Patents

Literature

52results about How to "Low steering resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

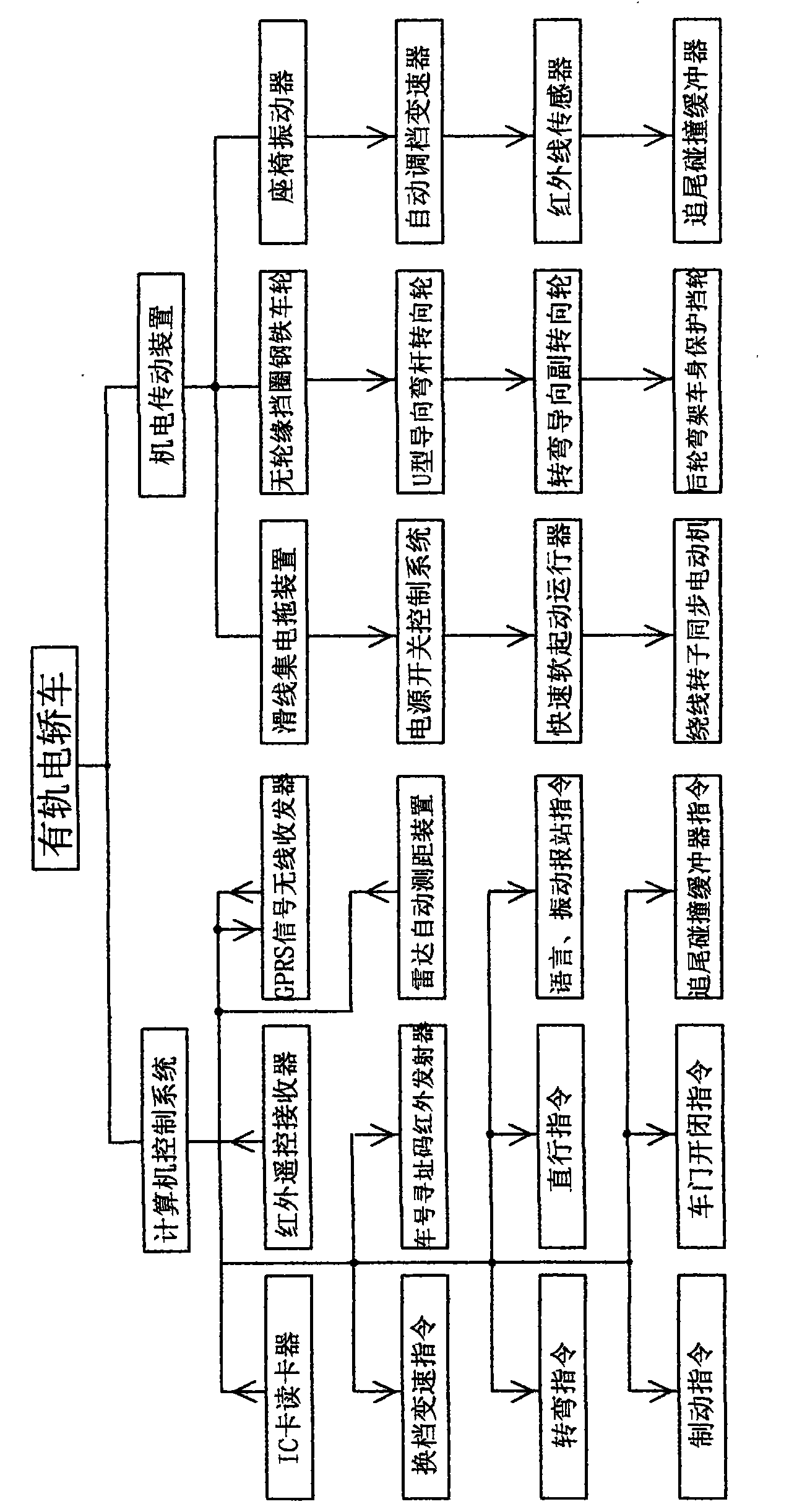

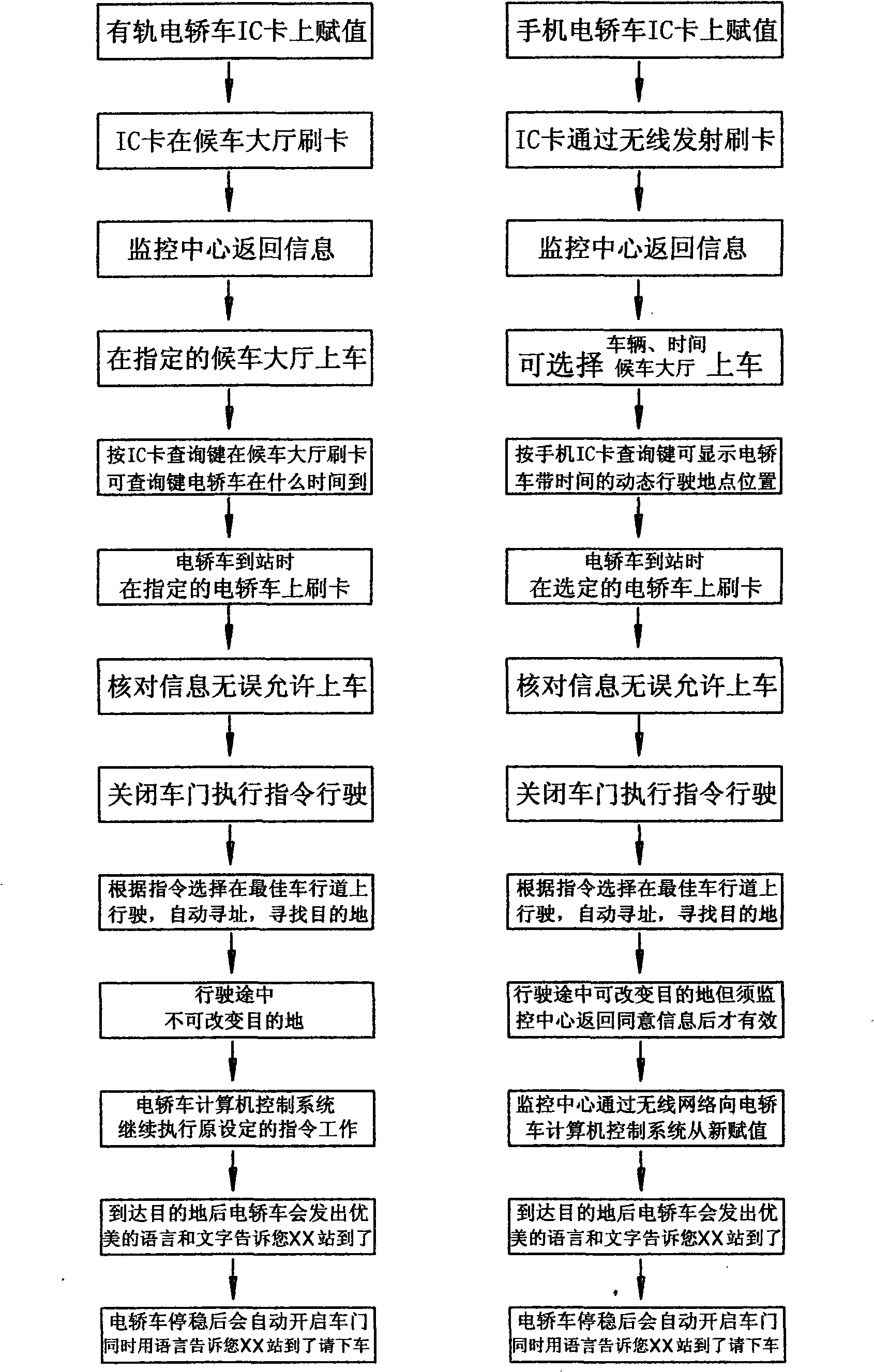

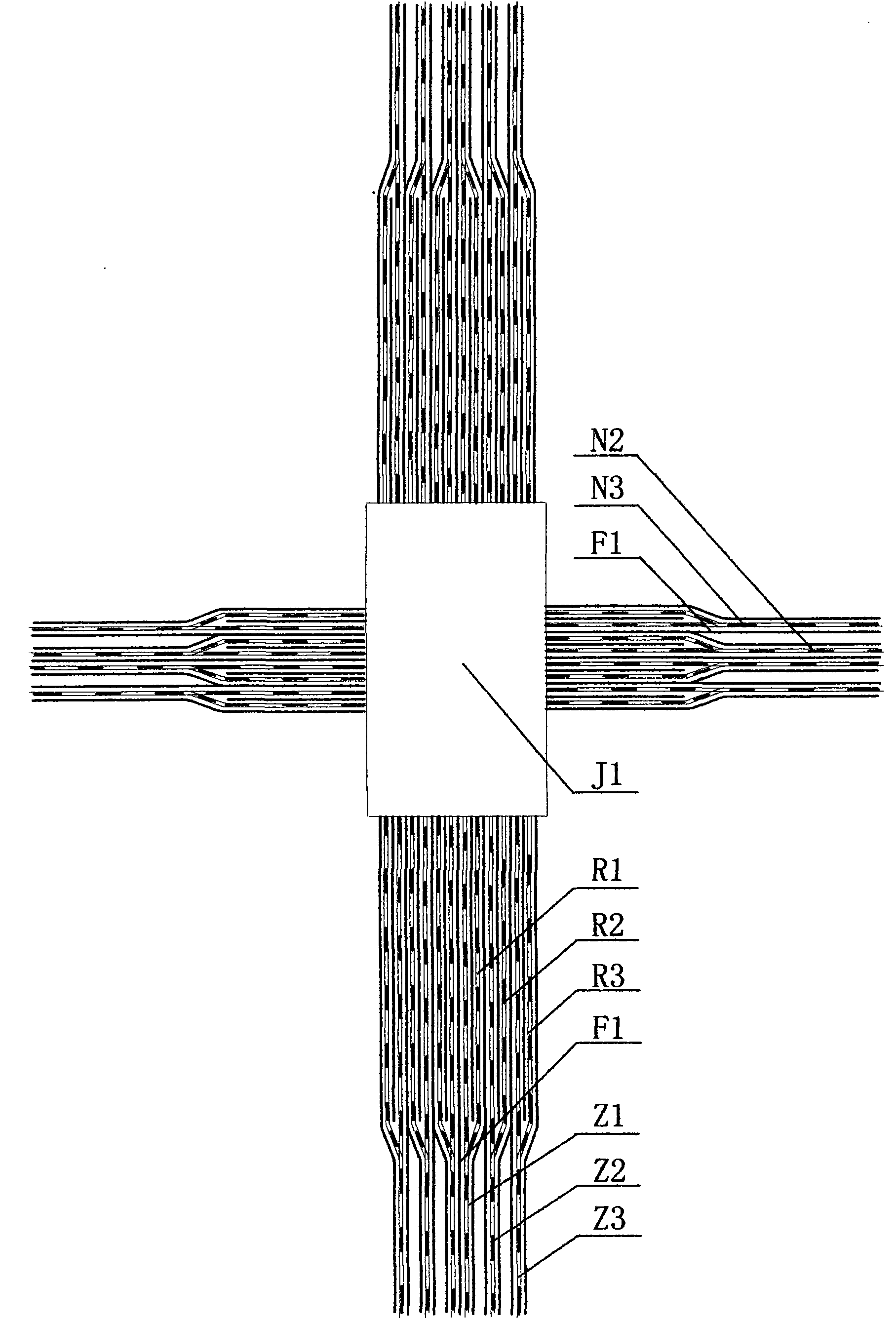

Unmanned rail electric vehicle and sky-train system

InactiveCN102107662ATravel convenienceConvenient carAutomatic systemsElectric locomotivesSteering wheelSky

The invention relates to an unmanned rail electric vehicle and a sky-train system. Regarding the rail electric vehicle, a lane is laid by turnout-free light rails and an anti-impact vertical guide pavement closed and laminate lane, and the vehicle runs on the railway, thus being named as sky-train; the rail electric vehicle adopts unmanned driving, and a destination is found through addressing codes by a vehicular computer system and through road infrared remote control information; a rail electric vehicle monitor center, an automatic indoor parking lot, a high-rise high-capacity indoor parking lot, an indoor platform and a waiting room are arranged; a bus-type rail electric vehicle ticket can be booked by a method which sends a short message via an internet mobile phone, and a taxi-type rail electric vehicle or a household rail electric vehicle can be reserved for pickup on time at a right station; a steering mechanism does not have a steering wheel, the vehicle steering can be completed by a main steering wheel and an auxiliary steering wheel through guiding pavement; and the rail electric vehicle can be a bus type, a taxi type, a household type and an online goods delivery and receiving type.

Owner:张兔生

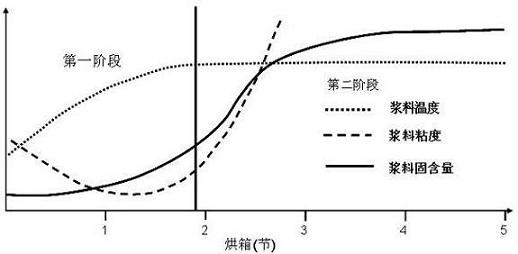

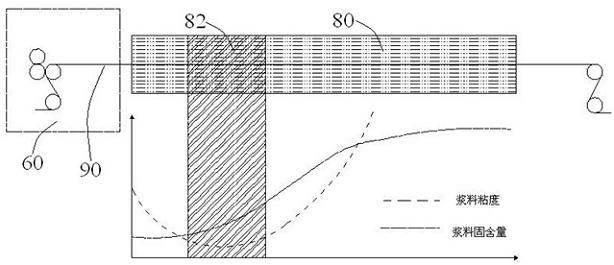

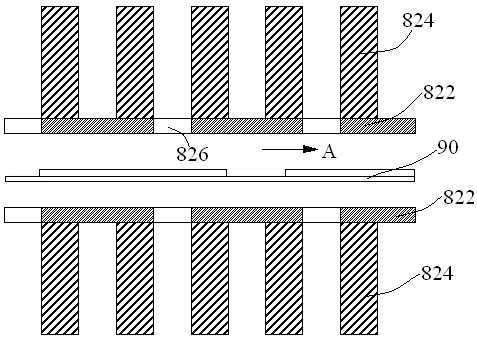

Preparation method of lithium ion battery cathode sheet, and film coating and drying apparatus

ActiveCN102306750AImprove performanceAchieve highly directional alignmentCell electrodesPretreated surfacesMagnetizationGraphite particle

The invention discloses a preparation method of a lithium ion battery cathode sheet. The method comprises steps that: a cathode slurry containing graphite is prepared and is coated on a substrate; slurry drying is carried out upon the coated substrate, and a magnetic field is applied on the slurry being dried during a phase when the viscosity of the slurry reaches the lowest point, such that (004) planes of graphite particles are perpendicular to the substrate plane; then the magnetic field is removed, and the slurry is continuously dried until the slurry turns solid. The invention also discloses a film coating and drying apparatus used for realizing the method. According to the invention, magnetization is carried out upon graphite during the drying phase when the viscosity of the slurry reaches the lowest point. Therefore, turning resistance is reduced, alignment consistency of the (004) planes of the graphite particles is improved. Also, when the graphite particles are turned, the slurry is instantly processed through a drying phase wherein the slurry solid content and the slurry viscosity are rapidly increased, such that high consistency on a graphite particle alignment direction is maintained, and highly-oriented alignment of graphite in the cathode sheet is realized.

