Diamond drill bit with high-efficiency water hole structure

A technology of diamond drill bit and water hole, which is applied in the direction of drill bit, drilling equipment, earthwork drilling, etc. It can solve problems such as insufficient cooling, untimely migration of cuttings, and reduced drilling performance of the drill bit, so as to improve utilization efficiency and improve Cooling effect, effect of reducing jet divergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

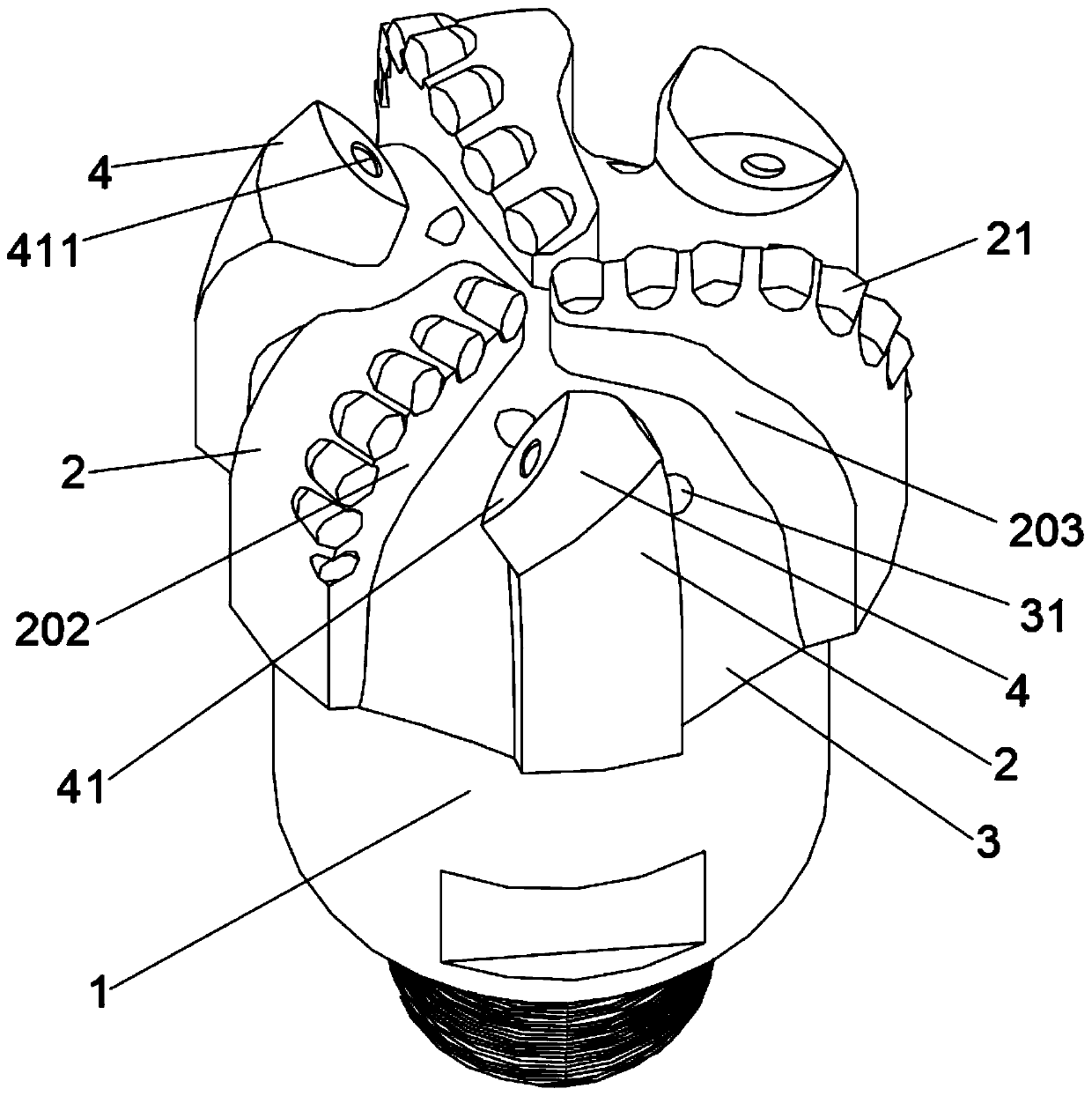

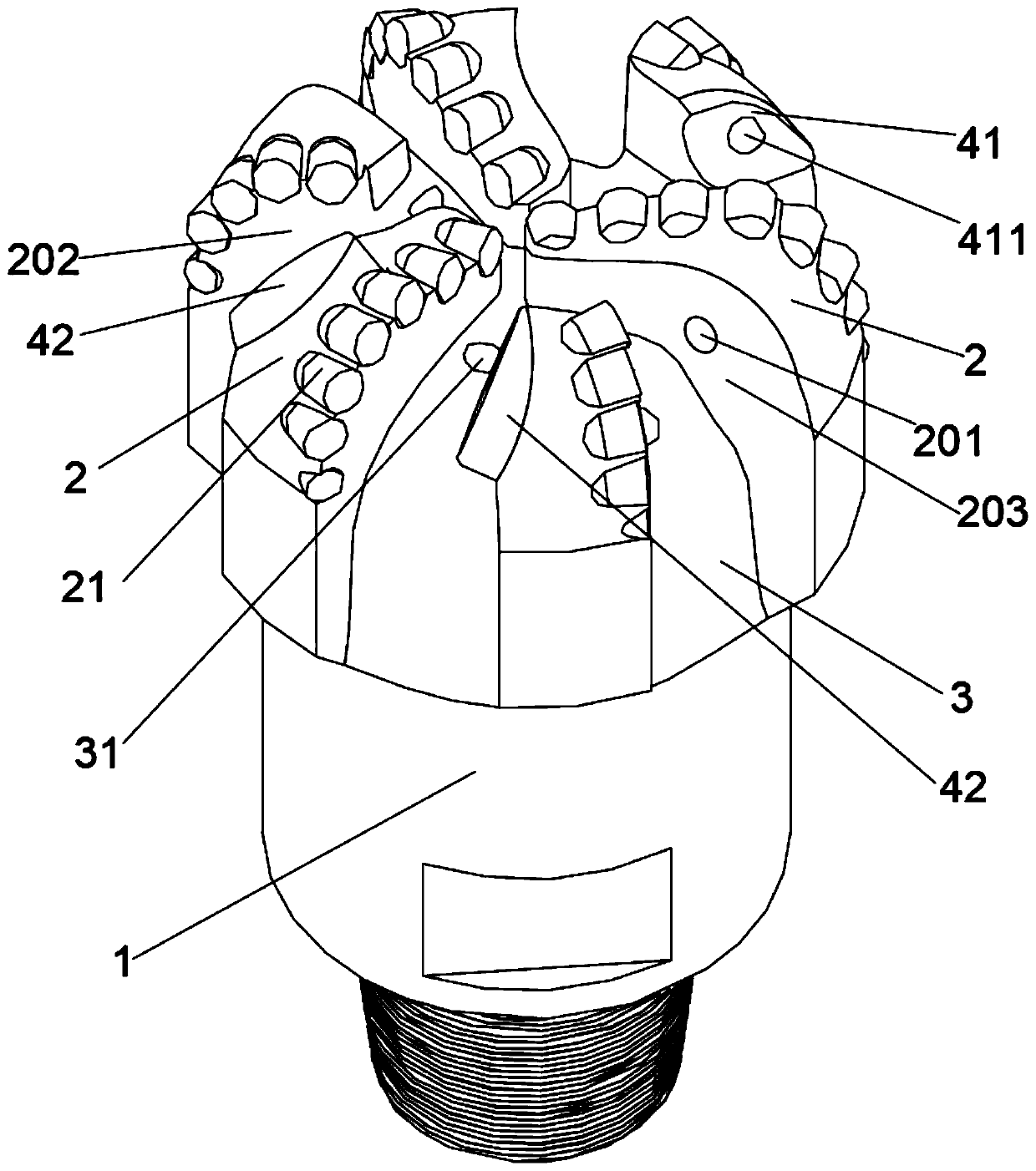

