Dual-controlling-channel impulse jet ball-tooth bit

A pulse jet and dual control technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling, etc., can solve the problems of poor cuttings removal effect, repeated crushing, and decreased drilling efficiency, so as to enhance the cuttings removal effect and increase the impact frequency , Improve the effect of easy accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

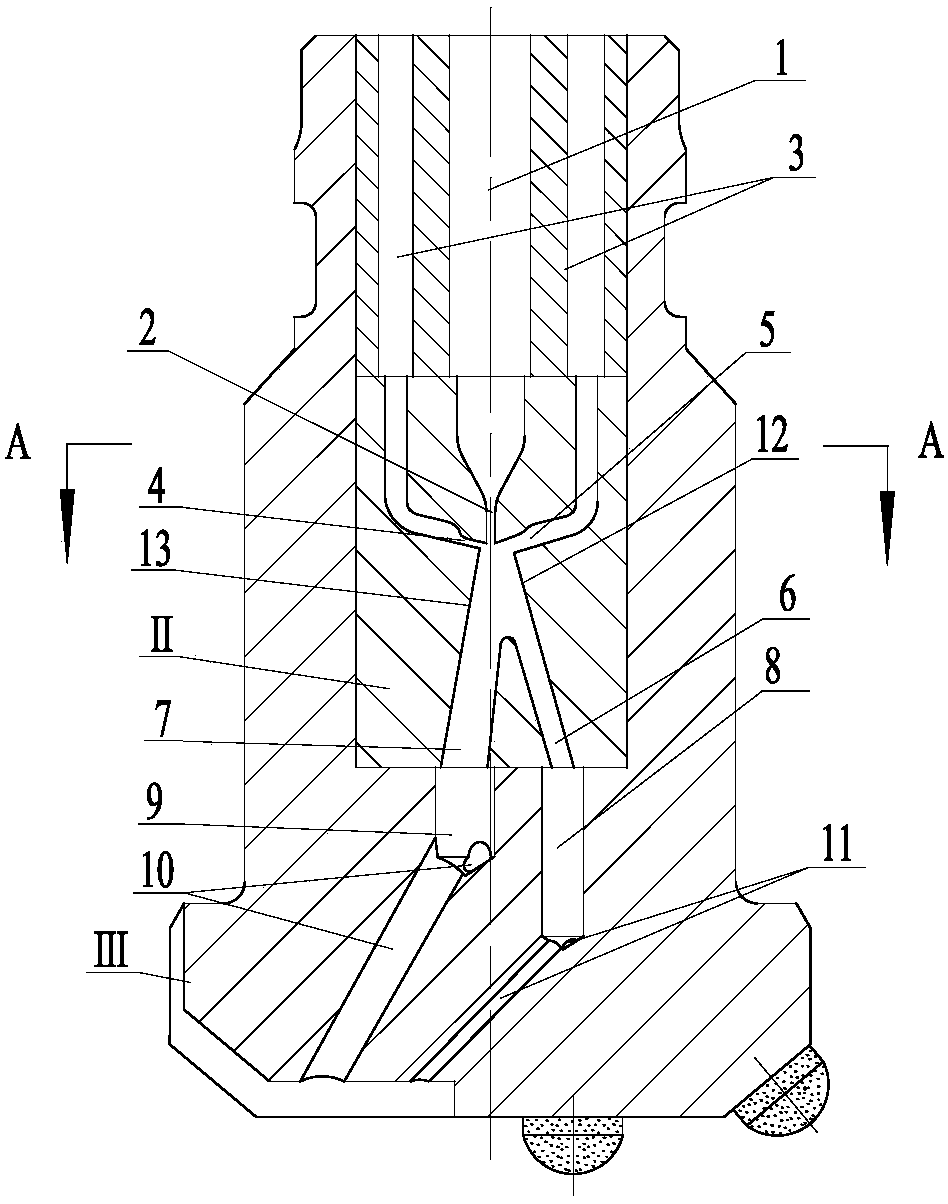

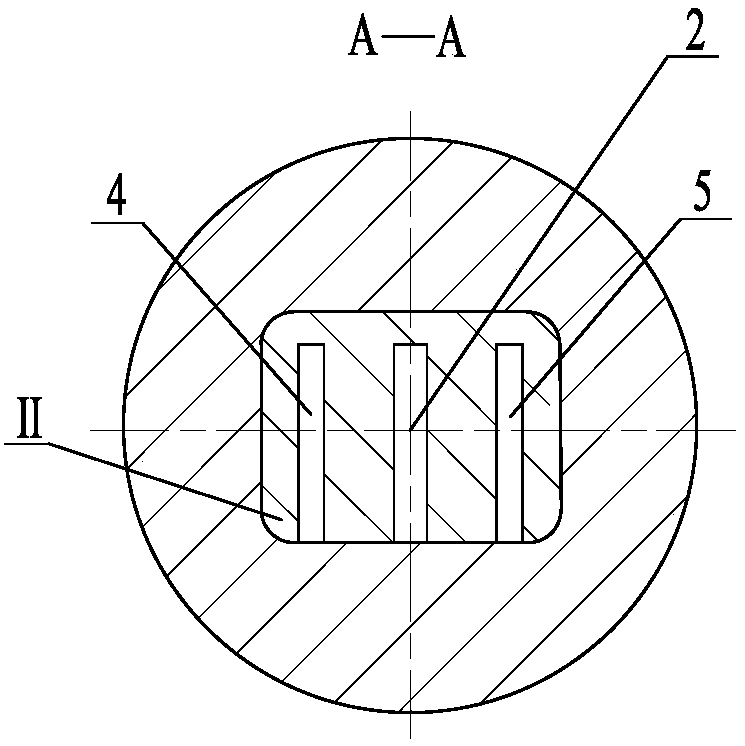

[0015] see Figure 1-2 , The pulse jet button drill bit with dual control channels in this embodiment mainly includes the indenter I, the monostable jet element II with dual control channels and the bit body III. A large blind hole 9 and a small blind hole 8 are respectively opened in the drill body III, wherein the large blind hole 9 is connected with two large nozzles 10, and the small blind hole 8 is connected with two small nozzles 11; There is a pressure head central channel 1 connected to the nozzle 2 of the monostable jet element with dual control channels and a control channel 3 of the pressure head connected to the nozzle 2 of the monostable jet element with dual control channels; the monostable jet element II with the dual control channels is one The complete rectangular block is processed by wire cutting on one side of the required flow channel, welded with the indenter I, ground and placed into the drill body III, and then the indenter I and the drill body III are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com