Owner:DONGGUAN AMPEREX TECH

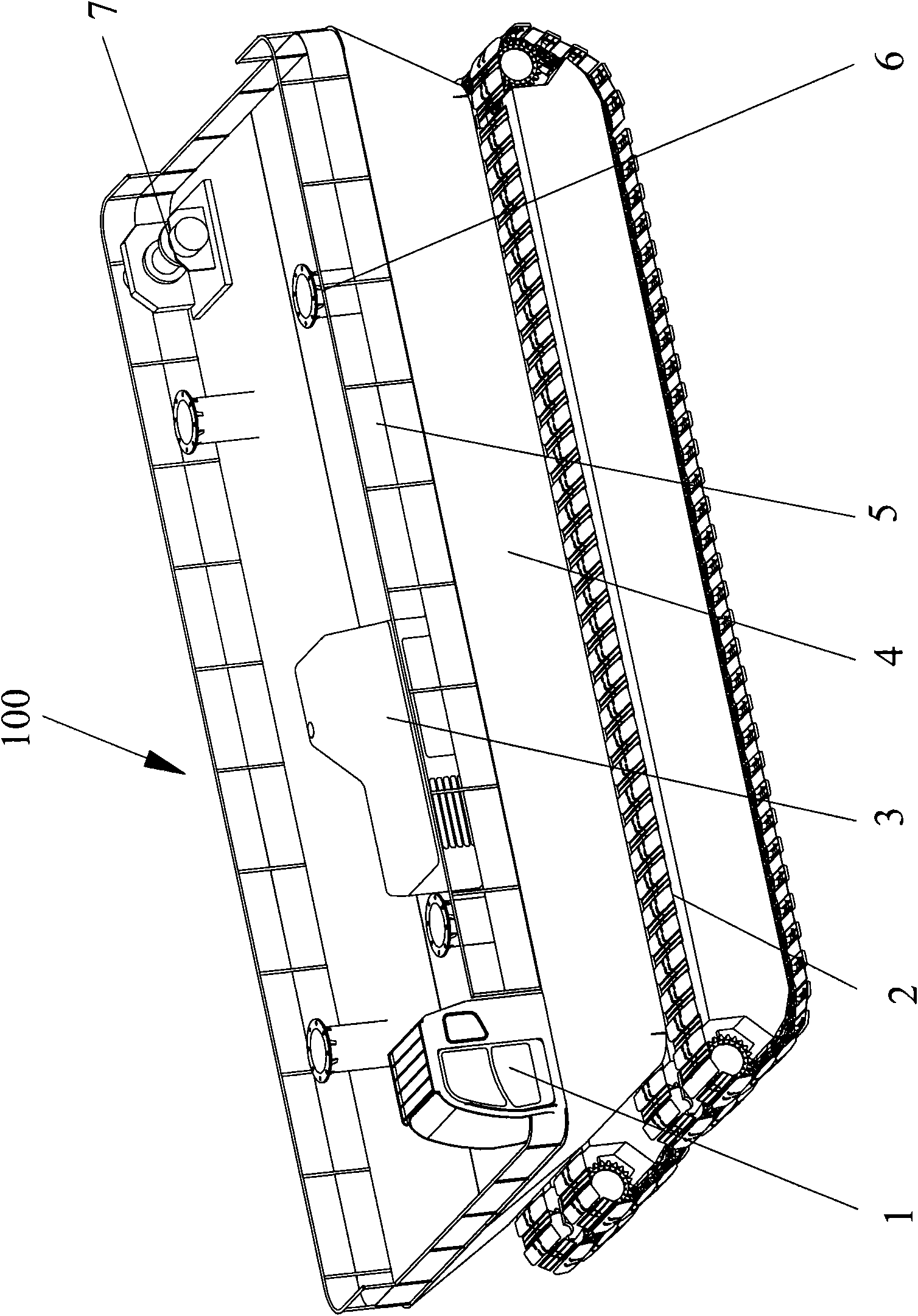

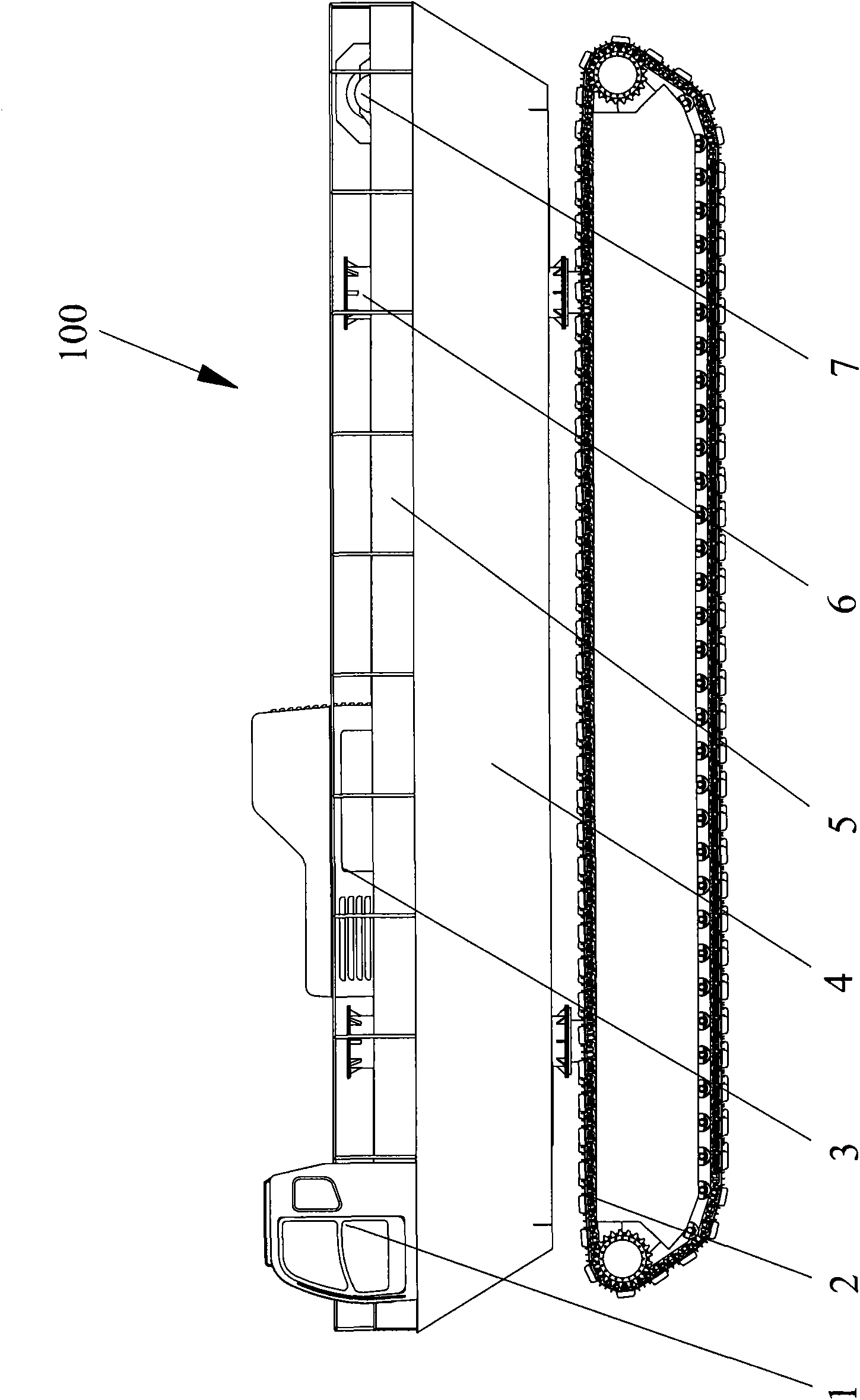

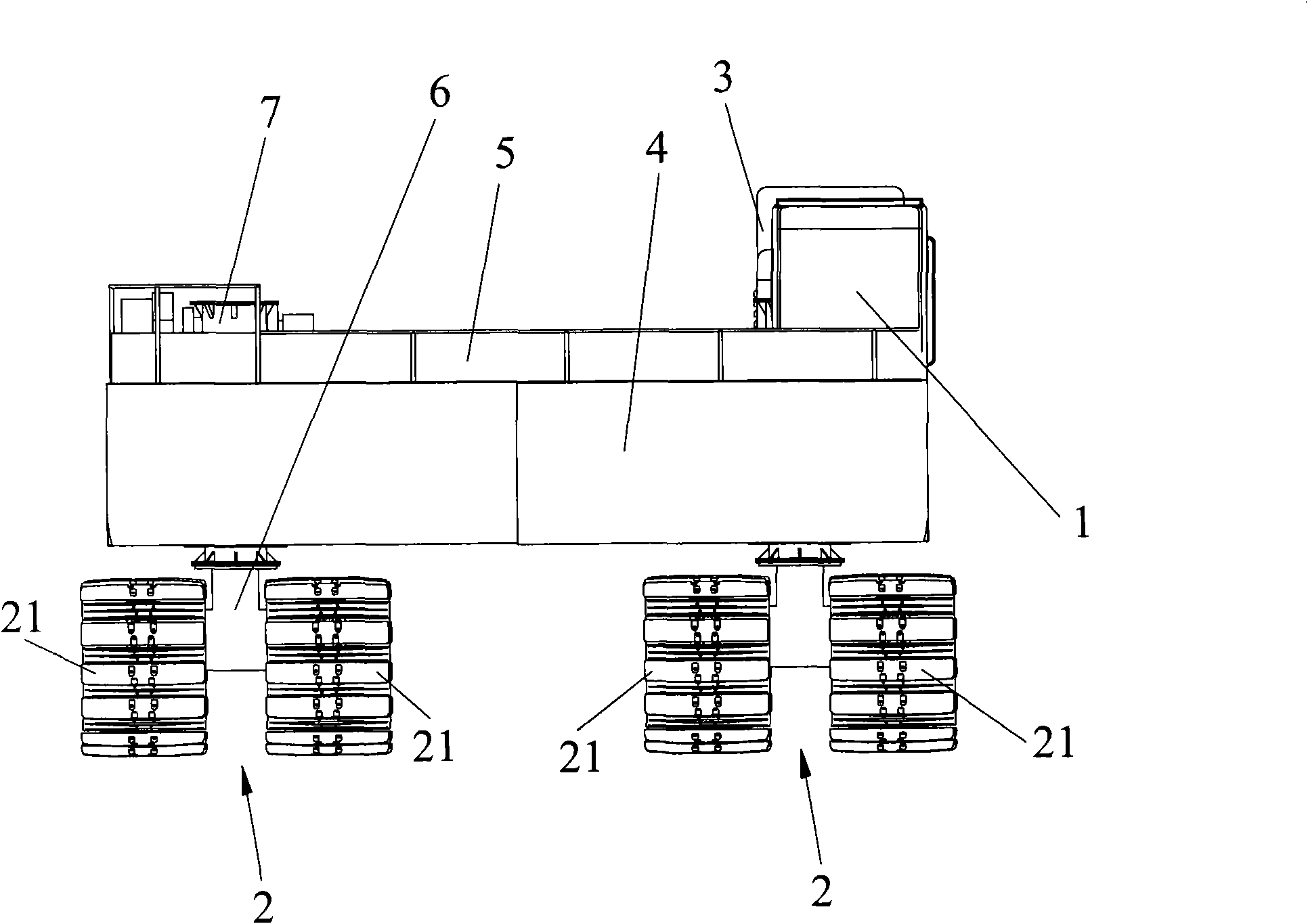

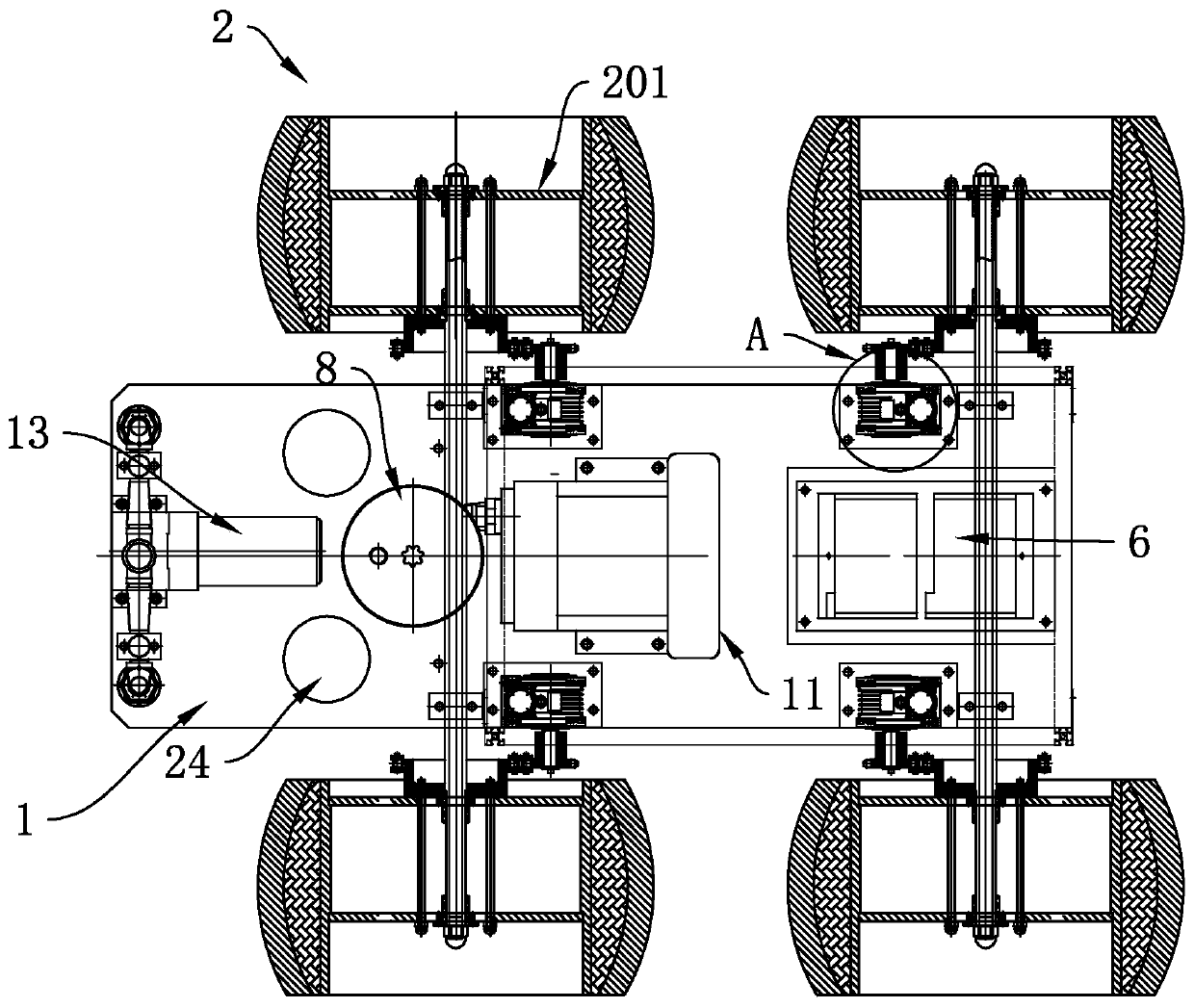

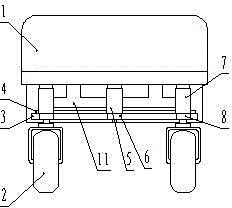

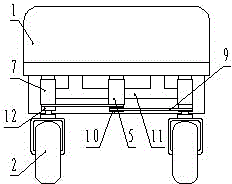

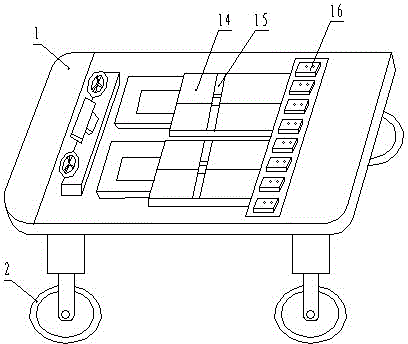

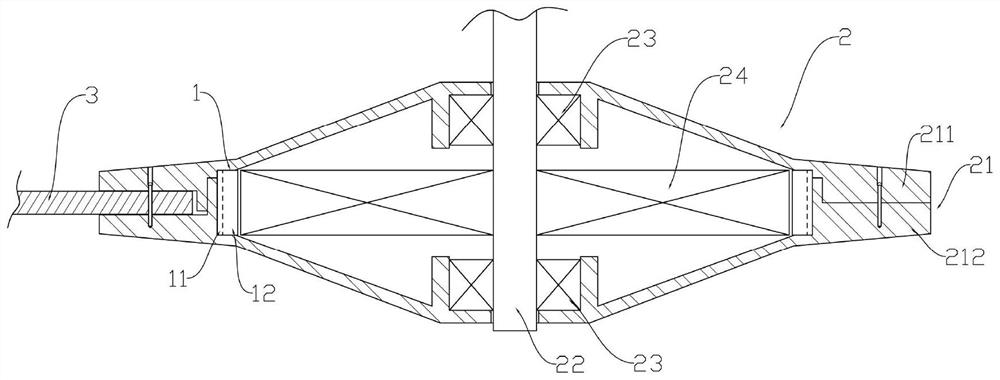

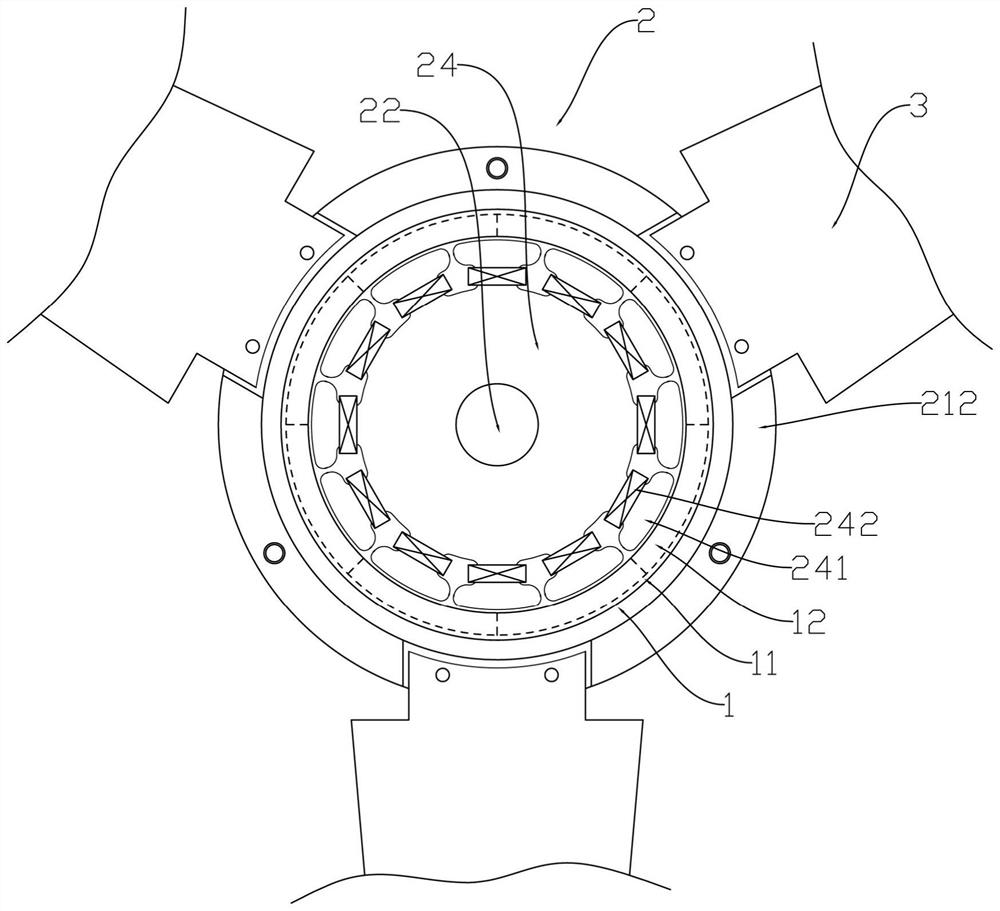

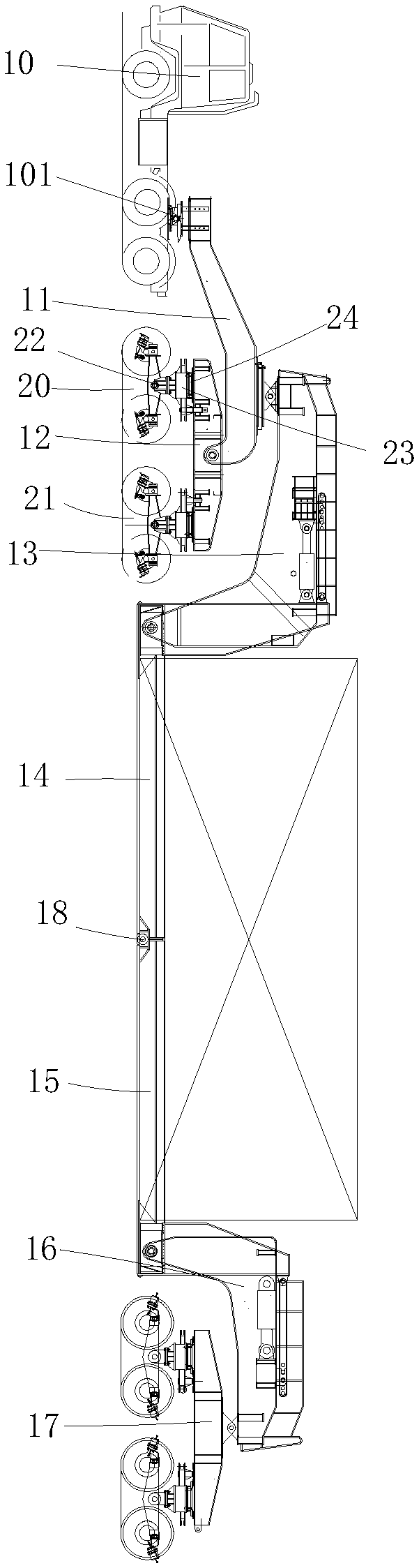

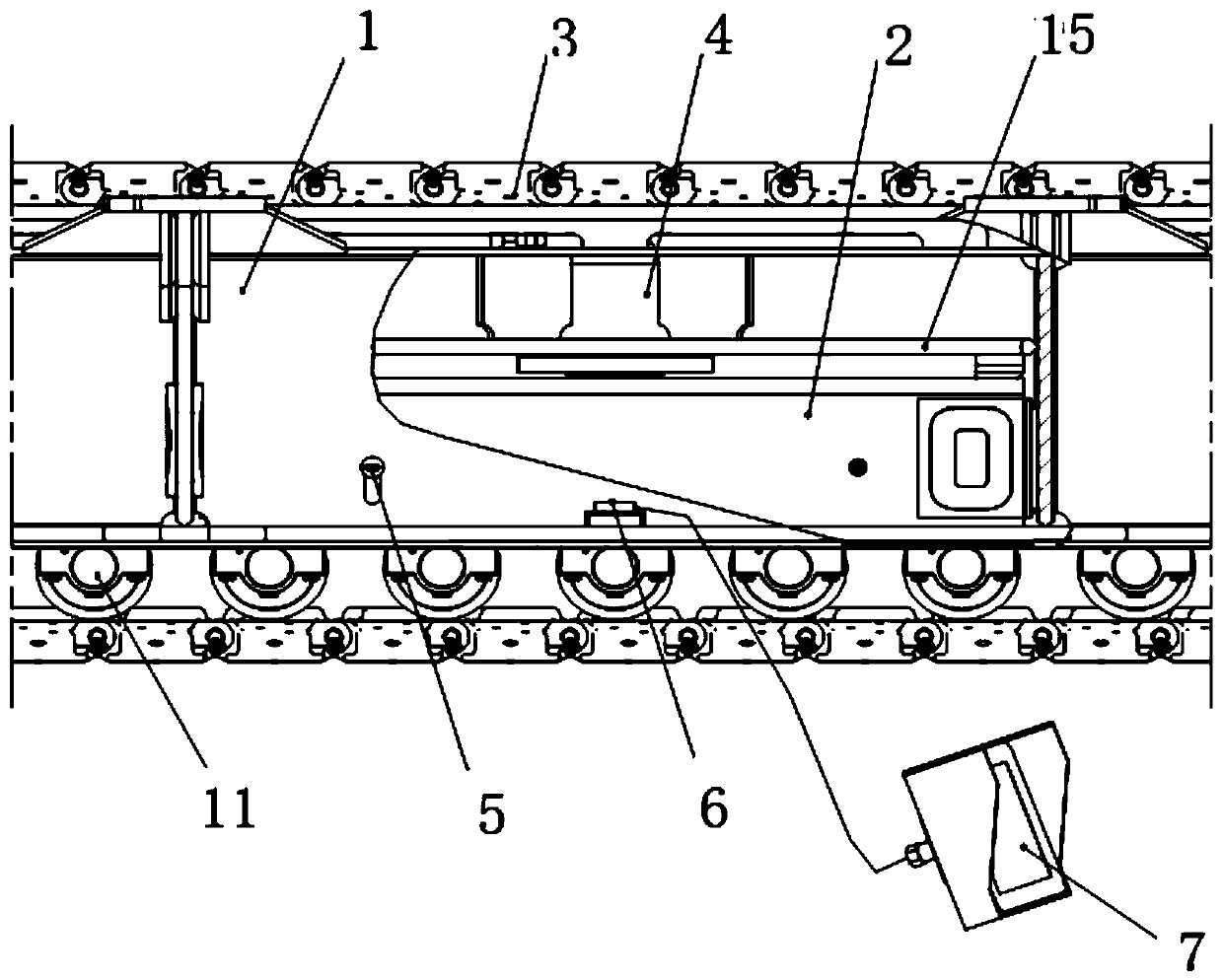

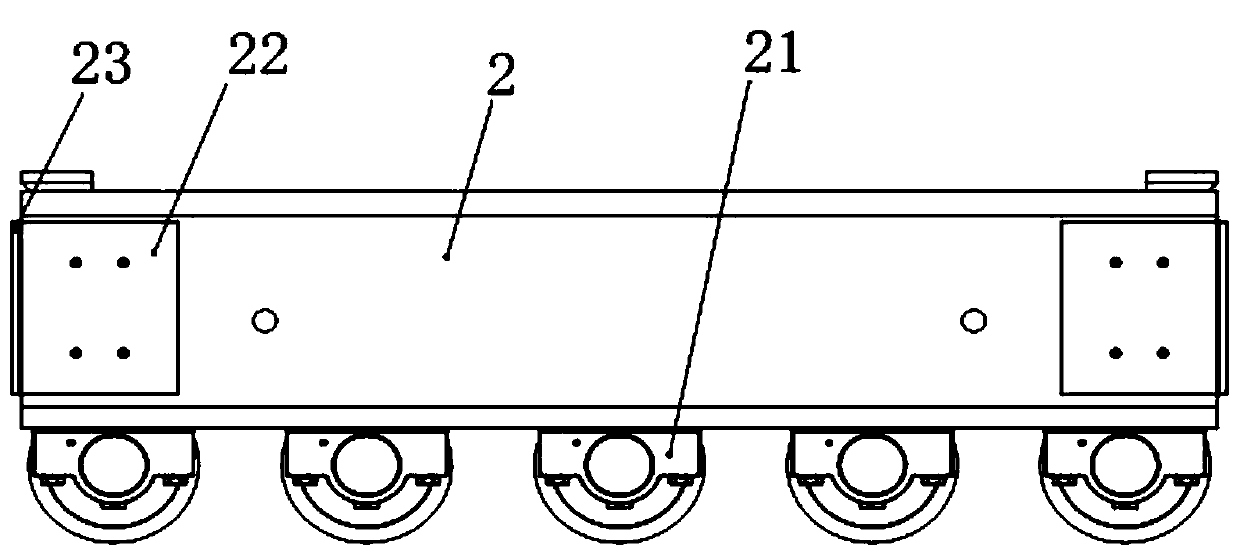

Amphibious haulage vehicle

InactiveCN102107595ACompact structureLow steering resistanceAmphibious vehiclesEndless track vehiclesResistance forceAutomotive engineering

The invention provides an amphibious haulage vehicle which comprises a vehicle body and two crawler travel units (2), wherein, the two crawler travel units (2) are respectively arranged on both sides of the lower part of the vehicle body; each crawler travel unit (2) comprises a floating box and at least two crawlers (21) which are arranged on the outer side of the floating box in parallel. Compared with the prior art, the crawler travel units comprising at least two crawlers that are arranged in parallel are respectively arranged on the left and the right sides of the amphibious haulage vehicle, so that the integral structure of the vehicle can be more compact and the steering resistance force is reduced when equivalent earthing specific pressure is ensured.

