Lithology identification based mechanical-hydraulic combined rock breaking TBM real-time tunneling method

A technology of lithology identification and machinery, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of TBM energy consumption increase, real-time adjustment, and excessive change is difficult to achieve, and achieve good cooling and anti-wear effects. The effect of solving engineering cost and reducing construction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

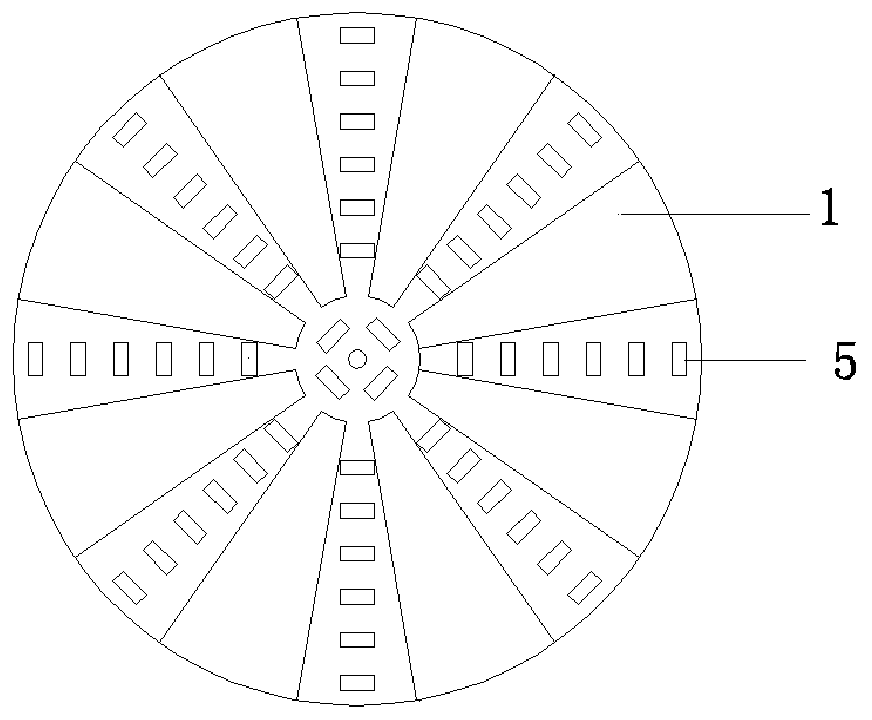

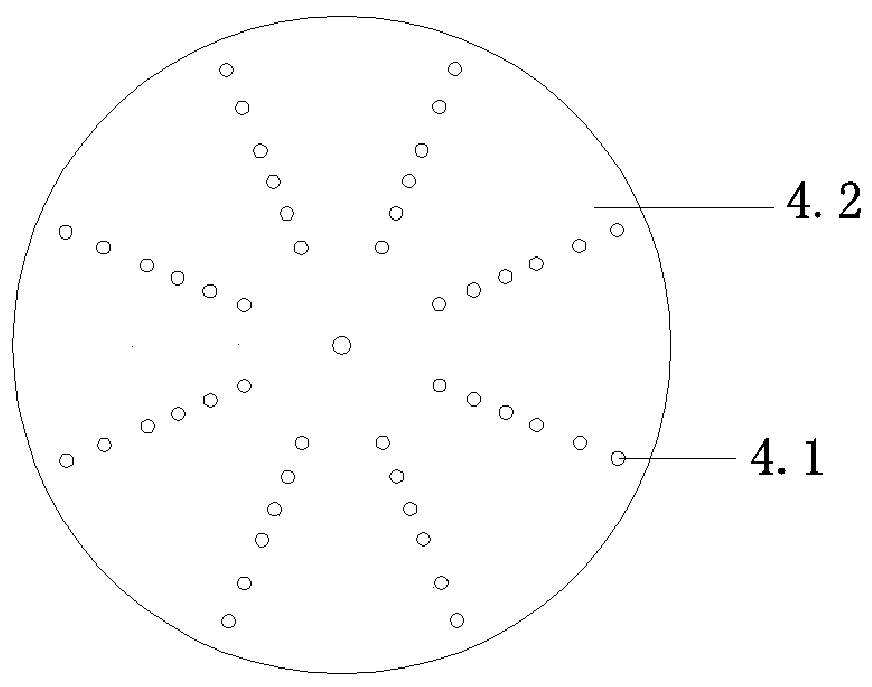

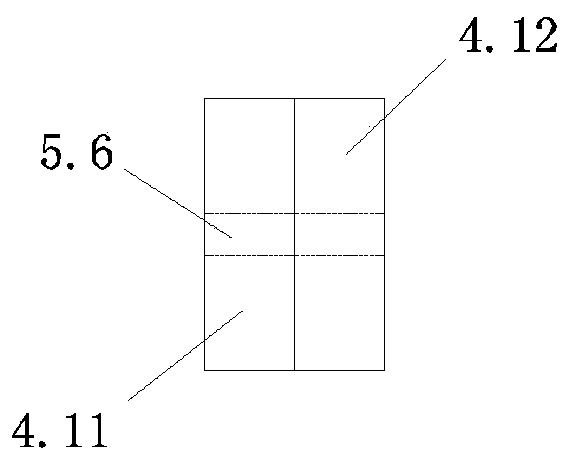

Method used

Image

Examples

Embodiment 1

[0187] Taking the white sandstone sample with a size of 150mm×150mm×100mm as an example, the penetration test is carried out on the white sandstone sample (the TBM hob breaks the rock mainly with normal force);

[0188] Using the mechanical hob of the prior art to carry out the penetration test on the white sandstone sample, the maximum force required to destroy the white sandstone sample reaches 140KN;

[0189] The mechanical-hydraulic combined rock-breaking TBM real-time tunneling method based on lithology identification described in the present invention is used to carry out the penetration test on the white sandstone sample, and the hob penetration test is carried out after the white sandstone sample is pre-grooved with a water knife , the maximum force required to destroy the white sandstone sample is only 40KN, the rock-breaking force is reduced by more than 70%, and the time for the white sandstone sample to be broken after the water jet pre-grooving treatment is shorter...

Embodiment 2

[0192] Now take the application of the present invention to the tunnel construction of Metro Line 2 in a certain place as an example to describe in detail, and it also has a guiding effect on the application of the present invention to tunnel construction and underground engineering construction in other regions.

[0193] Adopting the combined rock-breaking TBM complex stratum excavation method of realizing three-way force detection described in the present invention is to the construction of a certain section tunnel of Metro Line 2 in a certain ground, including the following steps (such as Figure 14 shown):

[0194] Firstly, the rock sample of the tunnel to be constructed on Metro Line 2 in a certain place is obtained through a sampling device. The section to be constructed on Metro Line 2 mainly includes three types of rocks (complex strata: rock types A, B, and C, respectively, such as Figure 12 shown);

[0195] According to the geological information such as the confin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com