Patents

Literature

39results about How to "Uniform contact force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

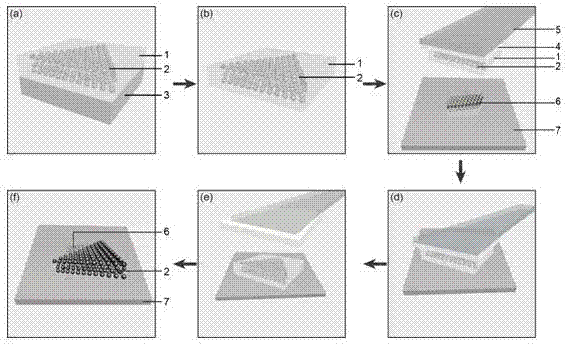

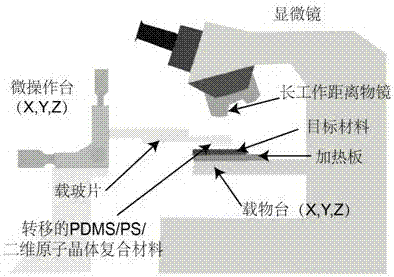

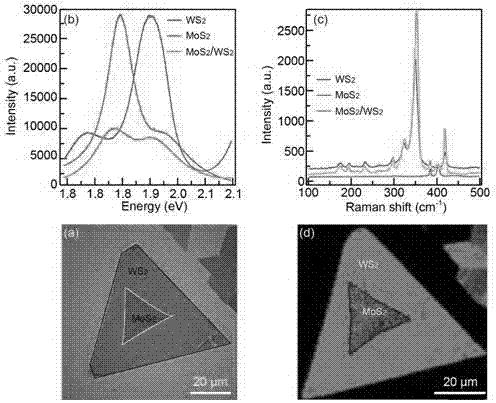

Method for transferring and preparing two-dimensional atomic crystal laminated structure

ActiveCN107170711AReduce doping and damageEasy to deal with residual glueSemiconductor/solid-state device manufacturingToluenePolystyrene

The invention discloses a method for transferring and preparing a two-dimensional atomic crystal laminated structure and relates to a stripping, positioning and transferring method for substrate-based two-dimensional atomic crystal film. The method comprises the specific steps of carrying out spin-coating on the surface of the two-dimensional atomic crystal film through utilization of polystyrene film, wherein the two-dimensional atomic crystal film is prepared based on a substrate; separating two-dimensional atomic crystals from the substrate through utilization of water tension and transferring the two-dimensional atomic crystals to dimethyl siloxane polymer; attaching the two-dimensional atomic crystals / polystyrene / dimethyl siloxane polymer on a target material through utilization of the van-der waals force; and separating the dimethyl siloxane polymer in a heating mode and removing the polystyrene through utilization of toluene solution or a vacuum annealing method, namely preparing the two-dimensional atomic crystal laminated structure. The method is simple in operation and is high in success rate, is fast and can be widely applied to the field of a large-area ultra-thin material photoelectric sensor.

Owner:SUN YAT SEN UNIV

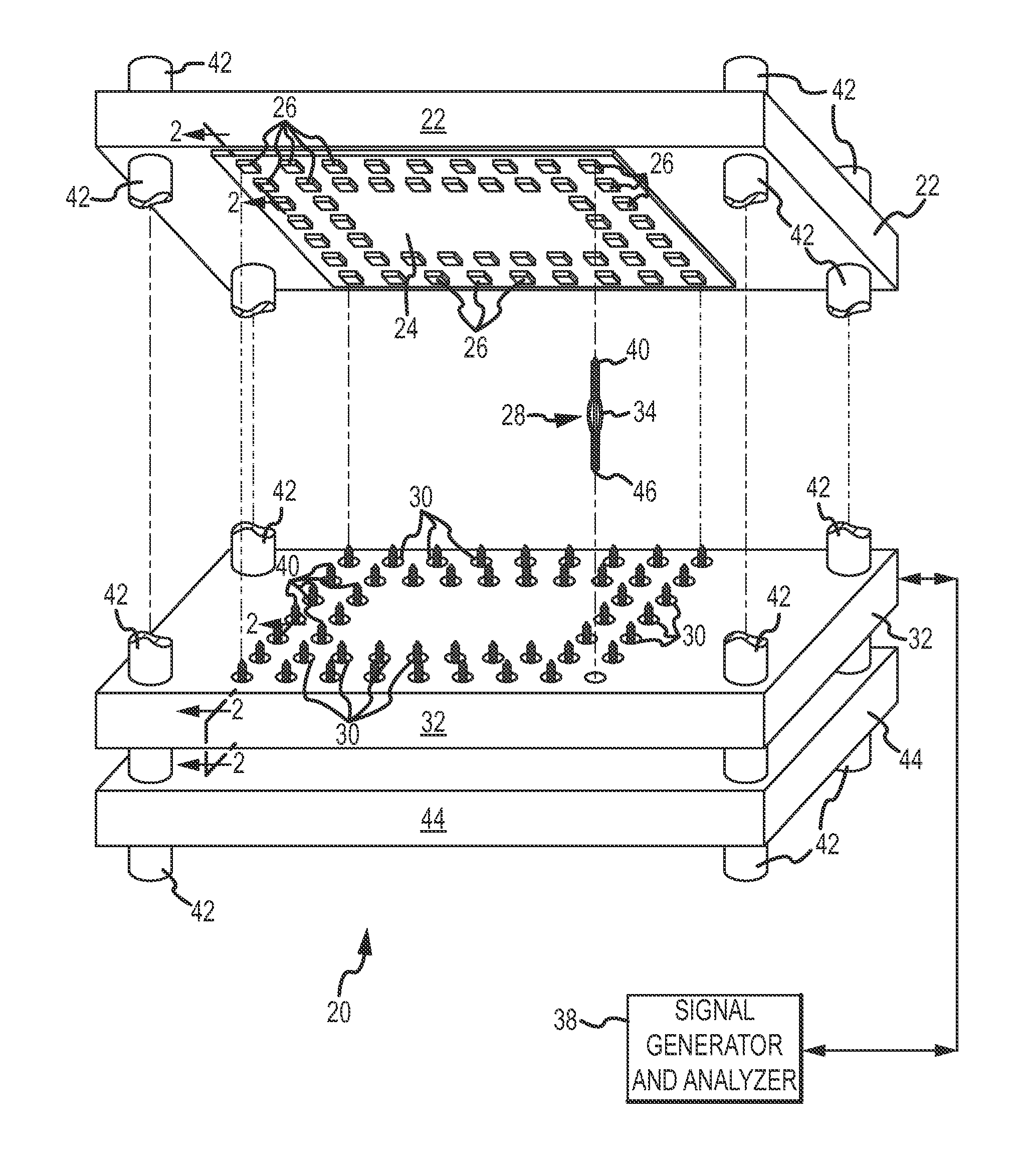

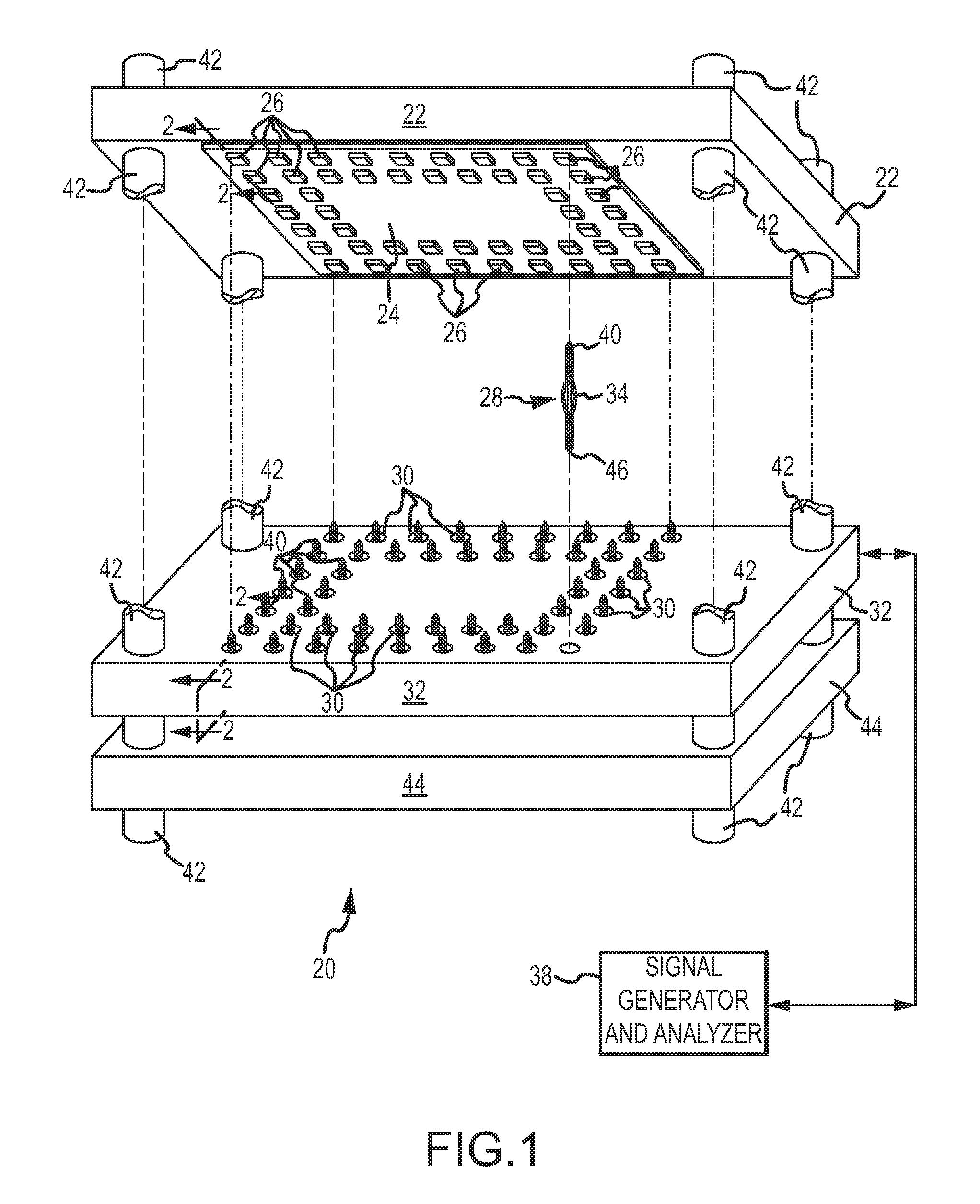

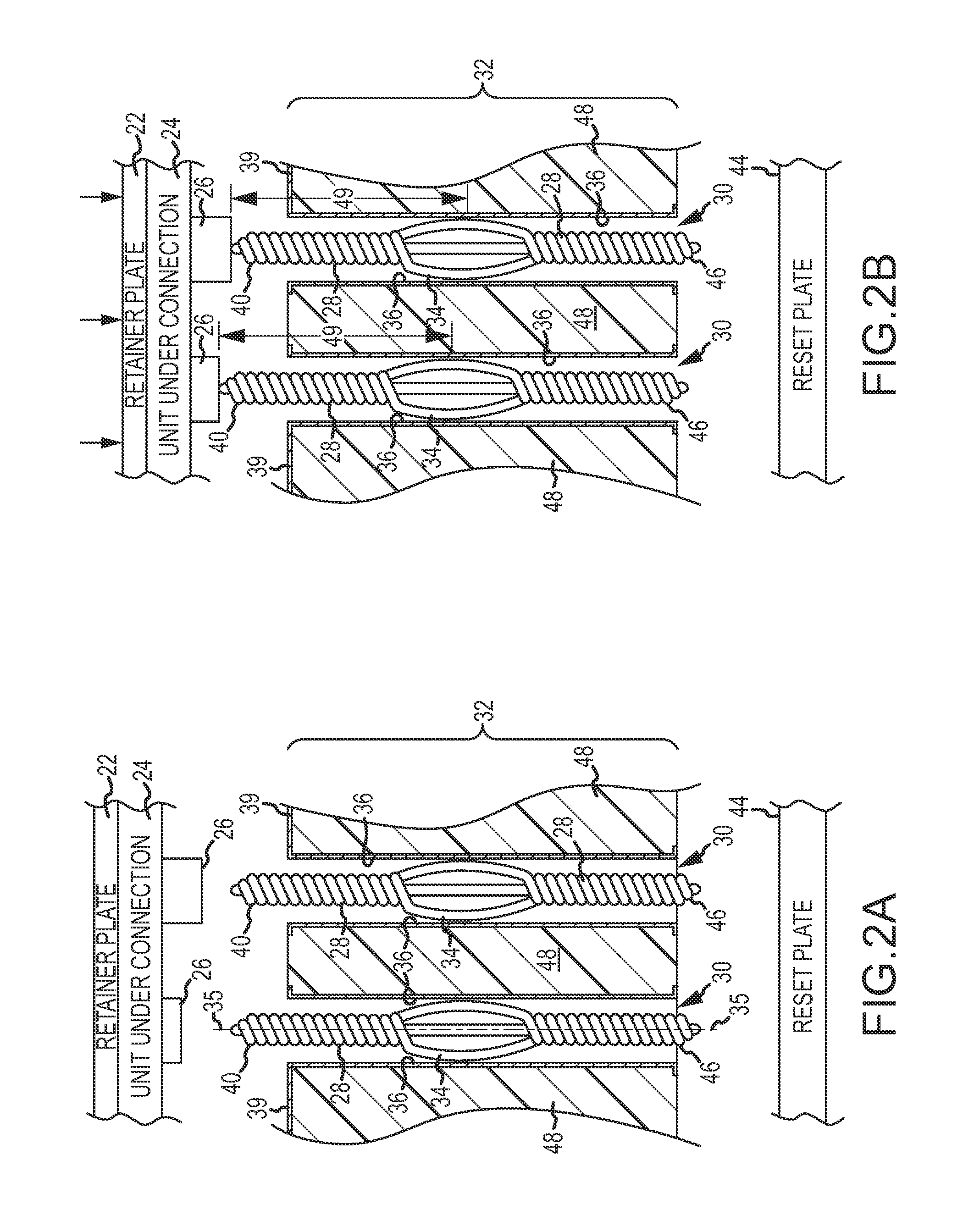

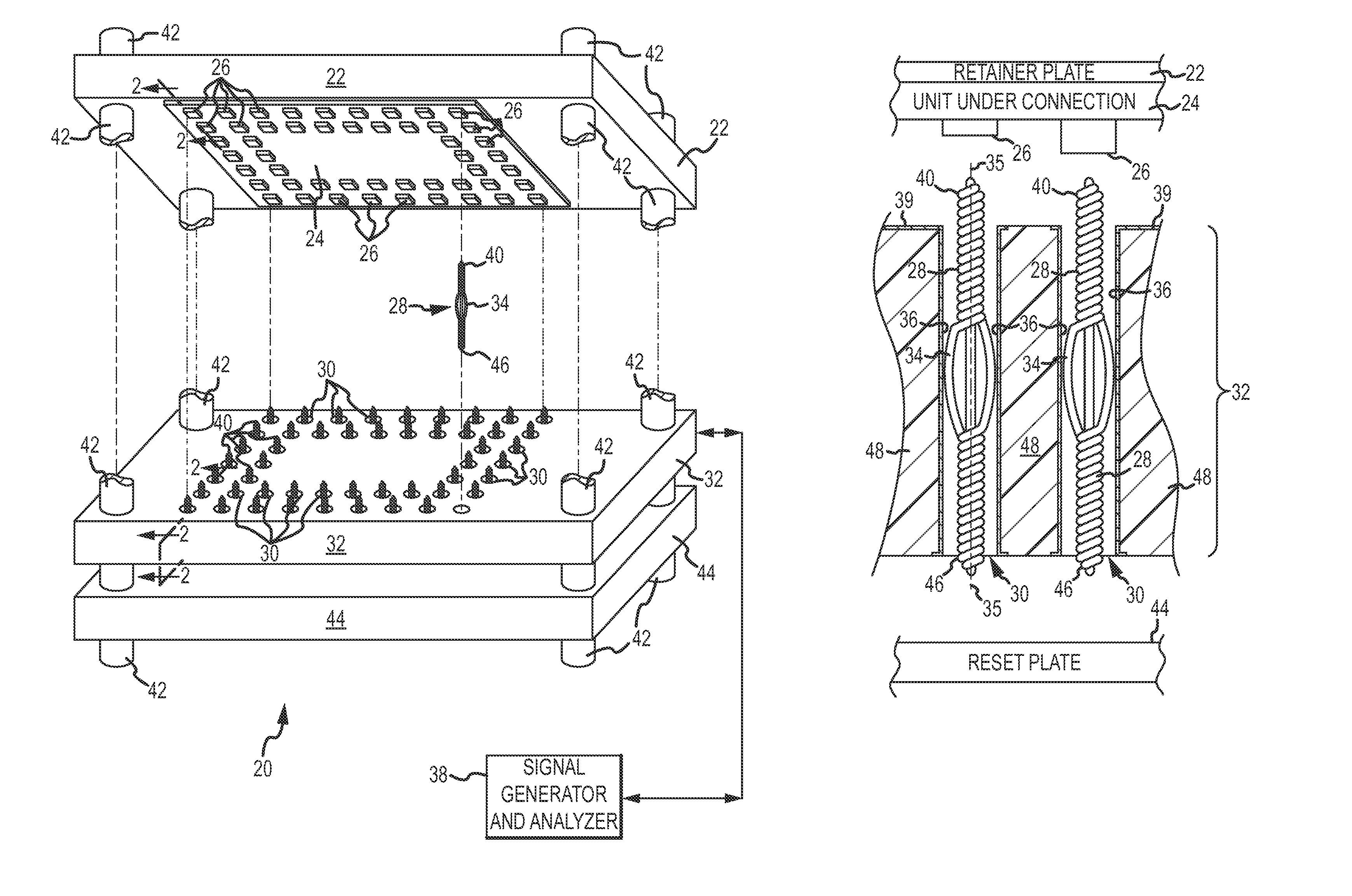

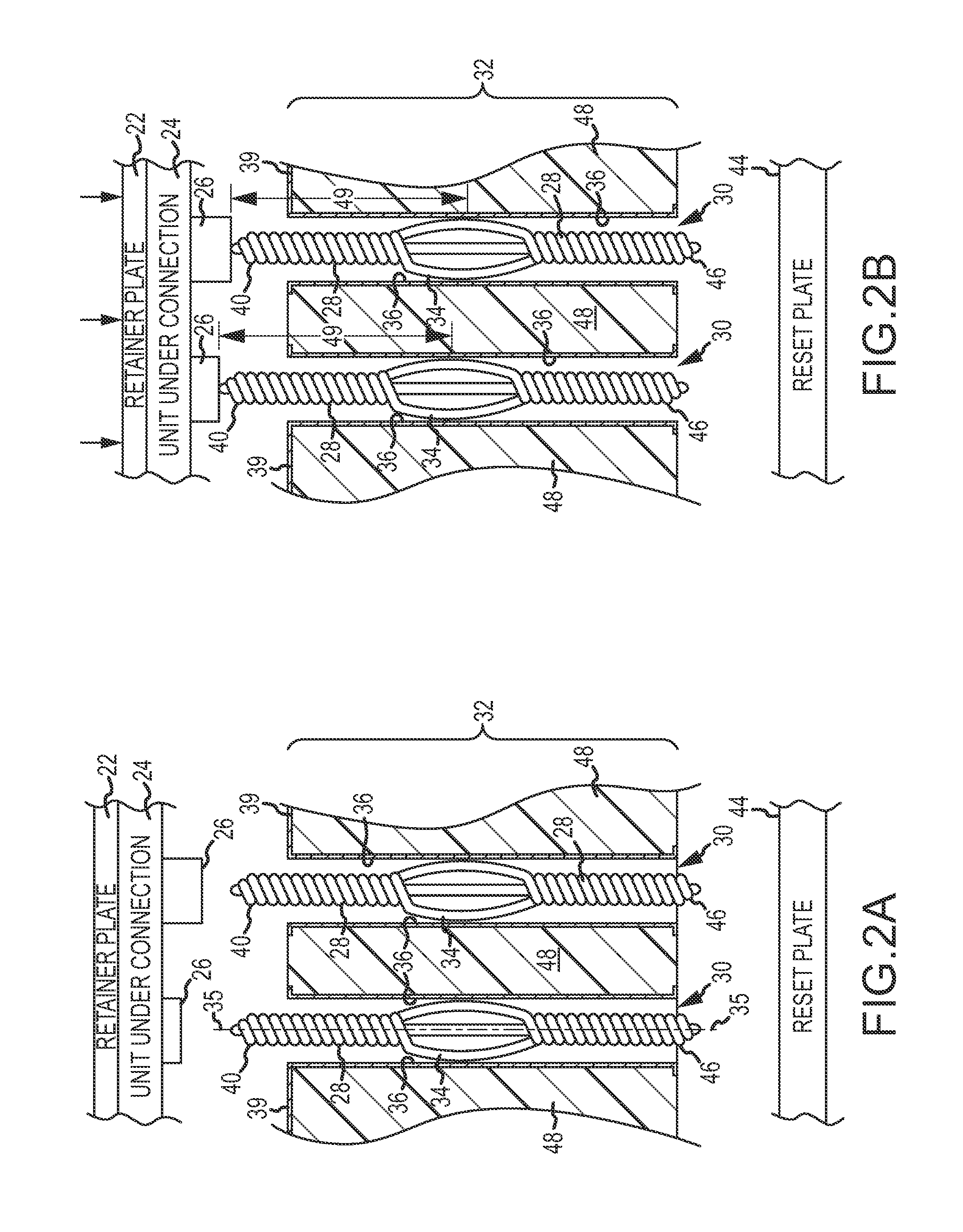

Interconnection Interface Using Twist Pins for Testing and Docking

InactiveUS20120208381A1Minimizing and eliminating anomalous signal effectEfficient and rapid and cost-effective registrationElectrical measurement instrument detailsCoupling device detailsEngineeringInterconnection

A twist pin is used as an interconnect interface to conduct signals to and from an electronic component. The twist pin includes a bulge which establishes compressive contact force with a sidewall of a via in which the twist pin resides, and the resulting force resists movement of the end of the twist pin away from the electronic component to assure good signal conductivity. The arrangement may be used as a test socket for testing integrated circuit components or permanently docking electronic components.

Owner:MEDALLION TECH

Interconnection interface using twist pins for testing and docking

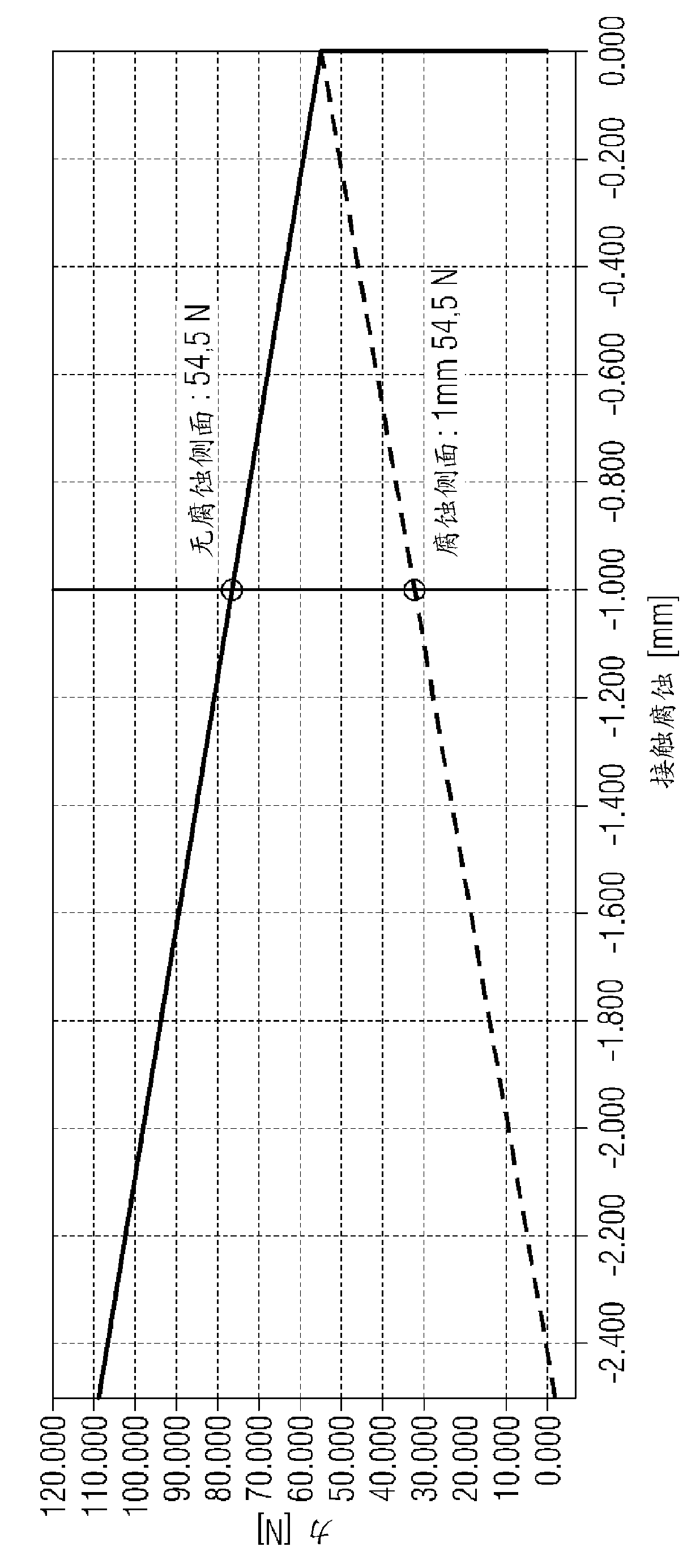

InactiveUS8613622B2Eliminating differential force distributionMinimizing or eliminating anomalous signal effectsElectrical measurement instrument detailsCoupling device detailsInterconnectionContact force

Owner:MEDALLION TECH

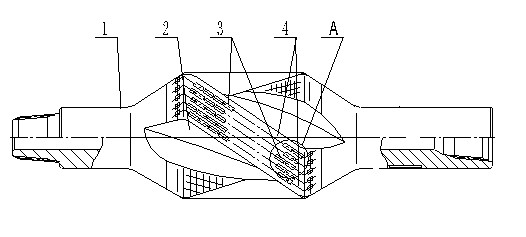

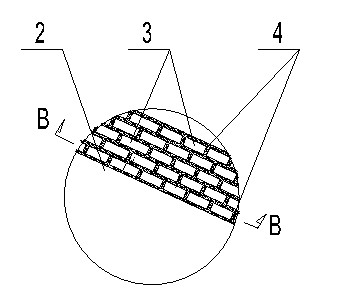

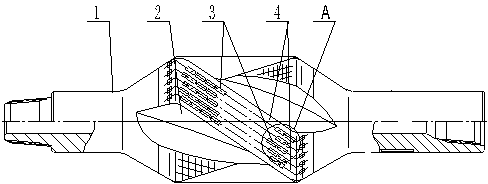

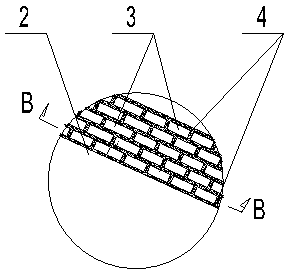

Stabilizer and manufacturing method thereof

ActiveCN102642112AUniform contact forceIncrease contact areaDrilling rodsDrilling casingsCemented carbideCylindrical grinding

The invention discloses a stabilizer and a manufacturing method thereof. The manufacturing method comprises the following steps that: hard alloy blocks are first welded on an edge band matrix by adopting a spot welding way; afterwards, spray welding is carried out on the edge band matrix around the hard alloy blocks by adopting a flame spray welding gun; burnt-out alloy powder sprayed out from the welding gun and the edge band matrix are melted integrally to form alloy powder melted layers around the hard alloy blocks; the hard alloy blocks are fixedly arranged on the edge bank matrix firmly; and after a spray-welded layer covers all the hard alloy blocks, the stabilizer is fed onto a cylindrical grinding machine to be subjected to cylindrical grinding, so that each hard alloy block is ground to be exposed and reach the diameter dimension of the outer circle of the needed stabilizer, thereby obtaining the stabilizer. The stabilizer not only has the advantages of being simple in structure and being easy to manufacture, but also has the advantages of high dimensional precision, high abrasive resistance, long service life and the like.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