Owner:SANY ELECTRIC CO LTD

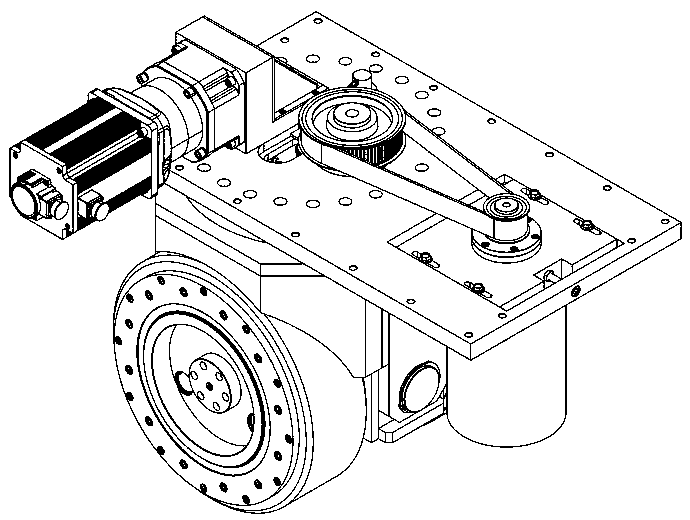

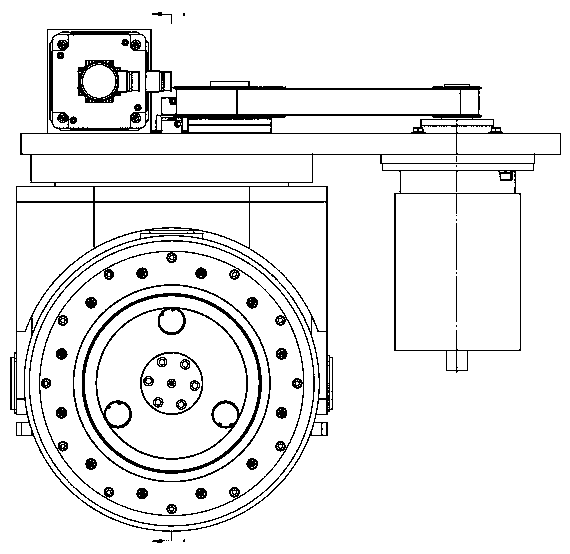

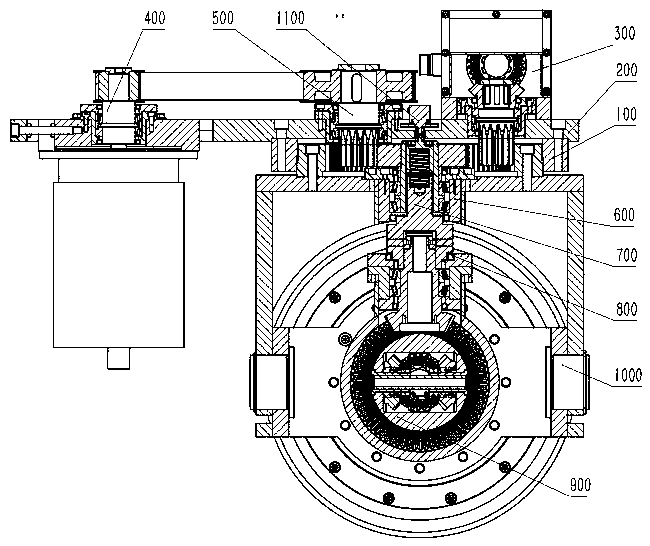

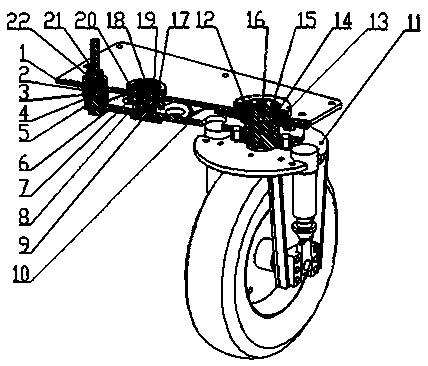

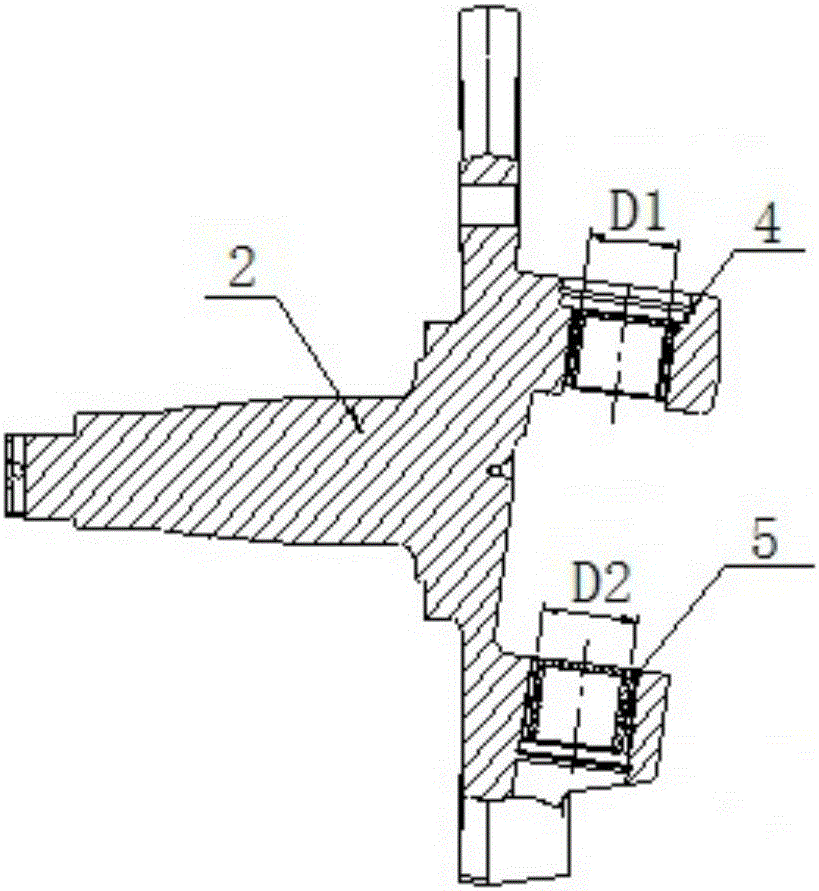

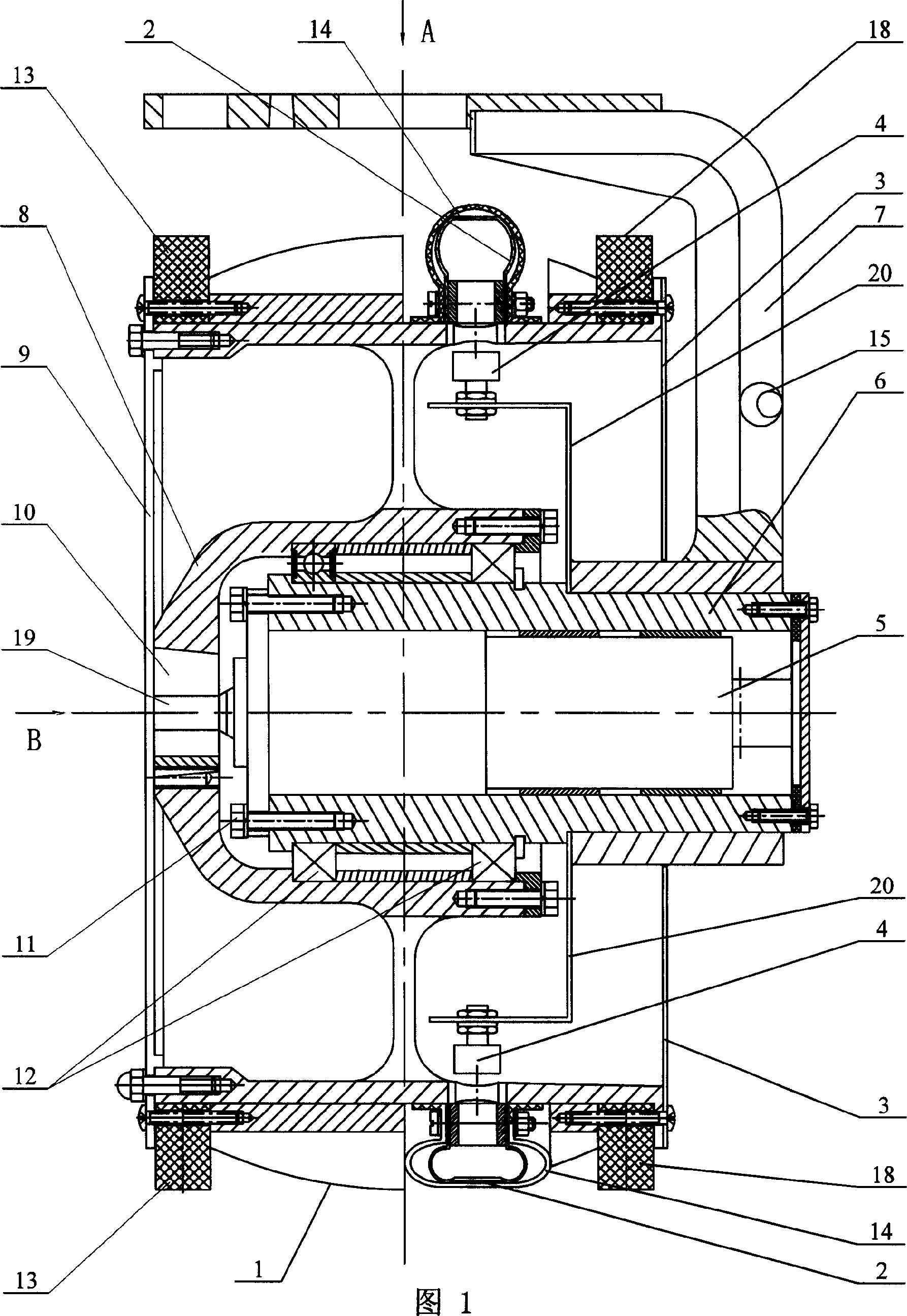

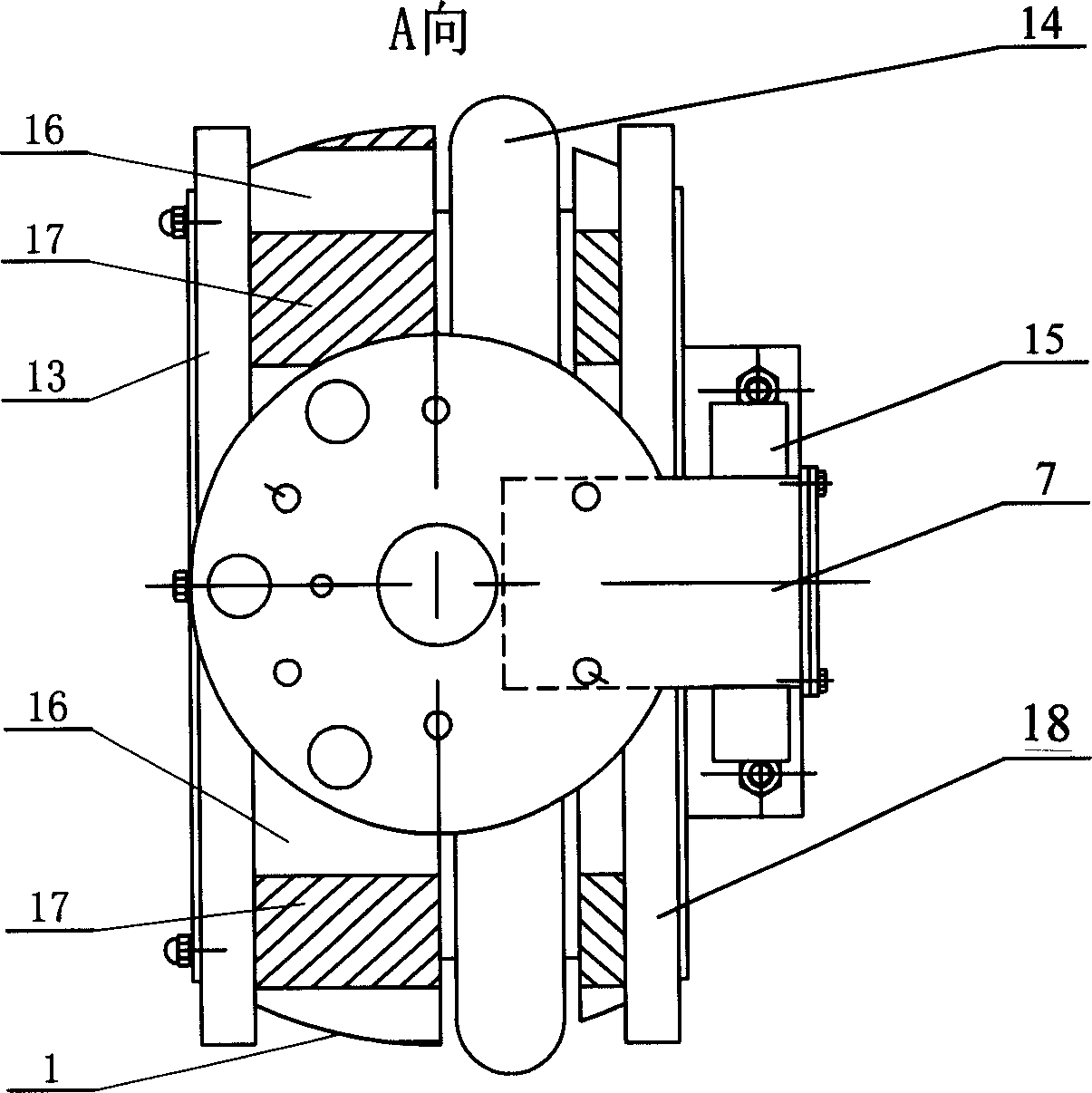

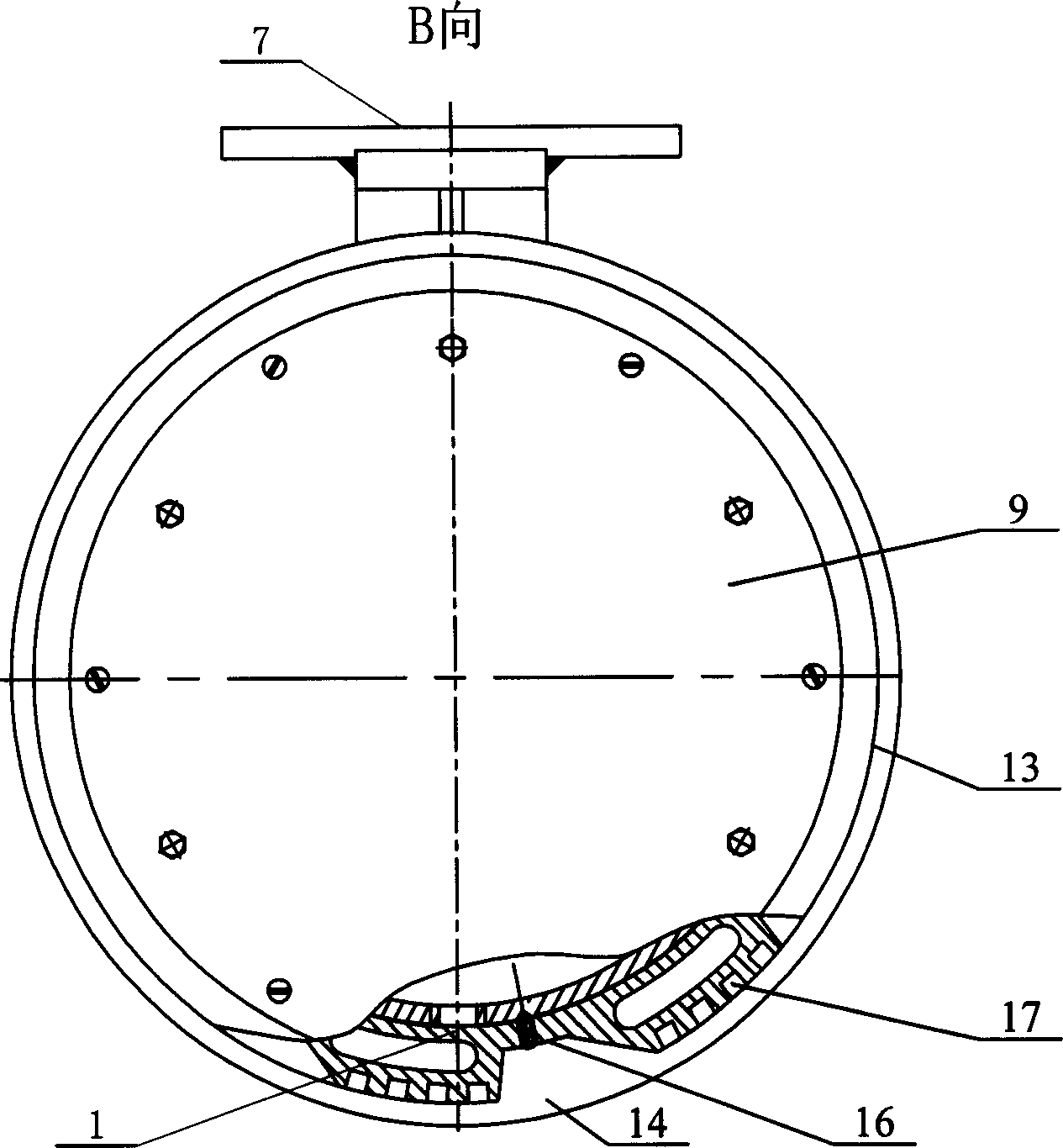

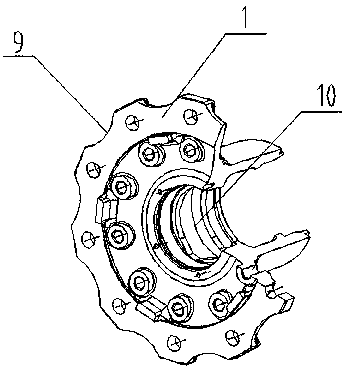

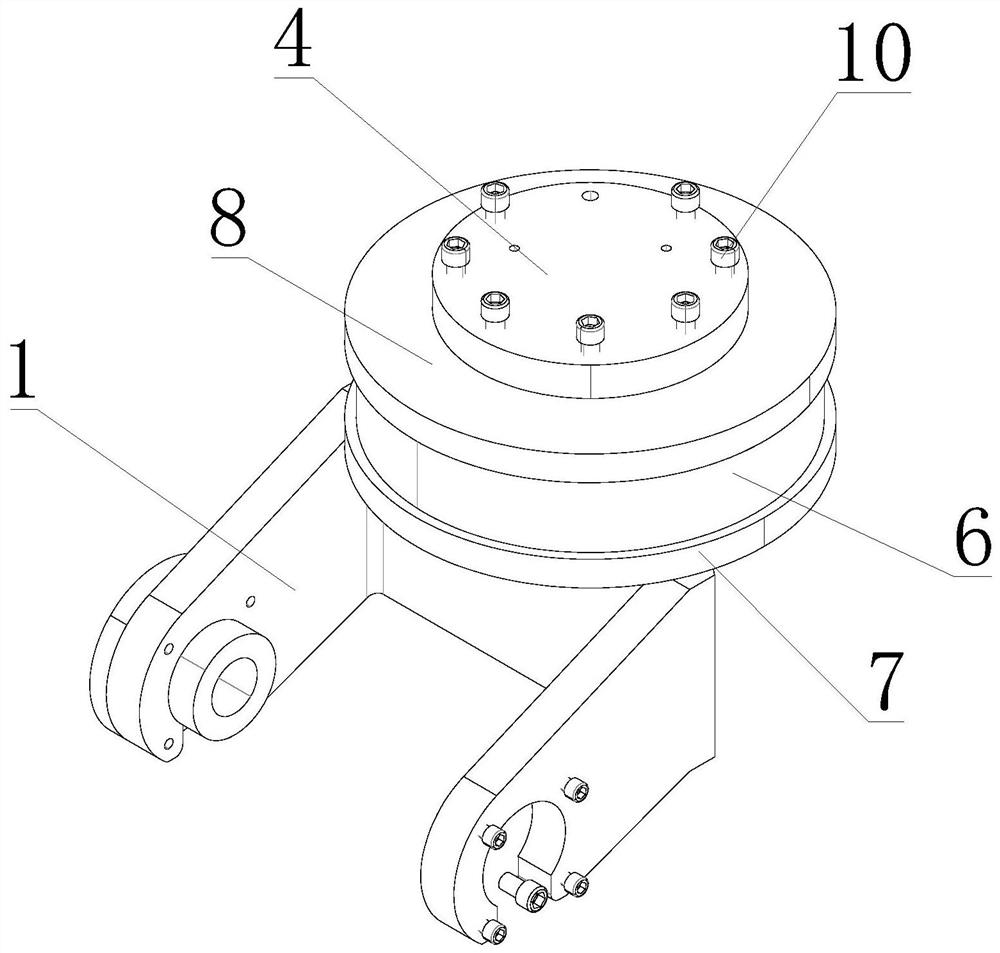

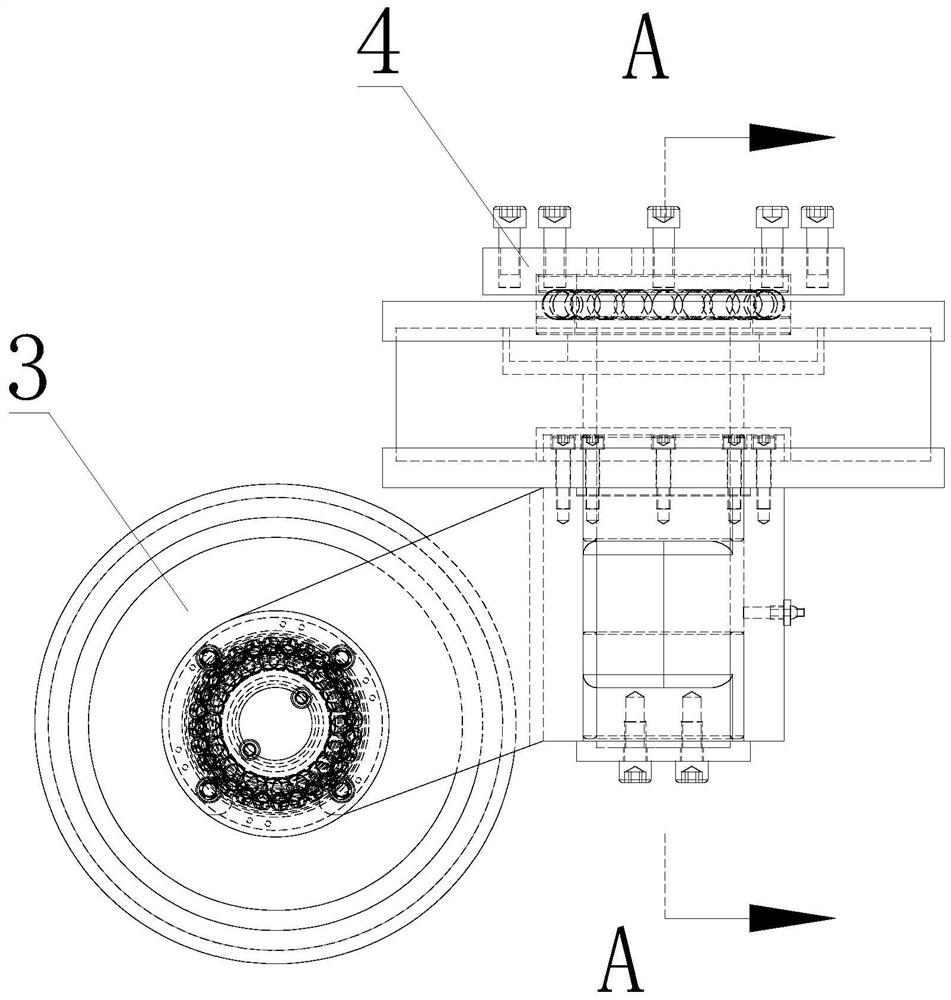

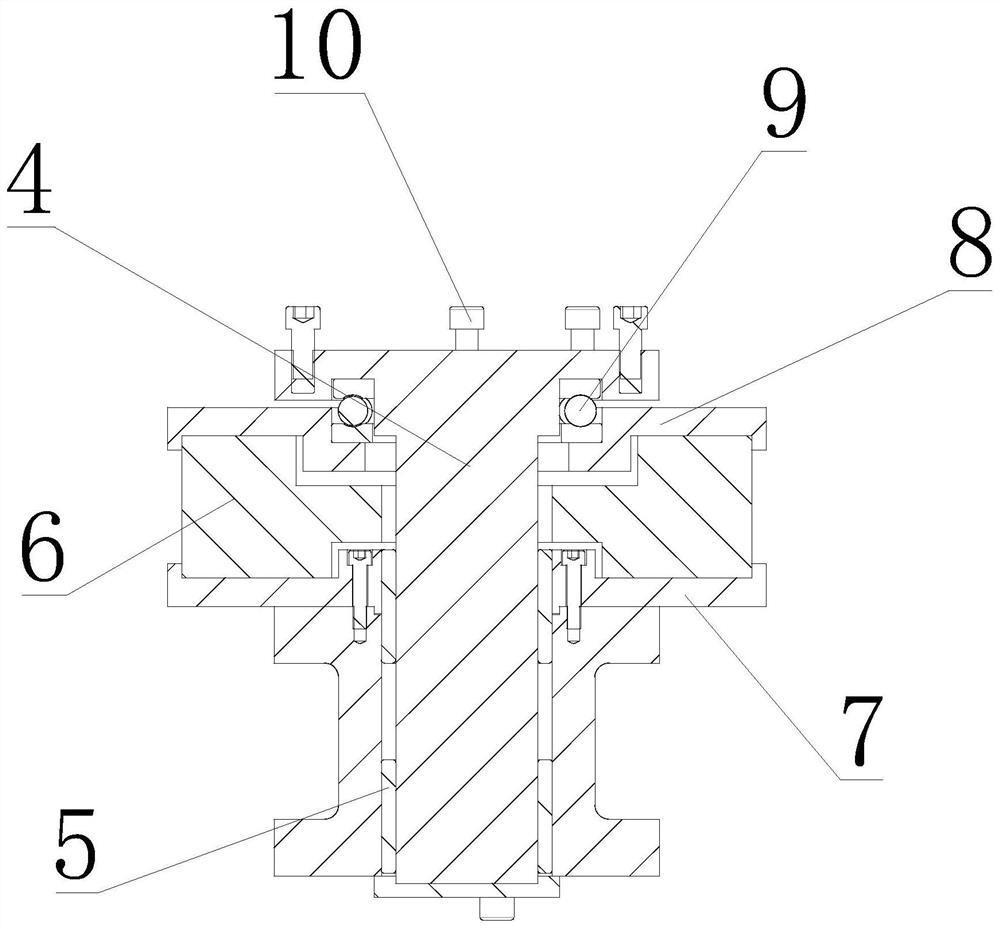

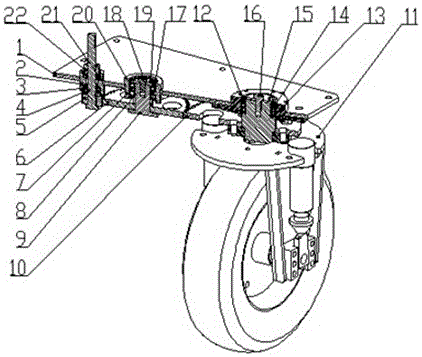

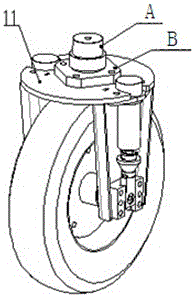

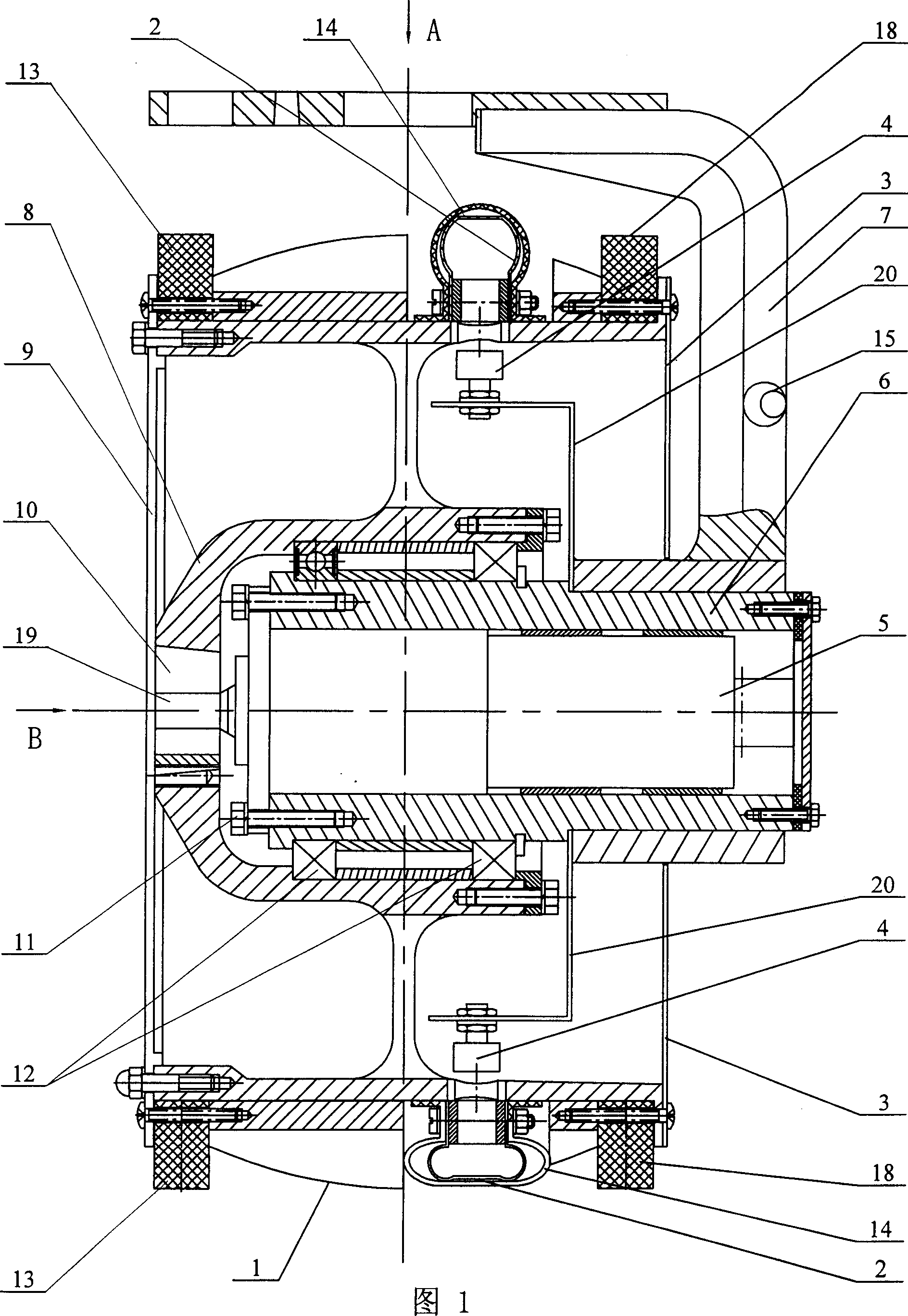

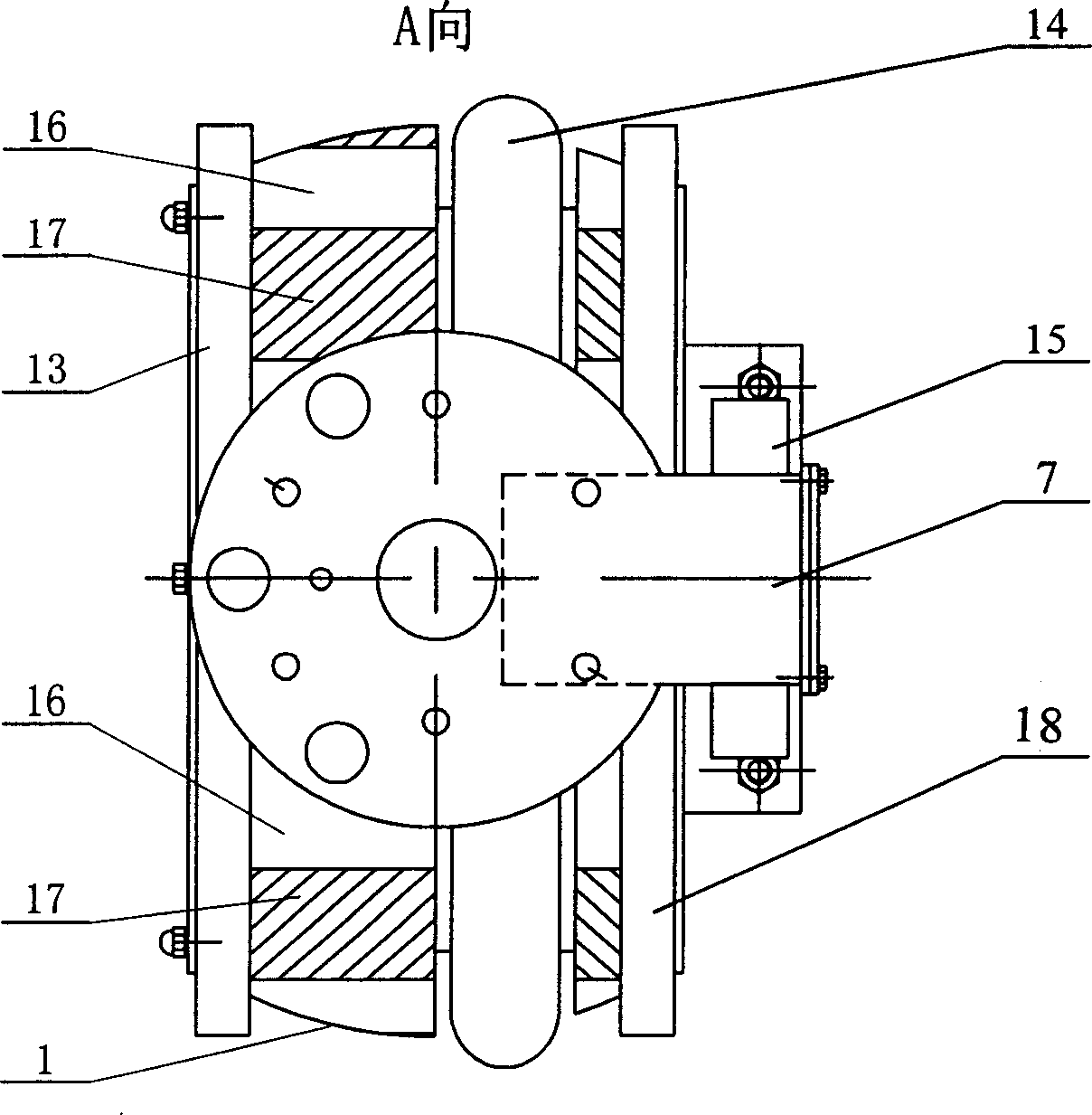

Double-wheel steering driving wheel

ActiveCN111152837ASmall turning radiusImprove carrying capacityMotor depositionElectrical steeringSupporting systemDrive wheel

The utility model relates to a double-wheel steering driving wheel, and belongs to a driving wheel for an electric loading vehicle, and the double-wheel steering driving wheel comprises a steering rotating support system and a walking system, the steering rotating supporting system comprises an internal tooth rotating supporting device, a rotating supporting mounting plate 200, a steering wheel steering driving device, a driving wheel steering encoder device, a connecting piece and a fastening piece. The walking system comprises a rotating support mounting plate, a steering wheel walking powerdriving device, a steering wheel walking power driving transition device, a third-stage transmission shaft device, a floating coupling power transmission device, a walking driving fourth-stage transmission shaft device, a walking power differential output device, a swing balance support assembly, a driving wheel walking position encoder device, a neutral gear clutch device, a rubber wheel, a built-in planetary reducer hub, a connecting piece and a fastening piece. The double-wheel steering driving wheel is suitable for application occasions with heavy loads and severe environment road conditions, and is safe and reliable.

