Large steel ingot rapid forging method and device

A steel ingot and large-scale technology, applied in the field of steel ingot forging, can solve the problems of low forging efficiency of large steel ingots, low impact frequency of punches, impact cracks of steel ingots, etc., and achieve the effect of lowering temperature, high forging efficiency and improving forging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

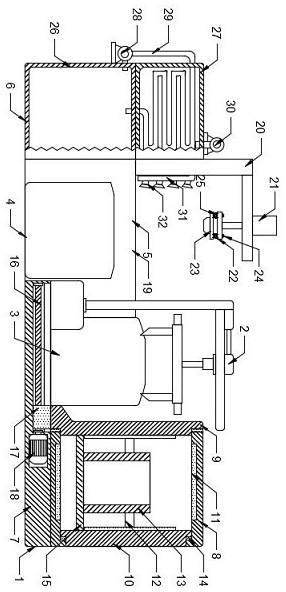

Image

Examples

Embodiment 1

[0025] A method for rapid forging of a large steel ingot, characterized in that it comprises the steps of:

[0026] Step 1: Place the steel ingot at the heating device, quickly heat the steel ingot to 1250 degrees, and keep it warm;

[0027] Step 2: Rapidly cooling down the temperature of the skin layer of the steel ingot obtained in Step 1 to 720 degrees;

[0028] Step 3: Place the steel ingot at the forging press for forging, speed up the impact frequency of the forging head and reduce the punch force during forging;

[0029] Step 4: After forging to the design size and shape, quickly cool down to 400 degrees to maintain the internal crystallization size of the forging;

[0030] Step 5: Place the steel ingot obtained in Step 5 in an annealing furnace for annealing, the annealing temperature is controlled at 640 degrees, and the annealing time is 2 hours.

[0031] In the step five, hydrogen expansion annealing or other annealing methods are selected for the annealing of the...

Embodiment 2

[0044] A method for rapidly forging a large steel ingot, comprising the steps of:

[0045] Step 1: Place the steel ingot at the heating device, quickly heat the steel ingot to 1250 degrees, and keep it warm;

[0046] Step 2: Rapidly cooling the temperature of the skin layer of the steel ingot obtained in Step 1 to 725 degrees;

[0047] Step 3: Place the steel ingot at the forging press for forging, speed up the impact frequency of the forging head and reduce the punch force during forging;

[0048] Step 4: After forging to the design size and shape, quickly cool down to 500 degrees to maintain the internal crystallization size of the forging;

[0049] Step 5: Place the steel ingot obtained in Step 5 in an annealing furnace for annealing, the annealing temperature is controlled at 660 degrees, and the annealing time is 3 hours.

[0050] In the step five, hydrogen expansion annealing or other annealing methods are selected for the annealing of the steel ingot.

[0051] The co...

Embodiment 3

[0063] A method for rapidly forging a large steel ingot, comprising the steps of:

[0064] Step 1: Place the steel ingot at the heating device, quickly heat the steel ingot to 1250 degrees, keep warm, consider the large steel ingot to be heated by electricity, use the resistance of the steel ingot to heat from the inside to the outside, and reduce the heating time;

[0065] Step 2: Rapidly cooling down the temperature of the skin layer of the steel ingot obtained in Step 1 to 730 degrees;

[0066] Step 3: Place the steel ingot at the forging press for forging. During forging, the impact frequency of the forging head is accelerated while the punch force is reduced, which can effectively prevent defects such as microcracks in the steel ingot;

[0067] Step 4: After forging to the design size and shape, quickly cool down to 600 degrees to maintain the internal crystallization size of the forging;

[0068] Step 5: Place the steel ingot obtained in Step 5 in an annealing furnace f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com