Composite type eccentric one-cone bit

A single-cone, compound technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of accelerated drill bit failure, unfavorable cleaning of cutting teeth, increased workload of PDC teeth, etc., to improve rock breaking efficiency and use. Life, improve rock breaking efficiency and service life, uniform and reasonable flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

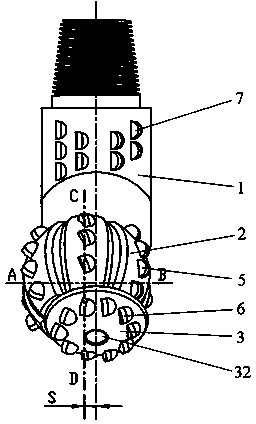

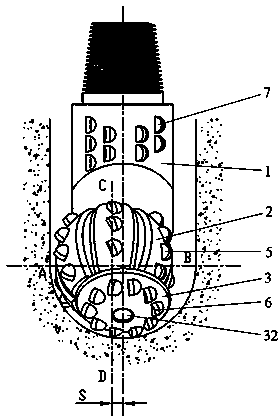

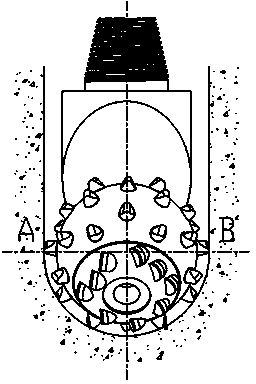

[0059] Such as Figures 1 to 10 As shown, the basic example is: a composite eccentric single-cone bit, including a bit body 1, a cone 2, and a fixed cutting structure 3 in front of the cone. The cutting structure 3 is arranged with fixed cutting teeth 6, the drill body 1 is provided with a journal 4, the cone 2 forms a rotational connection with the journal 4, the fixed cutting structure 3 in front of the cone is fixedly connected with the front end of the journal 4, and the journal There is an offset S between the axis of 4 and the axis of the drill bit, the value range of S is 0<|S|≤d / 3, and d is the outer diameter of the drill bit.

[0060] Option 1 as a basic example: the range of the shaft inclination angle α of the cone 2 is 45° Figure 5 , 8 ,9).

[0061] Option 2 as a basic example: an inner cone 31 is arranged on the front fixed cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com