Owner:上海鸣界机电科技有限公司

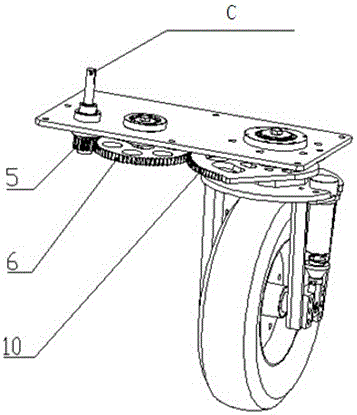

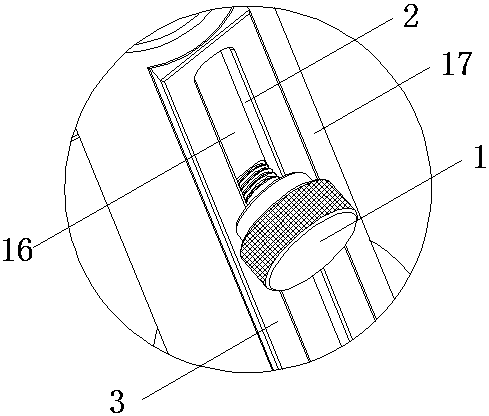

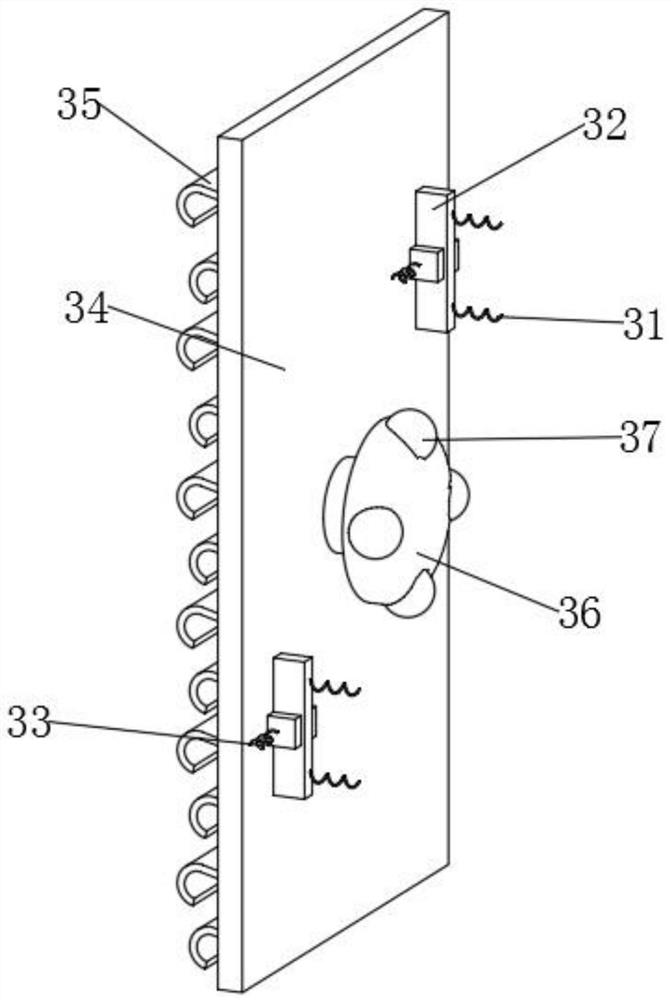

Steering wheel direction moving mechanism

ActiveCN104002910ALow steering resistanceEasy steeringSteering deviceMechanical steering gearsTurn angleOffset distance

The invention discloses a steering wheel direction moving mechanism. Synchronization opposite-direction transmission is carried out by meshing of three gears, then synchronization identical-direction transmission is carried out in a transition mode, and steering is achieved. A transition gear is arranged in the middle, so that offset distance transmission from input (an opposite-moving small gear) to output (a rotating disc) is achieved, and the purpose of offset steering is achieved. The opposite-moving small gear, the transition gear and the rotating disc in the steering wheel direction moving mechanism are arranged on a direction component fixing plate. The opposite-moving small gear, the transition gear and a rotating disc gear are arranged on the same plane in a meshing-transmission mode for transmission, and three points at the mounting center are on the same straight line. The rotating disc is provided with a sector tooth face, and the two ends of the sector tooth face are provided with rotating angle limiting clamping positions for limiting the rotating angle quantity of the rotating disc respectively. The rotating disc is arranged on a main shaft of a front wheel fork frame component in a sleeved mode. Offset steering of a direction is achieved through meshing transmission of the three gears, and meshing transmission of the three gears is carried out from synchronization opposite-direction transmission to synchronization identical-direction transmission in a transition mode.

Owner:FOSHAN GEMEI CLEANING EQUIP

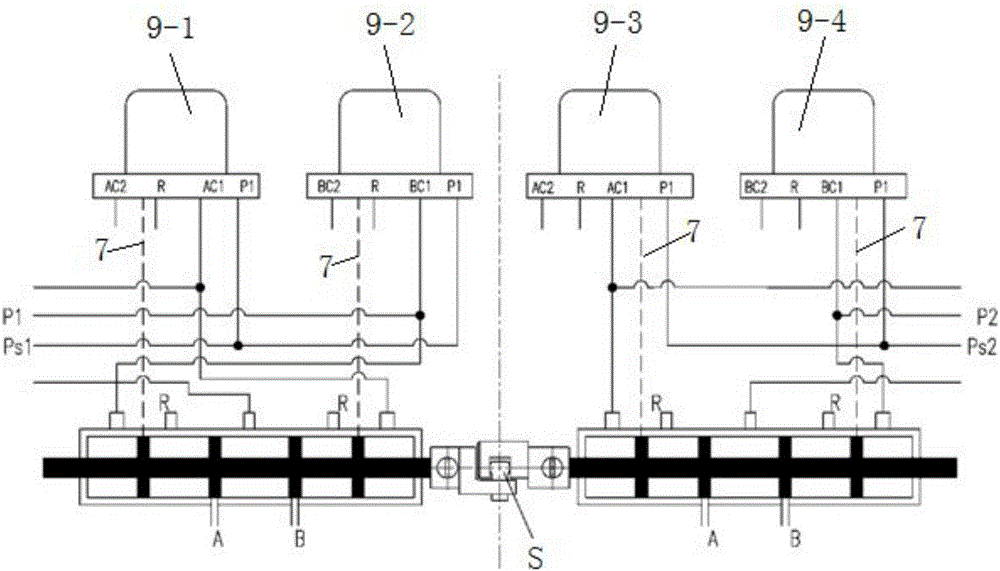

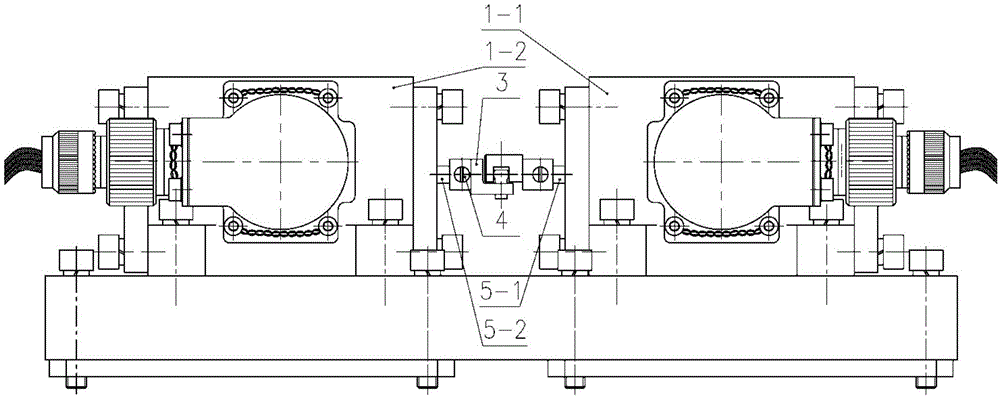

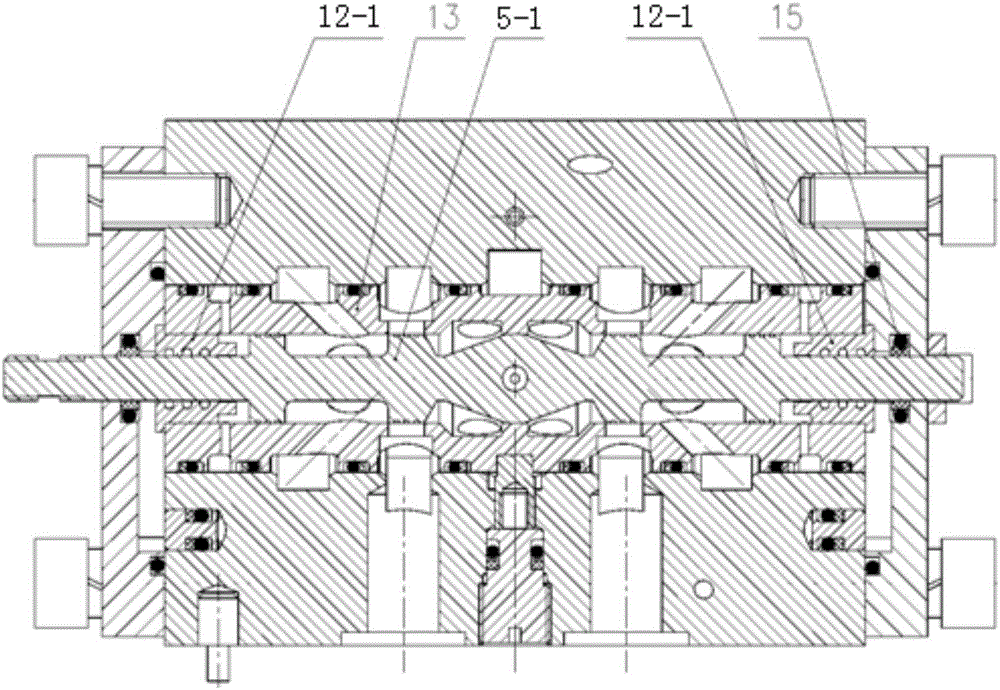

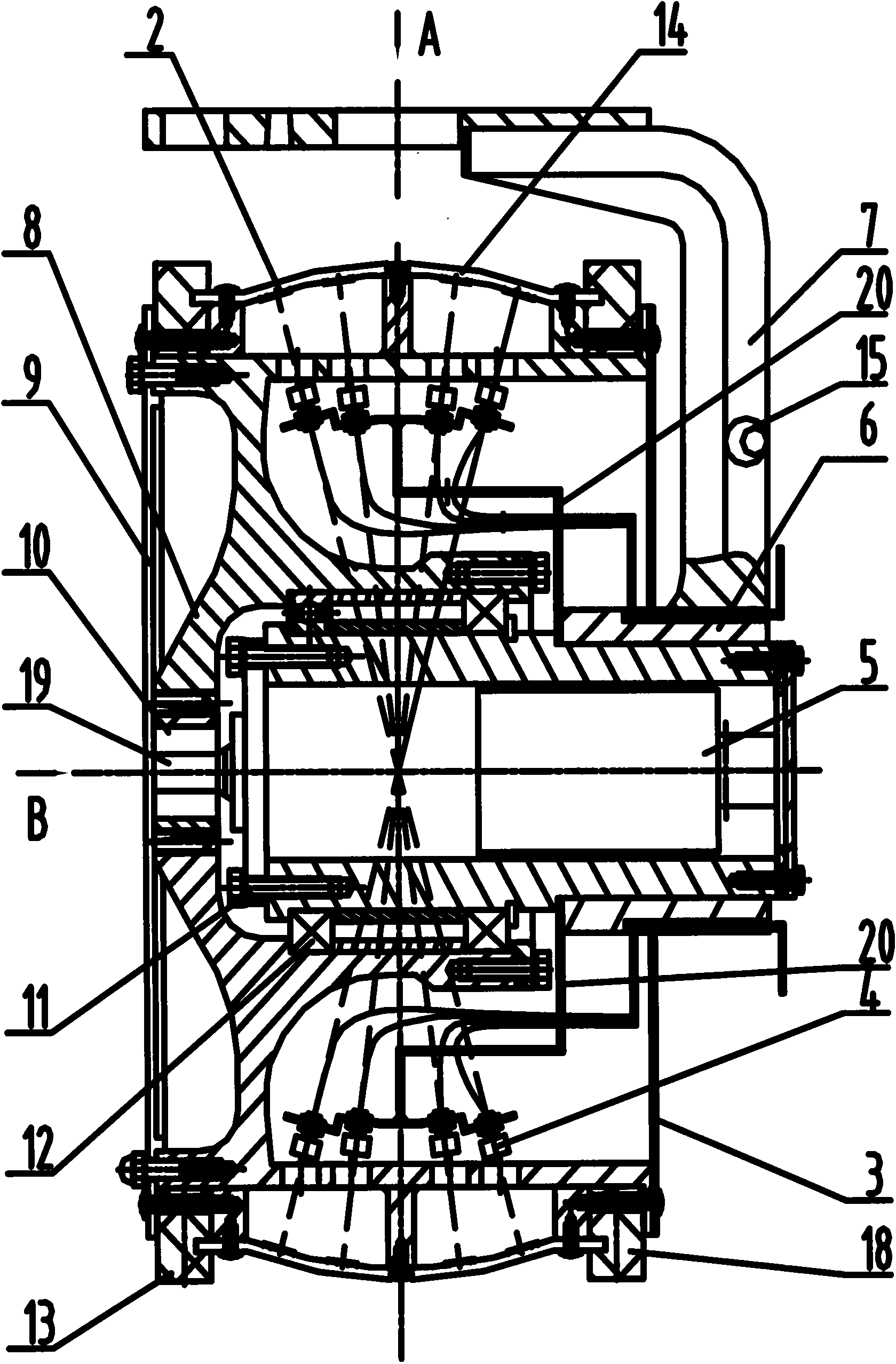

Double-main-control-valve integrated jet pipe servo valve

ActiveCN106762925AImprove reliabilityWith mechanical backup control capabilityServomotor componentsCouplingTorque motor

The invention relates to a double-main-control-valve integrated jet pipe servo valve. Two valve elements of two two-level servo valve bodies are connected through a coupling to form the integrated servo valve. Two pilot-level assemblies are symmetrically installed on the two-level servo valve bodies. Each pilot-level assembly is composed of a torque motor, a spray nozzle, a receiver and a feedback rod. Oil sources of the pilot-level assemblies of the two two-level servo valves are main standby oil sources which are mutually independent. Four fluid channels reserved in a valve body communicate with control pressure oil output by the two receivers in the two pilot-level assemblies. The feedback rods and the valve elements constitute a force feedback system. When the pressure values of the four fluid channels are unequal correspondingly, the electrical channel of the corresponding two-level servo valve body is isolated from a pilot-level hydraulic channel, an electrical channel of the two-level servo valve body in the normal state is made to communicate with the pilot-level hydraulic control oil channel. The double-main-control-valve integrated jet pipe servo valve is used as an important hydraulic control element in a redundancy high-performance actuation system and has the features of four electrical redundancies and two hydraulic redundancies and the mechanical backup capacity.

Owner:SHANGHAI HENGTUO HYDRAULIC CONTROL TECH

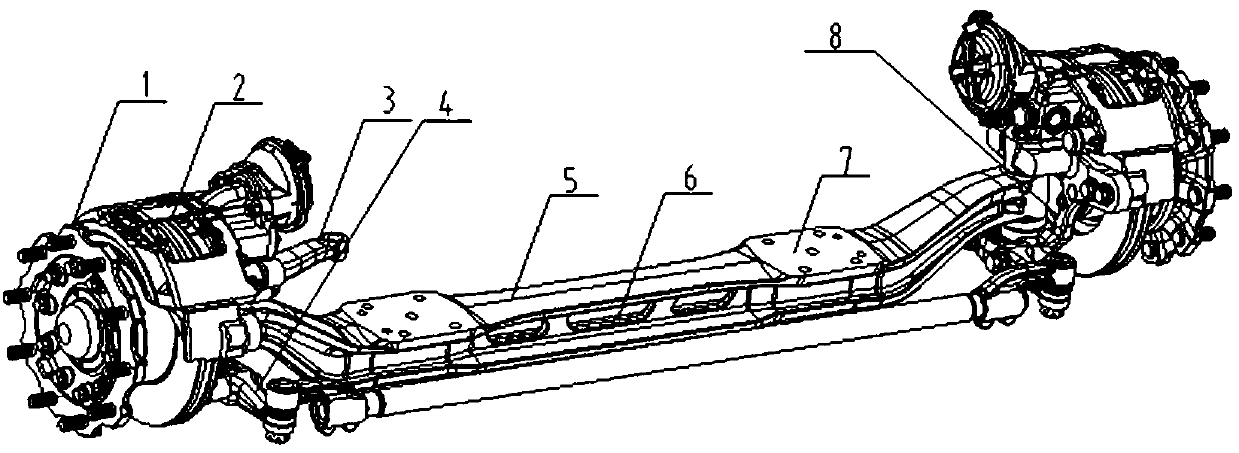

Front axle assembly and assembly method thereof

ActiveCN106515850AImprove reliabilityImprove stabilitySteering linkagesWheel manufactureNeedle roller bearingBiomedical engineering

The invention discloses a front axle assembly and an assembly method thereof. The front axle assembly comprises a front axle, a knuckle assembly and a main pin. The main pin of the front axle assembly adopts a structure of upper and lower needle bearings of unequal-diameter structures, the reliability and the stability of the front axle assembly can be obviously improved, the service life of the front axle assembly is obviously prolonged, steering resistance is reduced, the matching surfaces between the main pin and the needle bearings cannot be scratched during assembly and overhauling of the main pin, and a special tool is designed to facilitate assembly; and linings of the needle bearings adopt flanging structures and are assembled in the required direction, loosening of needles is prevented, the number of the assembly parts is decreased, the assembly technology is easy, and the structure is compact. The inner diameters of the upper and lower needle bearings used for the main pin are unequal, the diameter difference is smaller than half of the diameter of each needle bearing, the linings of the upper and lower needle bearings adopt the unilateral flanging structures, the flanging direction is toward the direction that the inner diameters of the needle bearings are decreased, and the two linings of the upper and lower needle bearings are pressed in in the same direction during pressing.

Owner:SINO TRUK JINAN POWER

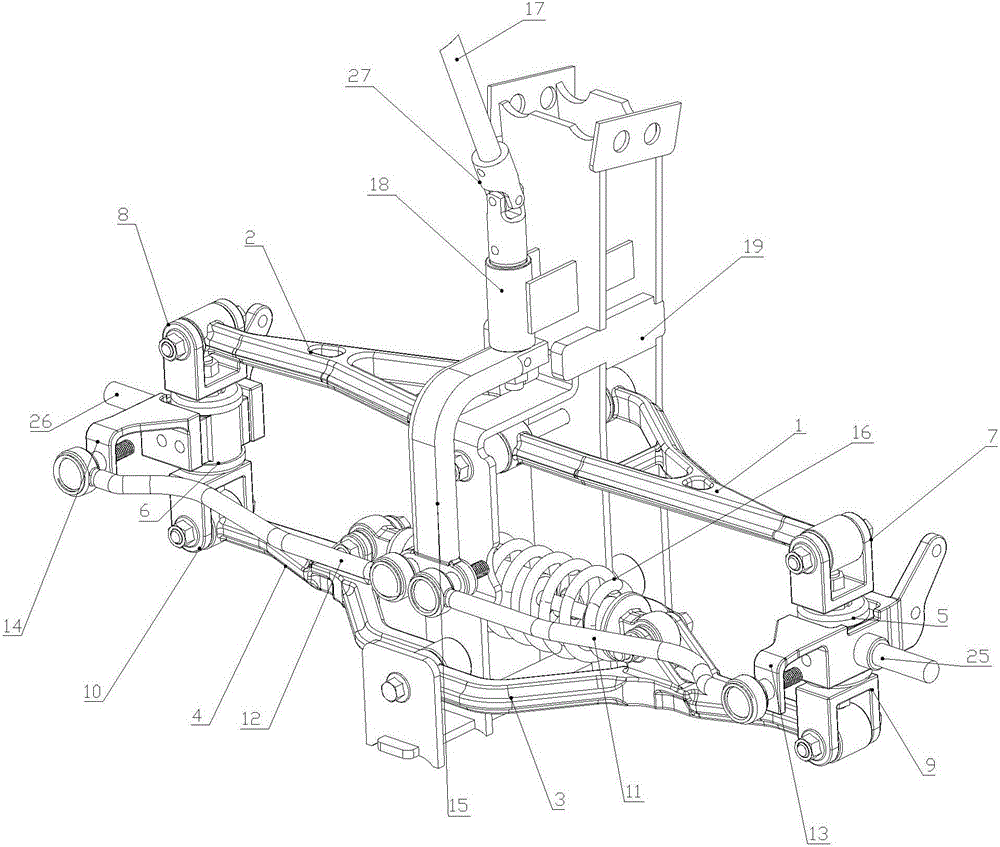

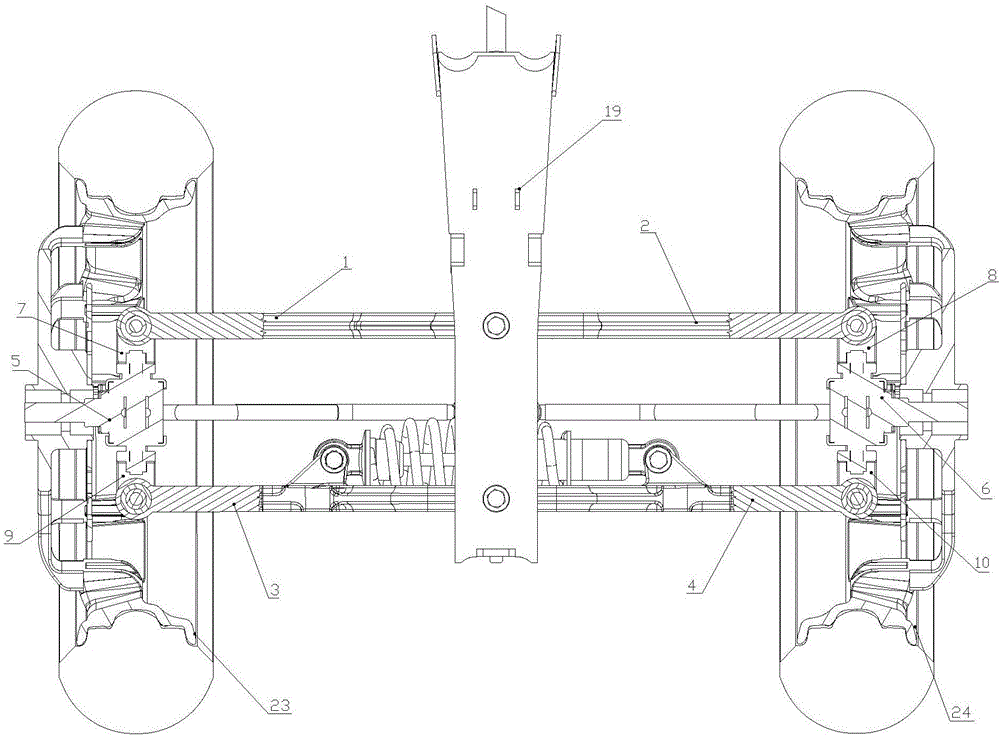

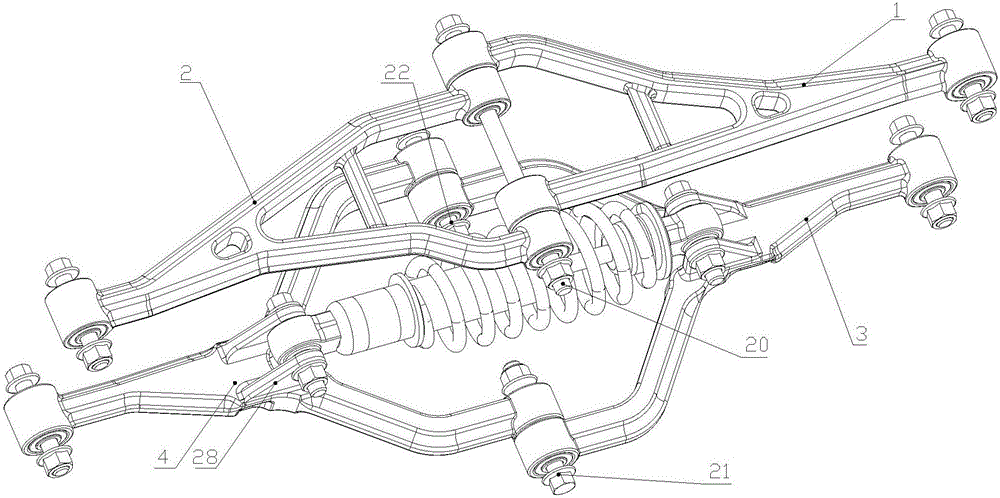

Front suspension deflection mechanism for reverse tricycle

InactiveCN106585830ALow steering resistanceImprove steering flexibilitySteering linkagesAxle suspensionsSteering angleCantilever

The invention relates to the technical field of vehicle suspensions, in particular to a front suspension deflection mechanism for a reverse tricycle. Steering pull rods are not coaxially arranged. A parallelogram structure is formed among the steering pull rods, an upper arm of a suspension and a lower arm of the suspension. The steering angle error of a left wheel and a right wheel in the steering process and the tricycle toe-in change in the cantilever swinging process are effectively reduced, the tricycle running and operation stability is improved, the wear rate of the left wheel and the right wheel is reduced, and the use reliability is greatly improved.