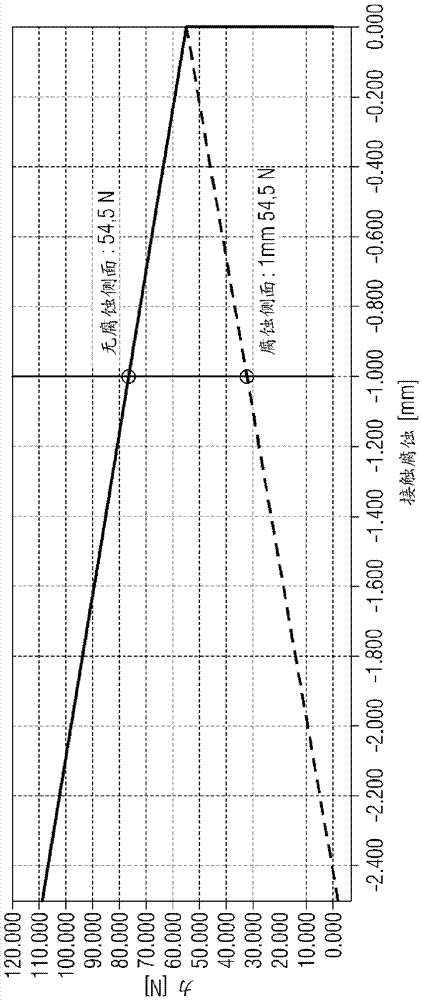

Rotor for an electric switch

ActiveCN103681131AUniform contact forceReduce contact resistanceSwitches with electromagnetic releaseContactsEngineeringElectrical switching

Owner:SIEMENS AG

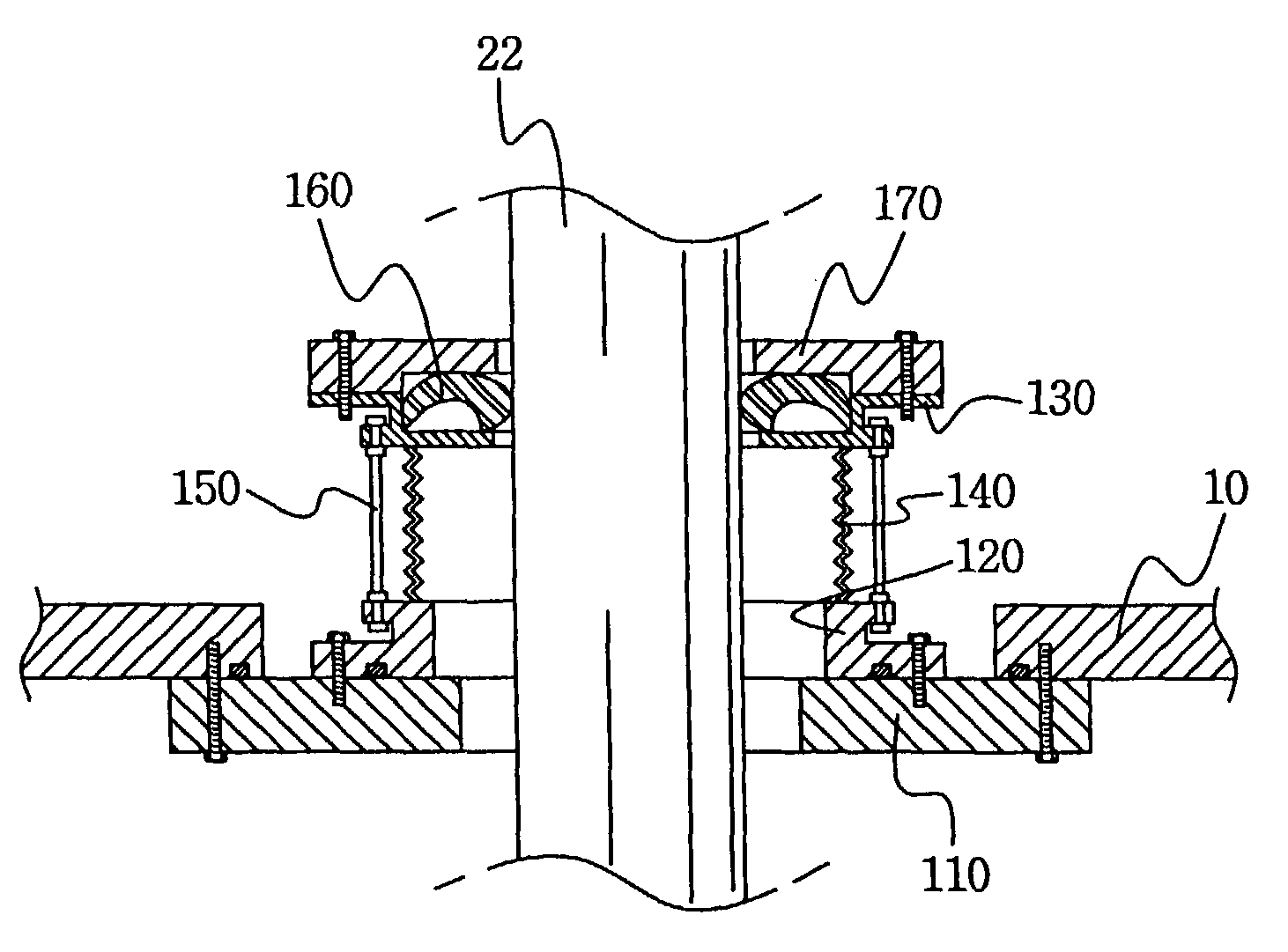

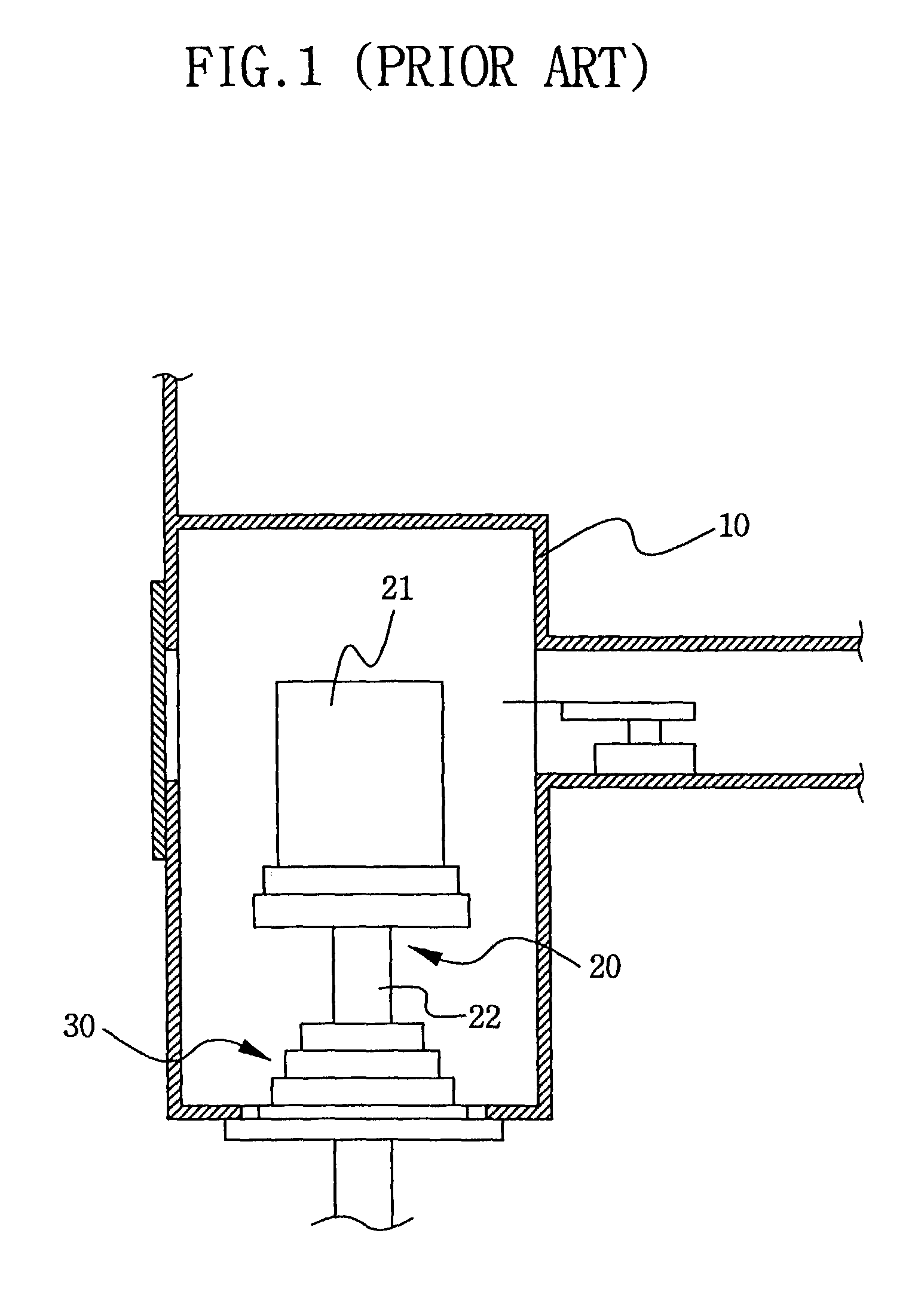

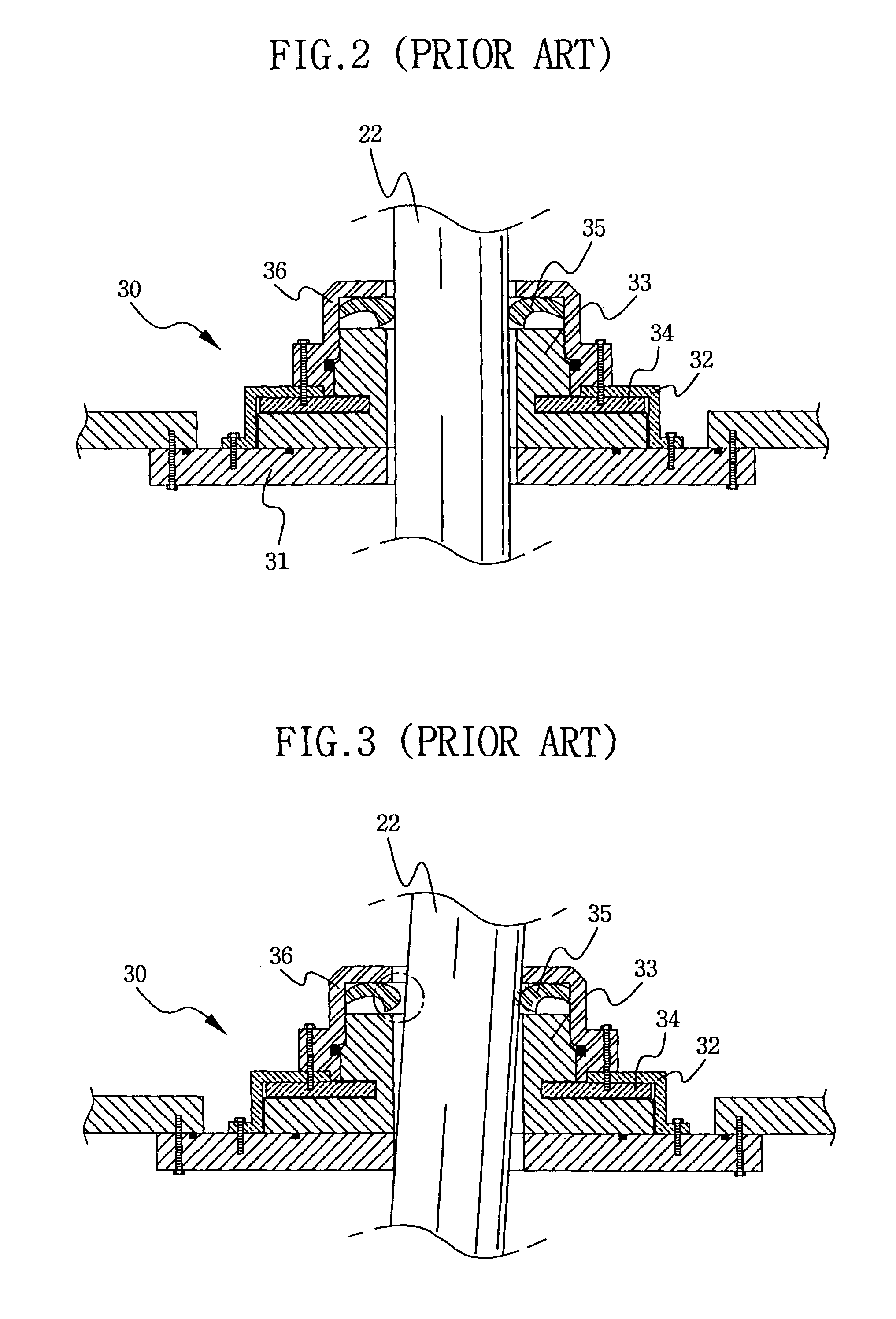

Loadlock apparatus and structure for creating a seal between an elevator drive shaft and the loadlock chamber thereof

InactiveUS7001129B2Improve sealingExtended service lifeEngine sealsSemiconductor/solid-state device manufacturingDrive shaftEngineering

Sealing structure for use in creating a seal between an elevator drive shaft and a loadlock chamber includes a base fastened over a hole in the bottom wall of the loadlock chamber, a fixed member fastened to an upper part of the base, a seal housing spaced above the fixed member, a cap in the form of a flexible bellows having a first end adhered to an upper surface of the fixed member and a second end adhered to a lower surface of the seal housing, one or more support shafts having upper and lower ends pivotally connected to the seal housing and the fixed member outside the cap, a seal seated in the seal housing and having an inner circumferential surface contacting the outer circumferential surface of the elevator drive shaft, and a seal cover fixed to an upper part of the seal housing. According to the present invention, uniform pressure is maintained between the shaft and the seal during assembly and operation of the apparatus. Thus, a seal is always maintained between the elevator drive shaft and the bottom wall of the loadlock chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

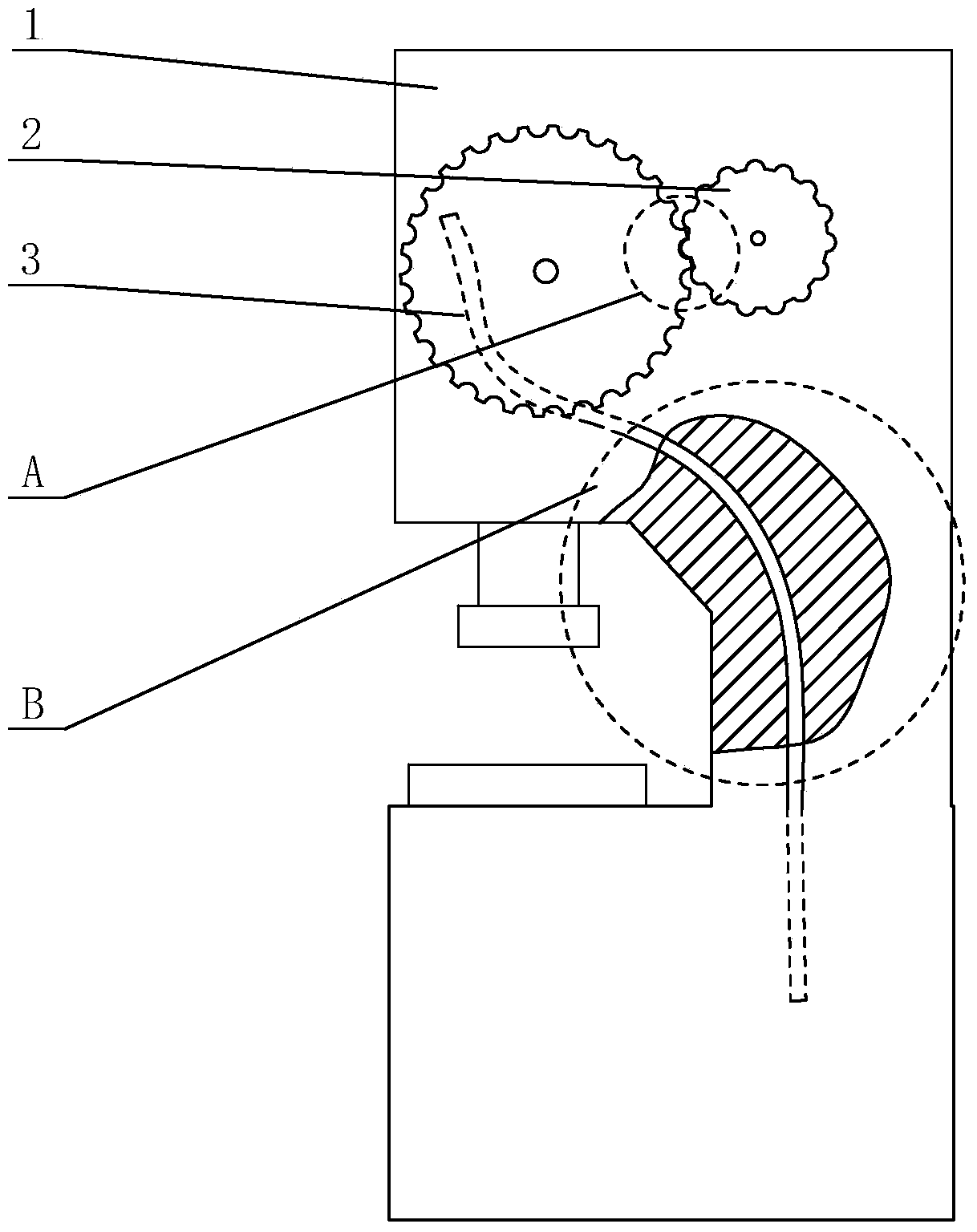

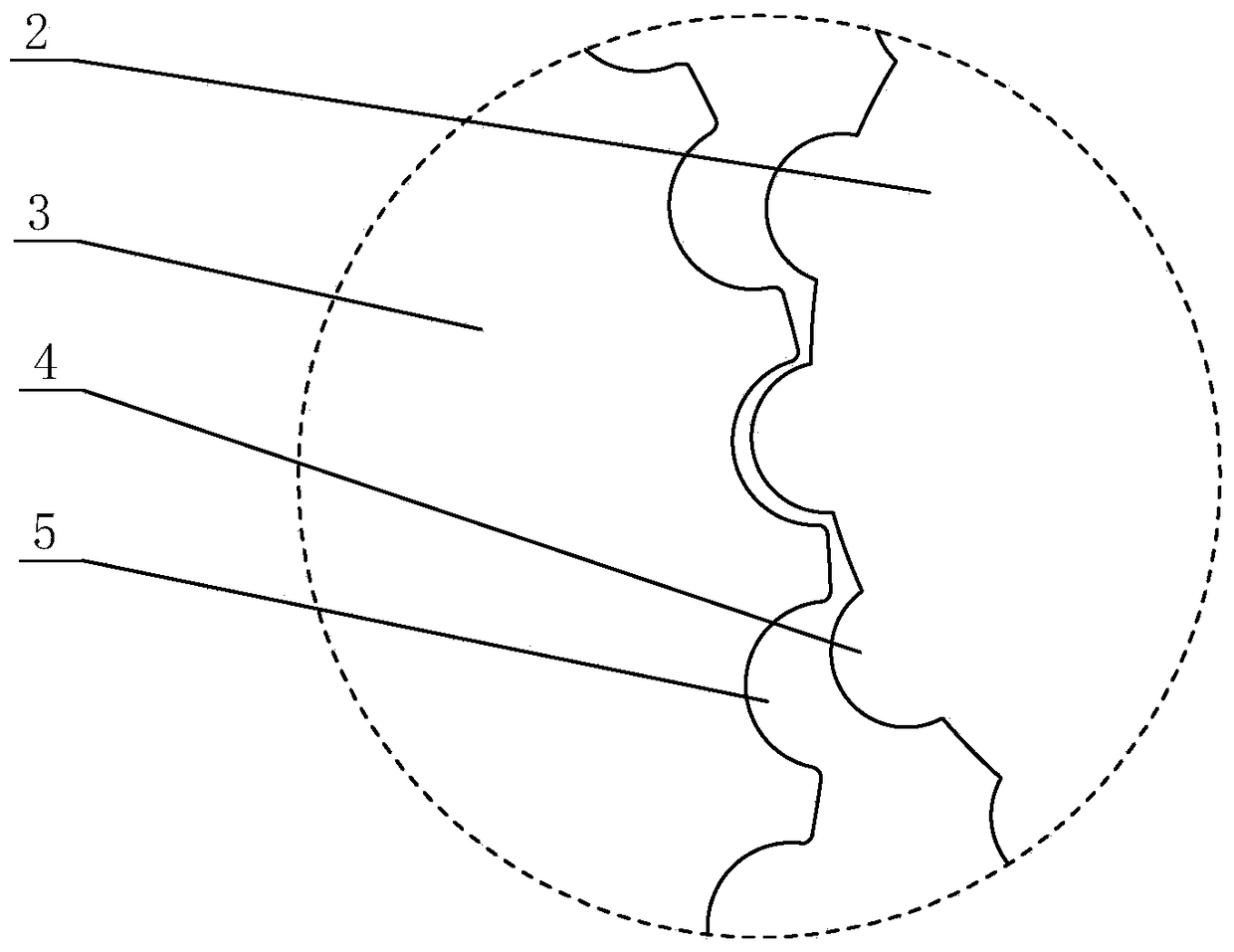

punching machine

The invention relates to a stamping machine, and belongs to the mechanical field. The stamping machine comprises a drive gear and a driven gear, wherein the drive gear is connected with a rotary shaft of a motor through a transmission device; the driven gear is fixed on a crankshaft; the drive gear transfers power in a manner of being engaged with the driven gear; the working surfaces of gear teeth on the drive gear are arc-shaped; arc-shaped grooves are arranged in the driven gear; the inner surfaces of the grooves are in close fit with the outer surfaces of the gear teeth when the grooves are engaged with the gear teeth. The gear teeth have the arc surfaces, the gears are engaged through the arc surfaces, the gear teeth form contact through the arc surfaces during the engagement process, and stresses on the parts of the gear teeth are uniform to prevent hard collision among the teeth.