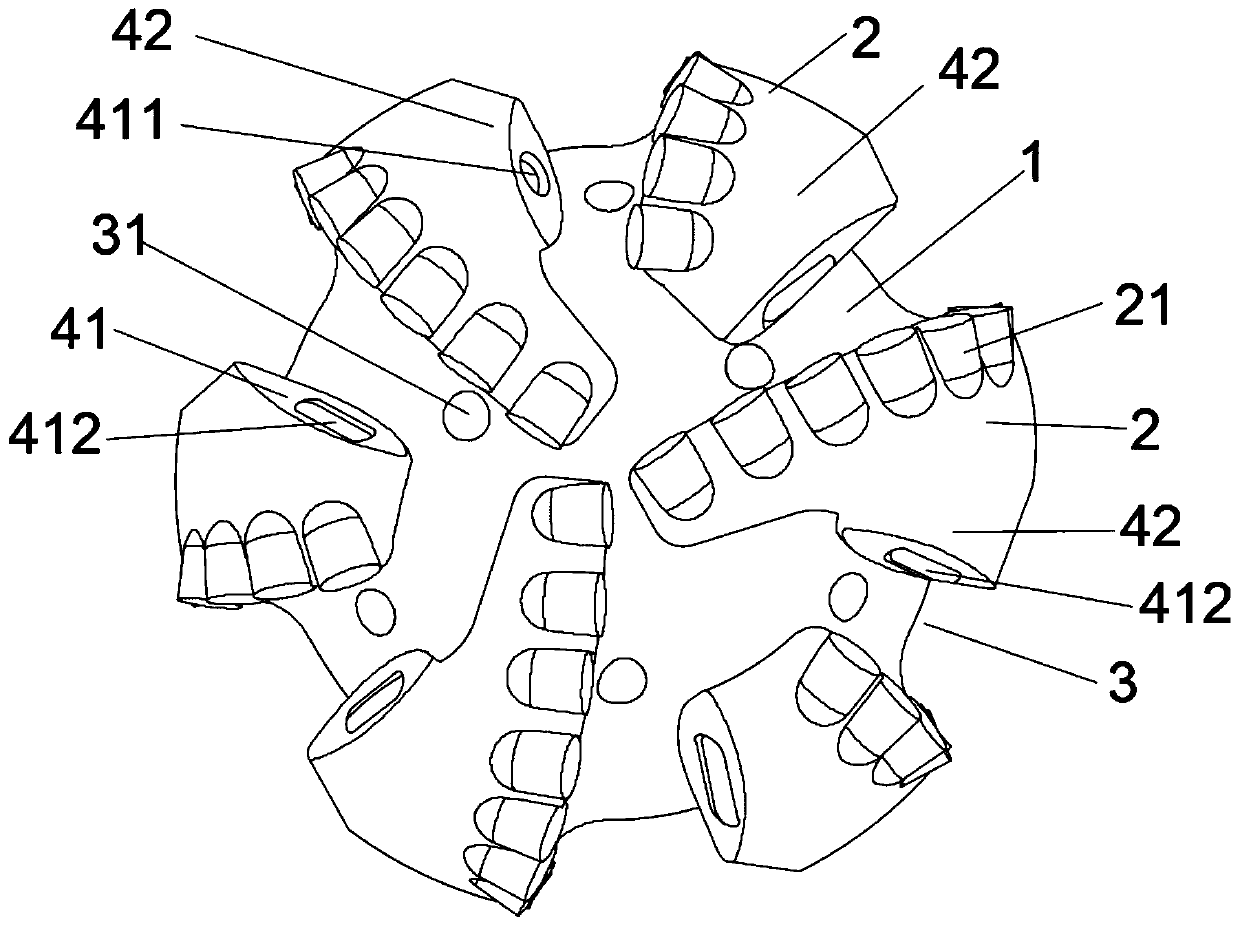

[0046] A diamond drill bit with efficient water hole structure, such as figure 1As shown, it includes a drill body 1 and a blade 2 extending from the drill body. The blade 2 includes a blade front side 202 and a blade rear side 203. The blade 2 is also provided with diamond cutting teeth 21 or cutting teeth. Components, water channel grooves 3 are formed between adjacent blades, and it is characterized in that: a rear spray hole seat 4 extending from the drill bit body or connected to the drill bit body 1 is provided in front of at least one of the blades 2, The end face 41 of the rear water spray hole seat 4 is provided with a rear water spray hole communicating with the inner flow channel 101 of the drill bit. That is, in the direction of drill bit rotation, a water hole seat is provided in front of at least one of the blades, and the water hole seat has a water hole that can spray backwards, and the rear water spray hole can directly spray to the cutting teeth on the blade....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com