Owner:ZONGSHEN NO 2 LOCOMOTIVE CO LTD CHONGQING

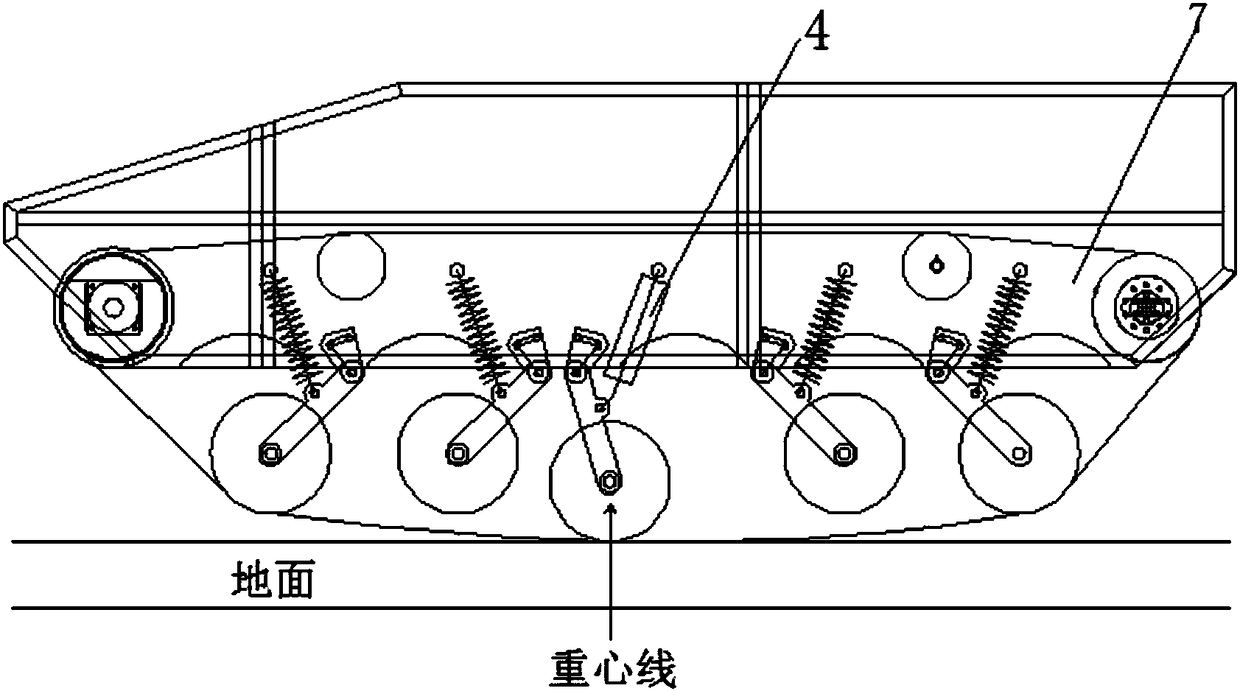

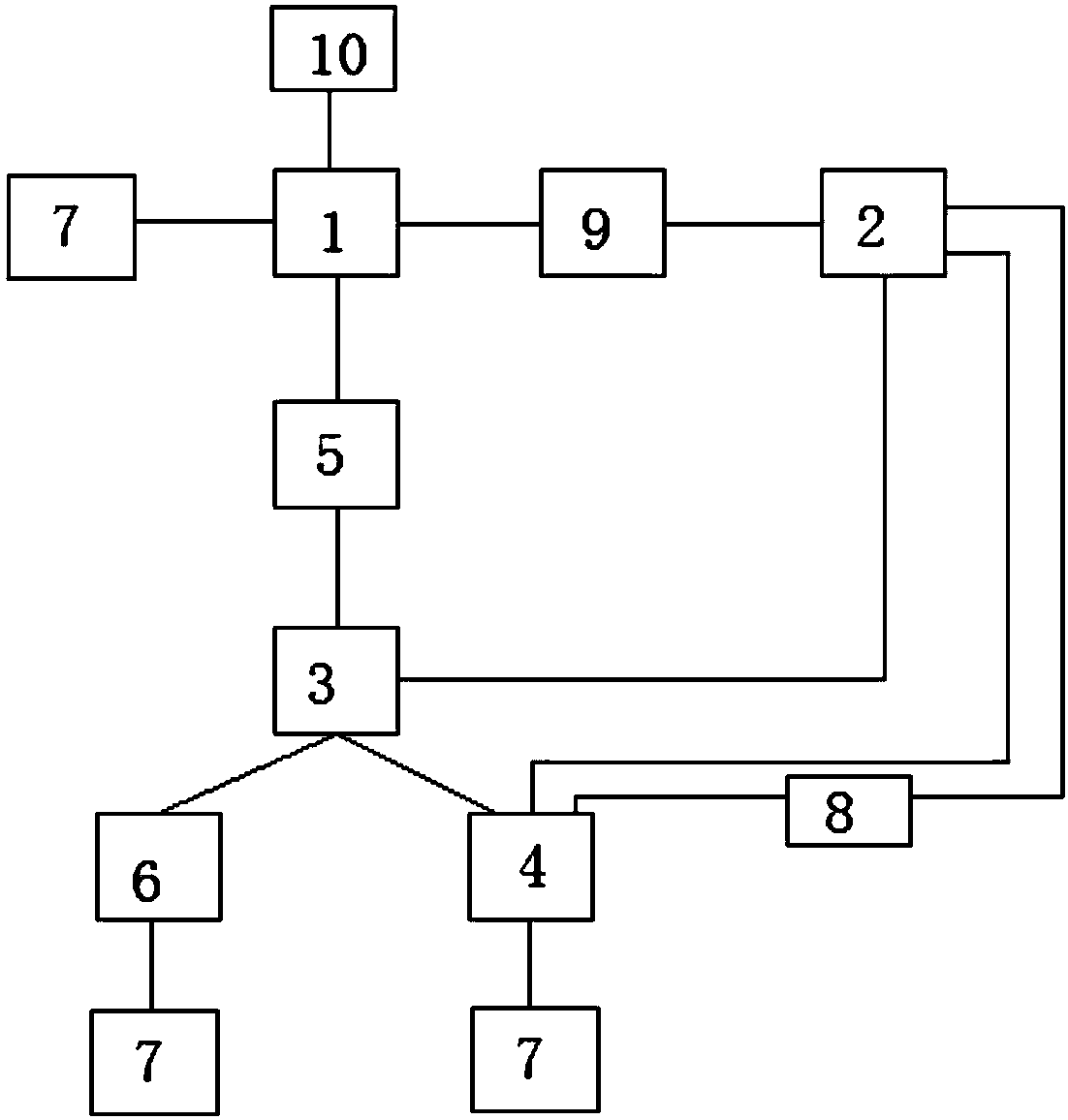

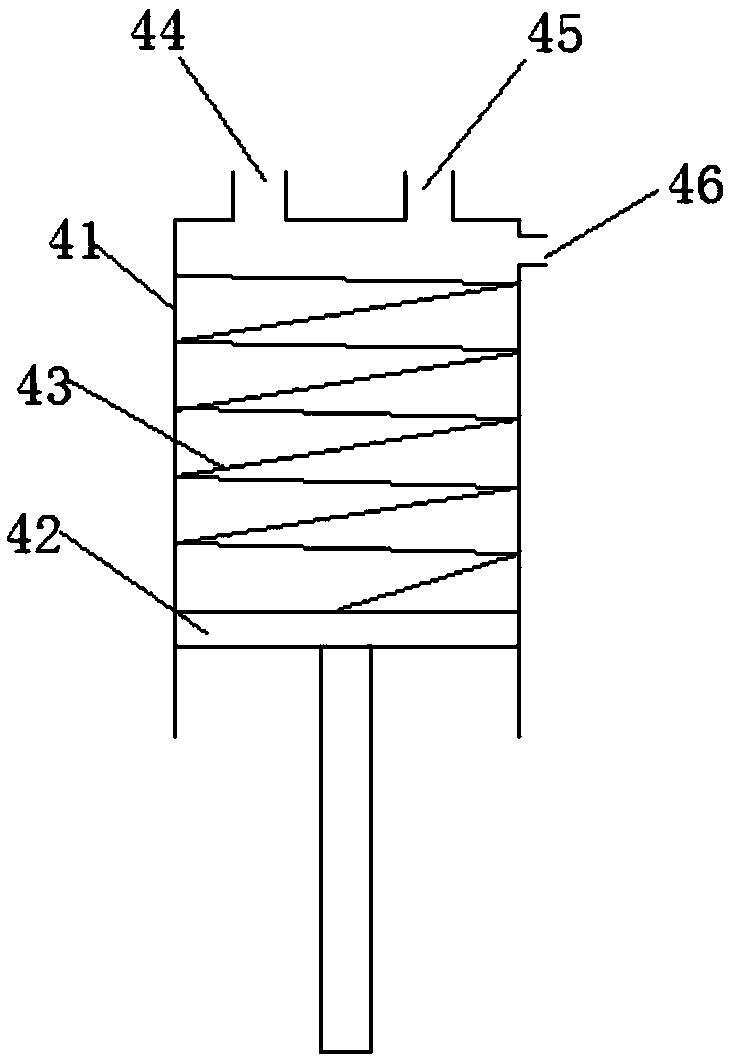

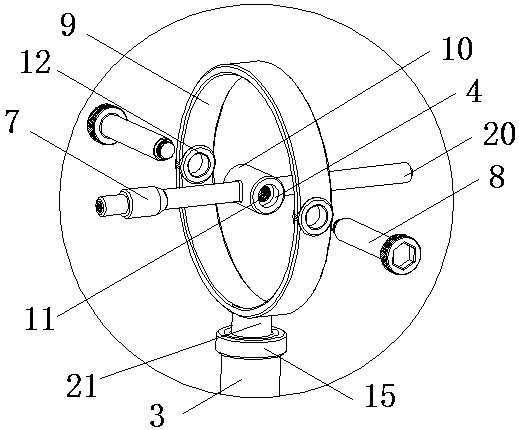

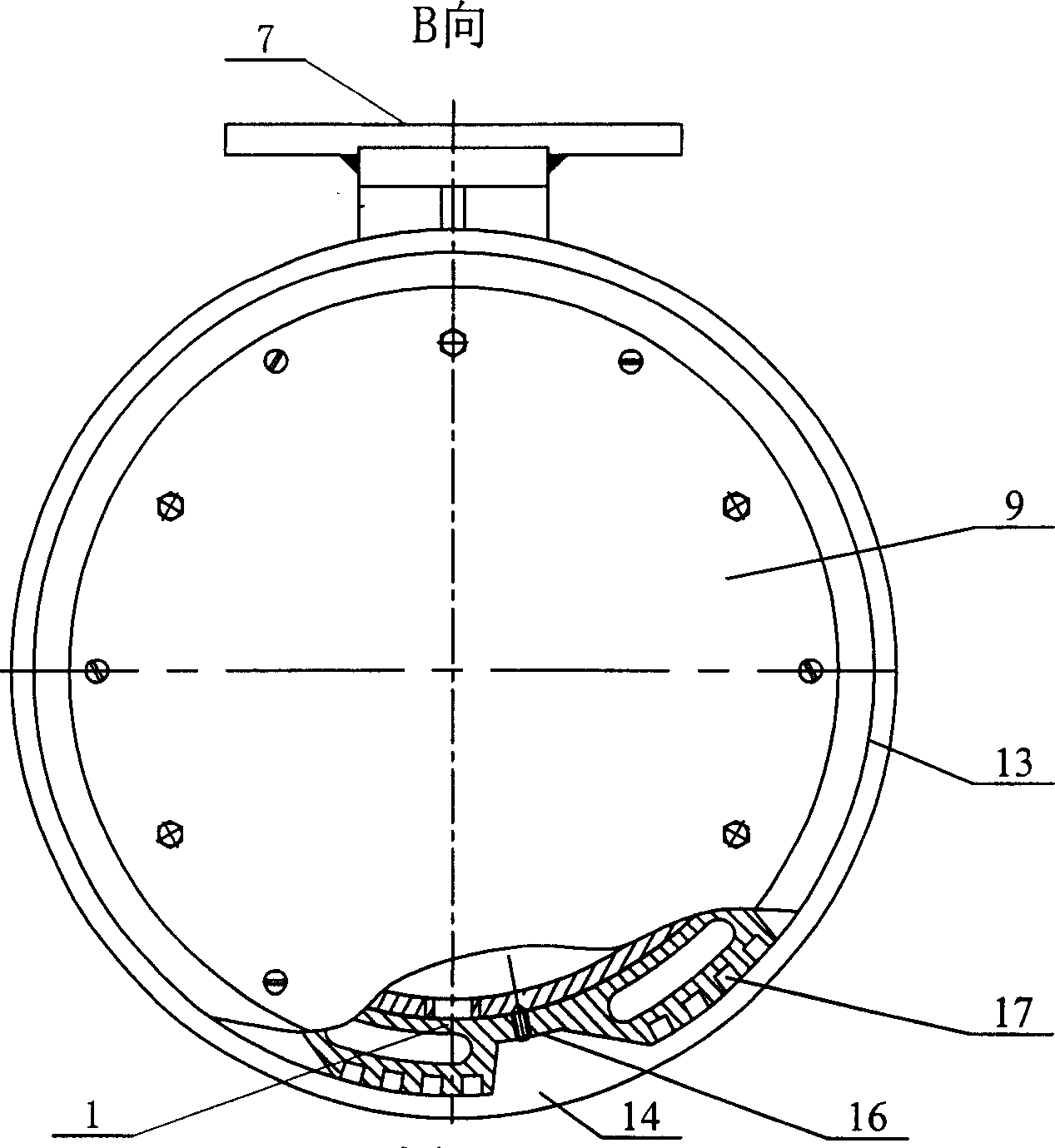

Steering auxiliary device for reducing caterpillar band steering resistance

PendingCN108177691AReduce weightReduced footprintEndless track vehiclesNon-deflectable wheel steeringAutomotive engineeringPower unit

The invention discloses a steering auxiliary device for reducing the caterpillar band steering resistance. The steering auxiliary device comprises a device body and a telescopic supporting rod matchedwith the device body; the device body is connected to a vehicle body, and the end portion of the telescopic supporting rod is connected to a supporting wheel swing arm. The steering auxiliary devicehas the beneficial effects that the arrangement number of power units is correspondingly reduced, and the weight of a vehicle body structure is reduced; and the gravity center of the vehicle body is found, the vehicle body is supported with the gravity center line as a fulcrum, the landing area of the vehicle body is reduced, and the caterpillar band steering resistance is reduced.

Owner:周韵

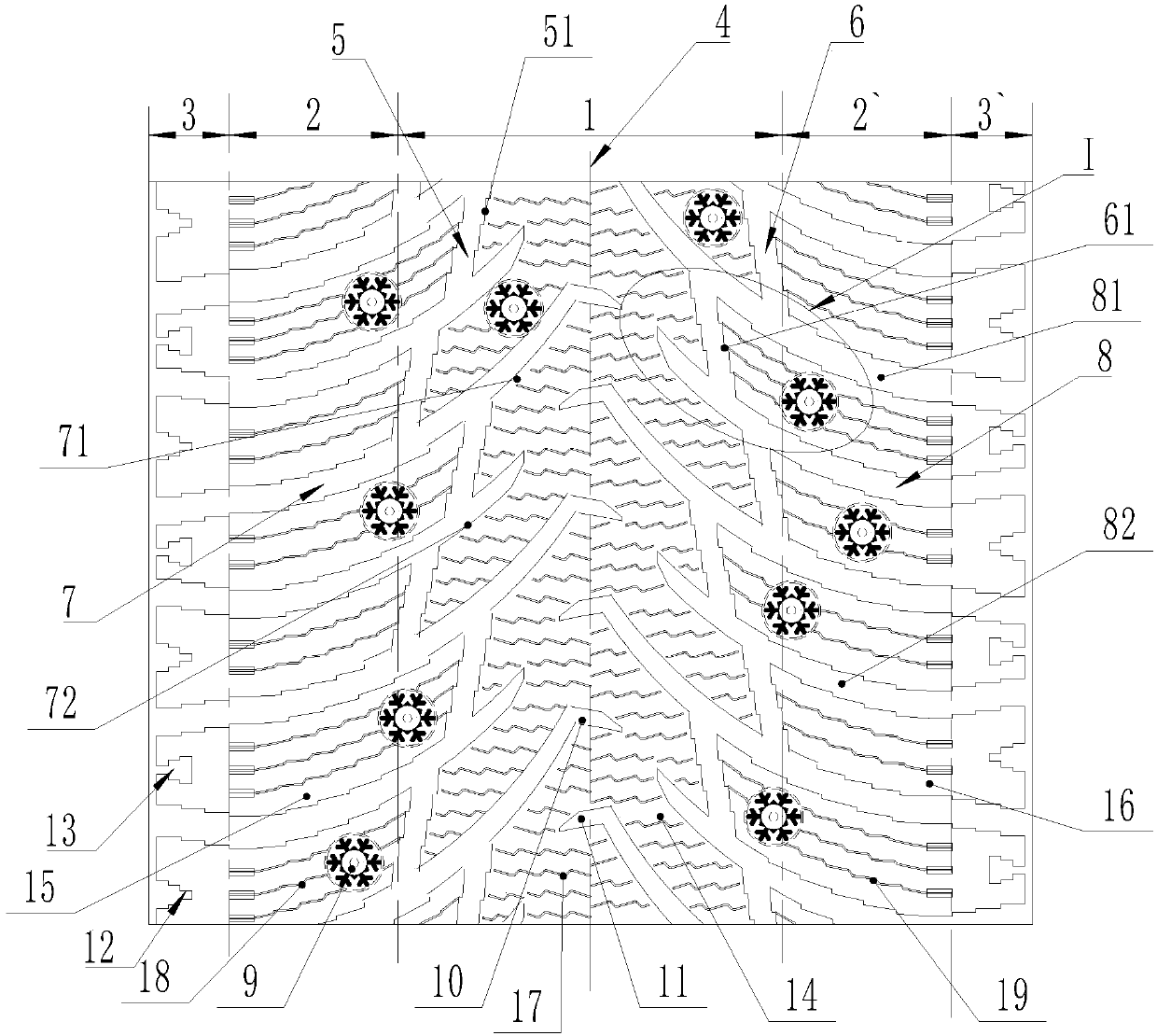

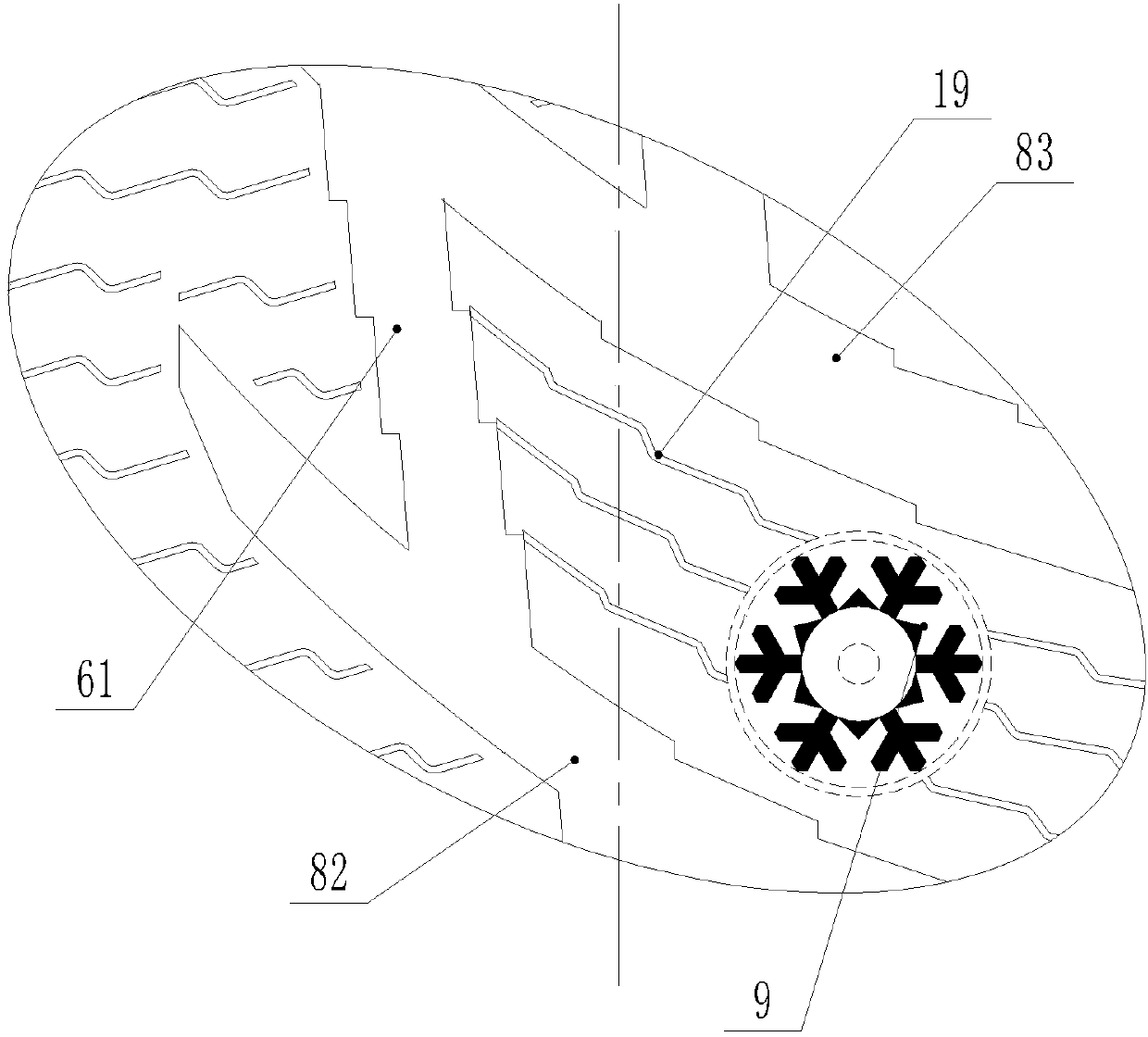

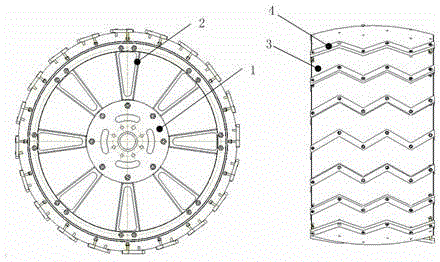

Pattern of snow tire

PendingCN107813662ASensitive contact forceUniform contact forceTyre tread bands/patternsBrakeStructural engineering

The invention discloses a pattern of a snow tire. The pattern comprises a tire crown pattern zone, a first tire shoulder pattern zone, a second tire shoulder pattern zone, a first tire sidewall pattern zone and a second tire sidewall pattern zone, wherein the tire crown pattern zone comprises first straight furrows, second straight furrows, first transverse furrows and second transverse furrows; each first straight furrow comprises a plurality of first straight furrow sections which are discrete; each second straight furrow comprises a plurality of second straight furrow sections which are discrete; circumferential and continuous tire crown pattern blocks are formed between the first straight furrows and the second furrows; the furrow walls of the first straight furrows and the second straight furrows are both set in sawtooth shapes; the first transverse furrows are located on the furrow walls of the outer sides of the first straight furrows and are set in sawtooth shapes; the second transverse furrows are located on the furrow walls of the outer sides of the second straight furrows and are set in the sawtooth shapes; snow nail installing holes are formed in the tire crown patternblocks, the first tire shoulder pattern zone and the second tire shoulder pattern zone. The pattern disclosed by the invention is capable of increasing the stability of straight movement and the sensitivity of steering, and the brake performance in snow is increased.