Owner:丁乃祥

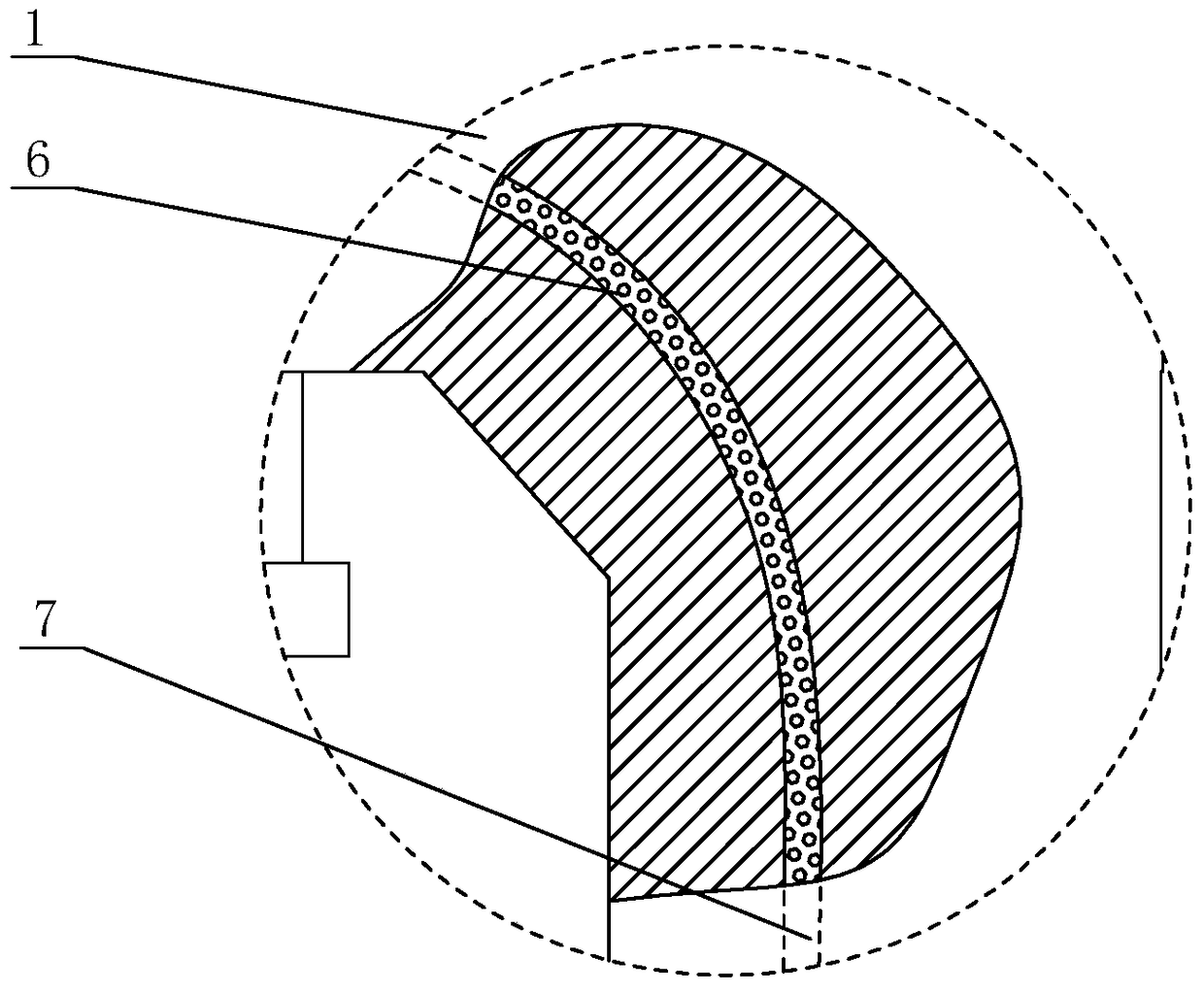

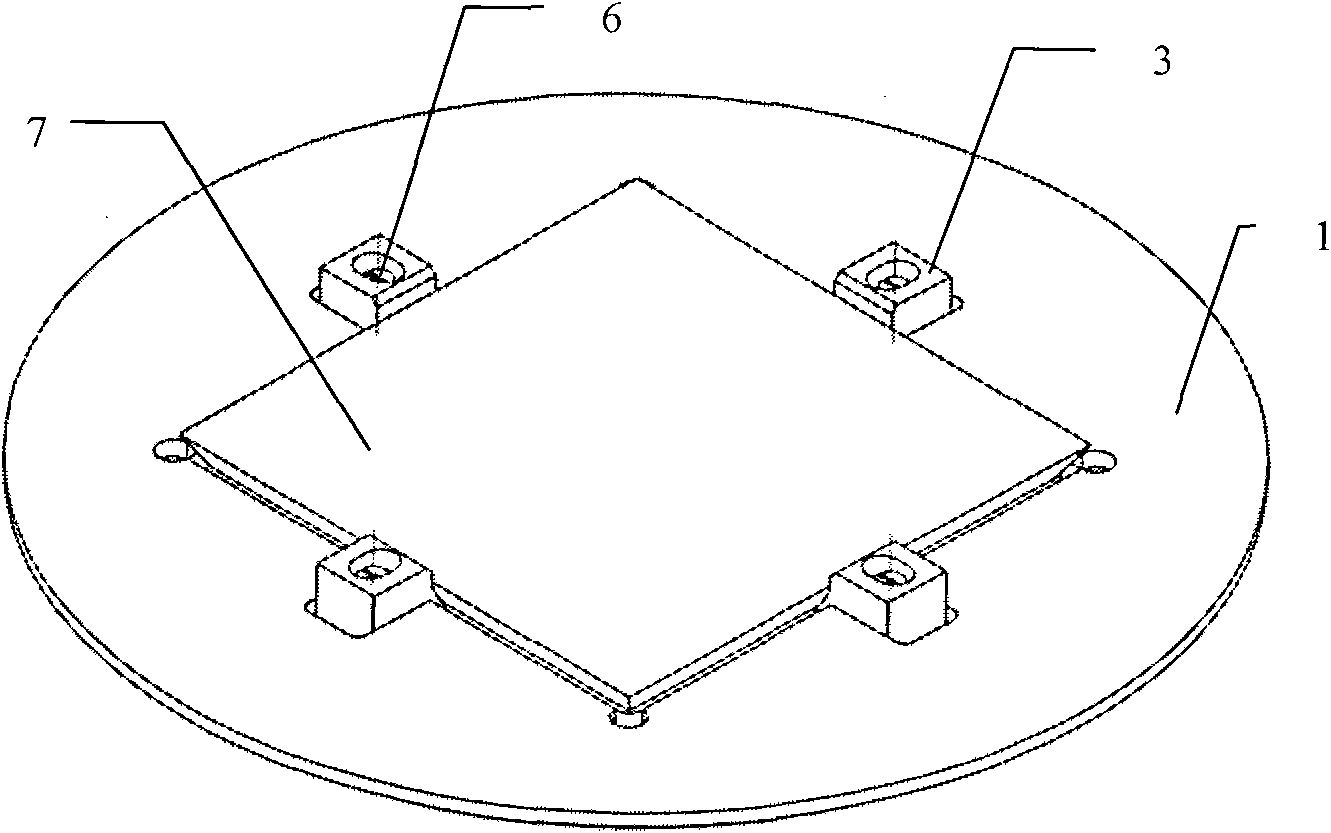

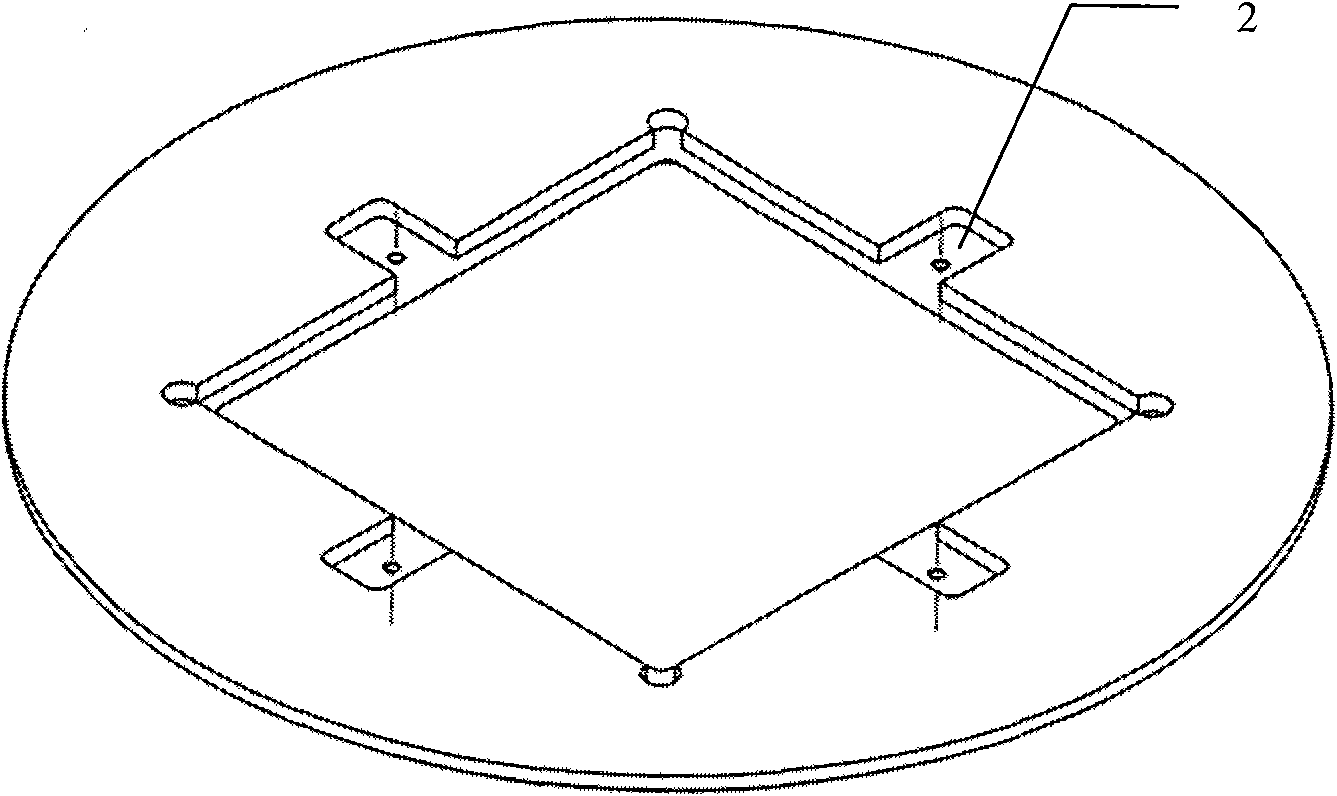

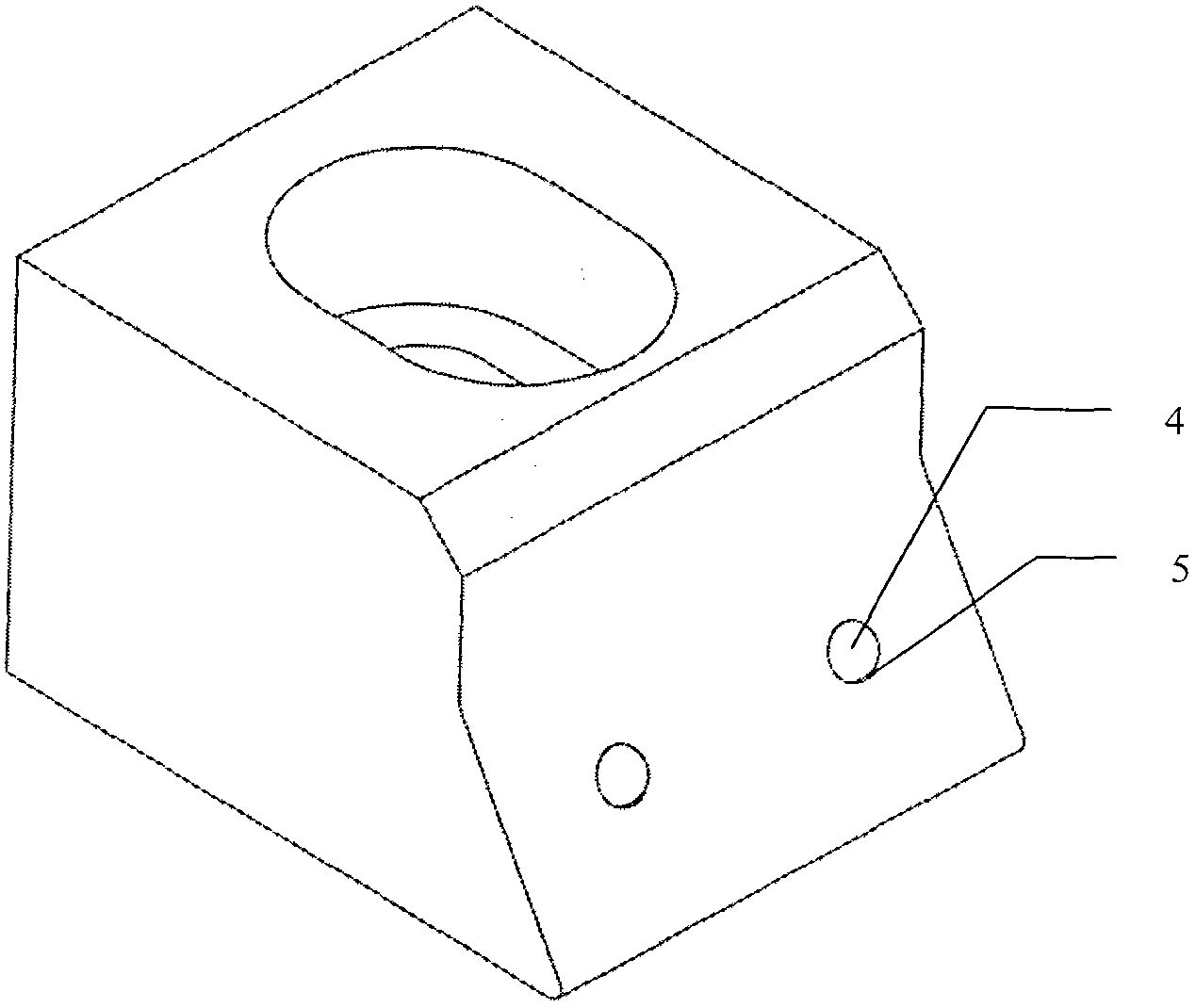

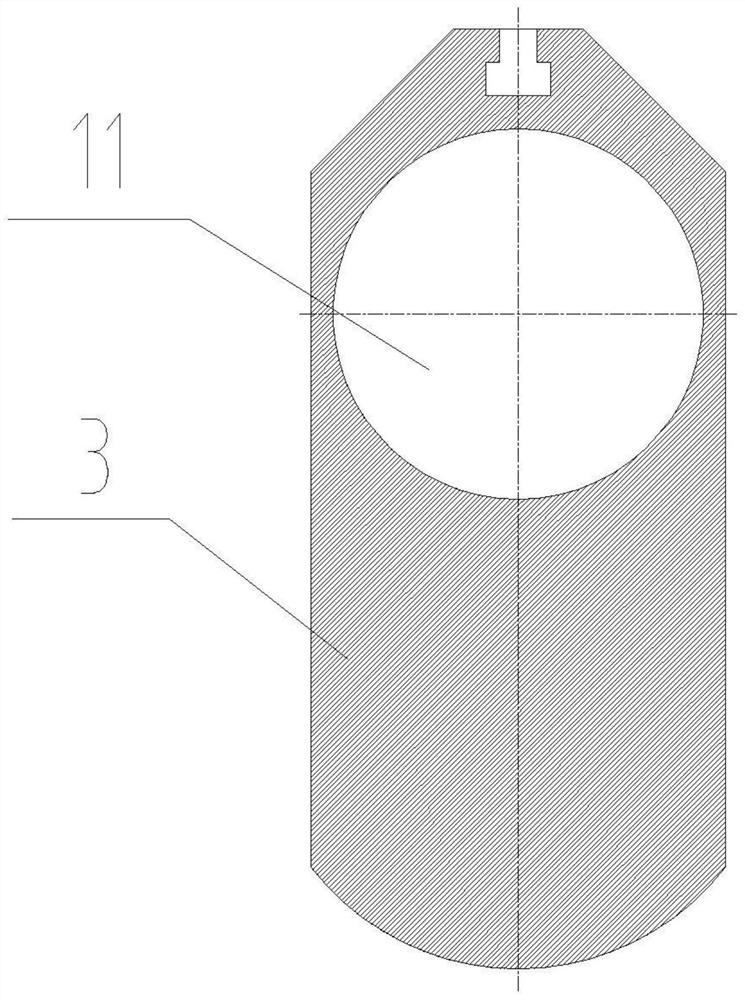

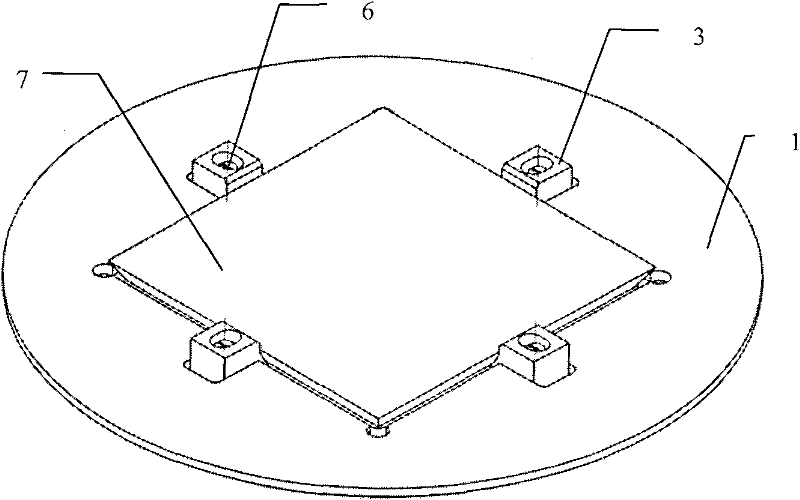

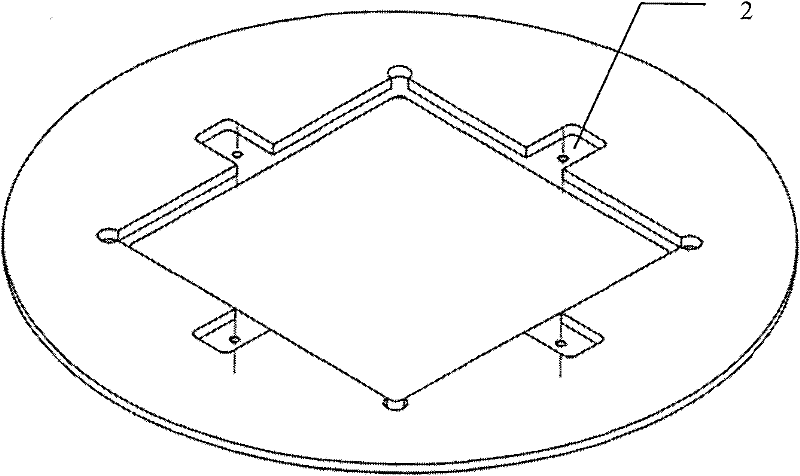

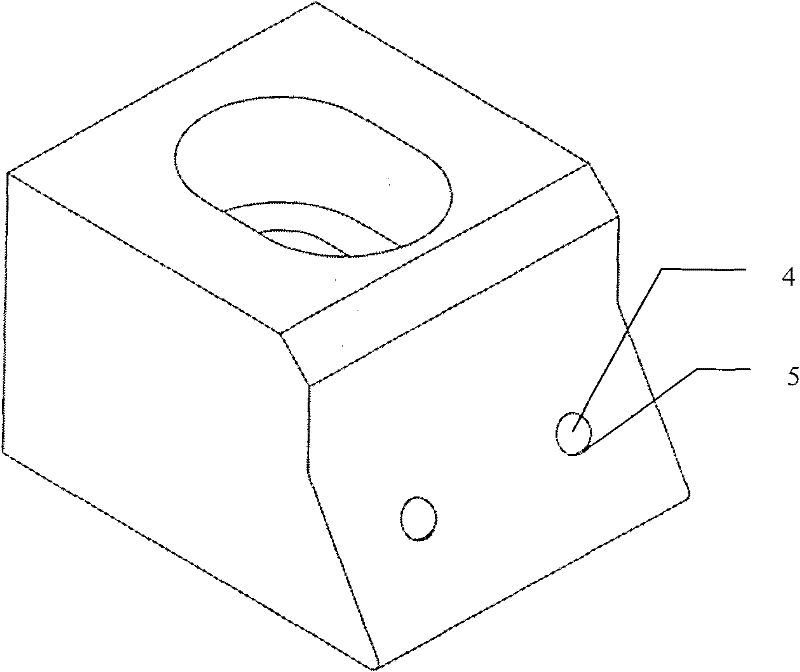

Coating film supporting mechanism of high temperature deposition hard mask of film coating workpiece

InactiveCN101928921AUniform contact forceMeet high and low temperature without deformation and failureVacuum evaporation coatingSputtering coatingOptical coatingSteel ball

The invention relates to a coating film supporting mechanism of a high temperature deposition hard mask of a film coating workpiece, belonging to auxiliary equipment of optical coating. The coating film supporting mechanism comprises a film coating tray, a stop dog groove, a workpiece stop dog, a locking screw, a steel ball and a steel ball caulking groove. The middle part of the film coating tray is provided with an opening for placing the film coating workpiece, the four sides of the tray are provided with radial stop dog grooves for installing the workpiece stop dog, the workpiece stop dog moves in the groove, the inclined plane of the workpiece stop dog is embedded with a steel ball (rolling ball), the steel ball rolls in the caulking groove, the workpiece stop dog is fixed in the stop dog groove by the locking screw, the edges of the film coating workpiece are all provided with tapers, the film coating workpiece is placed on the inclined plane of the workpiece stop dog and contacts with the steel evenly, and then the film coating workpiece and the entire device are both placed into a circular ring tray of the film coating machine. The mechanism of the invention can ensure that uniform force is exerted on each steel ball and the workpiece, the position of the stop dog can be freely adjusted in a certain scope according to the dimension of the workpiece; in addition, the chucking power for adjusting the workpiece can be provided by expansion or shrinkage force generated from high temperature or low temperature to drive the steel ball to roll; and the mechanism of the invention features in simple structure and high cost performance.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

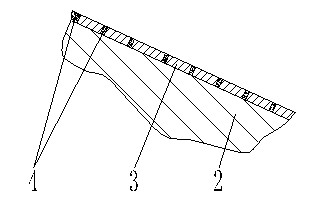

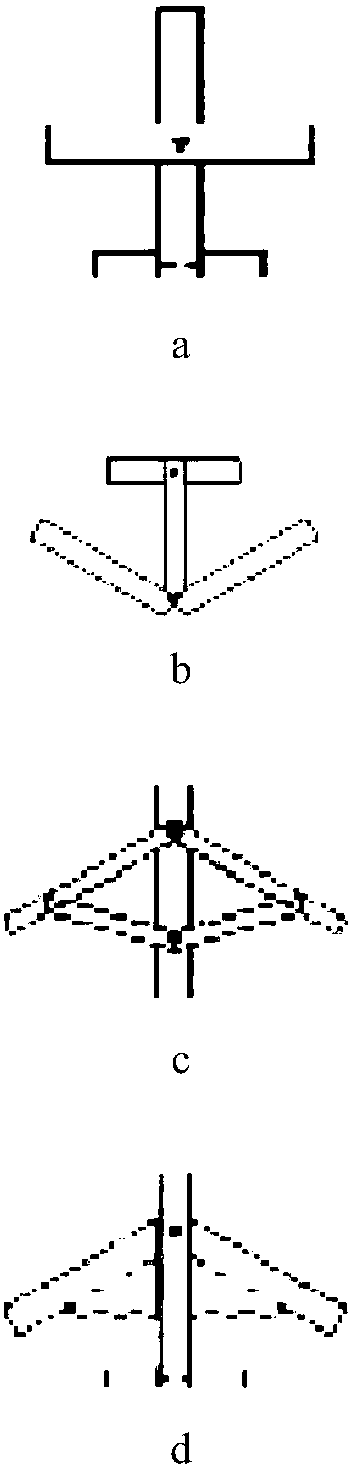

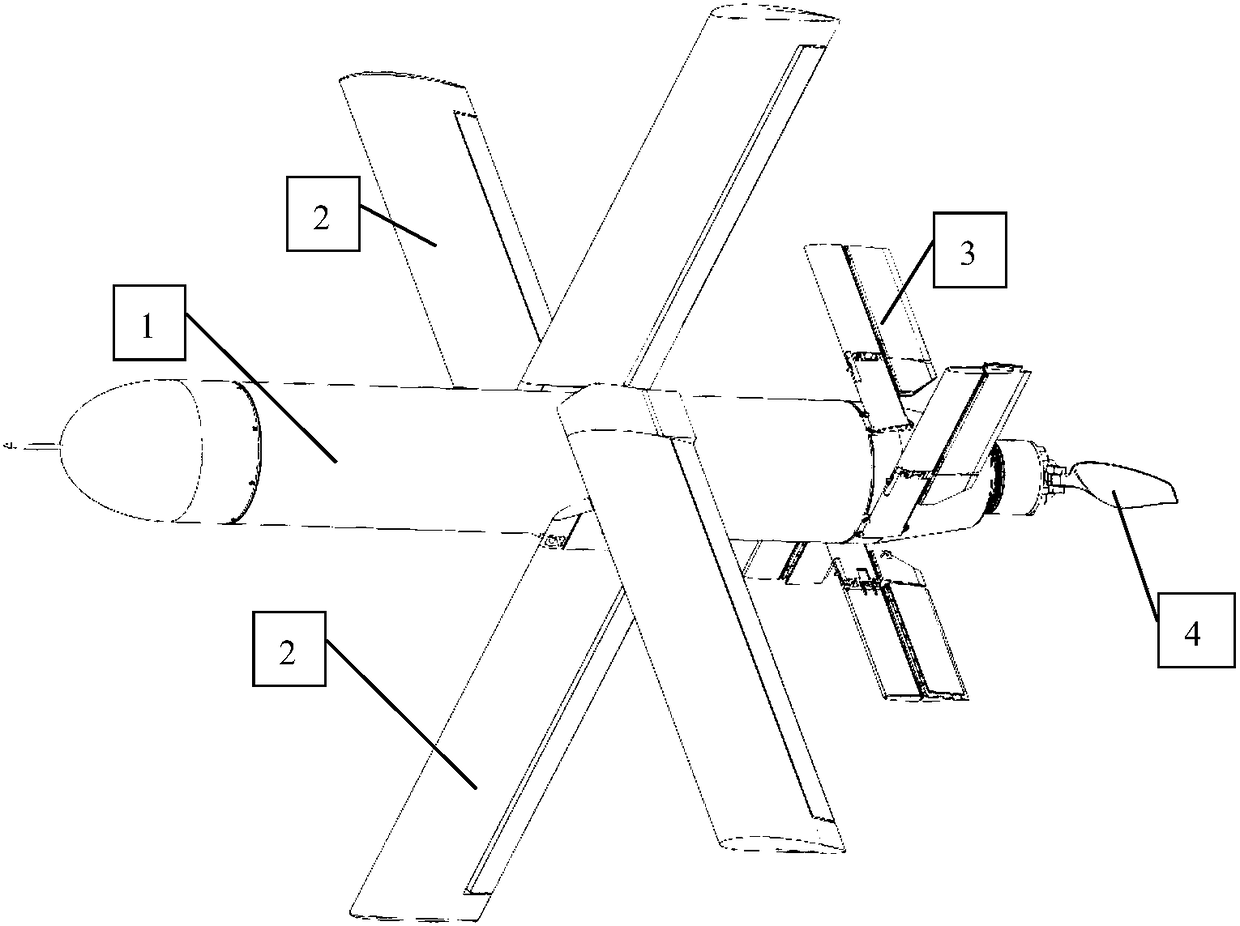

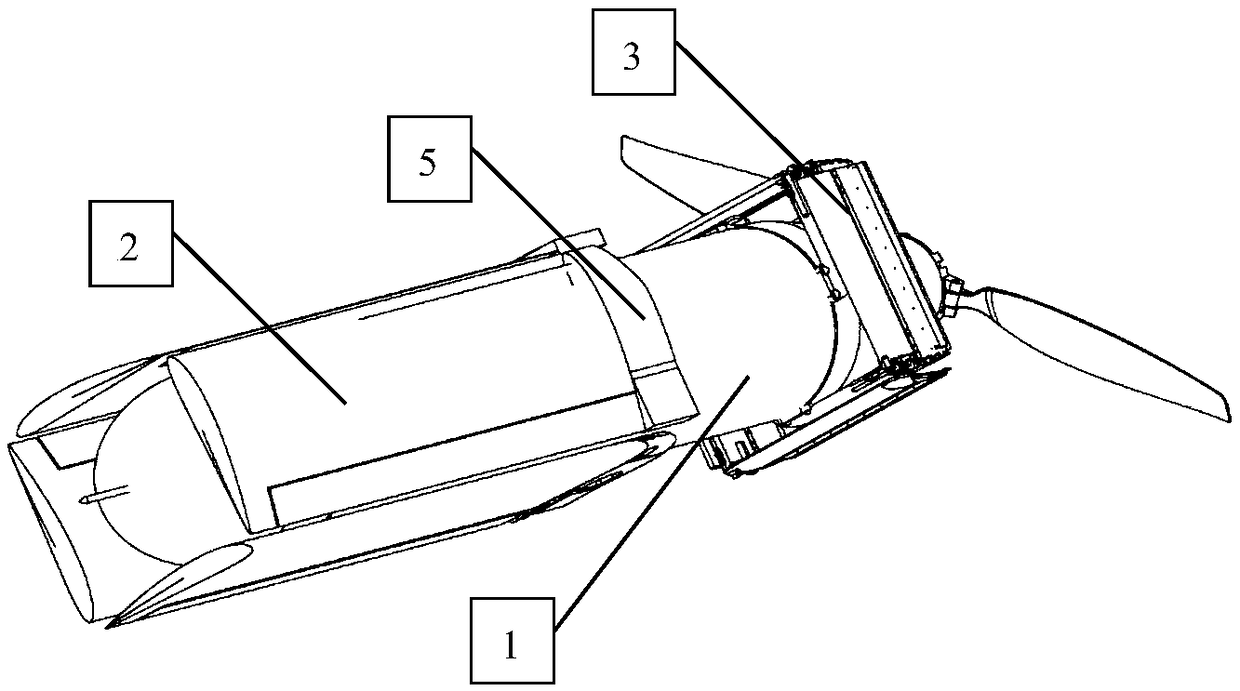

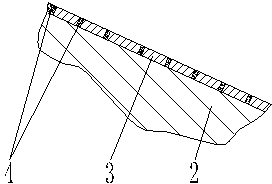

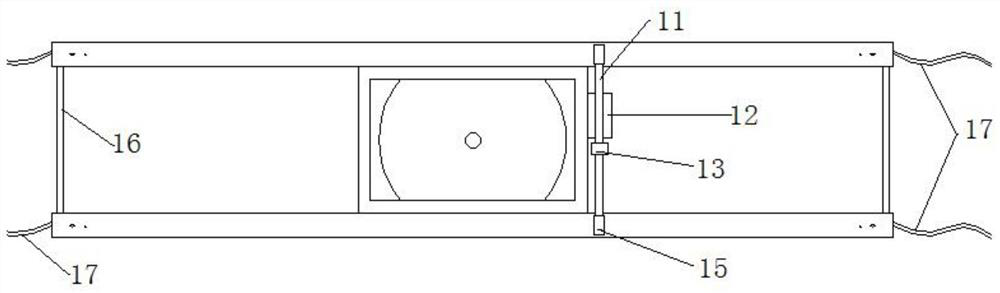

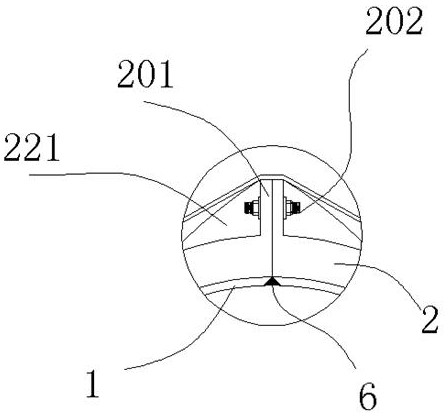

Unmanned aerial vehicle based on X-wing layout

The invention relates to the technical field of unmanned aerial vehicles, and provides an unmanned aerial vehicle based on X-wing layout. The unmanned aerial vehicle comprises a vehicle body, a plurality of main wings and a plurality of tail rings, wherein the cross section of the vehicle body is in a circle shape, the plurality of main wings are symmetrically arranged along the longitudinal axisof the vehicle body, and the installation plane of the main wings is tangential to the vehicle body; the plurality of tail wings are symmetrically arranged along the longitudinal axis of the vehicle body, and the installation plane of the tail wings is tangential to the vehicle body; the installation direction of the tail wings is opposite to the installation direction of the main wings; each mainwing is connected with a foldable mechanism in the vehicle body through an adapter, and can rotate around the adapter which is used as the rotation center; all the main wings and the tail wings are foldable. The unmanned aerial vehicle has the advantages that by adopting the novel aerodynamics layout, compared with the traditional unmanned aerial vehicle, the maneuverability is stronger, and thebattlefield survival ability is strong; the unmanned aerial vehicle can be folded, so that the occupation space after folding is smaller than the occupation space of other conventional unmanned aerialvehicles, the disassembly of parts for box loading is not needed in the transportation process, and the disassembly and assembly time is shortened; the structure is simple, novel and reasonable, andthe application prospect is broad.

