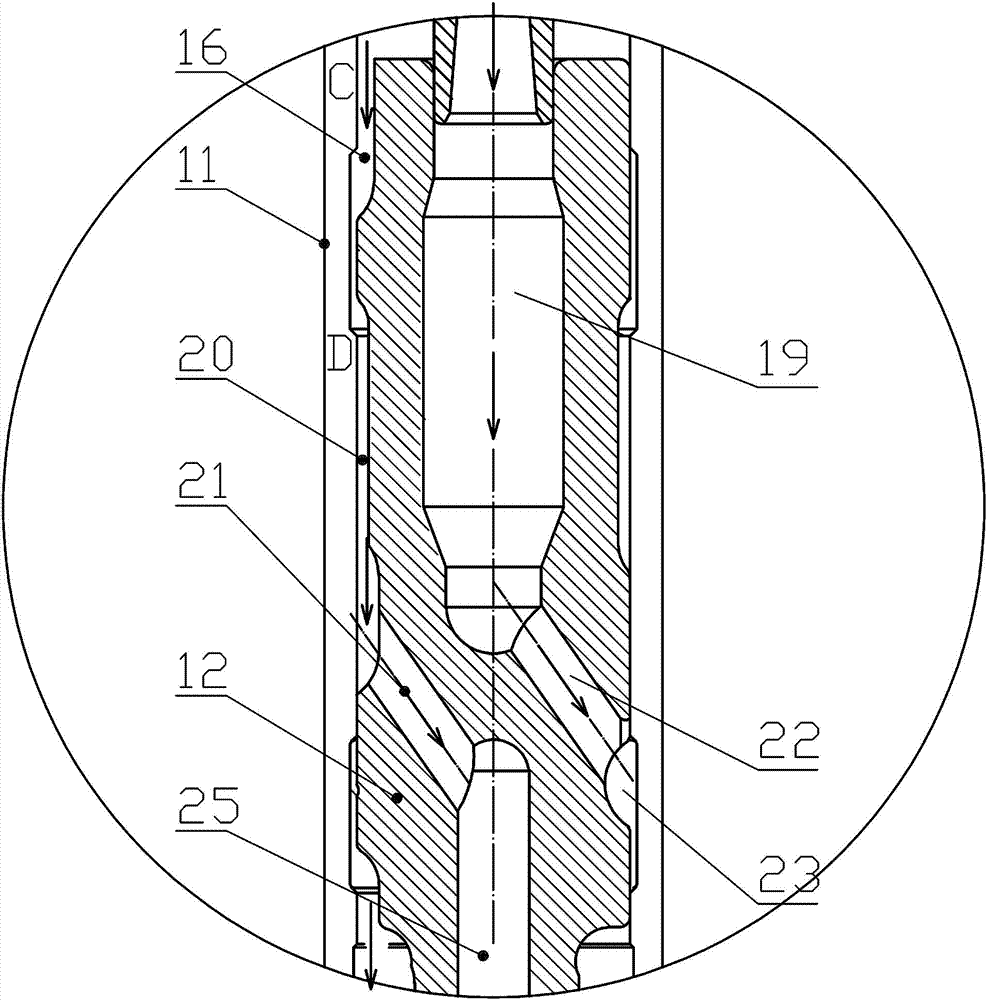

[0030] A valveless single-cylinder blind hole down-the-hole impactor, comprising a cylinder body 11, the upper end of the cylinder body 11 is connected to the rear joint 1, the one-way air inlet 2 of the rear joint 1 cooperates with the check valve 3, and the lower end of the cylinder body 11 The front joint 17 is connected with the drill bit 18, the check valve 3 is installed in the check valve seat 6, the check valve seat 6 is provided with an air distribution hole 4, the check valve seat 6 is provided with a positioning sleeve 9, and the positioning sleeve 9 The inner wall cooperates with the upper end of the gas distribution rod 10, and a plurality of rubber rings 7 are arranged between the inner wall of the positioning sleeve 9 and the upper end of the gas distribution rod 10, and the gas distribution hole 4 communicates with the central channel 8 of the gas distribution rod;

[0031] The lower end of the gas distribution rod 10 cooperates with the piston upper air supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com