Owner:南港(张家港保税区)橡胶工业有限公司

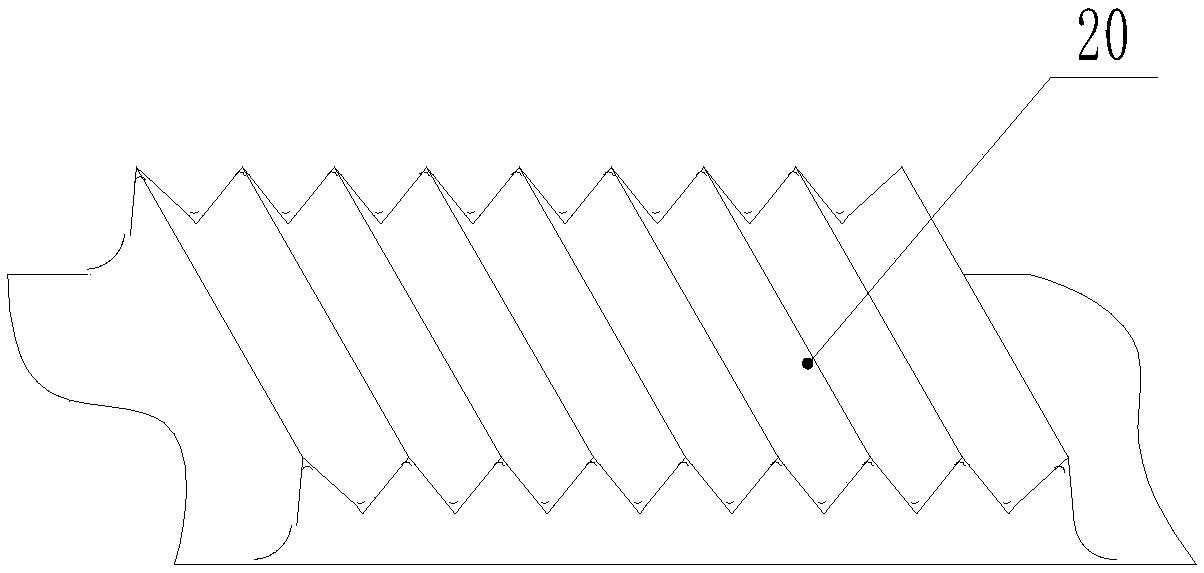

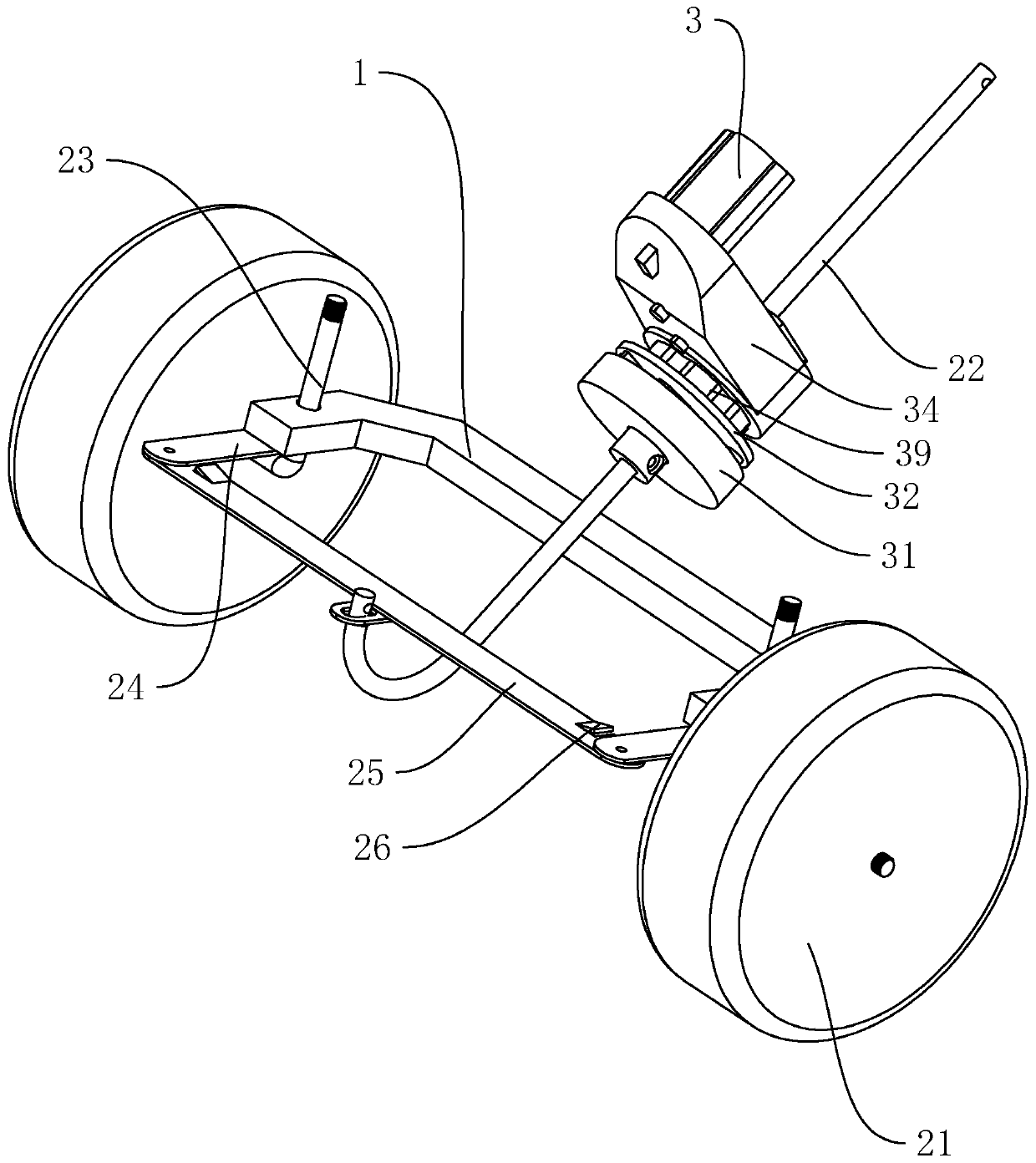

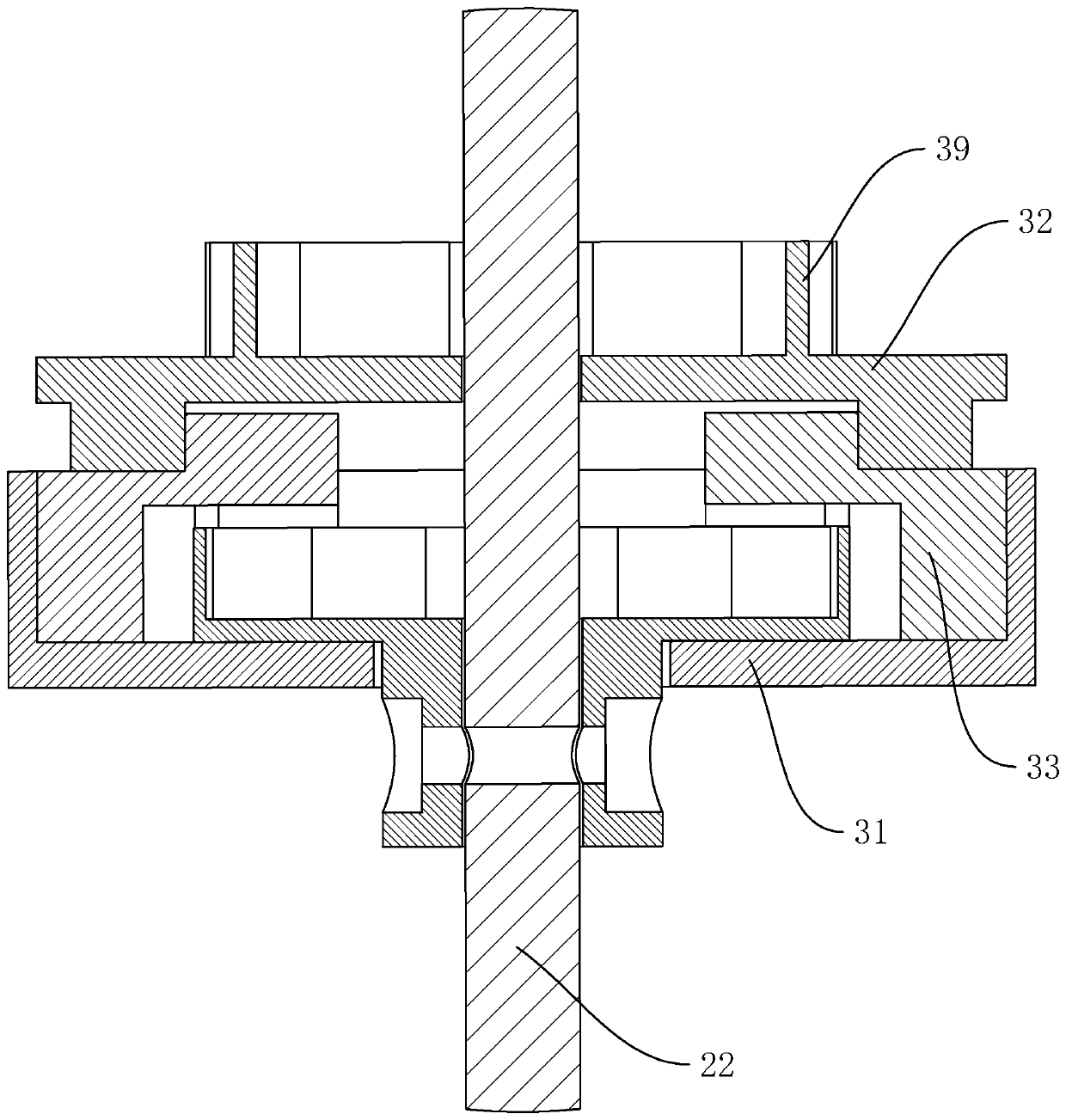

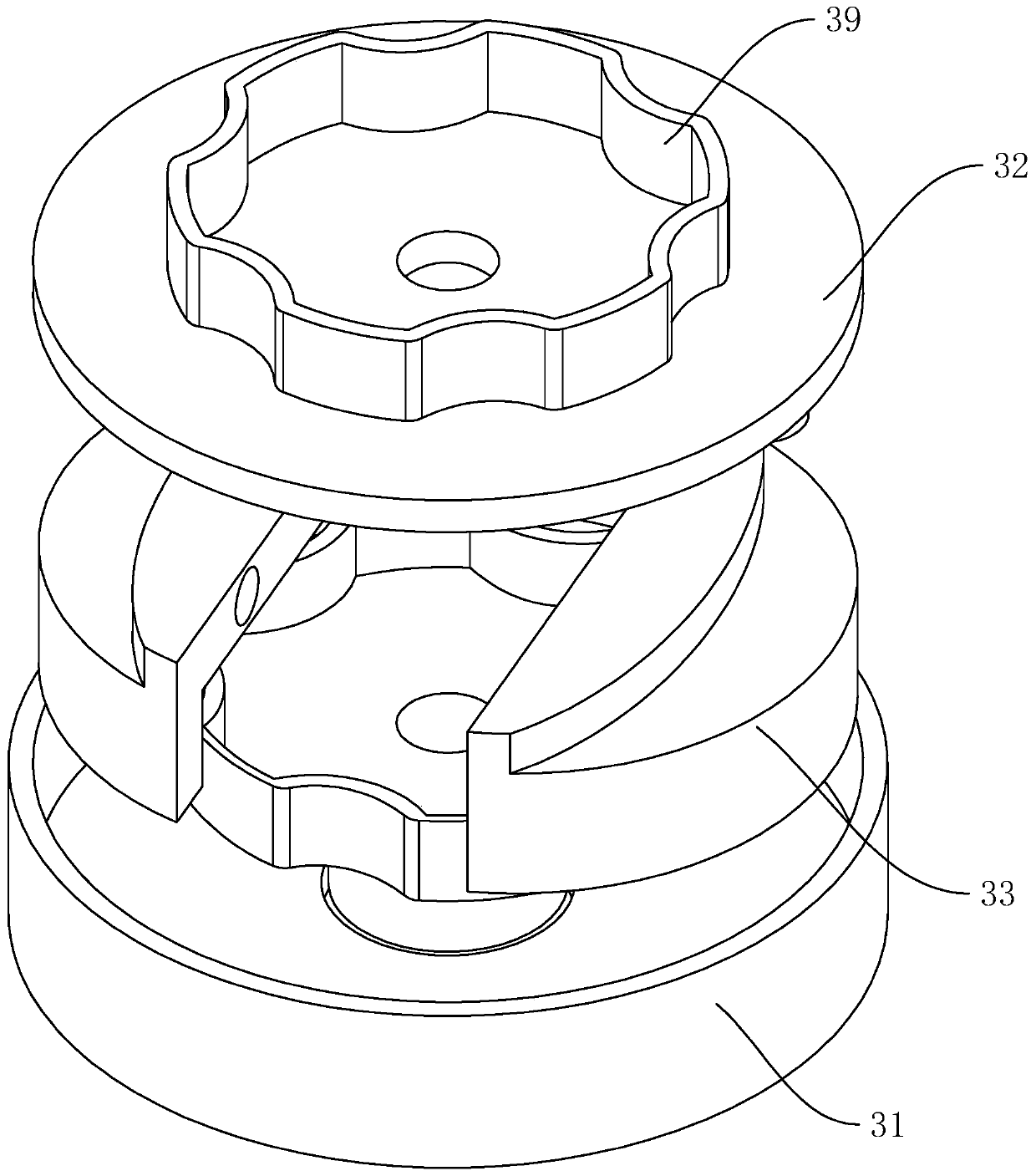

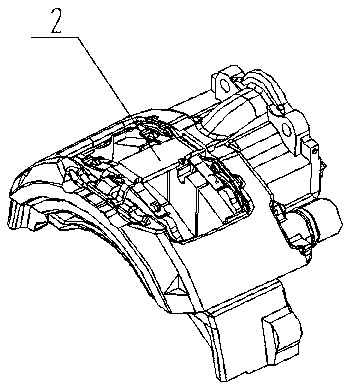

Tractor dual-purpose paddy wheel

The invention provides a traveling device of a tractor, in particular to a paddy wheel which is made of metal. The paddy wheel can produce the friction in a paddy field to be consistent with that on a hard pavement, so that the tractor can obtain the traction force in the paddy field which is consistent with that on the hard pavement; and moreover the tractor dual-purpose paddy wheel is convenient to operate and small in steering resistance. The tractor dual-purpose paddy wheel is applicable to the traveling machinery which moves on the paddy field or on the hard pavement and on the pavement falling in between the paddy field and the hard pavement.

Owner:骆宗涛

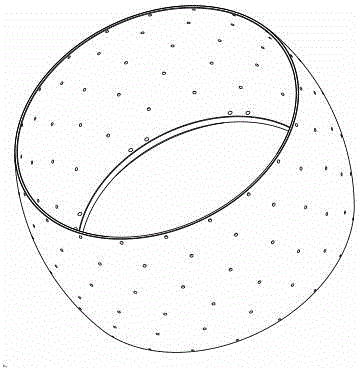

Wheel suitable for terrain environment of Mars

The invention discloses a wheel suitable for the terrain environment of the Mars. The wheel comprises a wheel body, a wheel driving joint, spokes, a driving mechanism, a hub, and pawls, wherein the wheel driving joint enables the wheel body and the driving mechanism to be connected, and connection joints connecting the spokes and connecting the driving mechanism are respectively designed; the wheel driving joint is connected with the spokes through screws and nuts; the spokes are rigid spokes and are mounted on one side of the wheel; the driving mechanism is arranged at the inner part of the hub; the spokes are connected with the hub through screws and nuts; the pawls are connected with the hub through screws and nuts. The wheel is beautiful in structural appearance, easy in machining, compact in structure, high in passability on the surface of the Mars and high in strength, can bear the weight of a Mars patrolling device, and can bear certain torque.

Owner:SHANGHAI AEROSPACE SYST ENG INST

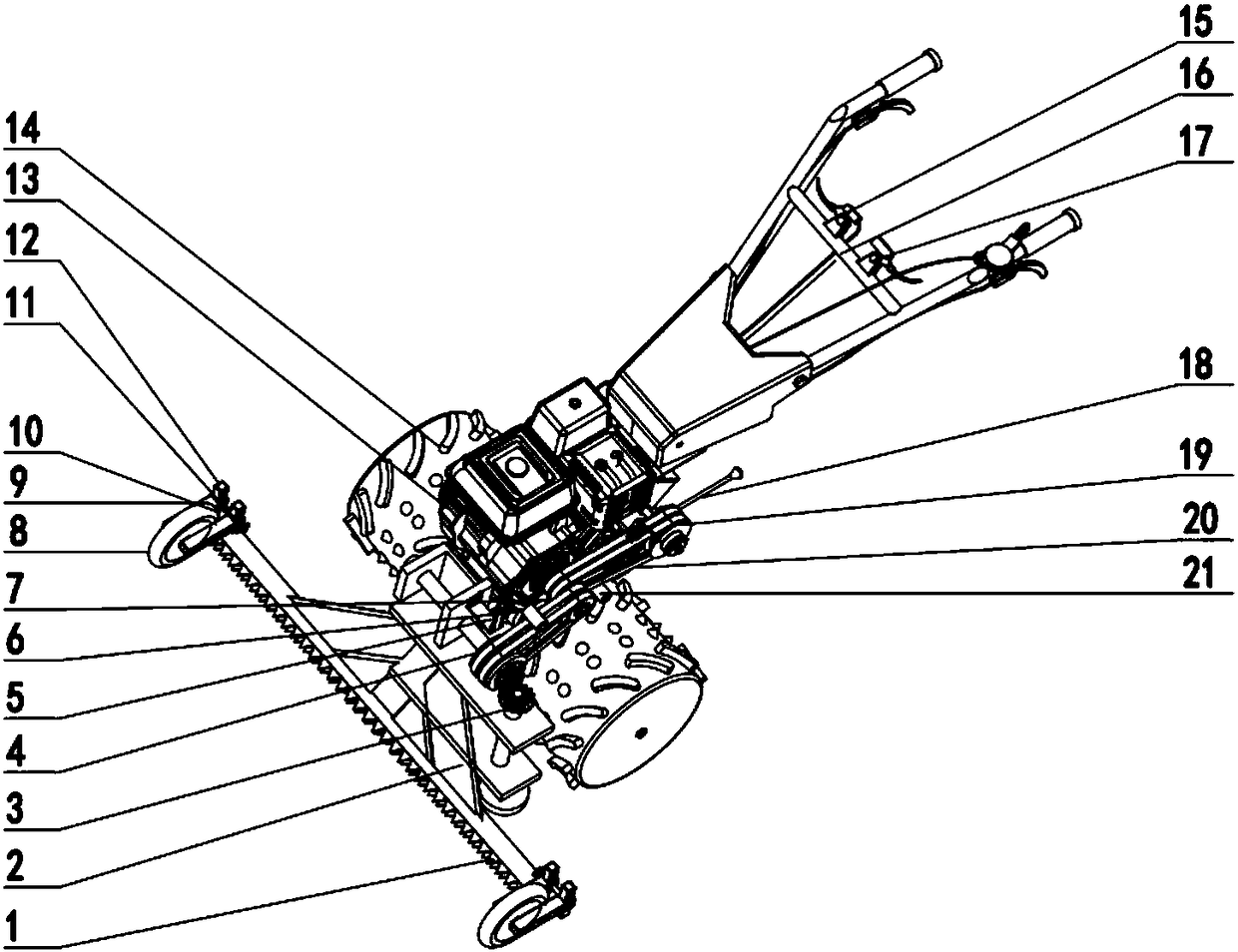

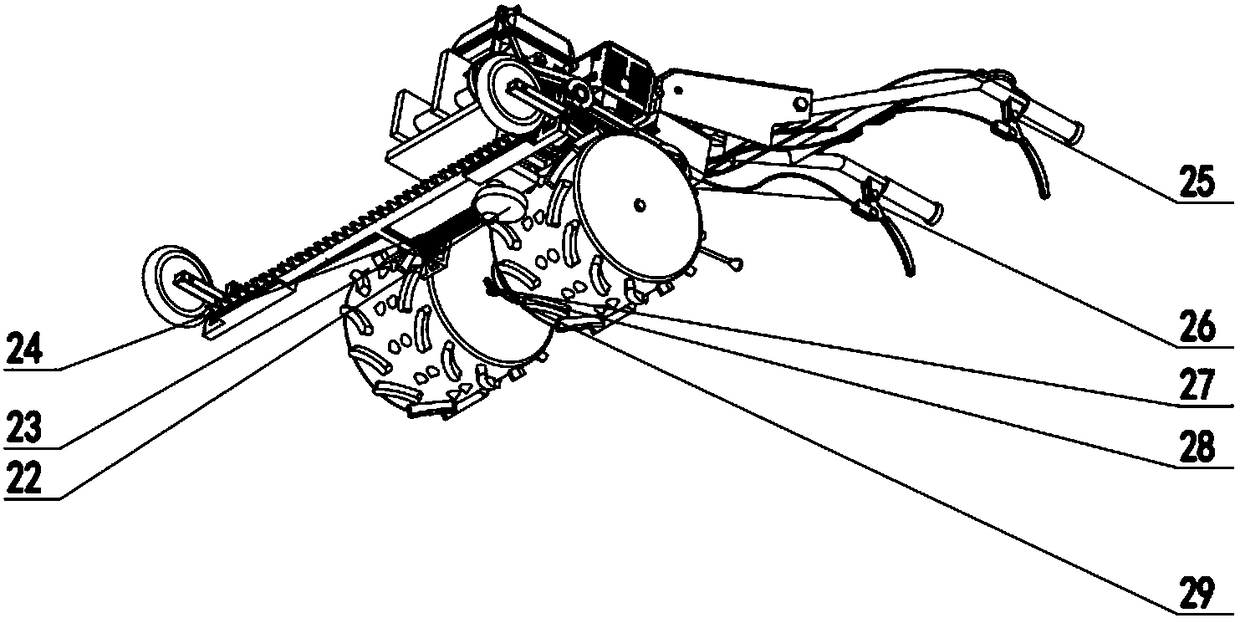

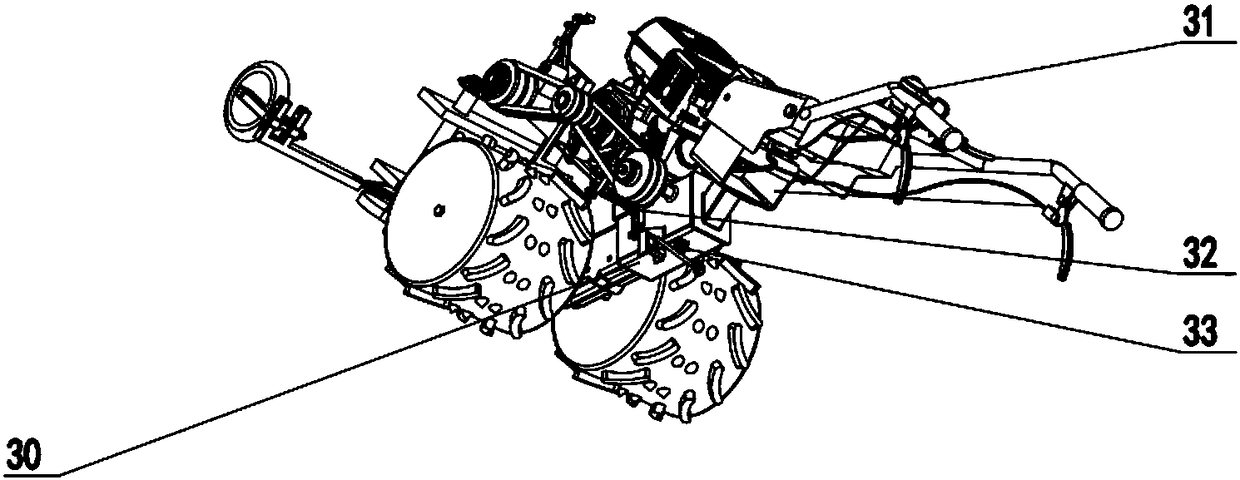

Multi-terrain mowing machine

The invention belongs to the field of agricultural machinery and particularly relates to a multi-terrain mowing machine. The multi-terrain mowing machine is suitable for weed elimination at hills, mountains and flat grounds; power is provided by a gasoline engine; the operating mode is to work by manually operating the multi-terrain mowing machine; and the multi-terrain mowing machine has the characteristic of high efficiency and can greatly reduce the labor intensity of workers. The multi-terrain mowing machine can prevent slideslip, can realize differential speed during steering, can adjustthe remaining height of grass roots after cutting, can independently cut off weeds by cutting power and walking power, and can reduce the working strength of workers.

Owner:CHINA AGRI UNIV

Steering control system and baby carrier applying same

PendingCN110435802ALow steering resistanceLow steering torqueSteering deviceMechanical steering gearsClutchControl system

The invention discloses a steering control system and a baby carrier applying the same, relates to the baby carrier and aims at solving a problem that the steering torque is too large when a child controls the steering of the baby carrier. According to the technical scheme, the steering control system comprises a steering axle, a steering mechanism, a steering front wheel and a steering motor, wherein a clutch mechanism is arranged between the steering motor and the steering mechanism; the steering mechanism comprises a J-shaped steering rod; the clutch mechanism comprises a speed reducer, a force bearing disc, a force applying disc and meshing valves; the speed reducer is connected to the steering motor; the force bearing disc is coaxially fixed on the J-shaped steering rod; the force applying disc is connected to the speed reducer; and the meshing valves are arranged between the force applying disc and the force bearing disc. According to the steering control system, the steering torque is effectively reduced on the premise that the manual and electric steering control modes are rapidly switched, and a problem that a steering wheel is not prone to rotate due to small force of thechild is avoided, so that the use experience is improved.

Owner:ZHEJIANG JIAJIA RIDE ON +1

Perception type reconfigurable bionic sand wheel for moving navigational platform

The present invention relates to the improvement of wheel structure for mobile navigation platform. In the perceptive bionic sands wheel capable of being reconfigured for mobile navigation platform, there are outside elastic rim board fixed outside the hub camber, inside elastic rim board fixed inside the hub camber, elastic tyre set inside the central line of the rim capable of being reconfigured, perception sensor reflecting devices set in the equal interval inside the elastic tyre, and perception sensor sending devices set in the equal interval on the rack camber. The present invention has the advantages of simple and compact structure, improved linear running stability and turning performance, increased contact area to ground, capacity of suiting various environment, relatively high passing capacity in sandy environment, environment temperature and obstacle sensing capacity, etc.

Owner:HARBIN INST OF TECH

Overhead front axle assembly for disc brake of truck

PendingCN107813657AImprove comfortImprove sealingBraking element arrangementsSteering linkagesNeedle roller bearingSteering wheel

The invention provides an overhead front axle assembly for a disc brake of a truck. The overhead front axle assembly comprises a front axle, disc brakes, hubs, steering knuckles, steering knuckle arms, transverse pull rod arms and longitudinal pull rod arms, wherein a plurality of openings are integrally formed in the outer edge of the disc surface of each hub so as to form a corrugated structureon the outer edge of the disc surface of the hub, and a plurality of hollow holes are integrally formed in a transverse H-shaped beam part of the front axle; and left wing plates are integrally arranged on one sides of the initial ends of steering knuckle shaft heads, right wing plates are integrally arranged on the other sides of the initial ends of the steering knuckle shaft heads, a bi-metal lining is arranged in a connecting hole of one fork arm in each steering knuckle, an FAG needle bearing is arranged in a connecting hole in the other fork arm in each steering knuckle, and framework oilseals are arranged at the joints between main pin holes and the connecting holes. The overhead front axle assembly is simple in structure and convenient to use; by utilizing the overhead disc brake,the distribution of the longitudinal pull rod arms is promoted, and an inner corner is enlarged, so that the front axle and the hubs are effectively lightened, the connection strength of the transverse pull rod arms and the longitudinal pull rod arms is increased, and the problems that the corner resistance is large, and a steering wheel is joggled are solved.

Owner:青岛海通车桥有限公司

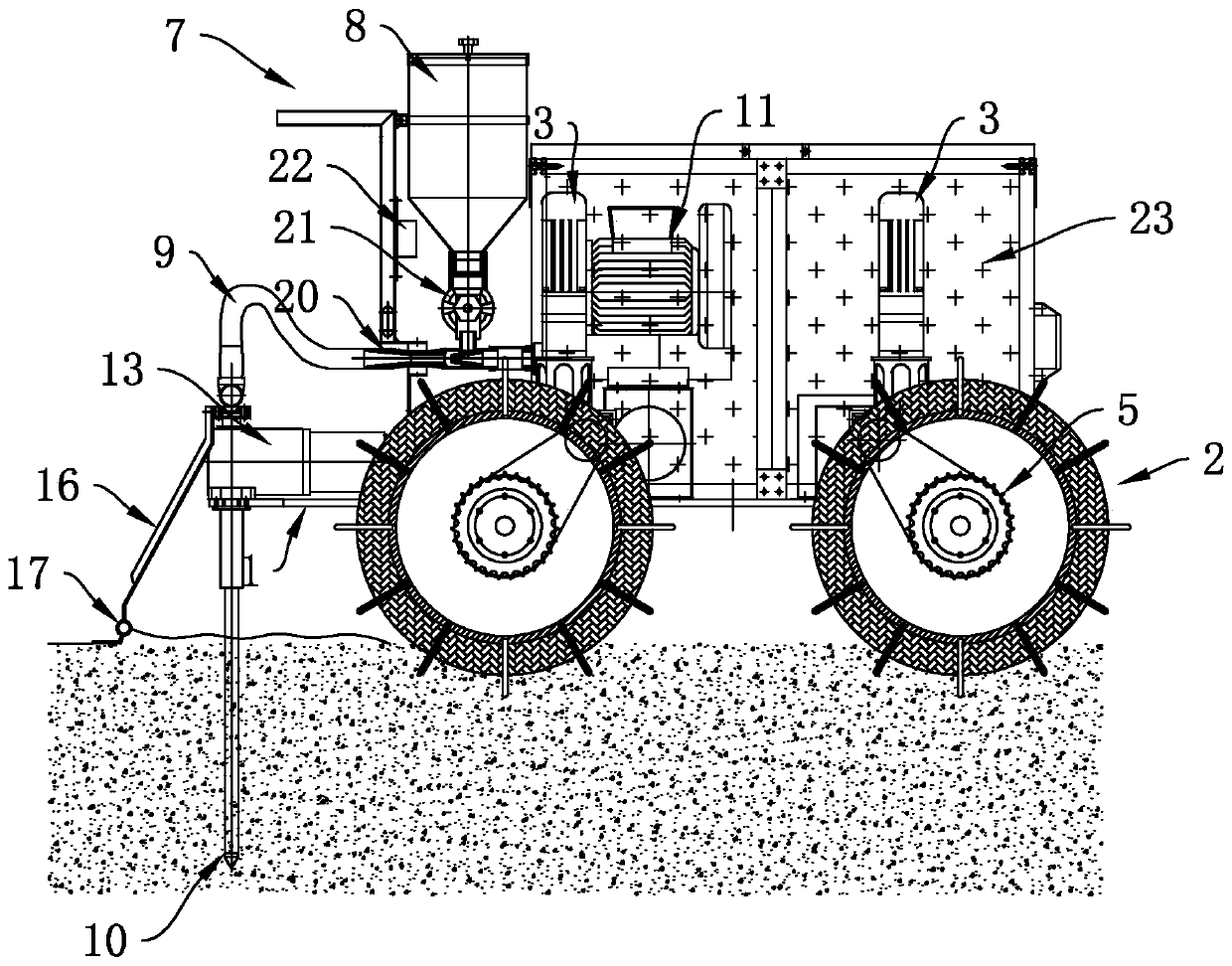

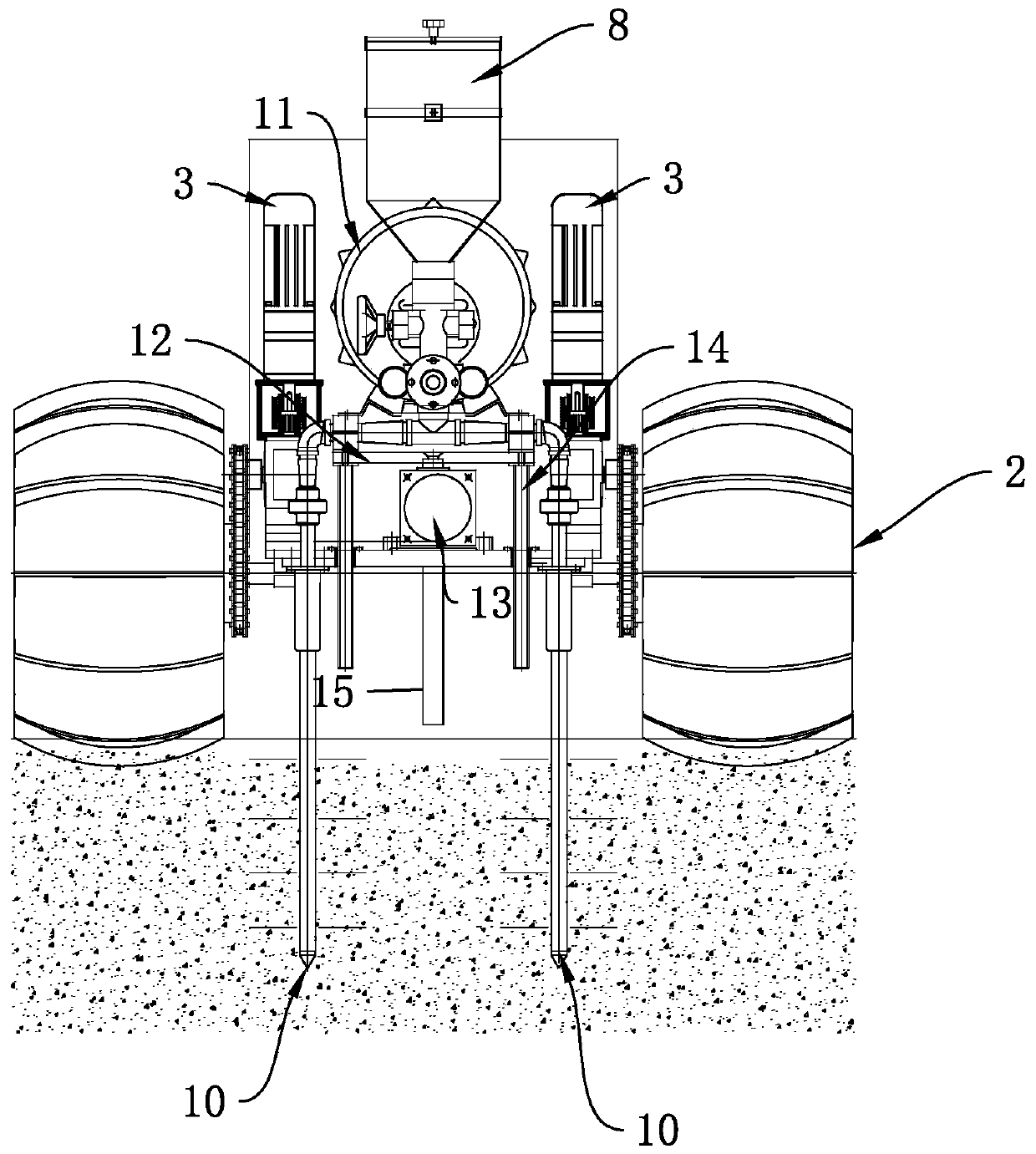

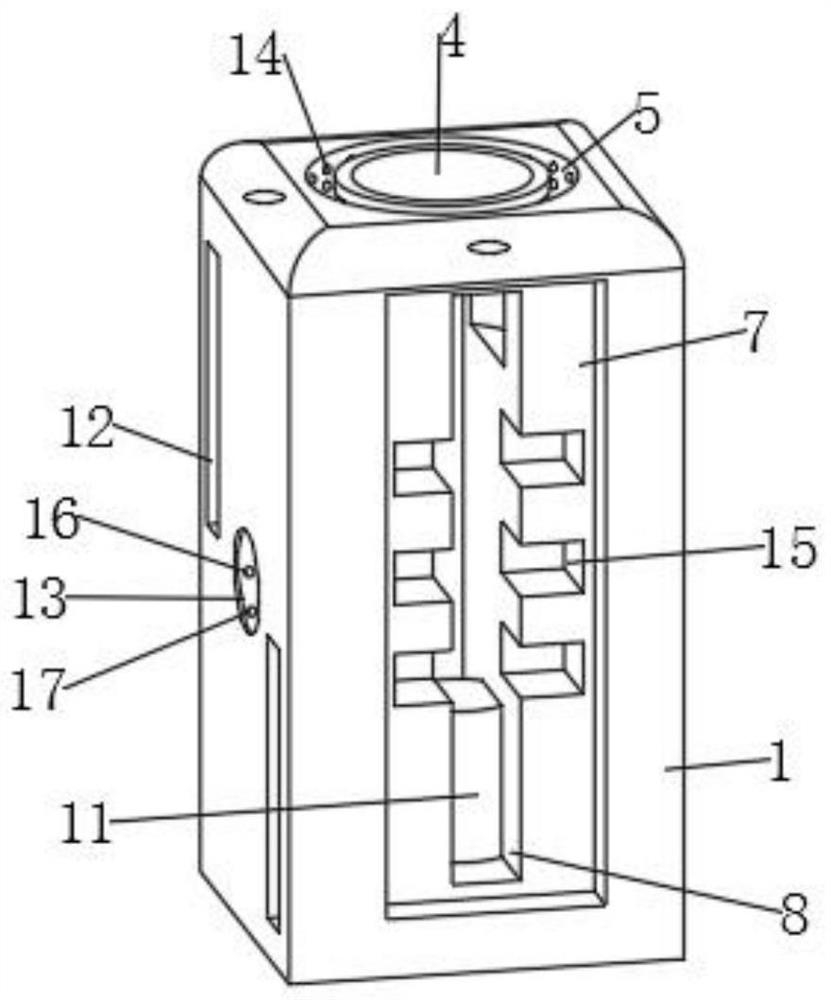

Automatic granary pesticide application equipment for preventing from lying down

PendingCN111034792AImprove application efficiencyGood application effectEdible seed preservationClimate change adaptationAgricultural scienceAgricultural engineering

The invention relates to the technical field of pesticide application equipment and discloses automatic granary pesticide application equipment for preventing lying down, the automatic pesticide application equipment comprises a main substrate, a transmission mechanism, a pesticide application mechanism and a PLC control module are arranged on the main substrate, the transmission mechanism comprises drum-shaped walking wheels, the drum-shaped walking wheels are driven by a servo motor, and the servo motor is electrically connected with the PLC control module; wherein a supporting frame is erected on the main substrate, a storage cylinder is fixedly arranged on the supporting frame, a pesticide spraying pipe is communicated with the bottom end of the storage cylinder, a pesticide spraying nozzle is communicated with the end, away from the storage cylinder, of the pesticide spraying pipe, a high-pressure fan is further arranged on the main substrate, an air outlet of the high-pressure fan is communicated with the pesticide spraying pipe through a guide pipe, and the high-pressure fan is electrically connected with the PLC module. The automatic pesticide application equipment is equipment walking in grains, is good in pesticide application effect and high in pesticide application efficiency, the labor cost is reduced, and the equipment is effectively prevented from lying down.