Owner:北京华信宇航科技有限公司

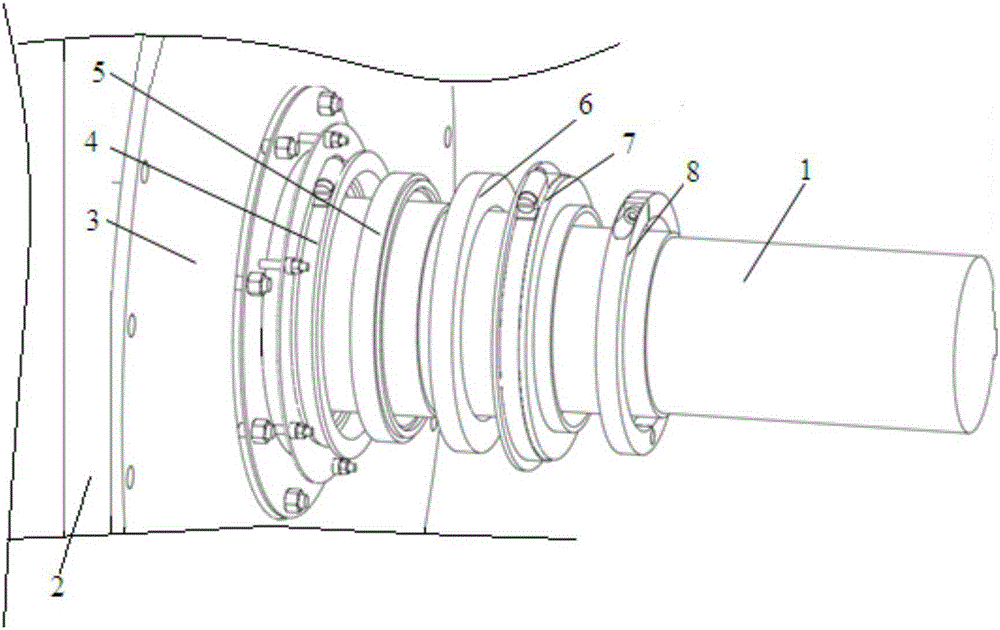

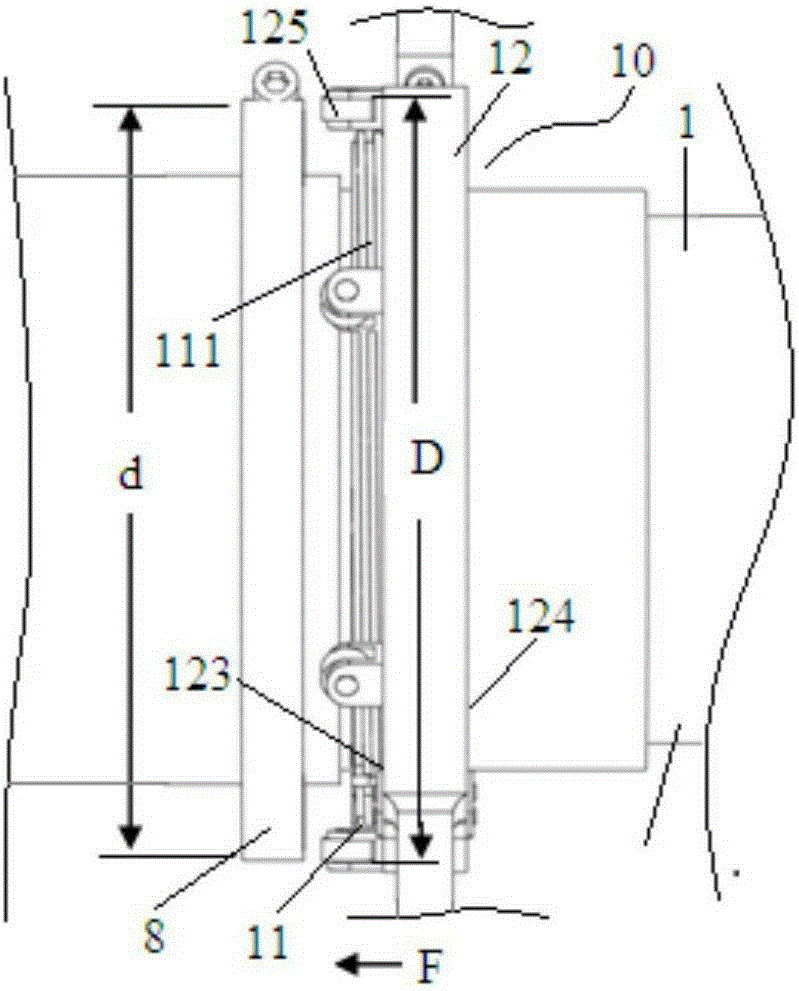

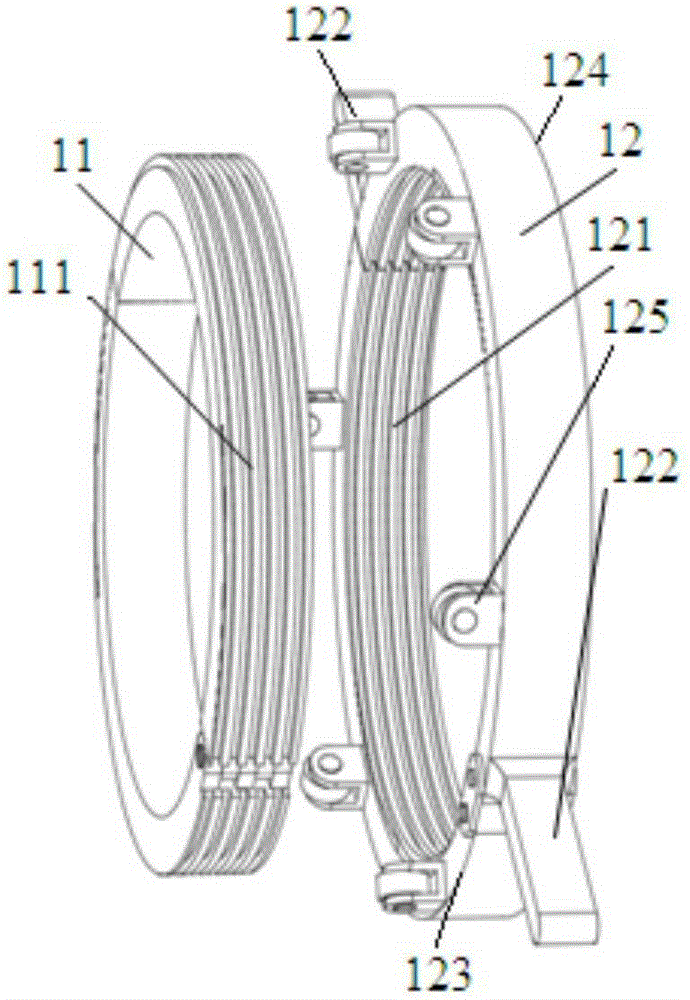

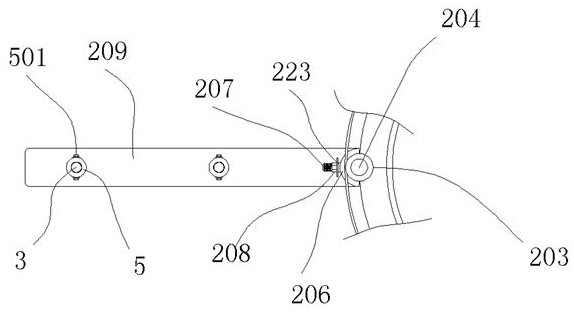

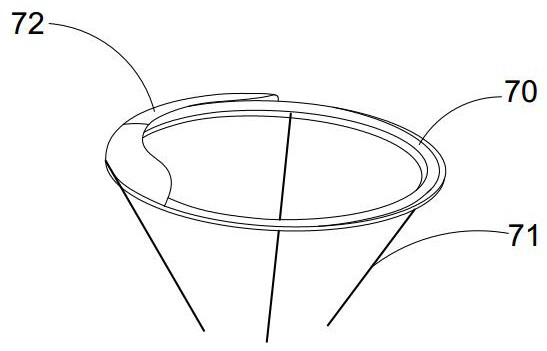

Synchronizing propeller provided with sealing gaskets

The invention discloses a synchronizing propeller provided with sealing gaskets. The synchronizing propeller is characterized by comprising an inner ring and an outer ring, wherein the inner ring is fixedly arranged, the outer ring surface of the inner ring is provided with an outer thread, the outer ring and the inner ring are coaxially arranged, the inner ring surface of the outer ring is provided with an inner thread meshed with the outer thread, the inner end face of the outer ring in the axial direction serves as a propelling end face, and the outer ring is subjected to axial feeding relative to the inner ring in the rotating process so as to enable the propelling end face to exert an axial propelling force. According to the synchronizing propeller provided with the sealing gaskets, it can be effectively guaranteed that propelling distances of sealing components in the propelling process are equal, and therefore contact between faying surfaces of the adjacent sealing components is stressed uniformly; therefore, it is guaranteed that an immersion tank has good sealing performance, and the immersion tank is prevented from leaking liquid.

Owner:宝钢日铁汽车板有限公司

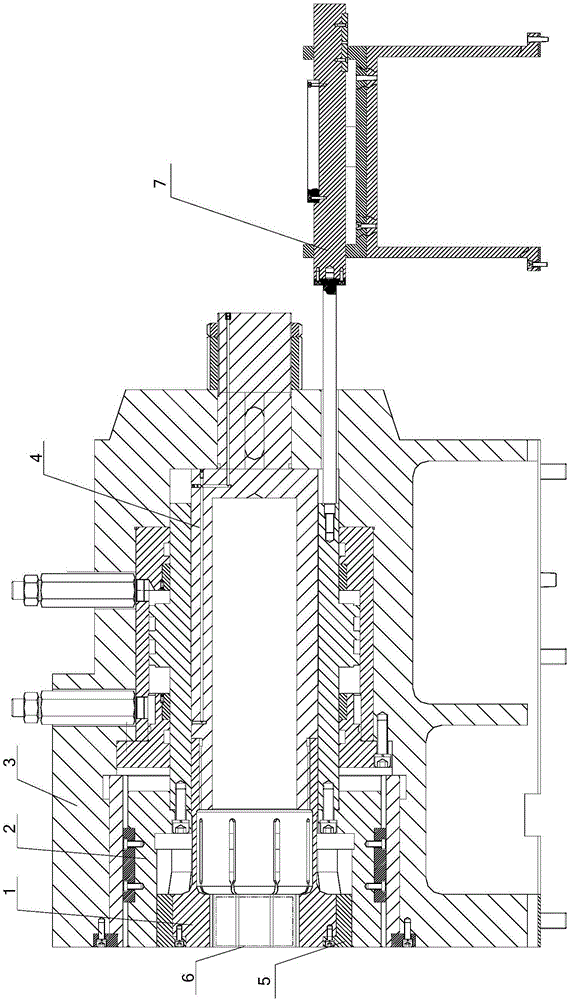

Friction welding machine and radial friction welding closed fixture

ActiveCN106271027AExtended service lifeFree from bumpsNon-electric welding apparatusFriction weldingEngineering

The invention discloses a friction welding machine and a radial friction welding closed fixture. The radial friction welding closed fixture comprises a spring chuck, a conical sleeve, a fixture body and a clamping sleeve; the fixture body coats the outer side of the spring chuck; the conical sleeve is slidingly arranged between the spring chuck and the fixture body; when the conical sleeve slides, the inner conical surface thereon is matched with the outer conical surface of the spring chuck to realize clamping or releasing of the spring chuck; the clamping sleeve is annular, and is clamped in the spring chuck; when the spring chuck is clamped, the clamping sleeve is elastically deformed to clamp a workpiece; when the workpiece is clamped, the spring chuck is clamped to apply pressure to the clamping sleeve, and the clamping sleeve is pressed to deform to clamp the workpiece; and as the clamping sleeve is clamped and matched with the spring chuck when the spring chuck is clamped, the contact stress of all components of the spring chuck with the clamping sleeve is uniform, the clamping sleeve can preferably protect the spring chuck from being collided by the workpiece, the service life of the spring chuck is prolonged, the workload of maintainers is reduced, and the production cost is reduced.

Owner:CHONGQING TURBO FLOW MACHINERY MFG

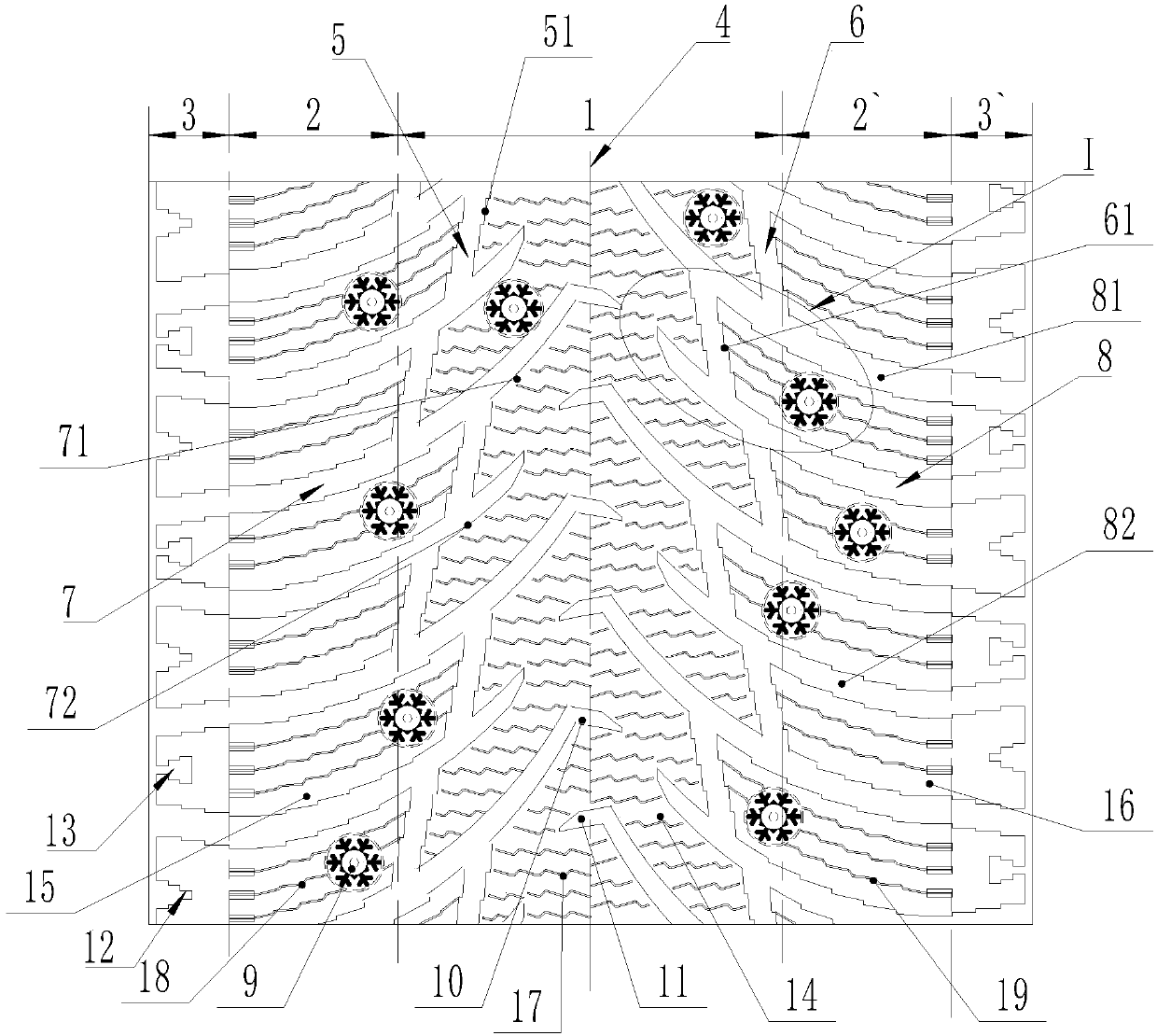

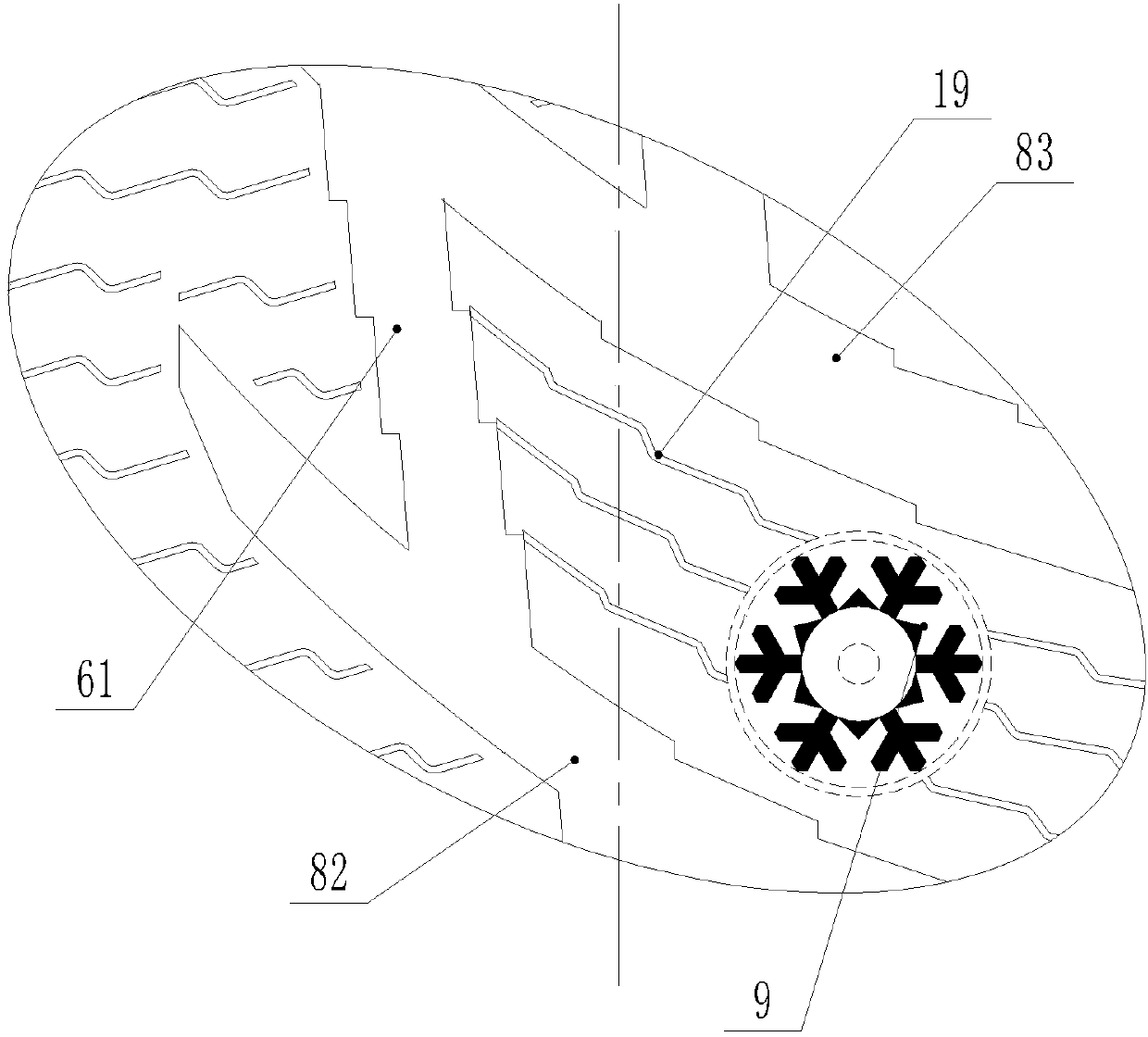

Pattern of snow tire

PendingCN107813662ASensitive contact forceUniform contact forceTyre tread bands/patternsBrakeStructural engineering

The invention discloses a pattern of a snow tire. The pattern comprises a tire crown pattern zone, a first tire shoulder pattern zone, a second tire shoulder pattern zone, a first tire sidewall pattern zone and a second tire sidewall pattern zone, wherein the tire crown pattern zone comprises first straight furrows, second straight furrows, first transverse furrows and second transverse furrows; each first straight furrow comprises a plurality of first straight furrow sections which are discrete; each second straight furrow comprises a plurality of second straight furrow sections which are discrete; circumferential and continuous tire crown pattern blocks are formed between the first straight furrows and the second furrows; the furrow walls of the first straight furrows and the second straight furrows are both set in sawtooth shapes; the first transverse furrows are located on the furrow walls of the outer sides of the first straight furrows and are set in sawtooth shapes; the second transverse furrows are located on the furrow walls of the outer sides of the second straight furrows and are set in the sawtooth shapes; snow nail installing holes are formed in the tire crown patternblocks, the first tire shoulder pattern zone and the second tire shoulder pattern zone. The pattern disclosed by the invention is capable of increasing the stability of straight movement and the sensitivity of steering, and the brake performance in snow is increased.

Owner:南港(张家港保税区)橡胶工业有限公司

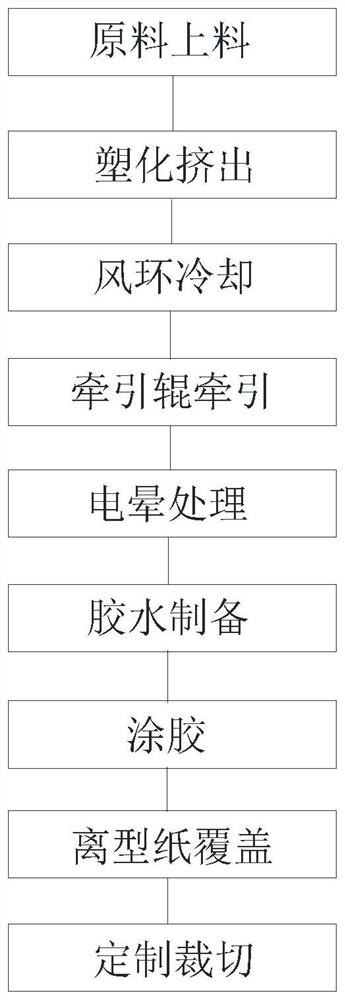

Preparation method of coating protective plastic capable of being bonded with metal

The invention relates to the technical field of coated plastic production, in particular to a preparation method of coated protective plastic capable of being bonded with metal, which comprises the following steps: S1, feeding raw materials; raw materials for manufacturing wrapping plastic are subjected to kneading and cold mixing treatment, kneading of the raw materials is completed through a kneading machine, side-by-side tangent differential arrangement is adopted, namely, the speed of one stirring paddle is high, the speed of the other stirring paddle is low, so that shearing force is generated, the mixed materials can be rapidly sheared due to different paddle speeds, and therefore the materials can be evenly mixed; cold mixing of raw materials is completed through the cold mixing machine, the cold mixing machine is provided with a cooling pipe, a cooling system is used for injecting a cooling agent into the cooling pipe through a water inlet, then the raw materials in a machine body are cooled, an automatic cutting machine is used for cutting a plastic film covered with release paper into a preset shape, and leftover materials are recycled; and the cut wrapping plastic finished products are collected and wrapped in a centralized mode, the metal parts can be directly wrapped after the release paper is torn off, and use is convenient.

Owner:重庆华众新型材料有限公司

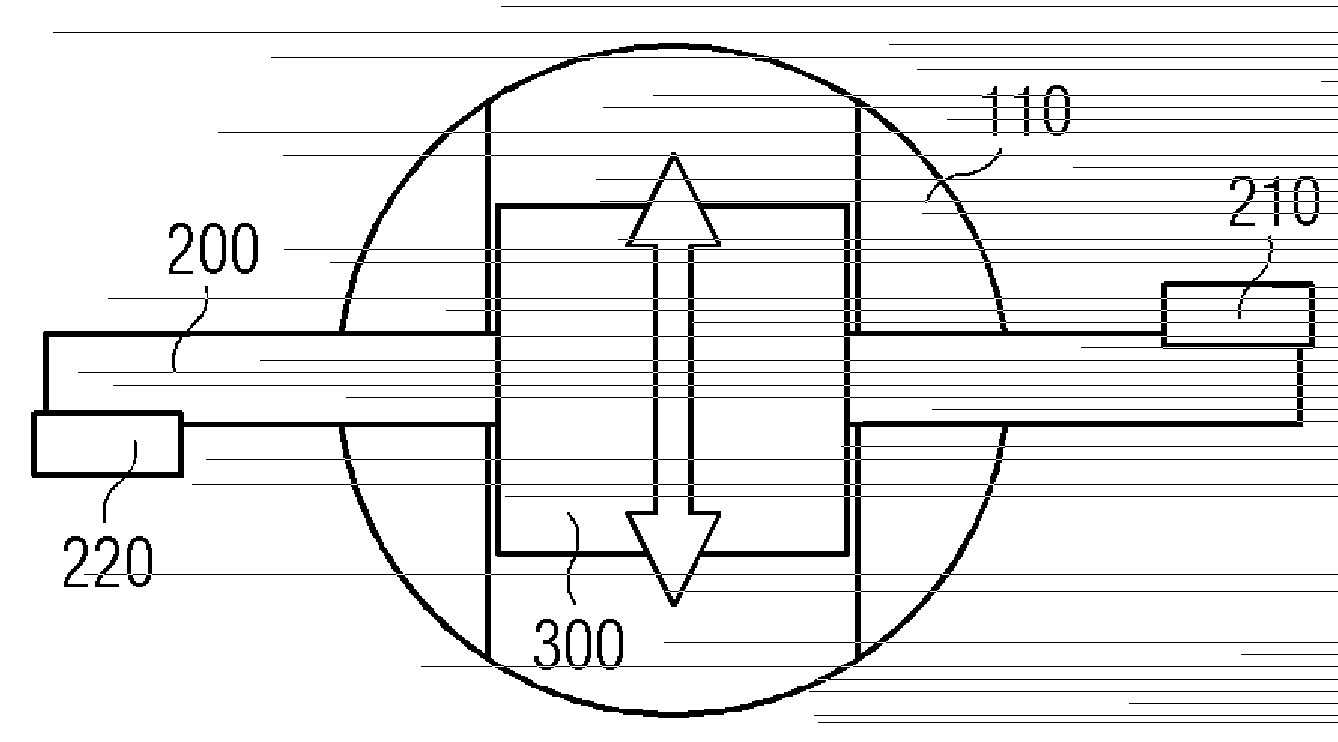

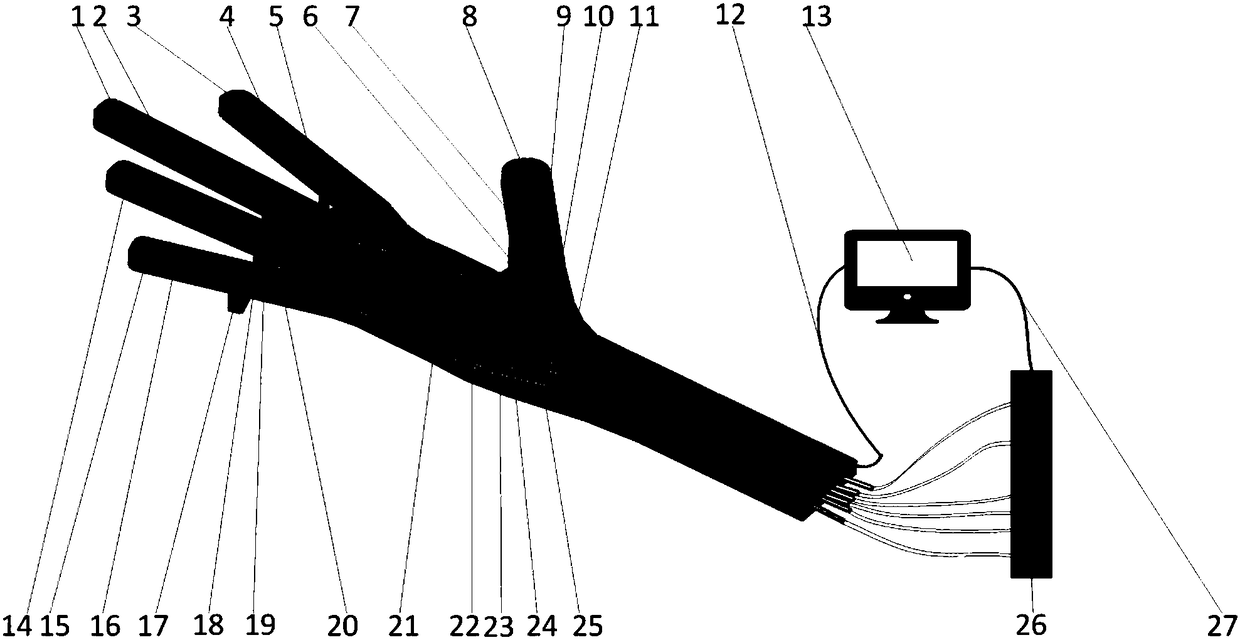

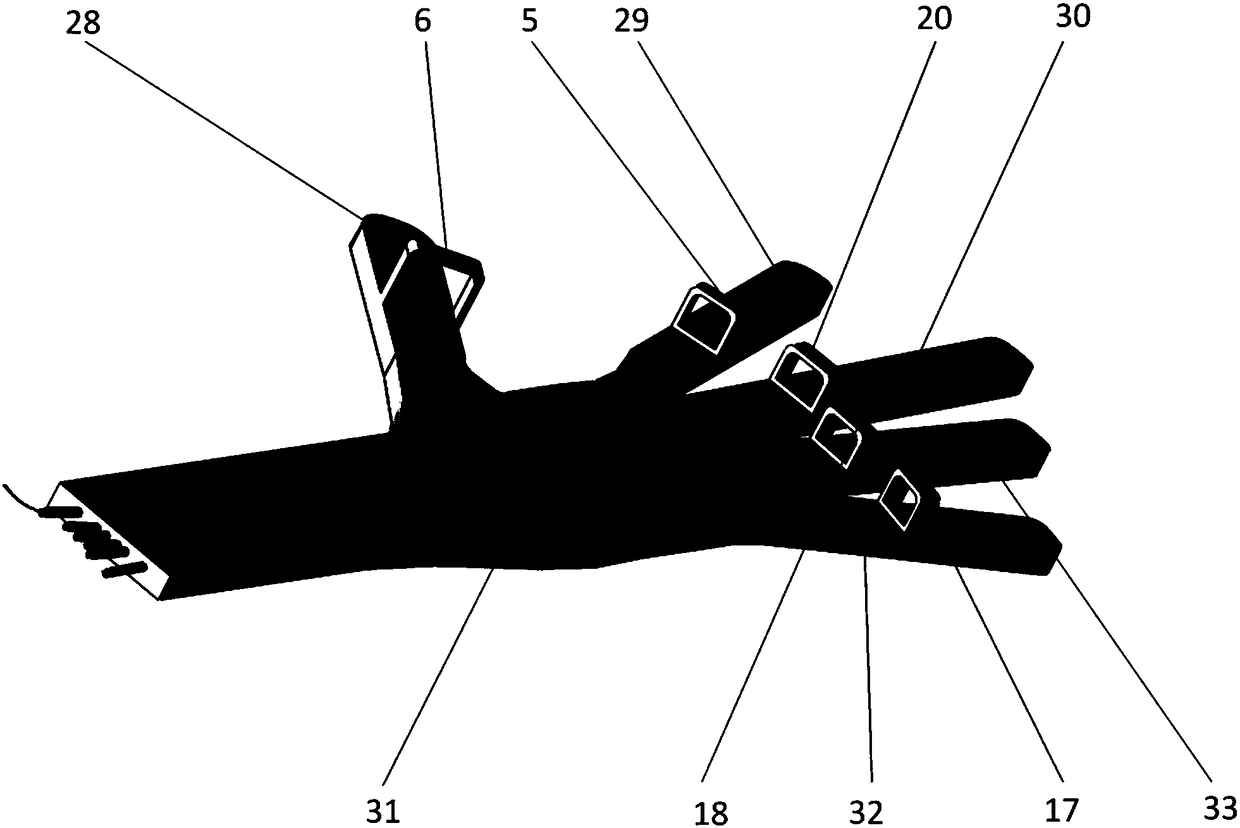

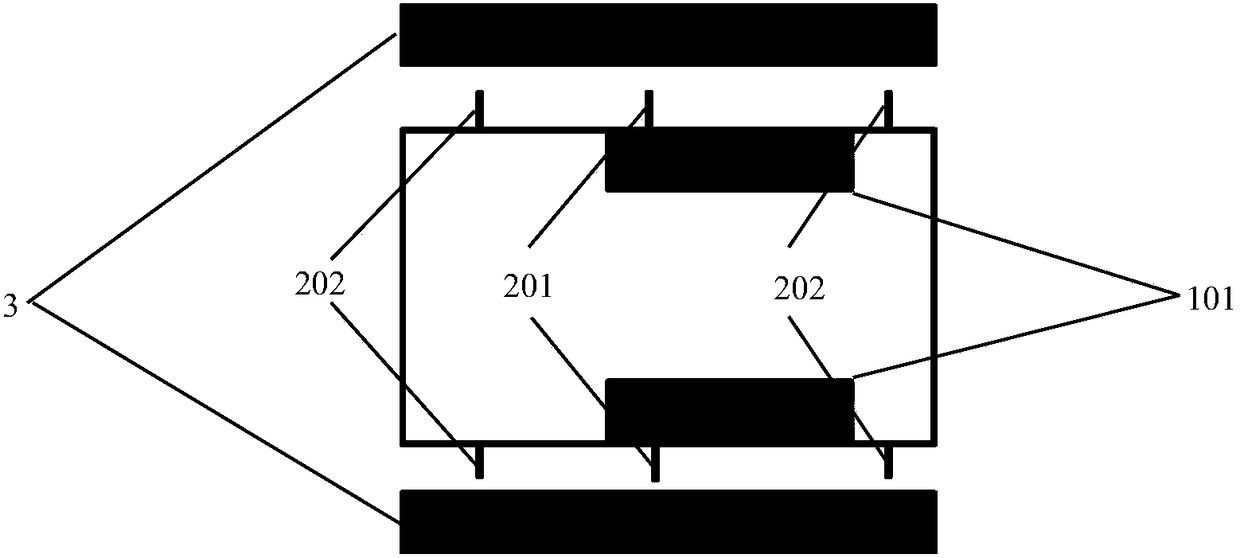

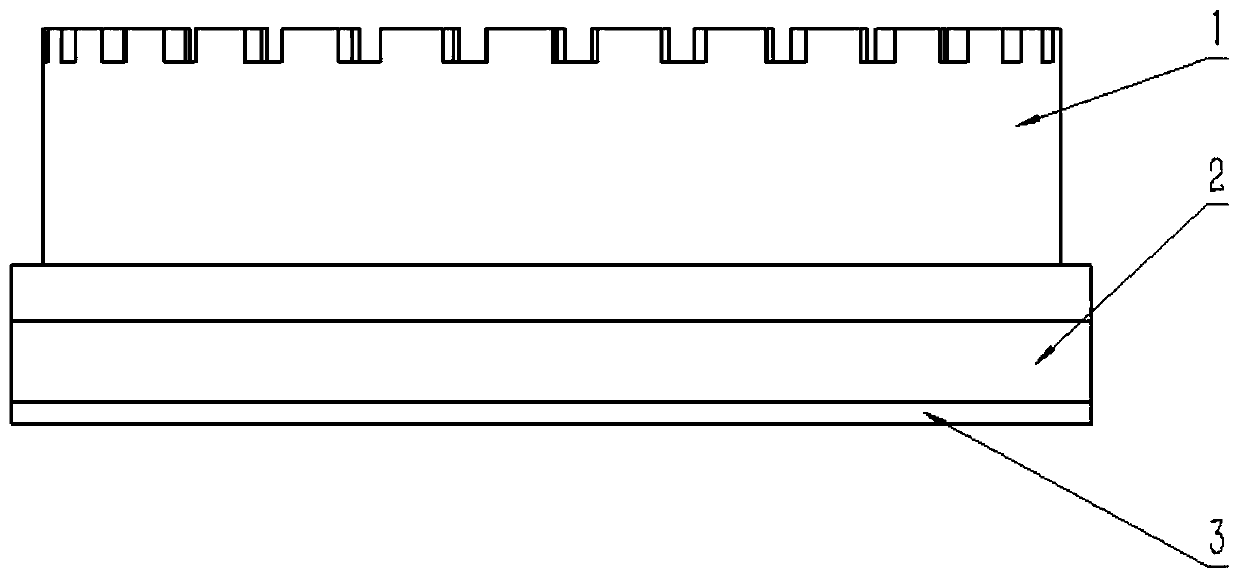

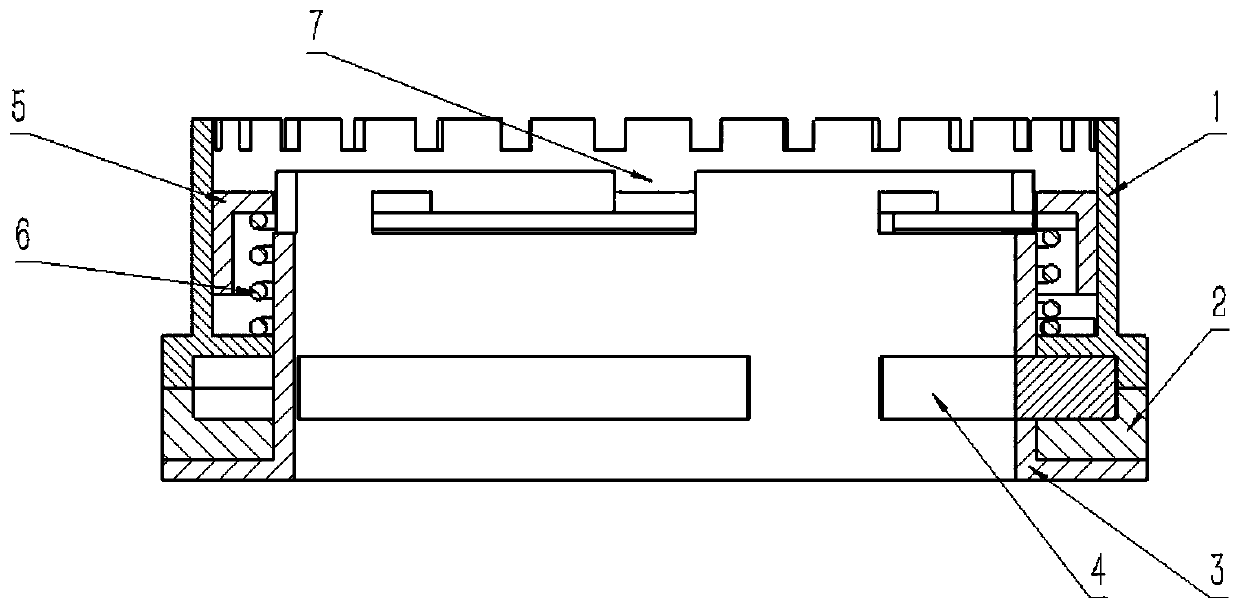

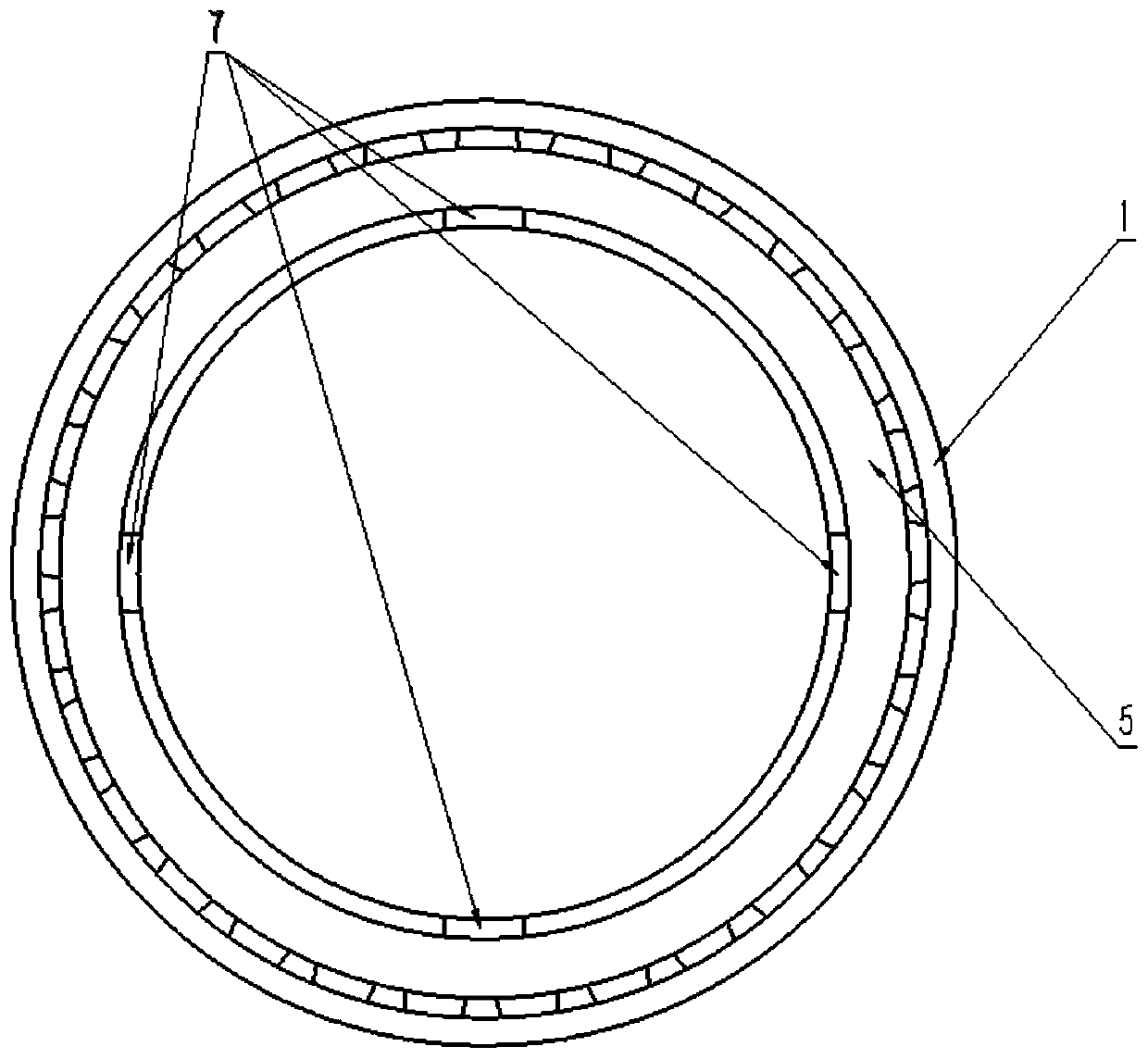

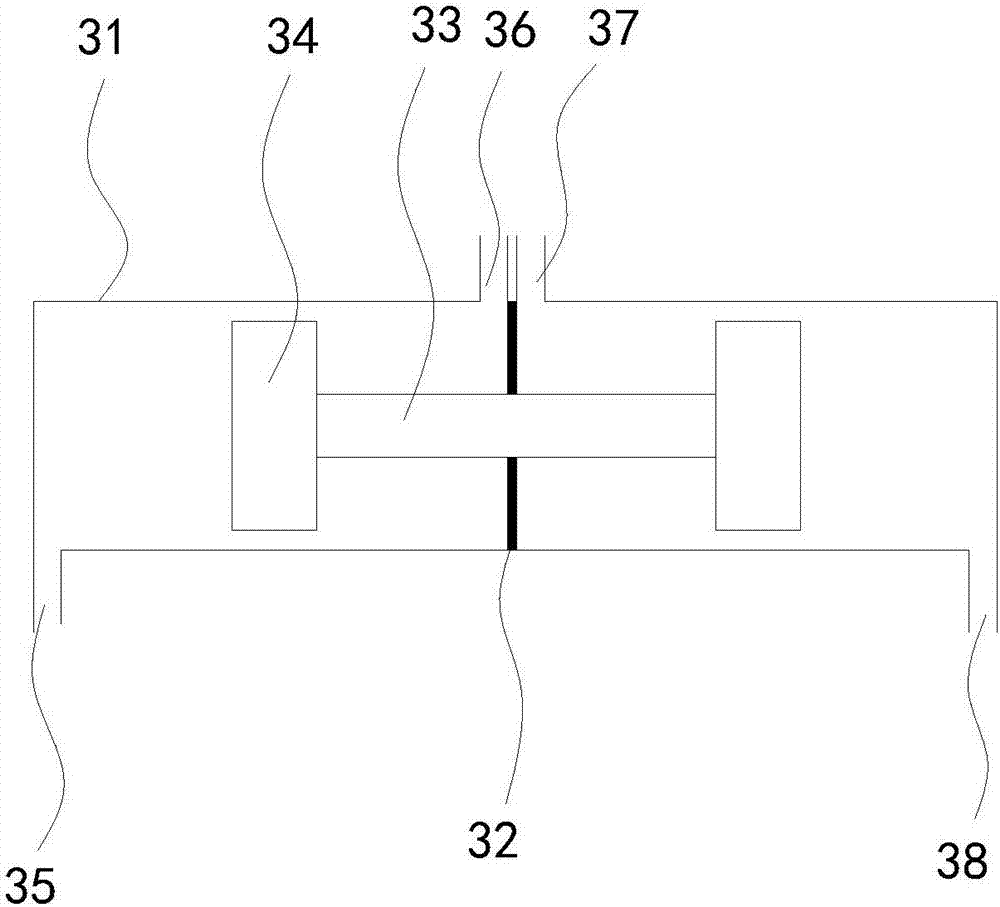

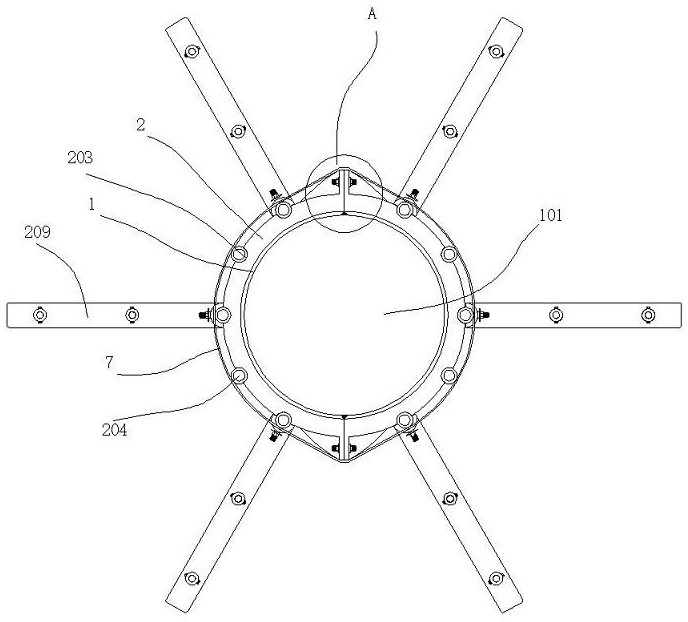

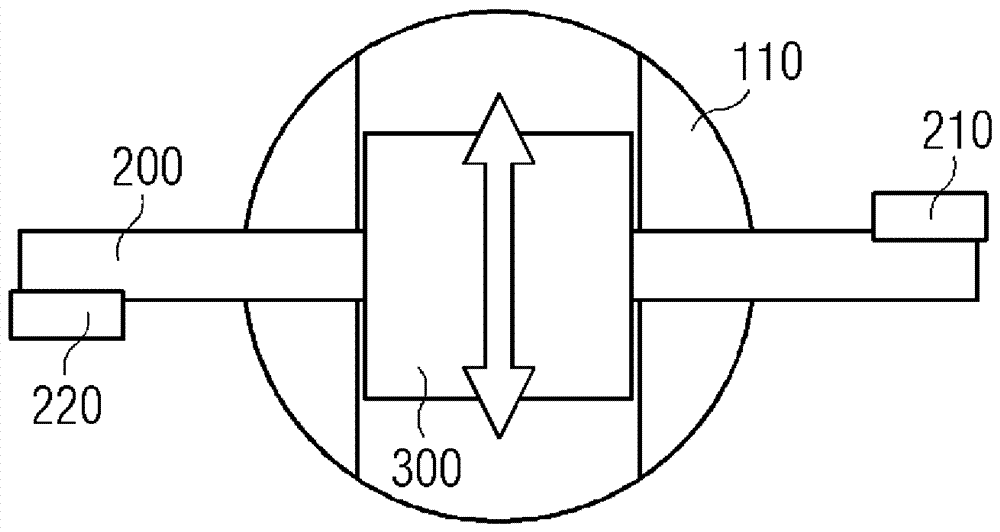

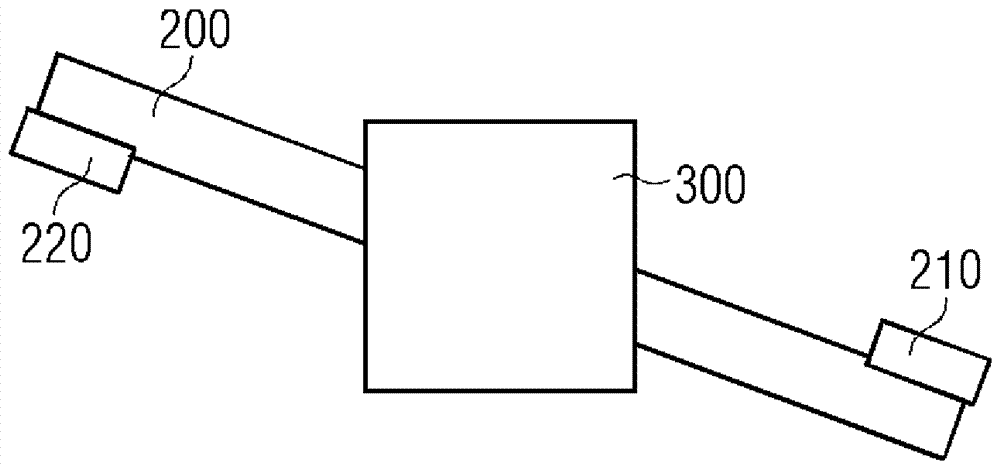

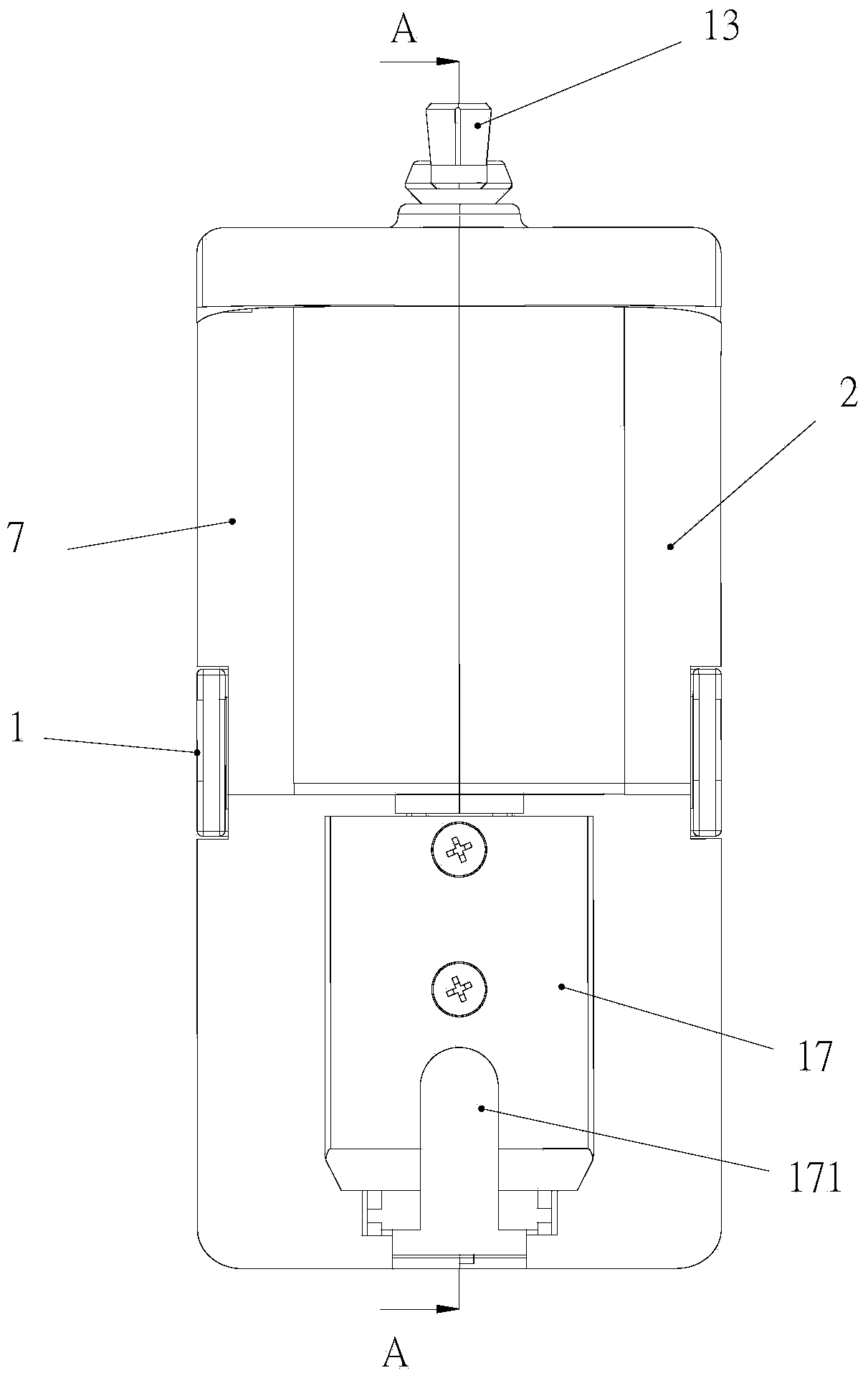

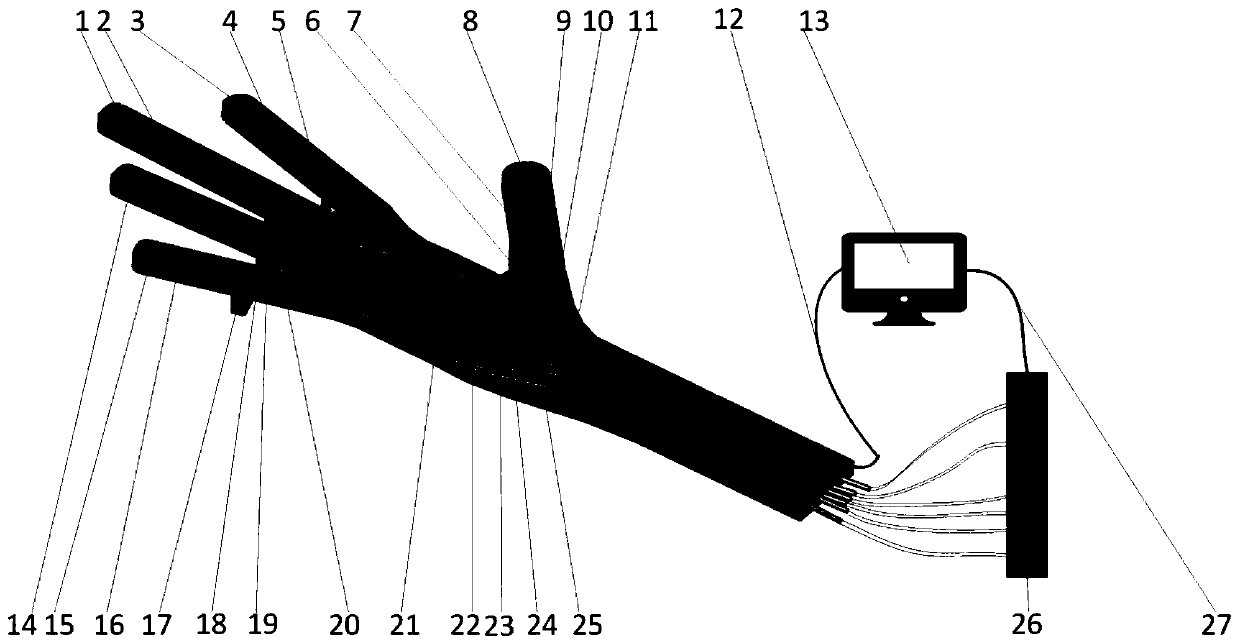

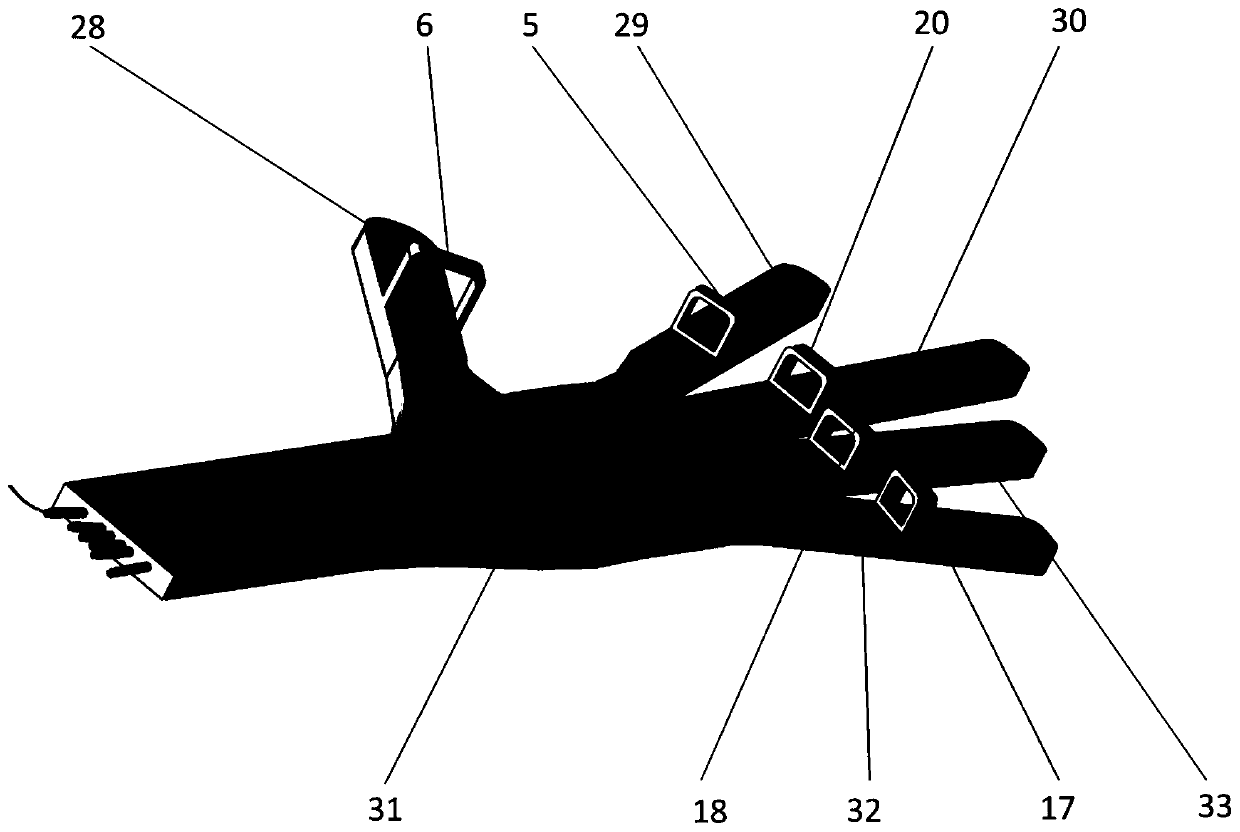

Soft-body robot capable of autonomously balancing contact force

ActiveCN108214521AUniform contact forceRealize air pressure regulationProgramme-controlled manipulatorGripping headsRobot fingerRobotic systems

The invention discloses a soft-body robot capable of autonomously balancing contact force, comprising a force sensor 1, a soft finger cavity 2, a force sensor 3, a soft finger cavity 4, a fixing ring5, a fixing ring 6, a soft finger cavity 7, a force sensor 8, a soft air tube 9, a soft air tube 10, a soft air tube 11, a wire 12, a control system 13, a force sensor 14, a force sensor 15, a soft finger cavity 16, a fixing ring 17, a fixing ring 18, a soft finger cavity 19, a fixing ring 20, a force sensor 21, a soft palm cavity 22, a soft air tube 23, a soft air tube 24, a soft air tube 25, anair pump 26, a wire 27, a soft robot finger 28, a soft robot finger 29, a soft robot finger 30, a hand module 31, a soft robot finger 32, and a soft robot finger 33. The soft-body robot herein can automatically balance and adjust contact force for an operation object.

Owner:北京科迈启元科技有限公司

Stabilizer and manufacturing method thereof

ActiveCN102642112BUniform contact forceIncrease contact areaDrilling rodsDrilling casingsAlloySpot welding

The invention discloses a stabilizer and a manufacturing method thereof. The manufacturing method comprises the following steps that: hard alloy blocks are first welded on an edge band matrix by adopting a spot welding way; afterwards, spray welding is carried out on the edge band matrix around the hard alloy blocks by adopting a flame spray welding gun; burnt-out alloy powder sprayed out from the welding gun and the edge band matrix are melted integrally to form alloy powder melted layers around the hard alloy blocks; the hard alloy blocks are fixedly arranged on the edge bank matrix firmly; and after a spray-welded layer covers all the hard alloy blocks, the stabilizer is fed onto a cylindrical grinding machine to be subjected to cylindrical grinding, so that each hard alloy block is ground to be exposed and reach the diameter dimension of the outer circle of the needed stabilizer, thereby obtaining the stabilizer. The stabilizer not only has the advantages of being simple in structure and being easy to manufacture, but also has the advantages of high dimensional precision, high abrasive resistance, long service life and the like.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

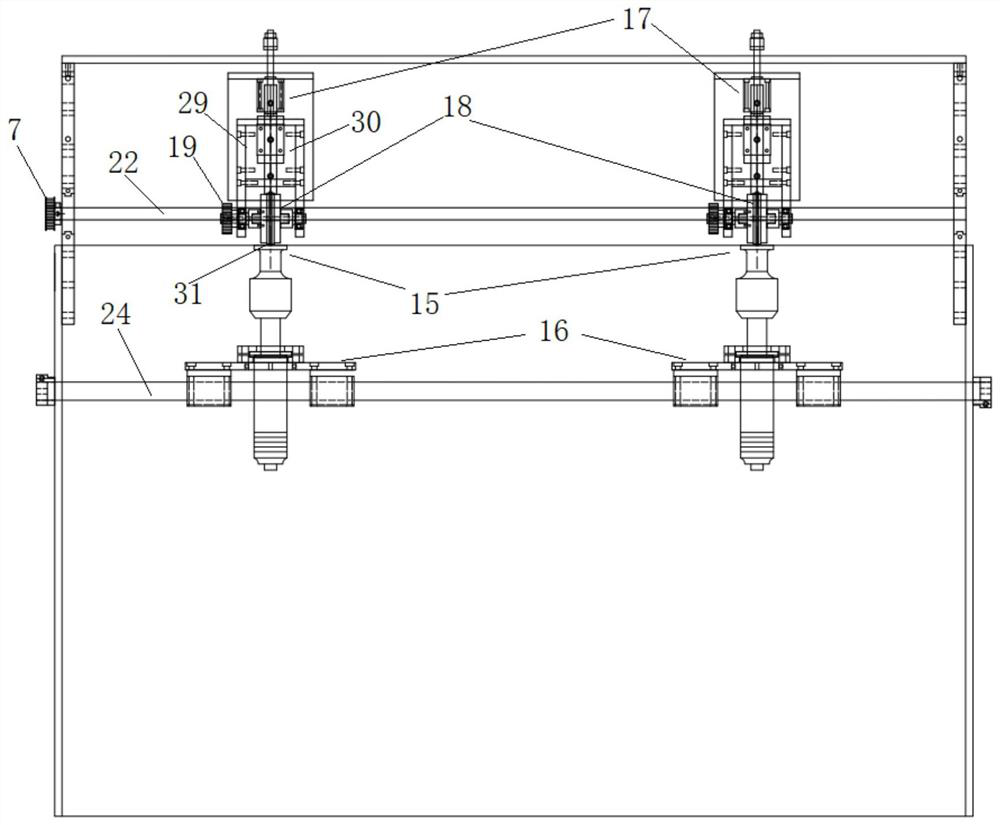

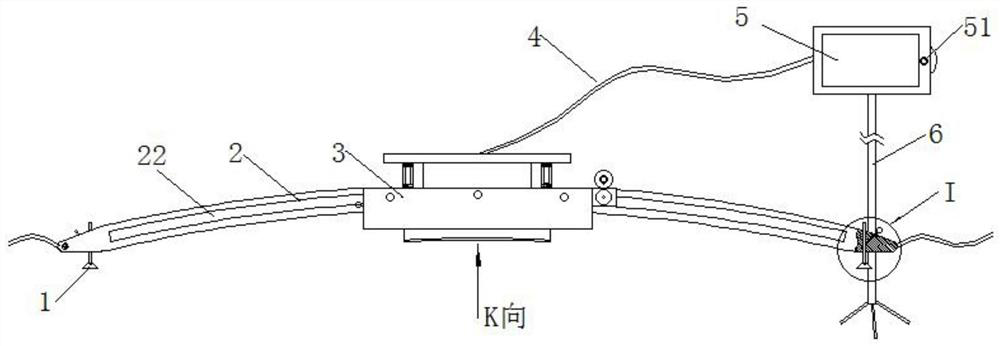

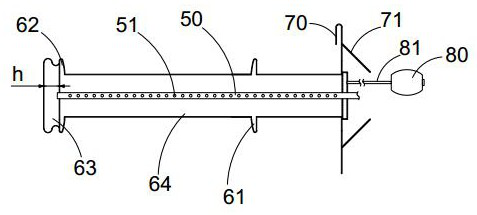

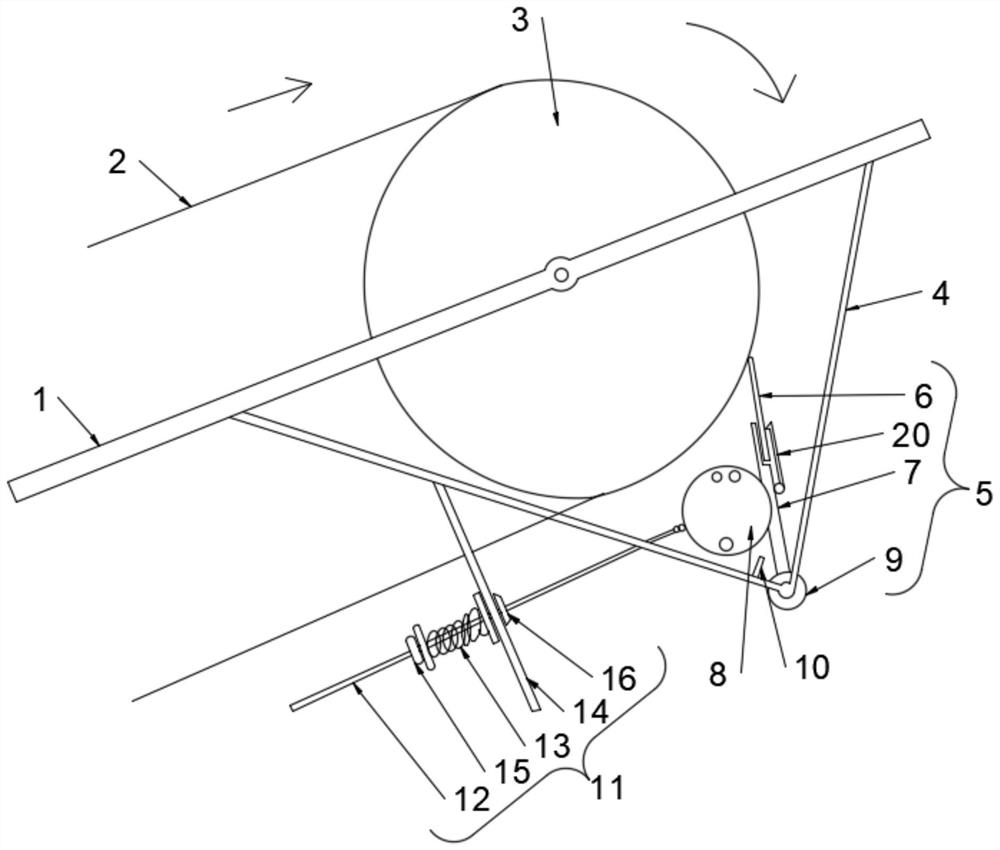

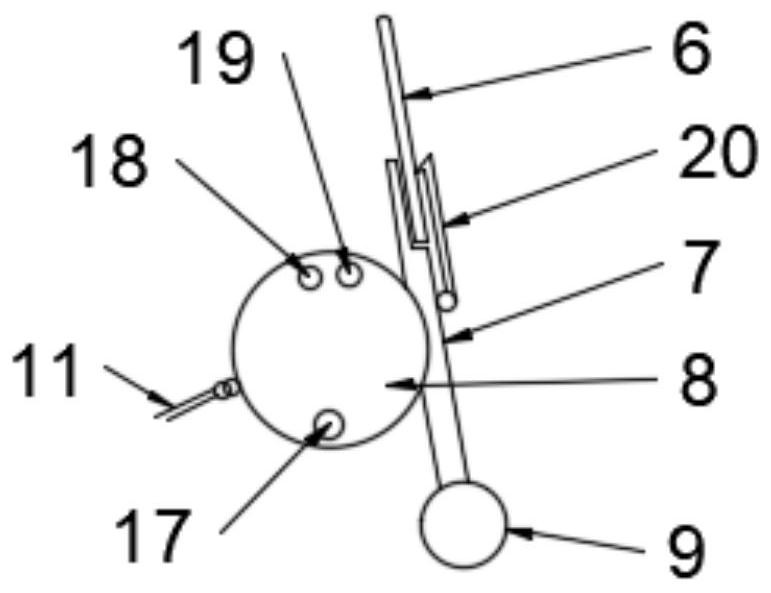

Ultrasonic pressing welding device for double-layer non-woven fabric

PendingCN113815234AEasy to moveThe process of pressing down is stableFlat articlesDomestic articlesUltrasonic weldingElectric machinery

The invention provides an ultrasonic pressing welding device for double-layer non-woven fabric. The ultrasonic pressing welding device comprises a rack, a group of front material passing rollers, a traction roller, an embossing wheel frame, an ultrasonic welding head frame and rear material passing rollers, and the front material passing rollers, the traction roller, the embossing wheel frame, the ultrasonic welding head frame and the rear material passing rollers are sequentially arranged on the rack. A swing arm is arranged below the front material passing rollers, the right end of the swing arm touches a traction roller motor switch to start a traction roller motor, the traction roller motor is connected with the traction roller, the traction roller is connected with an embossing wheel, the embossing wheel is fixed to the embossing wheel frame, and an ultrasonic welding head is fixed to the ultrasonic welding head frame. The traction roller operates to drive the embossing wheel to rotate, a traction pressing roller pulls the double-layer non-woven fabric penetrating through the space between the traction pressing roller and the traction roller to move forwards, the embossing wheel moves downwards under the action of an air cylinder, and the embossing wheel and the ultrasonic welding head conduct pressing welding on the two side edges of the double-layer non-woven fabric at the same time. The ultrasonic pressing welding device not only can adapt to embossing wheels with various different patterns to be used for pressing welding of non-woven fabric with different widths, but also is stable in pressing welding quality.