Owner:SHANGHAI FORWARD MASCH CO LTD

Automobile capable of steering and moving laterally conveniently

InactiveCN104925131AHigh sensitivityLow steering resistanceSteering linkagesDrive wheelVehicle frame

The invention relates to an automobile capable of steering and moving laterally conveniently and belongs to the professional technical field of automobiles. The automobile capable of steering and moving laterally conveniently comprises a frame and a steering device. The automobile capable of steering and moving laterally conveniently is characterized in that two driven wheel shafts are mounted on the frame in a rotary mode, and a driving wheel shaft located between the two driven wheel shafts is also mounted on the frame in a rotary mode; the driven wheel shafts and the driving wheel shaft are vertically arranged on the frame; driven wheels are mounted on the driven wheel shafts; a driving wheel is mounted on the driving wheel shaft; the steering device further comprises rotary pieces arranged between the driving wheel and the driven wheels; the driving wheel drives the driven wheels to rotate through the rotary pieces; steering wheels are mounted at the lower ends of the driven wheel shafts respectively. Compared with the prior art, the automobile capable of steering and moving laterally conveniently has the advantages of being capable of saving energy, environmentally friendly, high in safety performance and high in stability.

Owner:李丰超

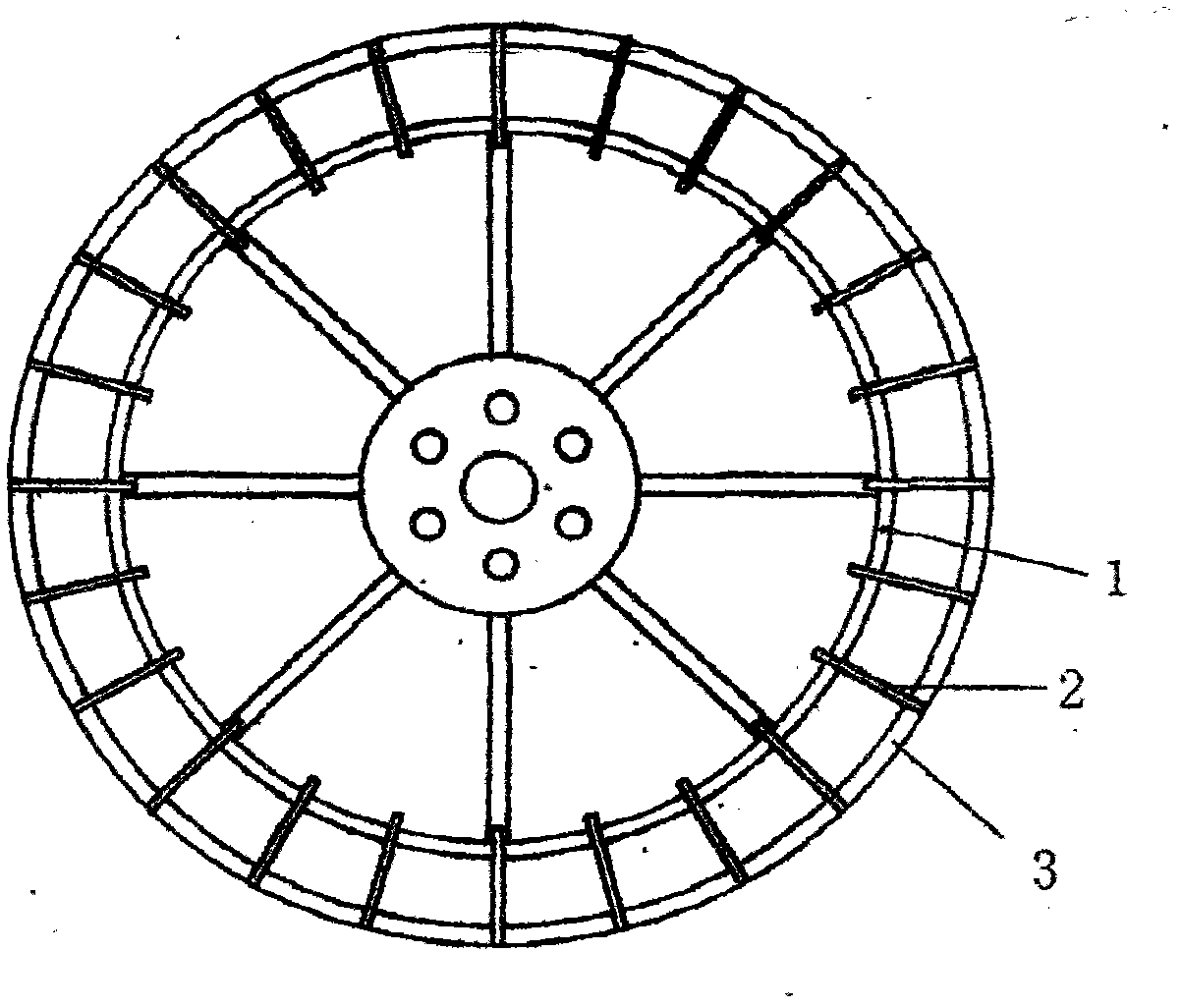

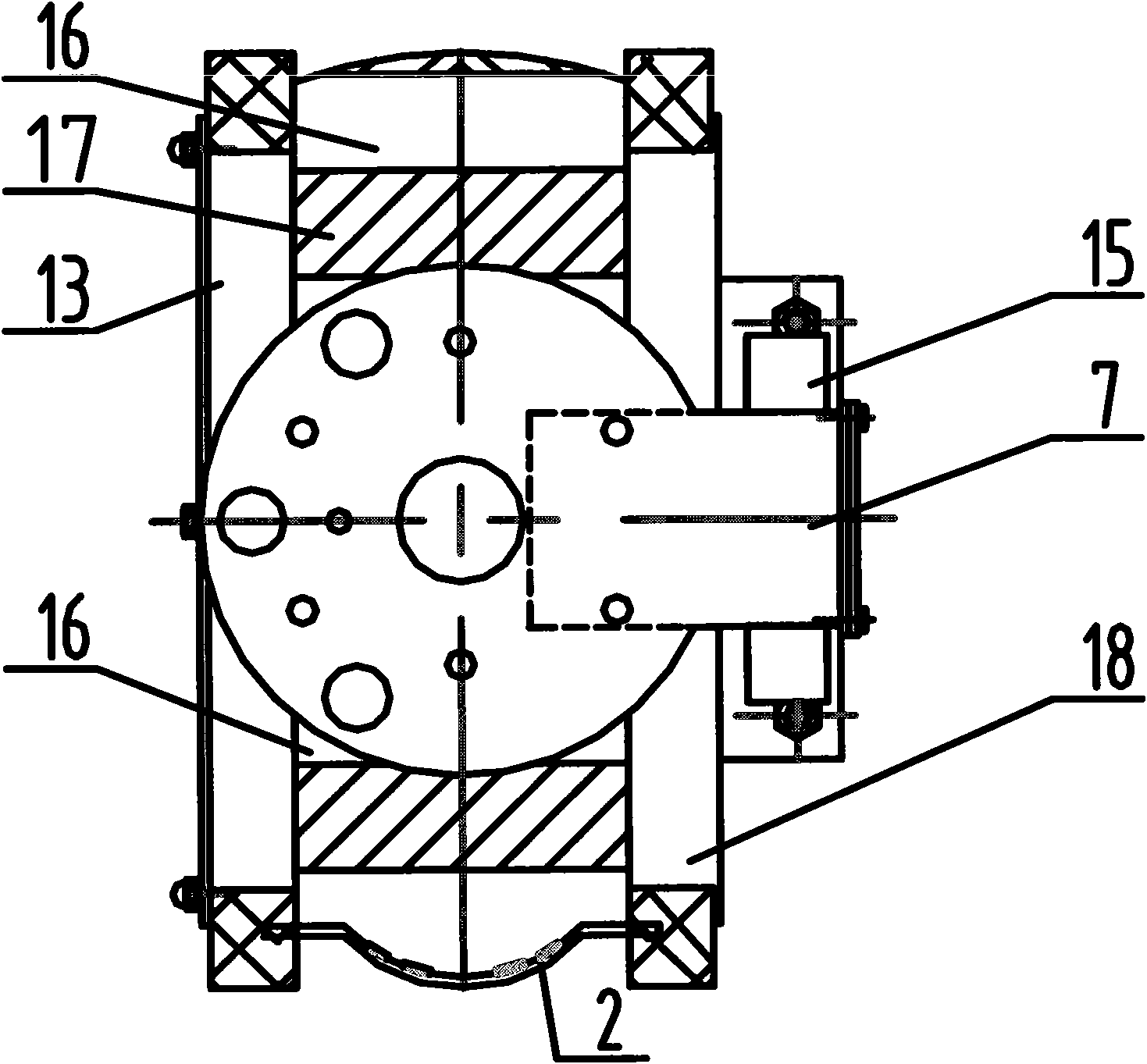

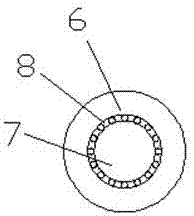

Wheels of mobile robot with non-contact transverse sensory ability

InactiveCN101628527AImprove stabilityImprove cornering performanceRadiation pyrometryWheelsPattern perceptionControl theory

The invention provides wheels of a mobile robot with non-contact transverse sensory ability which comprise a perception sensor reflection device (2), a perception sensor emission device (4), an electrical machine component (5), a clamping sleeve (6), a wheel arm (7), a wheel hub (8), a cone-shaped sleeve (10), an elastic wheel rim exterior plate (13), an elastic wheel rim interior panel (18), an elastic tyre (14), a non-contact temperature sensor (15) and a bracket (20). The wheels of the mobile robot have the advantages that the wheels have simple and compact structure, increase the traction capability, improve the stability of the straight linear driving and turning performance, increase the area of contacting ground, can adapt to various environments such as common roads, firm ground and sand environment, simultaneously have stronger through capacity and little steering resistance in sand environment and sensory ability on environment temperature and barrier.

Owner:HARBIN ENG UNIV

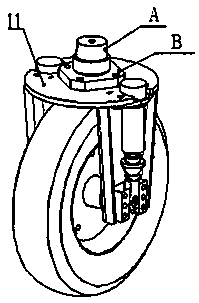

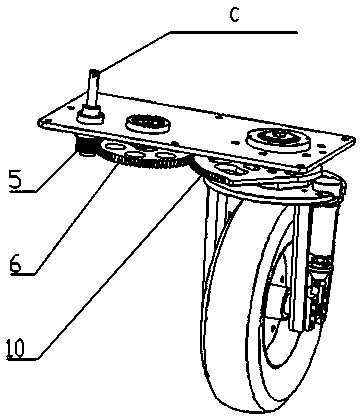

Heavy-load universal wheel

PendingCN111761991AGuaranteed StrengthImprove bearing capacityCastorsThrust bearingStructural engineering

The invention provides a heavy-load universal wheel, which is characterized in that a wheel carrier is made of a high-strength structural steel material; a wheel shaft is horizontally and fixedly mounted on the wheel carrier; wheels are rotationally connected with the wheel shaft through bearings; a rotating shaft is vertically mounted on the wheel carrier; an inner ring of a plane thrust bearingis connected with the rotating shaft; the outer ring of the plane thrust bearing is fixedly connected to the wheel carrier; the periphery of the rotating shaft is sleeved with a cushion; a cushion lower baffle is mounted on the wheel carrier; the cushion lower baffle is located at the lower end of the cushion; a cushion upper baffle is mounted on the wheel carrier, and the cushion upper baffle islocated at the upper end of the cushion. The difference between the universal wheel and other universal wheels is that the universal wheel is large in riding load, large in eccentric distance, capableof achieving the buffering function and the like, the advantages of being uniform in wheel pressure, small in steering resistance and the like are guaranteed when multiple wheels are used at the sametime, and the universal wheel is a preferred product of a multi-spool heavy-load AGV.

Owner:江苏宝诚重工科技有限公司

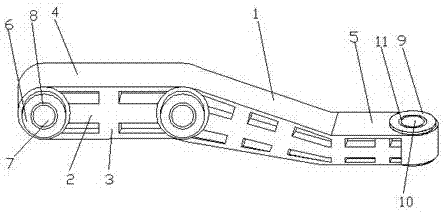

Steering trapezoidal arm for automobile

InactiveCN107298129AHigh mechanical strengthReduce weightSteering linkagesEngineeringTransverse reinforcement

The invention relates to a steering trapezoidal arm for automobiles, which comprises a body. The two sides of the body are symmetrically provided with transverse reinforcing ribs and longitudinal reinforcing ribs. A hole seat 1 is symmetrically arranged on both sides, and a fixing hole is arranged on the hole seat 1, and the transverse reinforcing rib is fixedly connected to the hole seat 1, and a bearing 1 is arranged in the fixing holes, and the cross arm 21 There is a hole seat 2 at the end, and a connection hole is provided on the hole seat 2, and a bearing 2 is arranged in the connection hole, and the bearing 1 and the bearing 2 are movably connected with the fixing hole and the connection hole, and are provided with transverse reinforcement Ribs and longitudinal ribs can not only increase the mechanical strength of the steering trapezoidal arm, but also reduce the weight of the steering trapezoidal arm and reduce the weight of the car. By providing hole seat 1 and hole seat 2, the two ends of the fixing hole and the connecting hole can be aligned with each other. The steering trapezoidal arm forms a certain distance to prevent friction between the mounting part and the first cross arm and the second cross arm.

Owner:GOLDACE METAL PROD WUJIANG

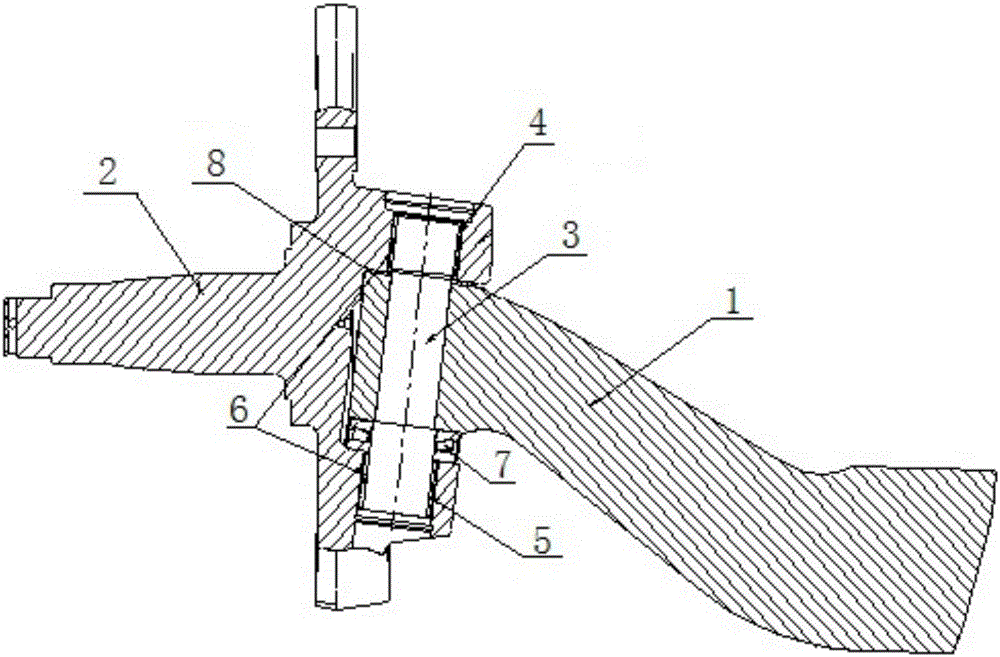

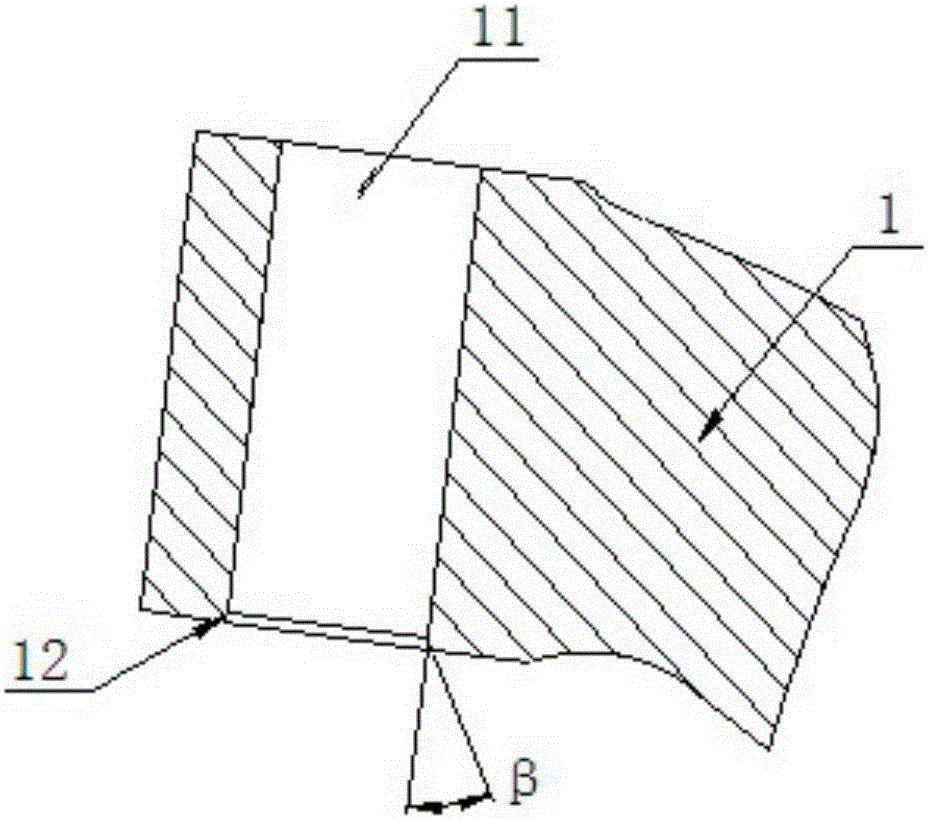

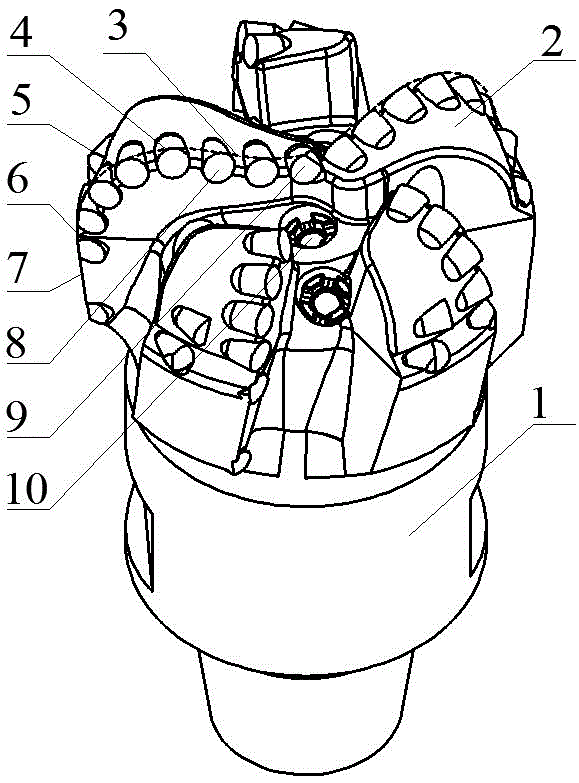

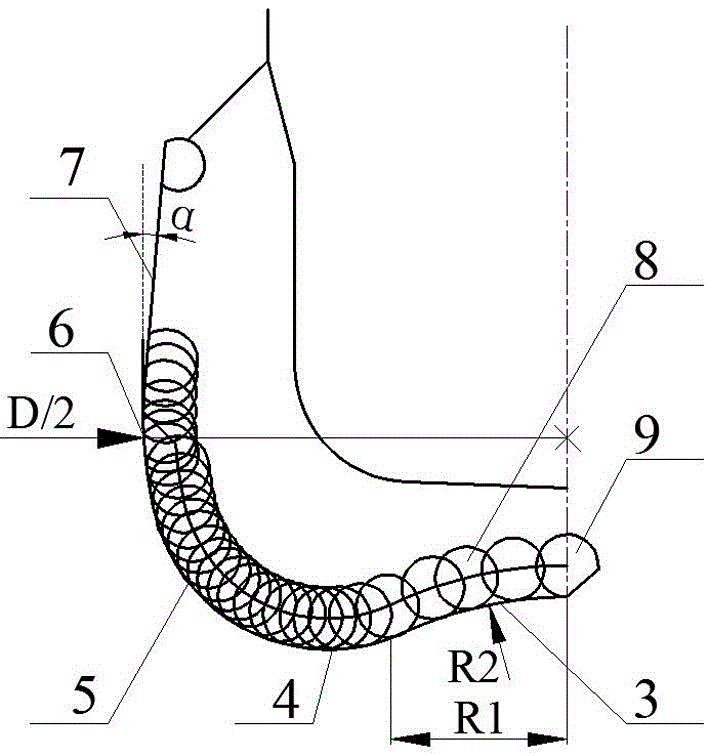

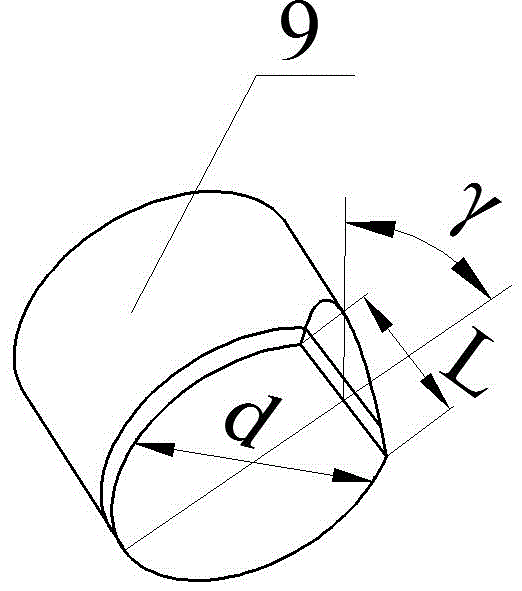

PDC drill bit with directional easy controllability enhancing performance

InactiveCN105464599ALow steering resistanceImprove fitDrill bitsPolycrystalline diamondControllability

The invention relates to a PDC (Polycrystalline Diamond Composite) drill bit with directional easy controllability enhancing performance. The PDC drill bit comprises a drill bit body, a crown part and cutting teeth, wherein a plurality of cutting teeth are arranged on the contour line of the crown part; the curved surface contour of the crown part of the drill bit is formed by sequentially and smoothly connecting a core part, a nose part, an outer side, a shoulder part and a gage section; the core part of the drill bit is a concave spherical surface; the cutting tooth near the center part of the drill bit is the cut-edge tooth; one intersection point of the cut edge of the cut-edge tooth with the excircle is positioned in the axial line of the drill bit body 1; the contour corresponding to the shoulder of the drill bit is of a spherical surface structure; and the contour corresponding to the gage section is of a conical structure. The PDC drill bit has the advantages that in the directional drilling and deflecting process, the fit of the core part of the drill bit with the shaft bottom is good; the steering resistance of the core part and the friction resistance of the gage are small; and the directional track deviation degree can be reduced through enhancing the directional operation and control performance of the drill bit and improving the shaft wall quality, so that the construction quality of directional drilling is improved.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

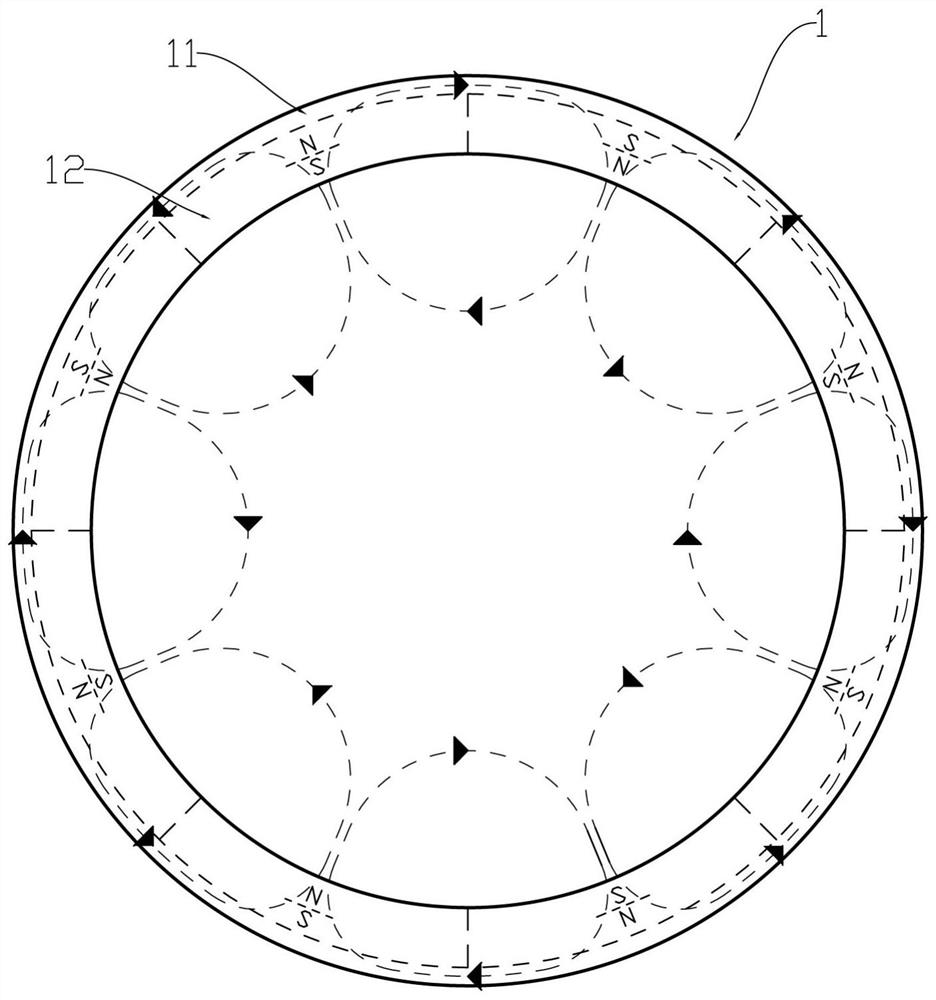

Permanent magnet ring, motor applying permanent magnet ring and manufacturing method and mold

PendingCN113964968AExpand the use of technologyLow costMagnetic circuit rotating partsMagnetic bodiesPermanent magnet rotorAdhesive

The invention discloses a permanent magnet ring, a motor applying the permanent magnet ring, a manufacturing method and a mold, and belongs to the field of motor permanent magnet rotors. The permanent magnet ring is of a circular ring columnar structure integrally formed by magnetic powder and an adhesive, and comprises a magnetic conductive ring layer and a magnetic pole ring layer, wherein the magnetic pole ring layer is uniformly provided with a plurality of adjacent and opposite magnetic poles in the circumferential direction, and the magnetic conductive ring layer can enable the magnetic field of each magnetic pole to be restrained in the magnetic conductive ring layer. According to the permanent magnet ring, a magnetic conductive component of a motor can be omitted, and the permanent magnet ring can be directly assembled as a rotor of the motor, so that the step of installing the magnetic conductive ring on the magnetic ring during motor processing and assembling is omitted, and the process is greatly simplified; and the installation component of the permanent magnet ring in the motor is allowed to be made of a non-magnetic conductive material so as to expand the material selection possibility of the motor part, so that the use process possibility of the motor is further expanded, the cost of the motor is reduced, and the processing efficiency is improved.