Owner:江苏建中医用材料有限公司

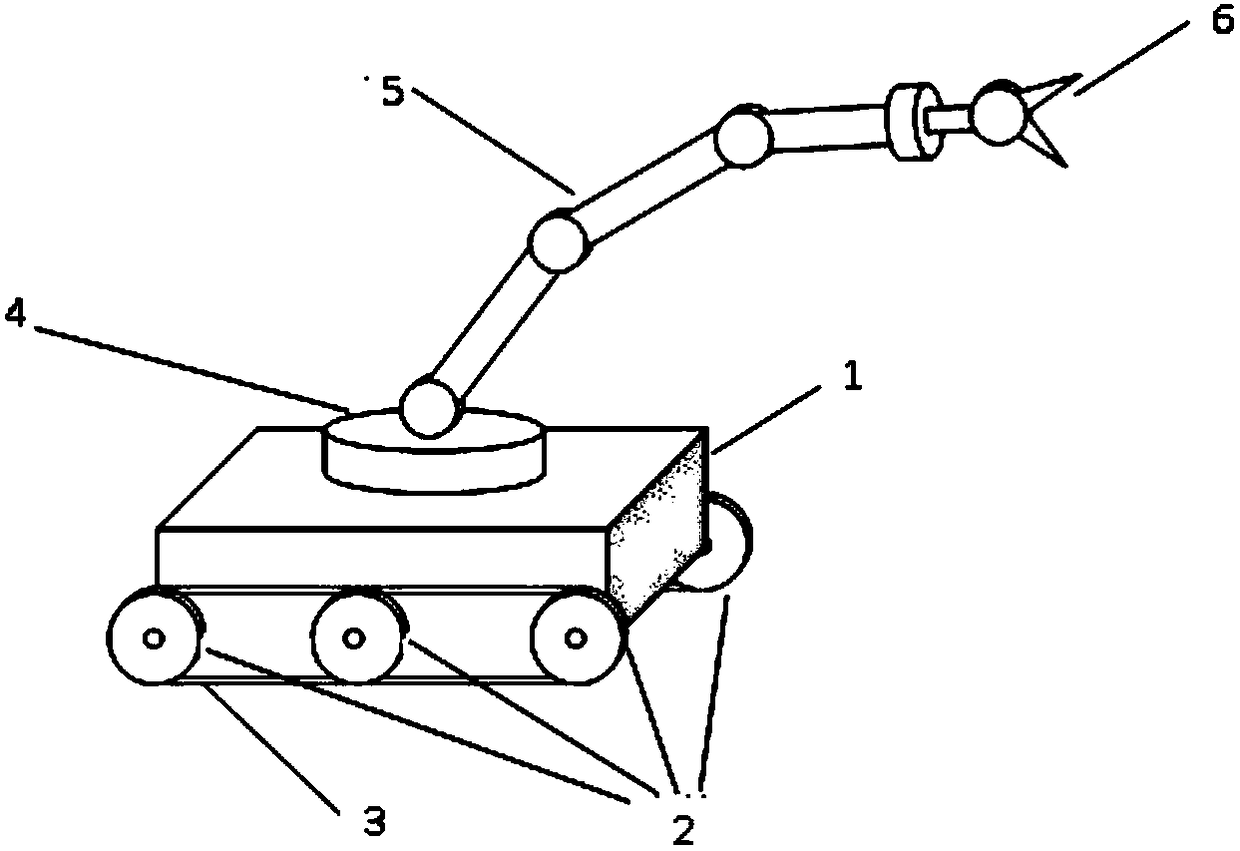

An autonomous troubleshooting intelligent vehicle system

The invention discloses an obstacle removal type intelligent vehicle system based on laser distance measurement. A vehicle body is driven to move in a track manner; wheels adopt right-angled steering speed reducing motors; a mechanical arm is mounted on a turntable base in the center of the vehicle body; the turntable base is of an all-aluminum alloy structure; a rotating part is a steel ball bearing, so that the arm can freely rotate; the mechanical arm is a six-degree-of-freedom arm, and a hard aluminum alloy two-degree-of-freedom mechanical jaw capable of grabbing objects is arranged at the tail end of the mechanical arm; the mechanical arm can be used for conventional grabbing operation, and also can autonomously remove non-fixed obstacles to develop an advancing road; the moving plan of the mechanical arm adopts a D-H coordinate system analysis method; the distance measurement adopts a pulse laser distance measurement system; and an emitting module, a receiving module and an MCU module for data processing are used for quickly removing any obstacle to measure the distance, so that the system reliability is improved. The system combines the autonomous mechanical arm with the intelligent vehicle, can help people to work under special environments untouchable by manpower, and is higher in reality application value.

Owner:BEIJING UNIV OF TECH

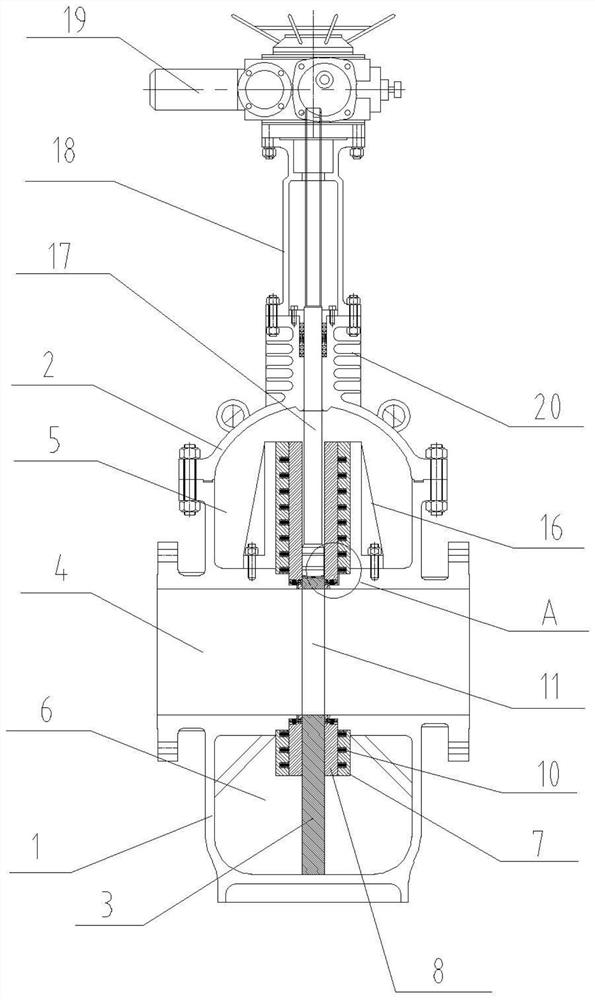

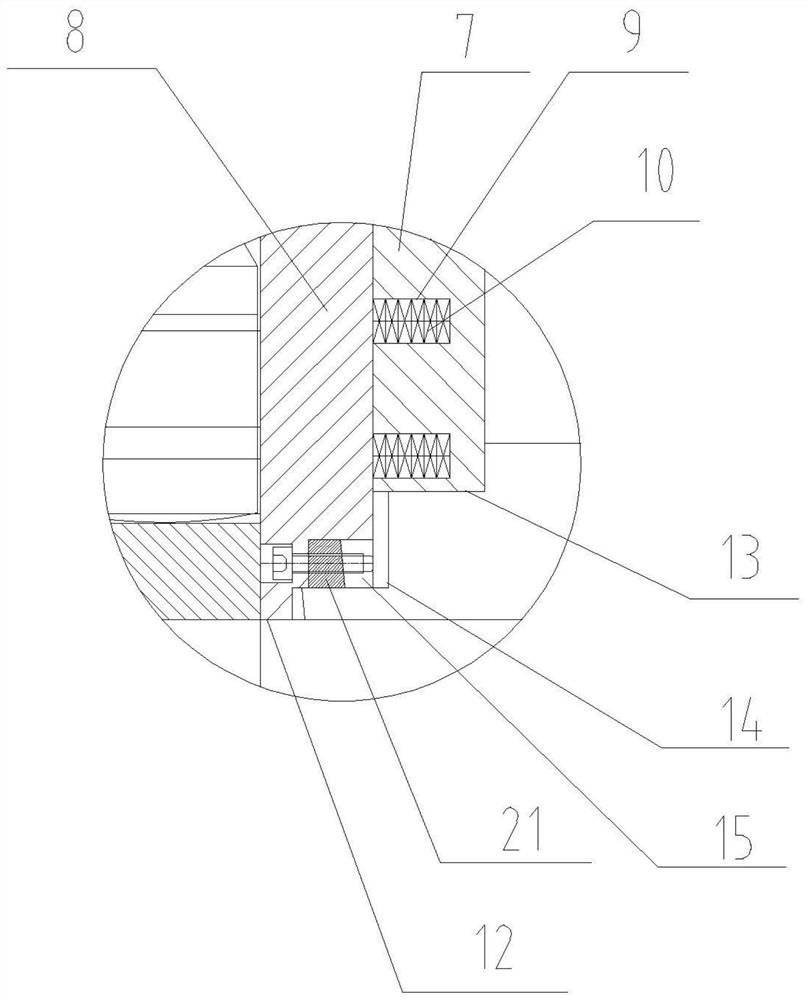

High-temperature wear-resistant stop valve

PendingCN113883287AImprove sealingExtended service lifeOperating means/releasing devices for valvesSlide valveEngineeringMaterials science

The invention discloses a high-temperature wear-resistant stop valve. The high-temperature wear-resistant stop valve comprises a valve body, a valve cover and a gate plate. An inlet and outlet flow channel is formed in the valve body, the valve cover is buckled to the upper portion of the valve body to form an upper valve cavity communicating with the inlet and outlet flow channel, and a lower valve cavity communicating with the inlet and outlet flow channel is formed in the lower portion of the valve body. Valve seats are arranged in the upper valve cavity and the lower valve cavity, and through holes matched with the inlet and outlet flow channel are formed in the middles of the valve seats. Each valve seat comprises two fixed baffles and two floating sealing plates, and the gate plate and the floating sealing plates are matched to form sealing pairs and seal connecting channels of the inlet and outlet flow channel and the upper valve cavity and the lower valve cavity. According to the high-temperature wear-resistant stop valve, the length of the valve seats is increased, when the gate plate is fully opened and fully closed and is in place, the lengthened valve seats can seal and prevent media from entering the upper valve cavity and the lower valve cavity of the valve, a good sealing effect is achieved, the sealing performance of the valve is improved, the anti-coking, high-temperature-resistant and wear-resistant performance is achieved, and the service life of the valve is prolonged.

Owner:余文孟

Rotary clamping system of mechanical gripper

ActiveCN111360855AUniform contact forceWide range of size optionsProgramme-controlled manipulatorGripping headsGear wheelPower apparatus

The invention discloses a rotary clamping system of a mechanical gripper. The rotary clamping system of the mechanical gripper comprises a rotary clamping device and a power device, a hollow main shaft of the rotary clamping device is in rigid connection with the front end of a mechanical arm, the power device is installed at the oblique rear of the rotary clamping device and on the side of the head end of the mechanical arm, an output shaft of the power device is connected with an intermittent gear, and the intermittent gear is engaged with a rotary shell to drive the rotary shell to rotate.According to the rotary clamping system of the mechanical gripper, the rotary shell and a clamp mounting shaft sleeve at the tail part of the mechanical gripper are mainly utilized to drive a rotary clamp inside the mechanical gripper to rotate, the deformation of a high-strength spring forms screwing motion, then the clamping and releasing actions of the rotary clamp are formed, the rotary clampis rotated out and rotated in by combining a mechanical structure, an object is clamped more stably, the contact stress with the clamped object is uniform, the selectable range of the size of the clamped object is relatively large, and the controllability is higher than that of a traditional mechanical gripper.

Owner:DALIAN MARITIME UNIVERSITY

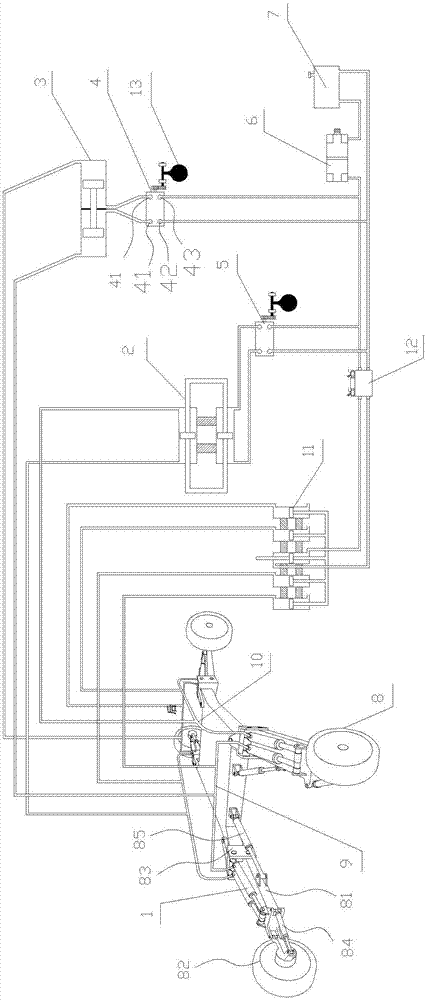

Multi-functional walking excavator

InactiveCN107059979AWork fasterImprove work efficiencySoil-shifting machines/dredgersRolloverExcavator

The invention provides a multi-functional walking excavator, and relates to the technical field of excavator technology. An interlinked suspension system of the multi-functional walking excavator comprises hydraulic jackings, a left-right balance control device, a front-back balance control device, a first steering gear, a second steering gear, a fluid pump and a fluid source; the hydraulic jackings are arranged on the upper sides of vehicle wheels of the excavator vehicle, two hydraulic jackings are arranged on the upper side of each vehicle wheel, the two hydraulic jackings, located at a same end, on different vehicle wheels, are connected with each other through first pipelines, and the rest of the hydraulic jackings, located at the same end, on different vehicle wheels are connected with the rest of the hydraulic jackings, located at the other end of a same side while on different vehicle wheels through second pipelines; and the left-right balance control device is connected with the second pipelines which are located on two sides of the vehicle through pipelines correspondingly, and the front-back balance control device are connected with the first pipelines located on two sides of the vehicle through the pipelines correspondingly. The multi-functional walking excavator rarely bumps on rough ground, is sensitive to response, good in stability and comfort performance, has the functions of anti-side-tipping, anti-side-rollover, and anti-pitching, and is high in climbing performance.

Owner:管中林

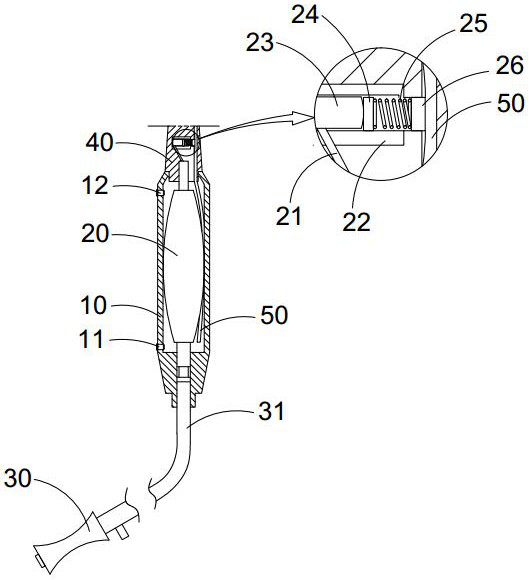

Pressure-adjustable fetus-voice meter and fetus-voice positioning method

InactiveCN111743572AAvoid oppressive physical damageAvoid numerical inaccuraciesHeart/pulse rate measurement devicesInfrasonic diagnosticsLiquid-crystal displayDisplay device

The invention provides a pressure-adjustable fetus-voice meter and a fetus-voice positioning method; the pressure-adjustable fetus-voice meter comprises a detection part and a liquid crystal display;the pressure-adjustable fetus-voice meter also comprises an arc-shaped slide rail, and the detection part comprises a moving seat; a first through cavity is formed in the moving seat, and a sliding sleeve is slidably connected into the first through cavity; the bottom of the sliding sleeve is connected with a probe body, and the top of the sliding sleeve is connected with an upper cover; a secondthrough cavity is formed in one side of the movable seat, an ejector block is slidably arranged in the second through cavity, and oblique teeth inclining downwards are arranged at one end of the ejector block; clamping grooves matched with the oblique teeth are formed in the sliding sleeve; a spring II sleeves the top block, one end of the spring II is connected with the top block, and the other end is connected with the inner wall of the second through cavity; the probe body is provided with a pressure sensor, and six ultrasonic probes are evenly arranged on the outer side of the pressure sensor; a microprocessor for implementing control is also provided. The invention is simple in structure and reasonable in design, the fetal heart can be accurately positioned, meanwhile, the pressure can be conveniently adjusted, and inaccurate detection numerical values caused by excessive force or too small force are prevented.

Owner:刘欣荣 +1

Cast-in-place mold for building bridge stand column pouring

InactiveCN112431141AImprove structural strengthIncrease contact areaBridge structural detailsBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a cast-in-place mold for pouring a building bridge upright post, which comprises two templates capable of being spliced and assembled, the templates adopt common carbon structural steel plates, and the wall thickness is 8mm-22mm; before pouring, an oil film needs to be brushed in the formwork or covered with a plastic film, and later demolding is facilitated; the two formworks are combined to form a formwork cavity for pouring concrete, arc-shaped reinforcing plates are welded to the outer walls of the formworks, the two ends of each reinforcing plate are bent to form lug plates, bolts are assembled between the two lug plates, and the two formworks are assembled after the bolts are tightened; a plurality of reinforcing plates are arranged in parallel up and down; the device can realize stable placement.

Owner:施娟丽

Post-operative nursing device for otology and laryngology

InactiveCN111671571AReduce impactIncrease exposureEar treatmentMedical devicesMedical equipmentPharmacy medicine

The invention discloses a post-operative nursing device for otology and laryngology, and belongs to the technical field of medical equipment. The nursing device includes a medicine storage tube body,wherein a chamber for accommodating liquid medicine is formed in the medicine storage tube body, the volume of the chamber is changed with the medicine storage tube body under the kneading action of an external force, and an opening of the upper end part of the medicine storage tube body, and is connected with an assembly unit; a medicine administration assembly is arranged on the end part of theassembly unit, a medicine guide tube is arranged in the medicine storage tube body, and the medicine guide tube penetrates the assembly unit, and is connected with the medicine administration assembly; and the medicine administration assembly includes an inflatable cylinder which is arranged around the outer wall of the medicine guide tube, medicine administration channels are formed by gap amongthe inflatable cylinder, and first through holes are formed in the parts, corresponding to the medicine administration channels, of the tube wall of the medicine guide tube. Uniform application of medicine and controllable force of medicine application are realized, the progress of medicine application can be controlled under the assistance of a patient, and secondary damage to the patient can beavoided in the application process; and medicine administration has no damage to tympanic membranes and ear canal walls, no plugging of ear canals is caused by medicine administration, and medicine leakage is avoided effectively.

Owner:赵舒欣

Rotors for electrical switches

InactiveCN103681131BUniform contact forceReduce contact resistanceSwitches with electromagnetic releaseContactsClassical mechanicsEngineering

Owner:SIEMENS AG

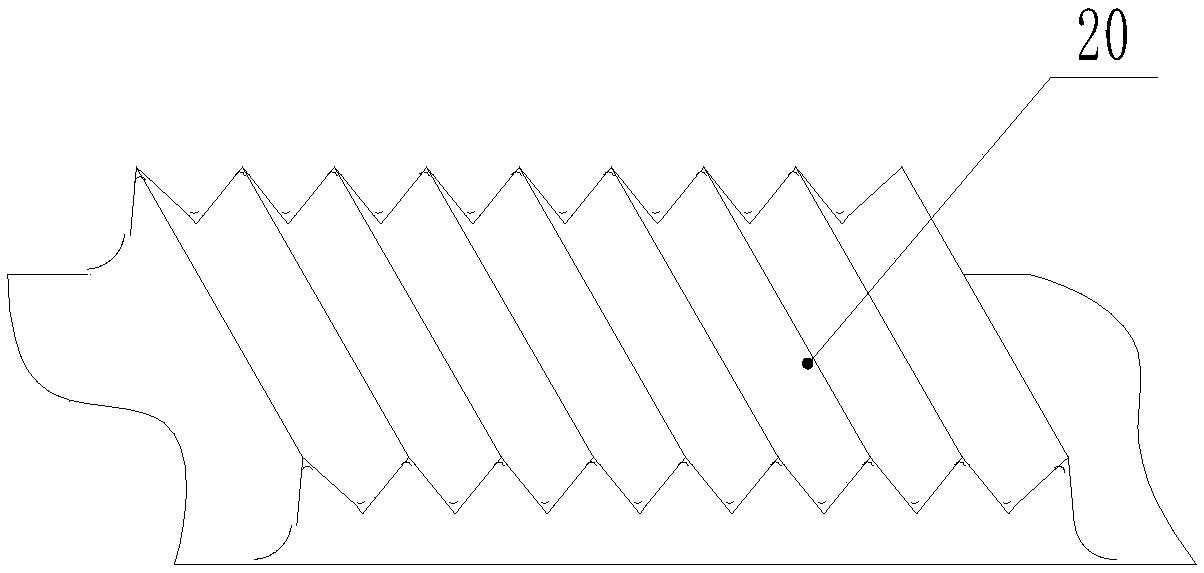

Material feeder of hard rubber type traditional Chinese medicine processor

The invention discloses a material feeder of a hard rubber type traditional Chinese medicine processor. The material feeder comprises a shell, an inner bag of the material feeder, and a material feeding mechanism, wherein the inner bag of the material feeder comprises a feeding chamber and a cutting chamber which are communicated with each other; the material feeding mechanism comprises a pressing block movably arranged in the feeding chamber and a screwed rod vertically arranged on the inner bag of the material feeder rotationally; the pressing block is in threaded connection with the screwed rod, and the screwed rod is connected with a manual rotating mechanism or an automatic rotating driving device; a connecting clamp block is fixedly arranged on the inner bag of the material feeder or the shell and is matched and fixed with a connecting clamping groove fixedly formed in a main machine of the processor, and a passing-through channel by using which a cutter is convenient for to horizontally stretch into the cutting chamber is arranged on the position, corresponding to the cutting chamber, of the inner bag of the material feeder. The material feeder replaces the mode of manually pushing hard rubber type traditional Chinese medicines to feed, utilizes the pressing block and the screwed rod to push the hard rubber type traditional Chinese medicines to be fed, and has the labor-saving and safe effects, and furthermore, the material feeder and the main machine of the processor can be quickly assembled or disassembled, and are convenient to clean.