Owner:江门市邦特电子电器有限公司

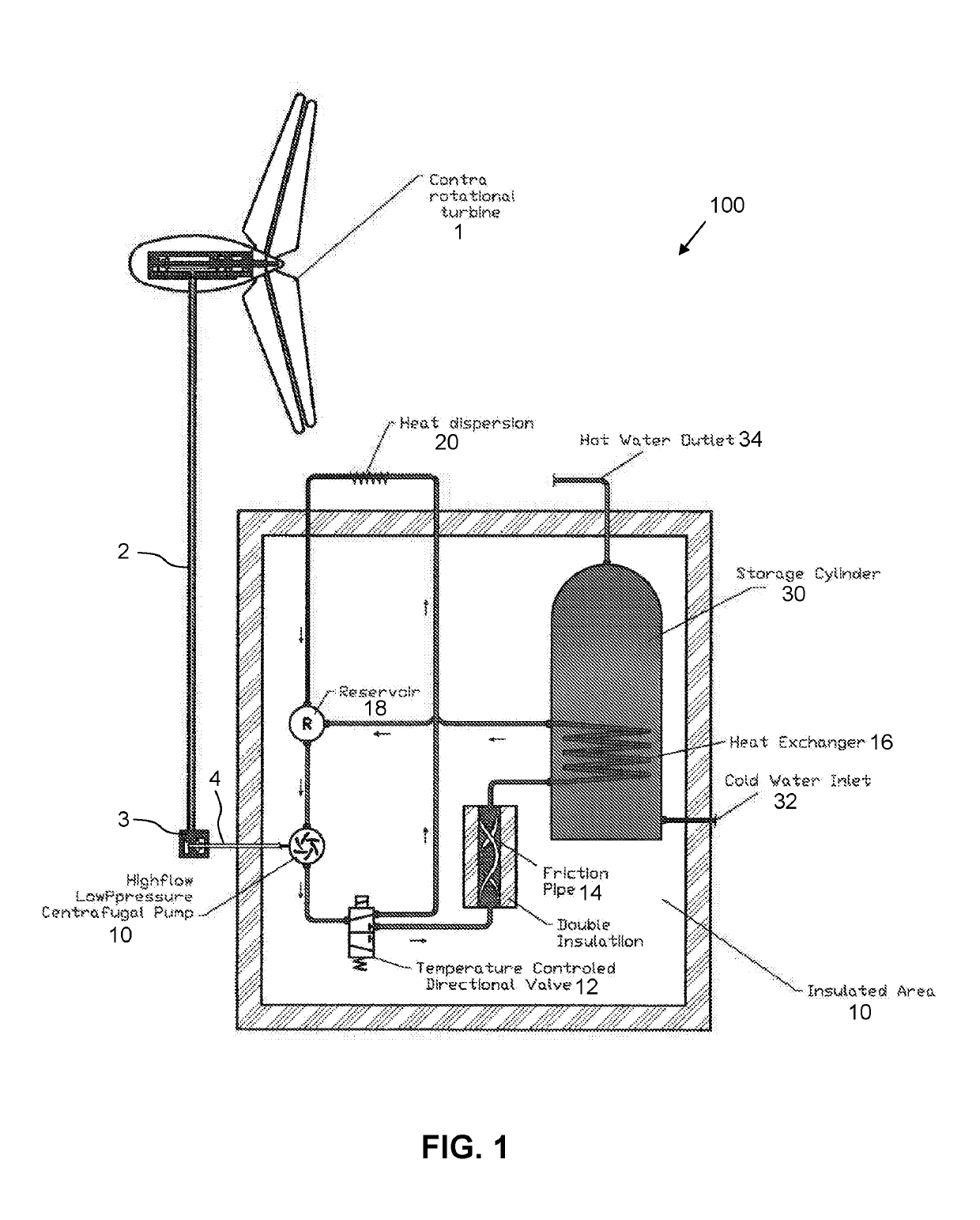

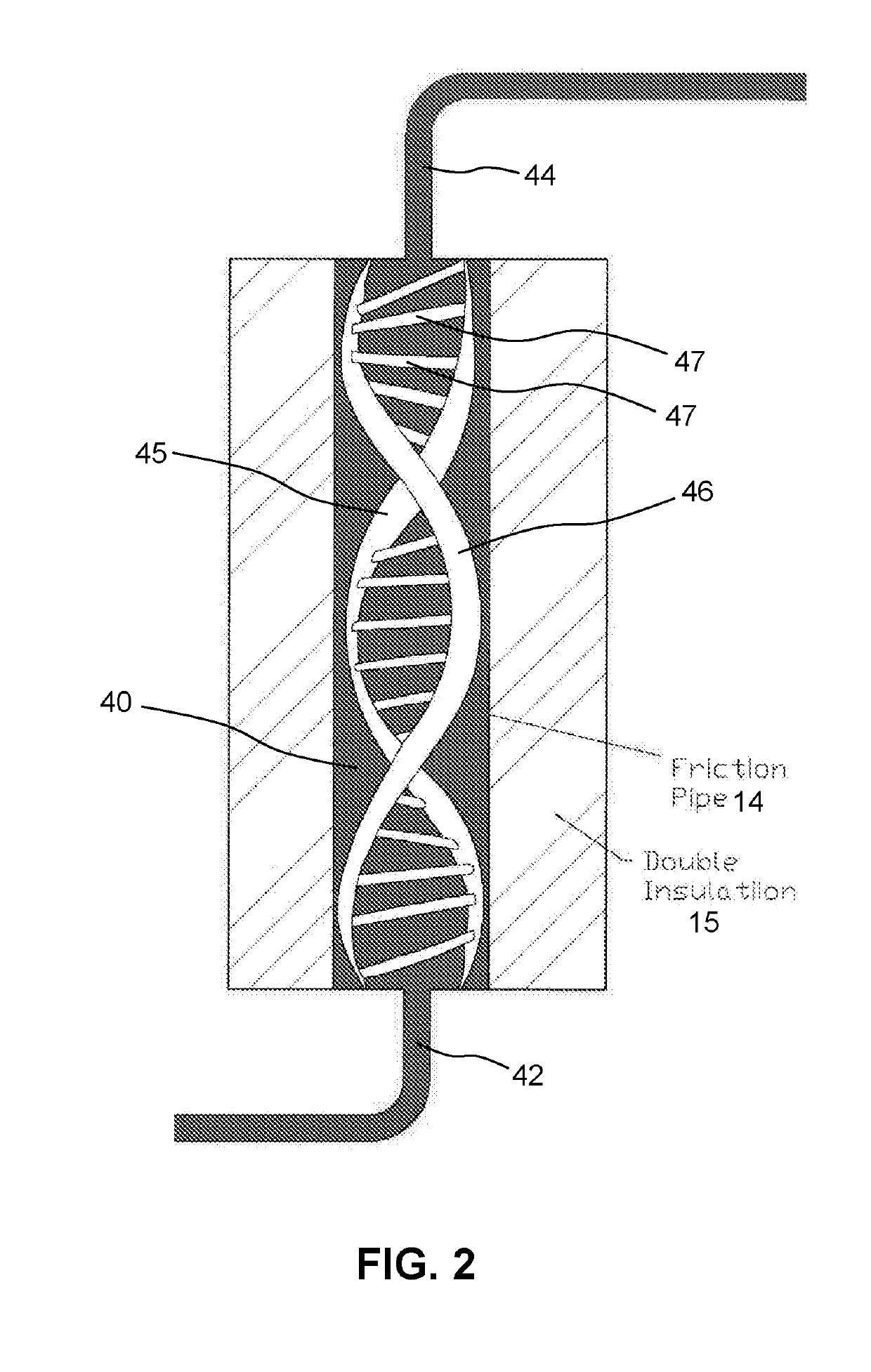

An apparatus for heating a liquid

InactiveUS20190285054A1Low steering resistanceSmooth rotationMachines/enginesWind motor combinationsEngineeringTurbine

There is provided an apparatus (100) for heating a liquid, comprising a wind turbine (1), a pump (5), and a circuit of piping. The wind turbine (1) drives the pump (5) to pump the liquid around the circuit of piping, and the circuit of piping comprises a friction pipe (14) through which the liquid is forced by the pump (5). Friction between the liquid and an inside of the friction pipe (14) generates heat, which gradually raises the temperature of the liquid by at least 20° C.

Owner:H2O TURBINES LTD

steering wheel steering mechanism

ActiveCN104002910BLow steering resistanceEasy steeringSteering deviceMechanical steering gearsSteering wheelOffset distance

The invention discloses a steering wheel direction moving mechanism. Synchronization opposite-direction transmission is carried out by meshing of three gears, then synchronization identical-direction transmission is carried out in a transition mode, and steering is achieved. A transition gear is arranged in the middle, so that offset distance transmission from input (an opposite-moving small gear) to output (a rotating disc) is achieved, and the purpose of offset steering is achieved. The opposite-moving small gear, the transition gear and the rotating disc in the steering wheel direction moving mechanism are arranged on a direction component fixing plate. The opposite-moving small gear, the transition gear and a rotating disc gear are arranged on the same plane in a meshing-transmission mode for transmission, and three points at the mounting center are on the same straight line. The rotating disc is provided with a sector tooth face, and the two ends of the sector tooth face are provided with rotating angle limiting clamping positions for limiting the rotating angle quantity of the rotating disc respectively. The rotating disc is arranged on a main shaft of a front wheel fork frame component in a sleeved mode. Offset steering of a direction is achieved through meshing transmission of the three gears, and meshing transmission of the three gears is carried out from synchronization opposite-direction transmission to synchronization identical-direction transmission in a transition mode.

Owner:FOSHAN GEMEI CLEANING EQUIP

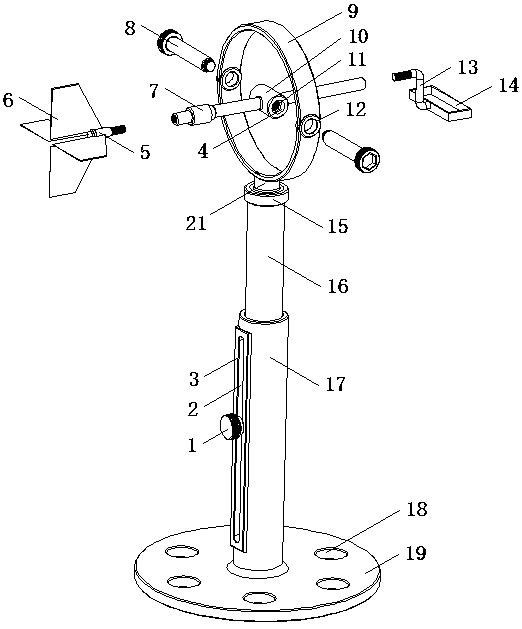

Fixing device for detection electronic air speed gauge of mine

PendingCN109163197ALow steering resistanceHigh measurement accuracyStands/trestlesSpeed/acceleration/shock instrument detailsBalance shaftEngineering

The invention discloses a fixing device for a detection electronic air speed gauge of a mine. The fixing device comprises a bottom plate, a vertical pipe, a sliding column, a rotating ring, a wind rudder, a connecting column, a metal hoop and a balance shaft, wherein the outer contour of the bottom plate is of a round shape, bottom holes in the annular array are formed in the bottom plate, the vertical pipe is welded to the bottom plate, the sliding column is located inside the vertical pipe, a middle bearing is fixed at the top of the sliding column, a ring column is inserted into the middlebearing, the rotating ring is welded above the ring column, a top bearing is installed inside the rotating ring, the connecting column is located inside the rotating ring, a counter bore and a threaded hole are formed in the connecting column, a threaded part of a rotating bolt is located in the threaded hole, a shaft body of the rotating bolt is located inside the top bearing, the two ends of thebalance shaft are in threaded connection with a rudder frame and a bent shaft, the wind rudder is welded on the rudder frame, and the metal hoop is welded to one end, far away from the threads, of the bent shaft. According to the fixing device for the detection electronic air speed gauge of the mine, the air speed gauge can be always made to face the air flow of an air hole, the measurement precision is improved conveniently, and the device is suitable for being widely popularized and used.

Owner:江苏安科中矿科技有限公司

Combined heavy hydraulic truck

InactiveCN109436108AFlexible steeringLarge steering angleFluid steeringTractor-trailer combinationsTruckTractor

The invention discloses a combined heavy hydraulic truck. The truck comprises a tractor, a wolf vehicle main beam, a wolf vehicle platform, a front gooseneck, a front cargo platform, a rear cargo platform, a rear gooseneck and a wolf-like animal vehicle platform, one end of the wolf vehicle main beam is connected to a saddle on the tractor, and the other end is hinged to the wolf vehicle platform;the wolf vehicle platform is provided with a steering mechanism, one end of the front gooseneck is hinged to the wolf vehicle main beam, and the other end is hinged to the front cargo platform; the front cargo platform is connected to the rear cargo platform through an intermediate connecting seat; one end of the rear gooseneck is hinged to the rear cargo platform, and the other end is hinged tothe wolf-like animal vehicle platform. The truck has the advantage of improving the longitudinal swing angle of a wolf vehicle, so that the stability is better.

Owner:XUZHOU HUABANG SPECIAL VEHICLE

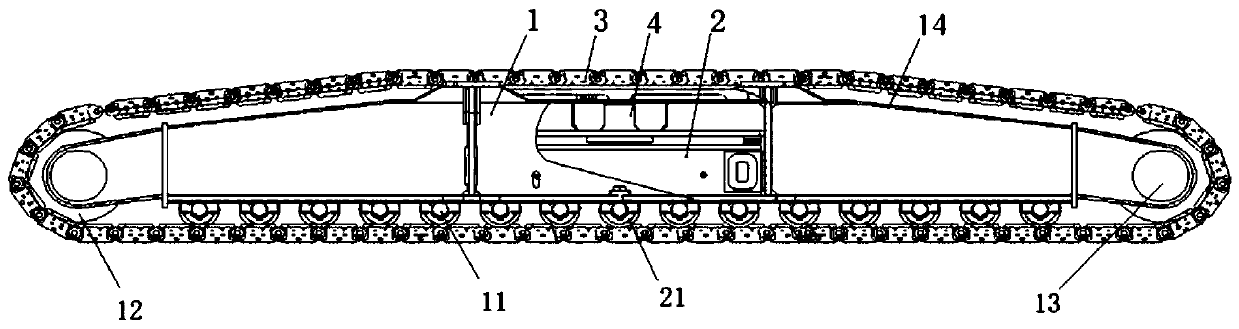

Track type running mechanism and track vehicle

PendingCN110329374ATurn easilyReduce contact lengthEndless track vehiclesEngineeringMechanical engineering

Owner:ZHEJIANG SANY EQUIP

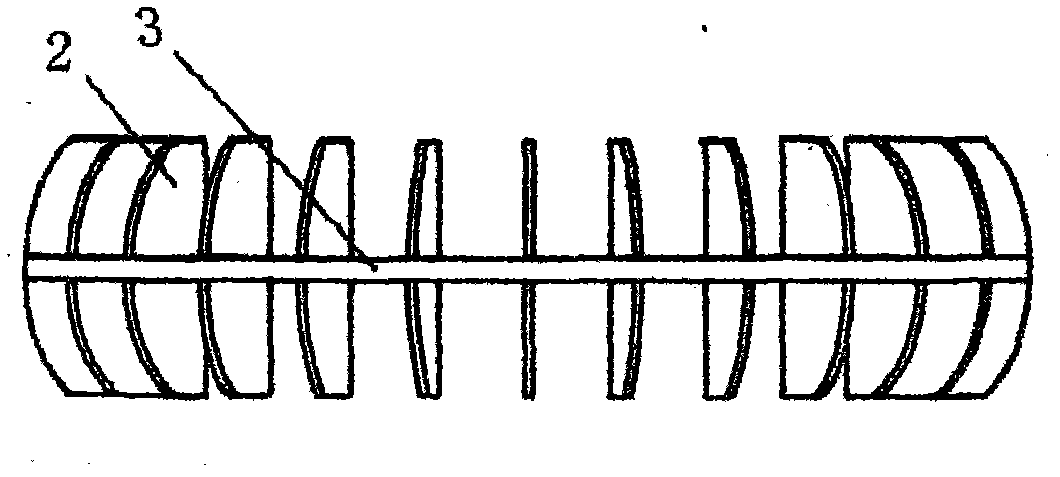

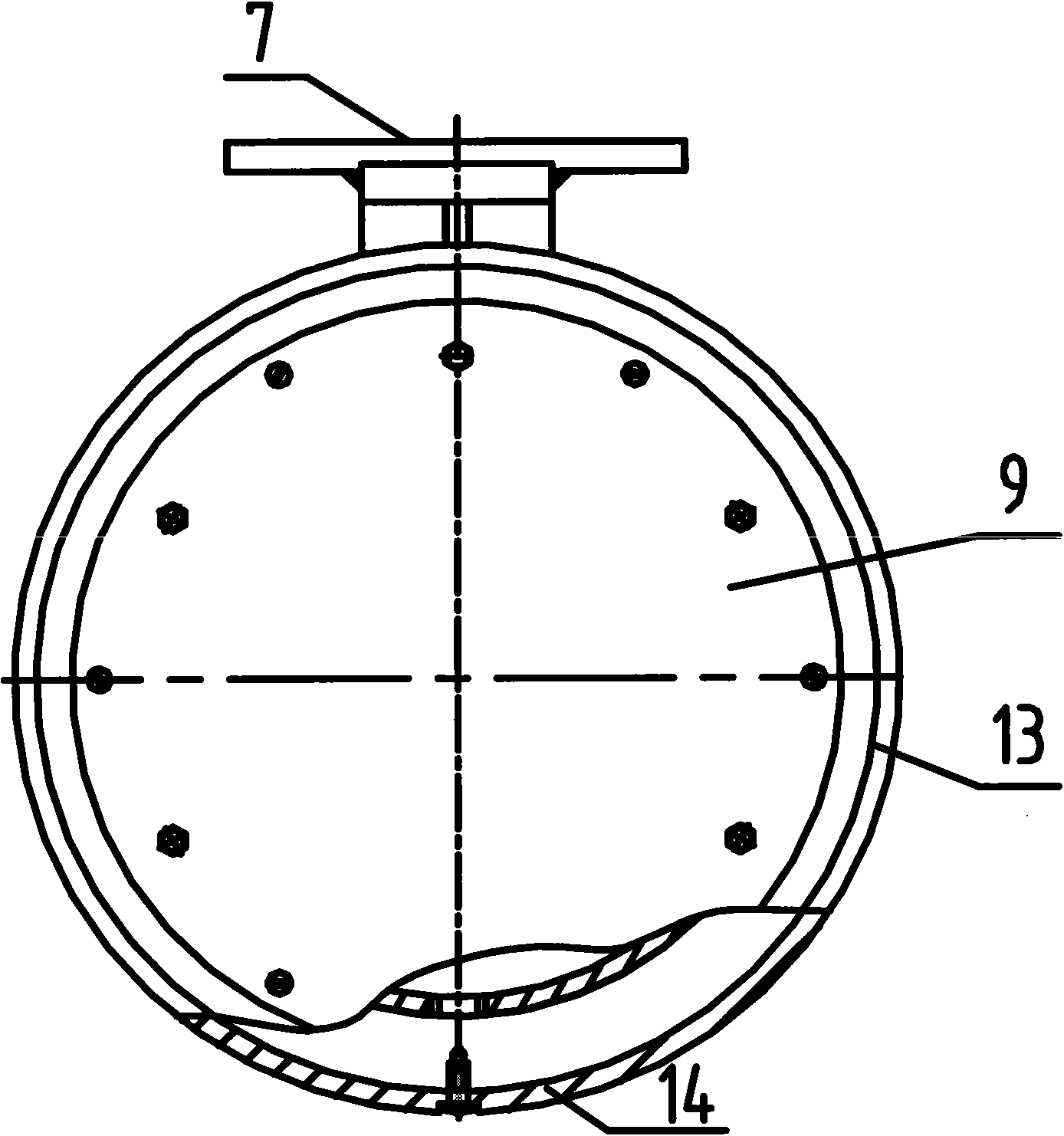

Perception type reconfigurable bionic sand wheel for moving navigational platform

InactiveCN1297374CSimple structureCompact structureWheelsManipulatorMobile navigationPattern perception

The present invention relates to the improvement of wheel structure for mobile navigation platform. In the perceptive bionic sands wheel capable of being reconfigured for mobile navigation platform, there are outside elastic rim board fixed outside the hub camber, inside elastic rim board fixed inside the hub camber, elastic tyre set inside the central line of the rim capable of being reconfigured, perception sensor reflecting devices set in the equal interval inside the elastic tyre, and perception sensor sending devices set in the equal interval on the rack camber. The present invention has the advantages of simple and compact structure, improved linear running stability and turning performance, increased contact area to ground, capacity of suiting various environment, relatively high passing capacity in sandy environment, environment temperature and obstacle sensing capacity, etc.

Owner:HARBIN INST OF TECH

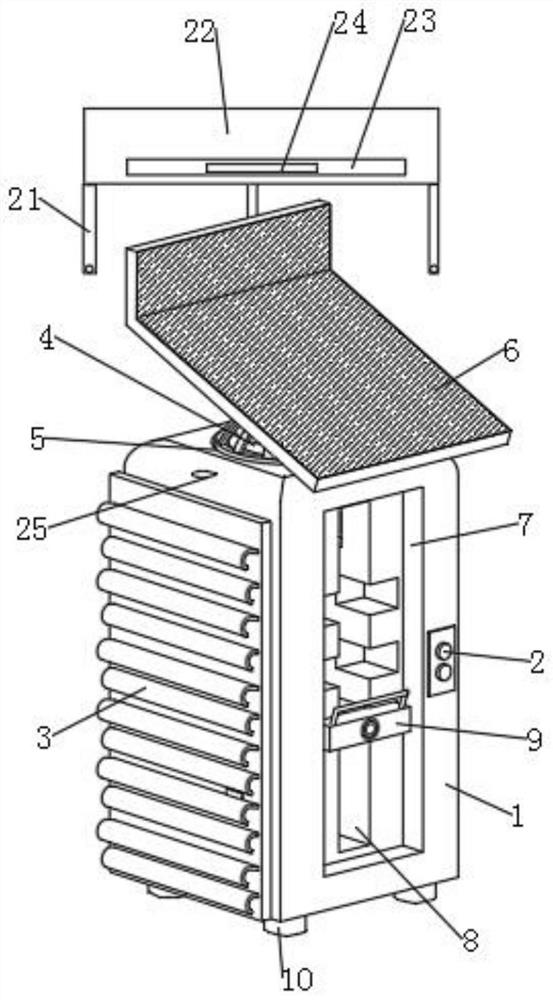

Intelligent charging pile based on photovoltaic power generation

ActiveCN114347832AHigh energy absorption efficiencyImprove stabilityPhotovoltaic supportsCharging stationsEnergy absorptionPhotovoltaic power generation

The intelligent charging pile comprises a charging pile body, a switch button is arranged on the rear portion of the right end of the charging pile body, a protection structure is fixedly connected to the front end of the charging pile body, and a steering groove and a rotating groove are formed in the upper end of the charging pile body; the charging pile body is jointly provided with a photovoltaic structure through a steering groove and a rotating groove, adjusting grooves are formed in the left end and the right end of the charging pile body correspondingly, a device groove is formed in the charging pile body and communicates with the two adjusting grooves, and charging structures are arranged in the two adjusting grooves correspondingly. The lower end of the charging pile body is fixedly connected with a set of supporting legs, and each set of supporting legs comprises four supporting legs which are symmetrically distributed in pairs. According to the invention, the characteristic of real-time follow-up energy absorption angle of sun movement is realized, the buffering performance and the protection area of the charging pile in collision are improved, the charging height is adjustable, and the charging pile is convenient for a user to use.

Owner:日照宇通坤和电力科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com