Owner:JIANGSU HAGONG PHARMA MACHINE TECH CO LTD

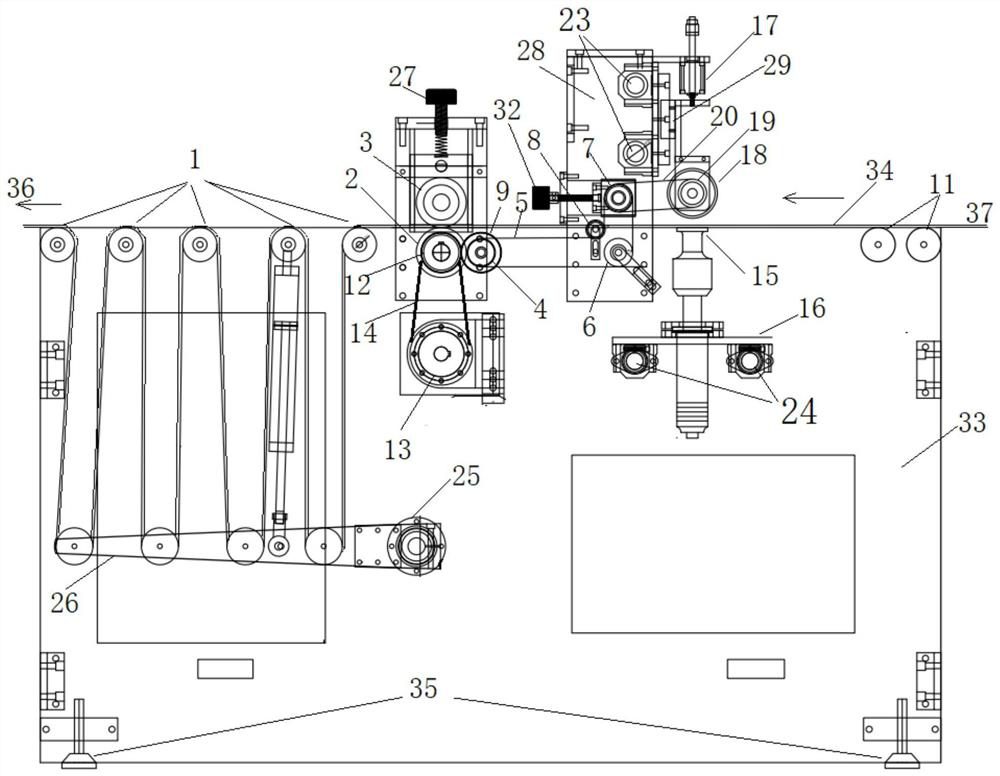

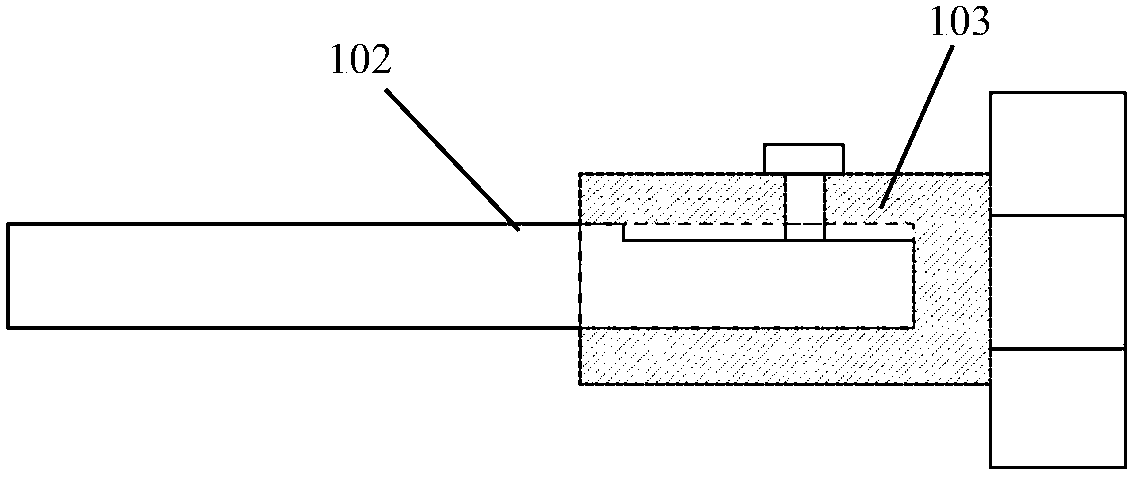

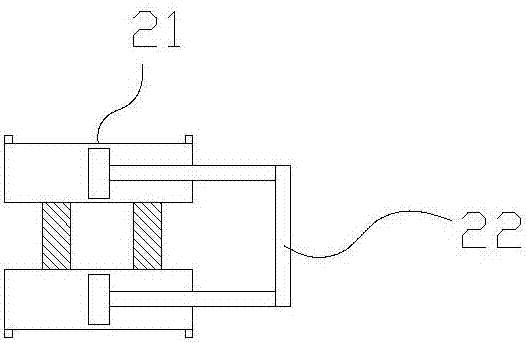

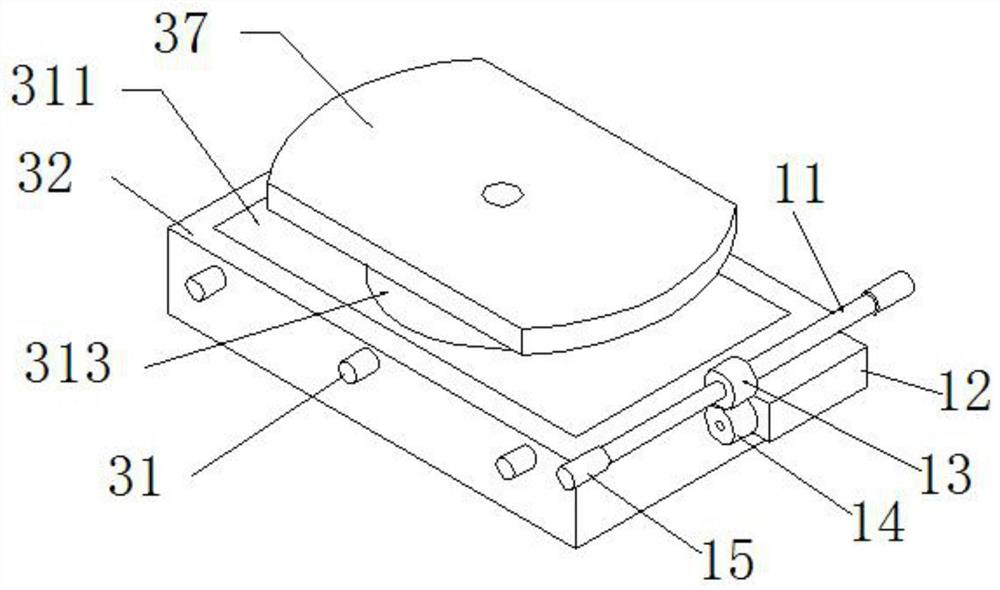

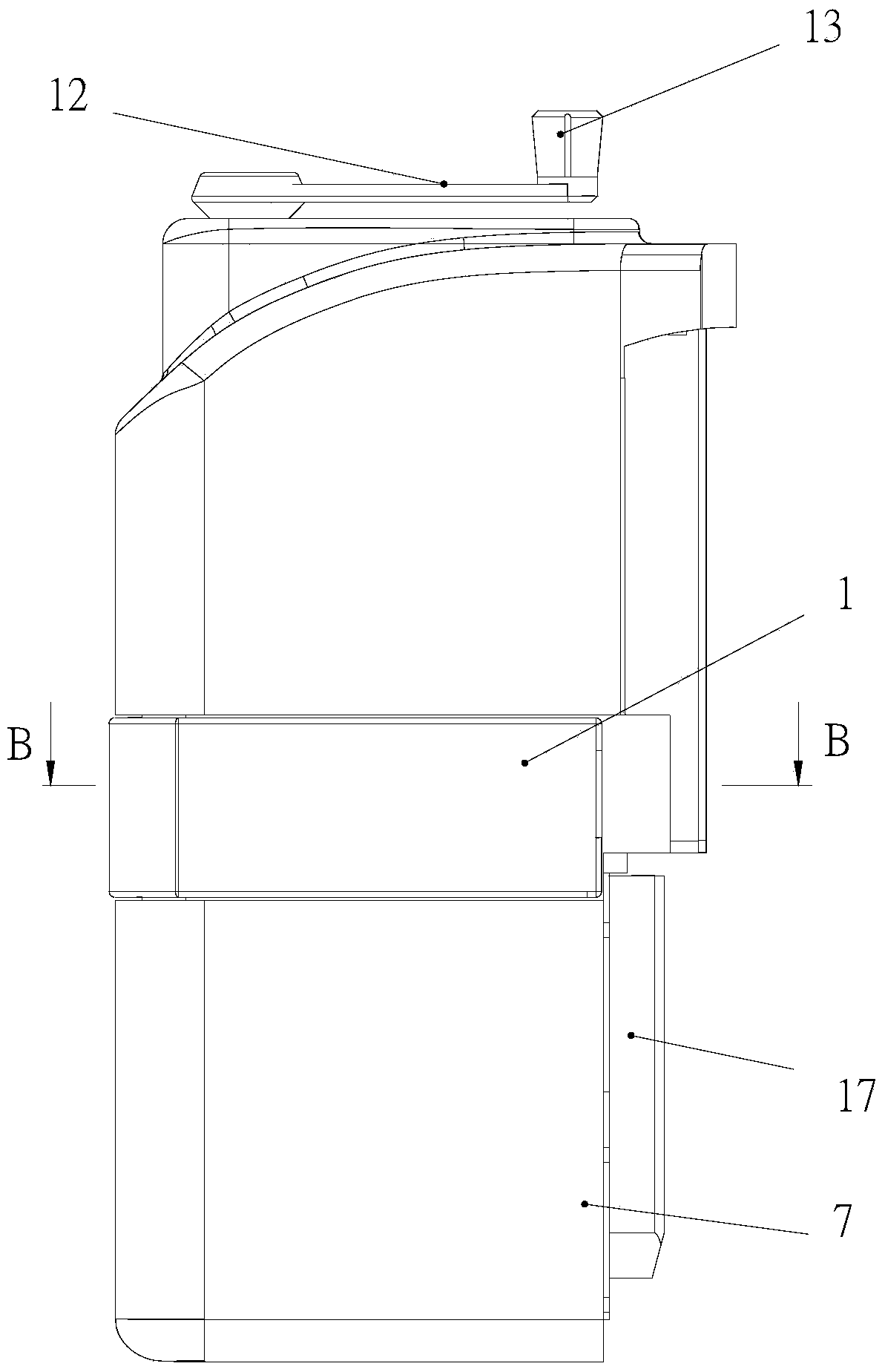

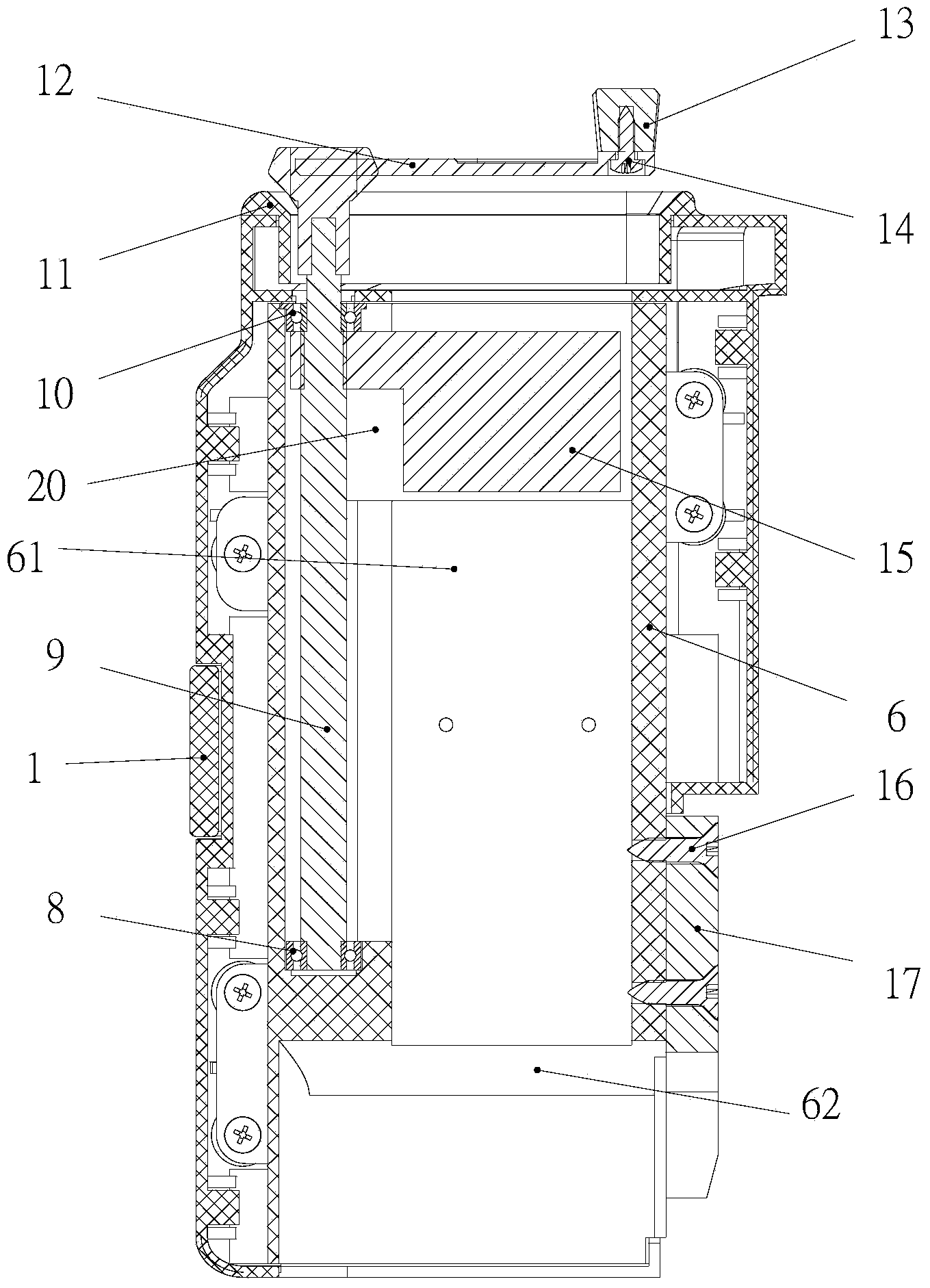

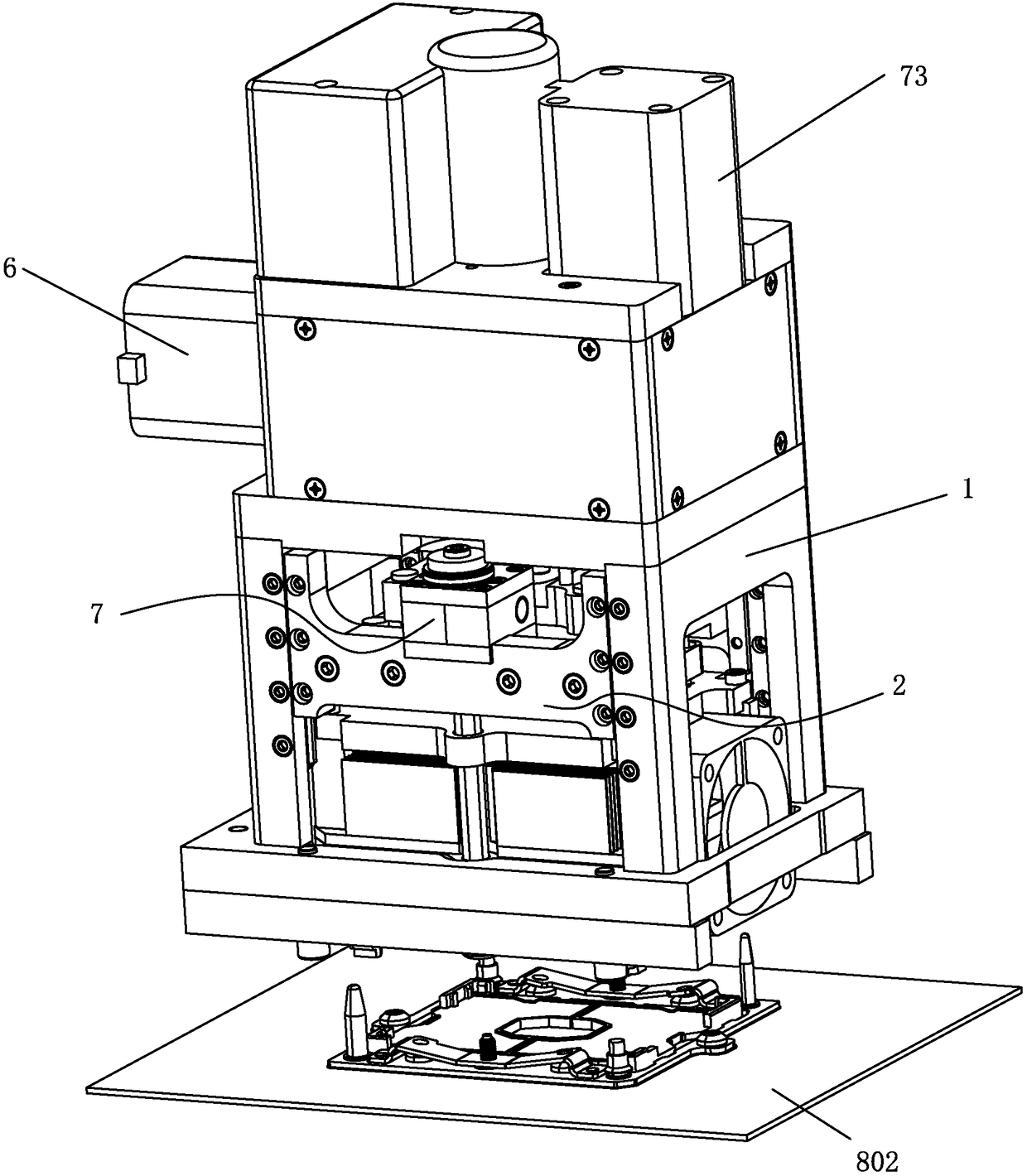

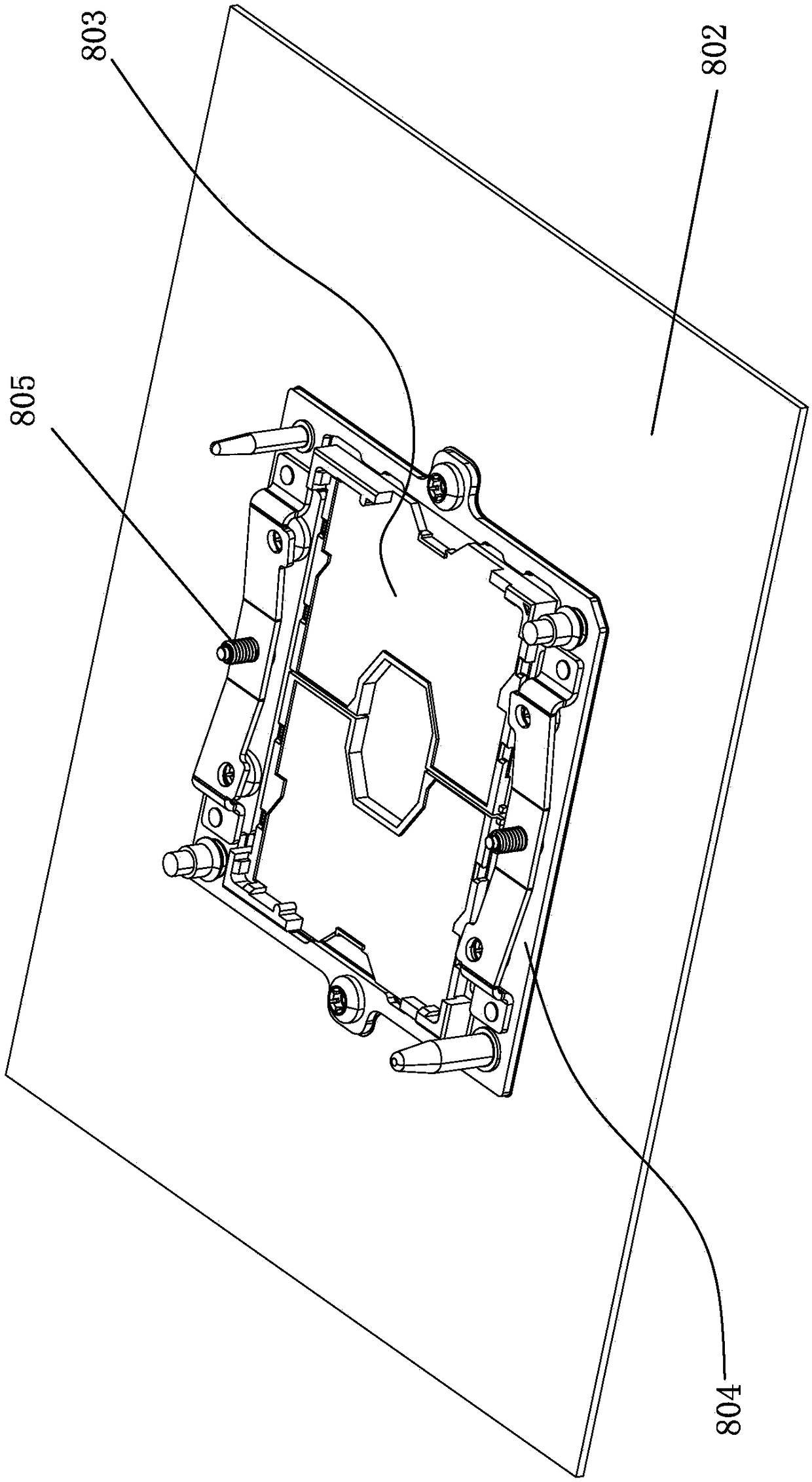

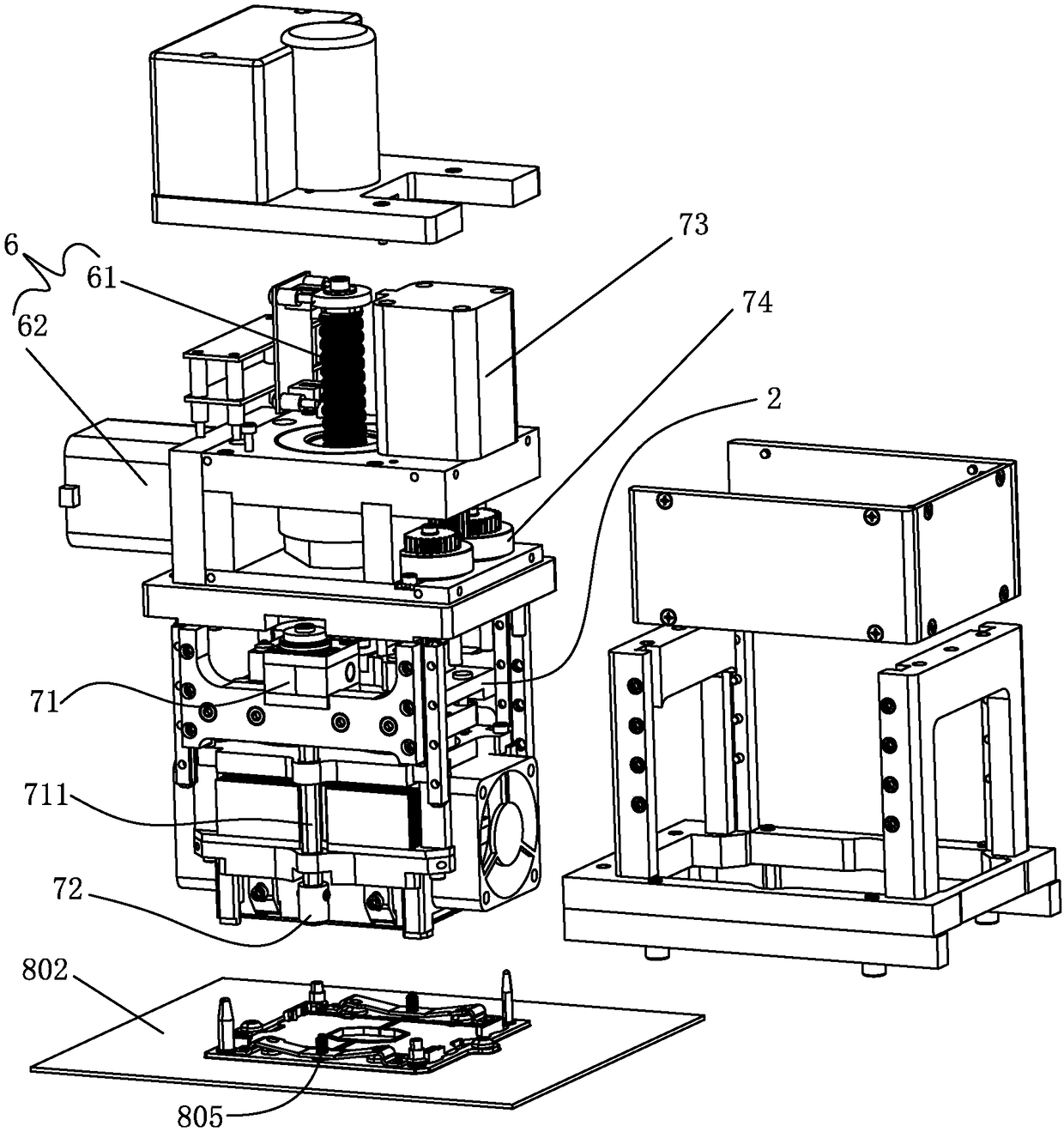

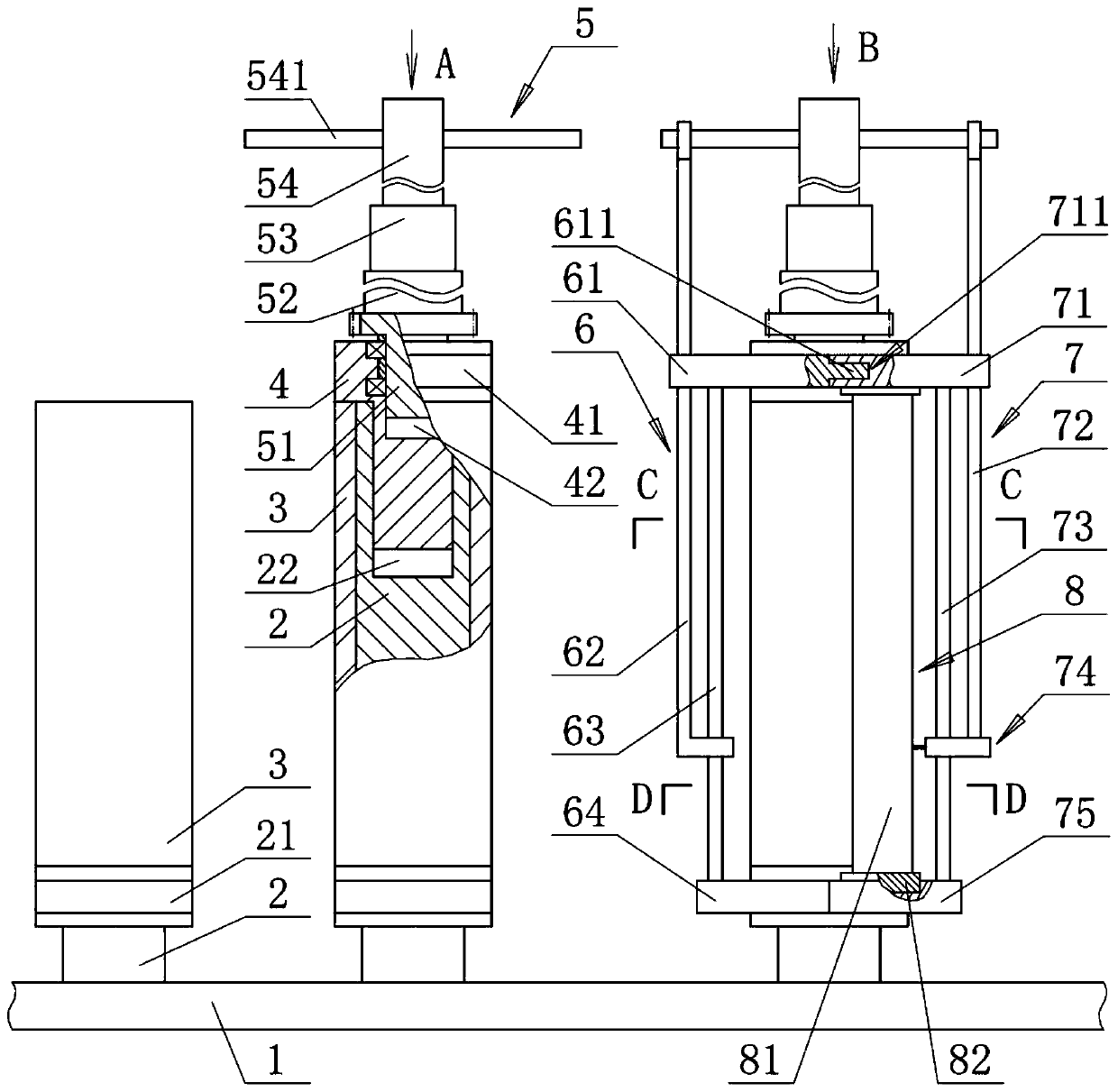

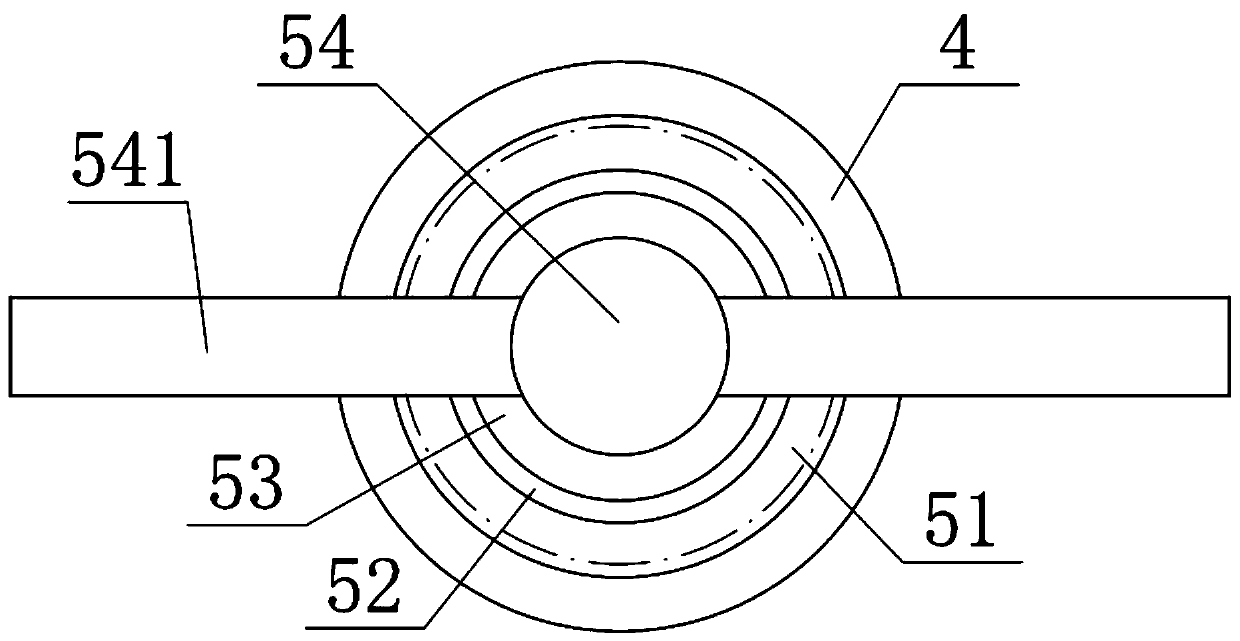

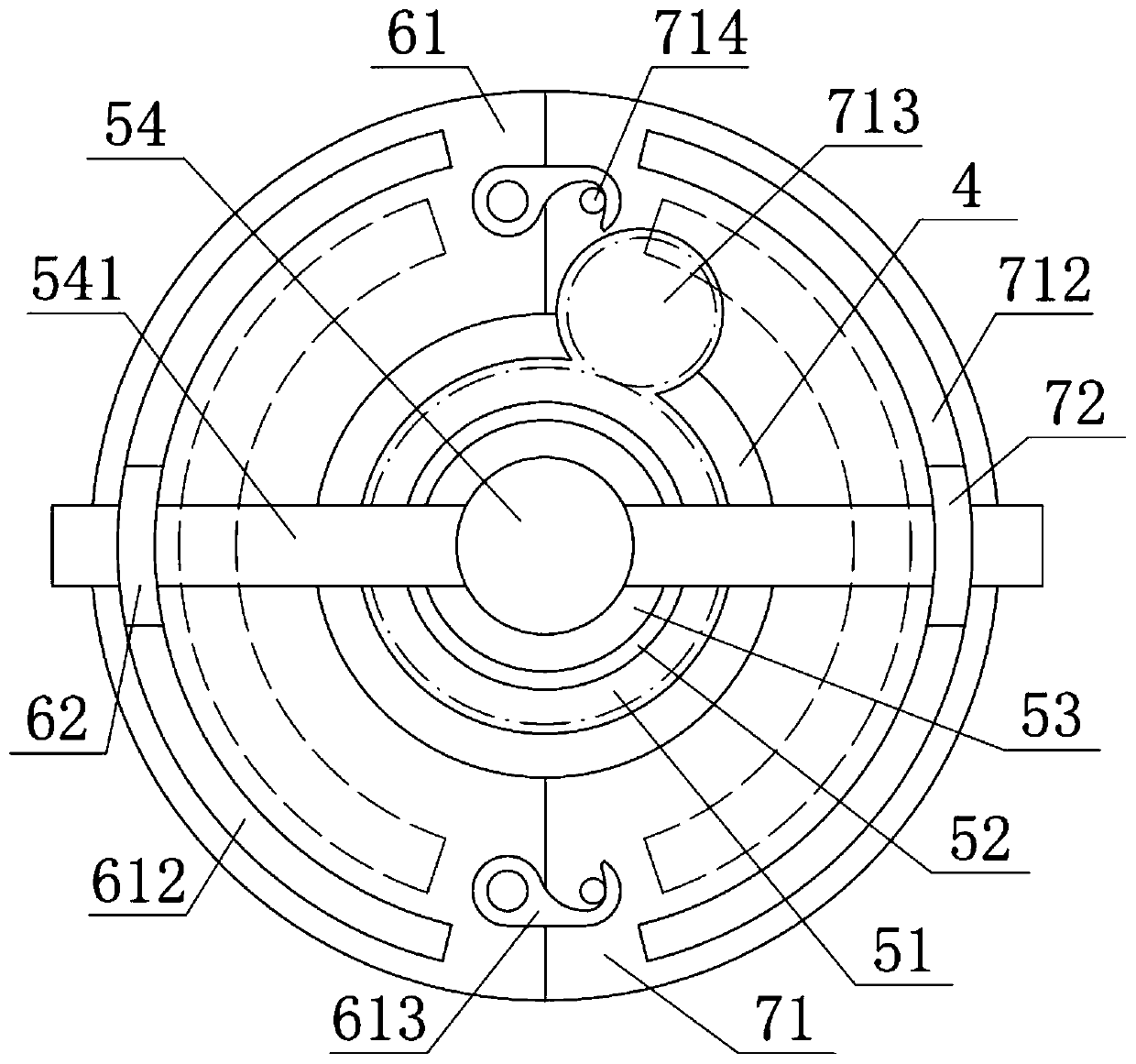

Automatic CPU pick-place module provided with lever propping-pressing device

ActiveCN108188691AQuick installationEffective installationMetal working apparatusContact forceComputer science

The invention discloses an automatic CPU pick-place module provided with a lever propping-pressing device. The automatic CPU pick-place module comprises a rack, a slide connecting base, a first drivedevice, a CPU clamping assembly, an adaptive positioning device and a locking device, wherein relative position between a CPU and a CPU installation base can be adaptively adjusted during CPU installation, so that the CPU fits the CPU installation base completely, propping-pressing force is perpendicular to the plane of the CPU all along during pressure loading, and contact force of the CPU and the CPU installation base is uniform. The lever propping-pressing device of the automatic CPU pick-place module adopts the principle of the equal armed lever, when the CPU clamping assembly inclines, two force guide posts located on a transitional connecting plate and taking the symmetry axis of the transitional connecting plate as the center prop and press the CPU clamping assembly all along, a pressure head assembly props and presses the center of the transitional connecting plate, so that force of the two force guide posts applied to the CPU clamping assembly is always the same, the propping-pressing force is always perpendicular to the CPU, and accordingly, the contact force of the CPU and the CPU installation base is always uniform.

Owner:ZHONGSHAN TUODIAN ELECTRONICS TECH

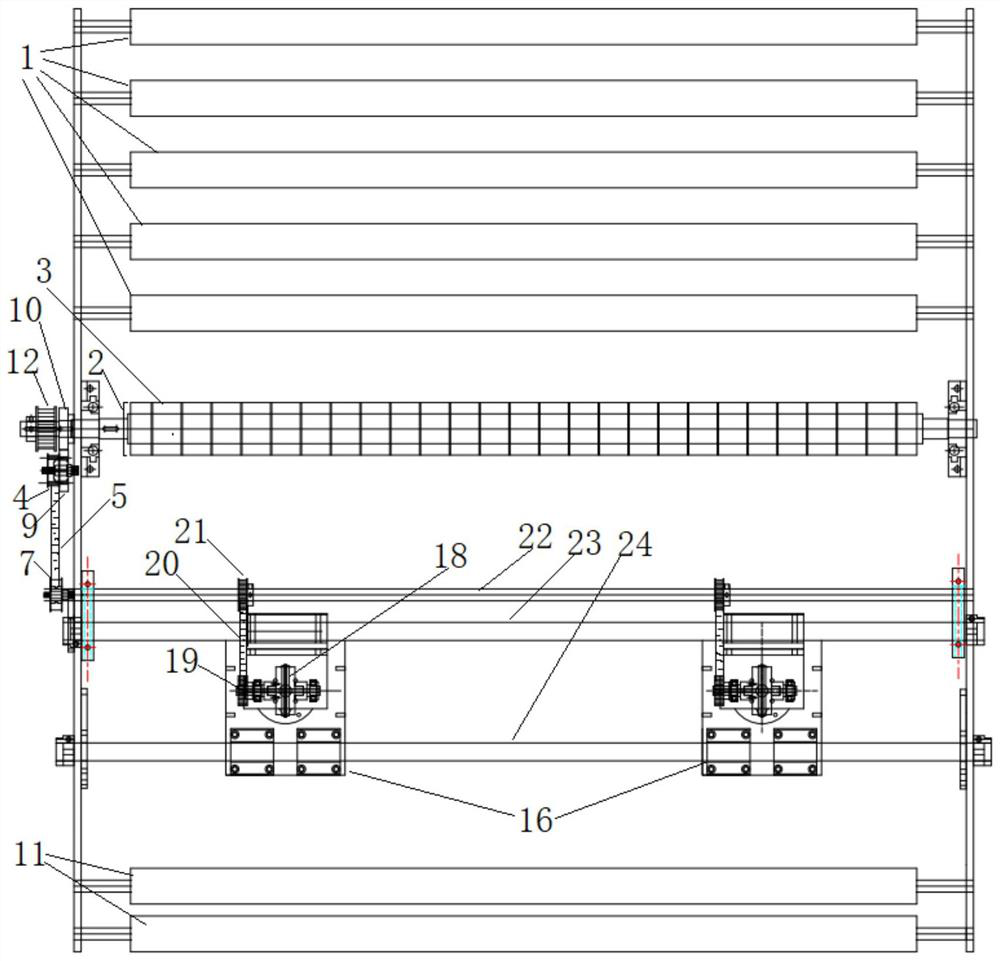

Curved surface screen printing device

PendingCN111300969ASuitable for mass productionEven by forceScreen printersScreen printingAssembly line

The invention provides a screen printing device for the outer surface of a cylindrical curved surface and suitable for use in an assembly line, and relates to the technical field of printing. The screen printing device includes a conveyor belt and cylindrical printing stocks, the conveyor belt is connected with stepped cylindrical plug pins, the printing stocks are connected with the plug pins ina sleeving mode, the outer surfaces of the printing stocks are covered with printing plate components, pressing blocks are inserted in the plug pins, the pressing blocks are rotatably connected with squeegee driving mechanisms, balance mechanisms and guide mechanisms are connected to the plug pins and the pressing blocks in a clamping mode, and the balance mechanisms are matched with the guide mechanisms. The screen printing device solves the technical problems of low production efficiency due to the fact that screen printing cannot be carried out on assembly lines in the prior art. The screenprinting device has the beneficial effects that the screen printing is carried out on the assembly line of the conveyor belt, multiple times of carrying and assembly and disassembly are not required,and product damage links are reduced; manual intervention is not required, the screen printing device is convenient to use, the labor intensity is reduced, and the production efficiency is improved.The screen printing device is simple and reasonable, is low in manufacturing cost and convenient to operate, and is suitable for mass production in the assembly line.

Owner:杭州众宙科技有限公司

Simple liquid storage type scraper and conveying device

PendingCN112141654AGuaranteed stabilitySolve the problem of active resetConveyorsCleaningEngineeringPhysics

The invention relates to a simple liquid storage type scraper device and a conveying device. The simple liquid storage type scraper device comprises a scraper frame, a scraper assembly, a liquid storage device and an anti-disengagement protection assembly, wherein the scraper frame is fixed to the lower side of a conveying frame; the upper end of the scraper assembly is in abut joint with a conveying belt; and the lower end of the scraper assembly is rotationally connected with the scraper frame; liquid used for providing the gravity effect is stored in the liquid storage device; the liquid storage device adjusts the acting force of the upper end of the scraper assembly abutting against the conveying belt by changing the weight of the liquid; the anti-disengagement protection assembly is fixed onto the scraper frame; and when the scraper assembly is separated from the conveying belt, the anti-disengagement protection assembly transmits the scraper assembly to reset. The conveying device comprises a conveying frame, a conveying belt, a driving roller and the simple liquid storage type scraper device, wherein the driving roller is connected onto the conveying frame and supports the conveying belt. Through the liquid storage device, the material scraping pressure in contact with the conveying belt can be adjusted according to practical material scraping requirements, and the problem that the pressure is not adjustable in the material scraping process is solved.

Owner:ZHAOJIN MINING

Soft robot that can balance contact force autonomously

ActiveCN108214521BUniform contact forceRealize air pressure regulationProgramme-controlled manipulatorGripping headsRobotic systemsControl system

The invention discloses a soft-body robot capable of autonomously balancing contact force, comprising a force sensor 1, a soft finger cavity 2, a force sensor 3, a soft finger cavity 4, a fixing ring5, a fixing ring 6, a soft finger cavity 7, a force sensor 8, a soft air tube 9, a soft air tube 10, a soft air tube 11, a wire 12, a control system 13, a force sensor 14, a force sensor 15, a soft finger cavity 16, a fixing ring 17, a fixing ring 18, a soft finger cavity 19, a fixing ring 20, a force sensor 21, a soft palm cavity 22, a soft air tube 23, a soft air tube 24, a soft air tube 25, anair pump 26, a wire 27, a soft robot finger 28, a soft robot finger 29, a soft robot finger 30, a hand module 31, a soft robot finger 32, and a soft robot finger 33. The soft-body robot herein can automatically balance and adjust contact force for an operation object.

Owner:北京科迈启元科技有限公司

Coating film supporting mechanism of high temperature deposition hard mask of film coating workpiece

InactiveCN101928921BUniform contact forceGood value for moneyVacuum evaporation coatingSputtering coatingOptical coatingEngineering

The invention relates to a coating film supporting mechanism of a high temperature deposition hard mask of a film coating workpiece, belonging to auxiliary equipment of optical coating. The coating film supporting mechanism comprises a film coating tray, a stop dog groove, a workpiece stop dog, a locking screw, a steel ball and a steel ball caulking groove. The middle part of the film coating tray is provided with an opening for placing the film coating workpiece, the four sides of the tray are provided with radial stop dog grooves for installing the workpiece stop dog, the workpiece stop dogmoves in the groove, the inclined plane of the workpiece stop dog is embedded with a steel ball (rolling ball), the steel ball rolls in the caulking groove, the workpiece stop dog is fixed in the stop dog groove by the locking screw, the edges of the film coating workpiece are all provided with tapers, the film coating workpiece is placed on the inclined plane of the workpiece stop dog and contacts with the steel evenly, and then the film coating workpiece and the entire device are both placed into a circular ring tray of the film coating machine. The mechanism of the invention can ensure that uniform force is exerted on each steel ball and the workpiece, the position of the stop dog can be freely adjusted in a certain scope according to the dimension of the workpiece; in addition, the chucking power for adjusting the workpiece can be provided by expansion or shrinkage force generated from high temperature or low temperature to drive the steel ball to roll; and the mechanism of the invention features in simple structure and high cost performance.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com