Synchronizing propeller provided with sealing gaskets

A technology of propellers and gaskets, which is applied in hand-held tools and manufacturing tools, can solve problems such as liquid leakage in immersion tanks, poor sealing effects, and poor mechanical seals, and achieve uniform overall stress state, simple structure, and good propulsion. The effect of equal distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the following, the synchronous propeller with sealing pads installed in the present invention will be further explained in conjunction with the description of the drawings and specific embodiments, but the explanation does not constitute an improper limitation on the technical solution of the present invention.

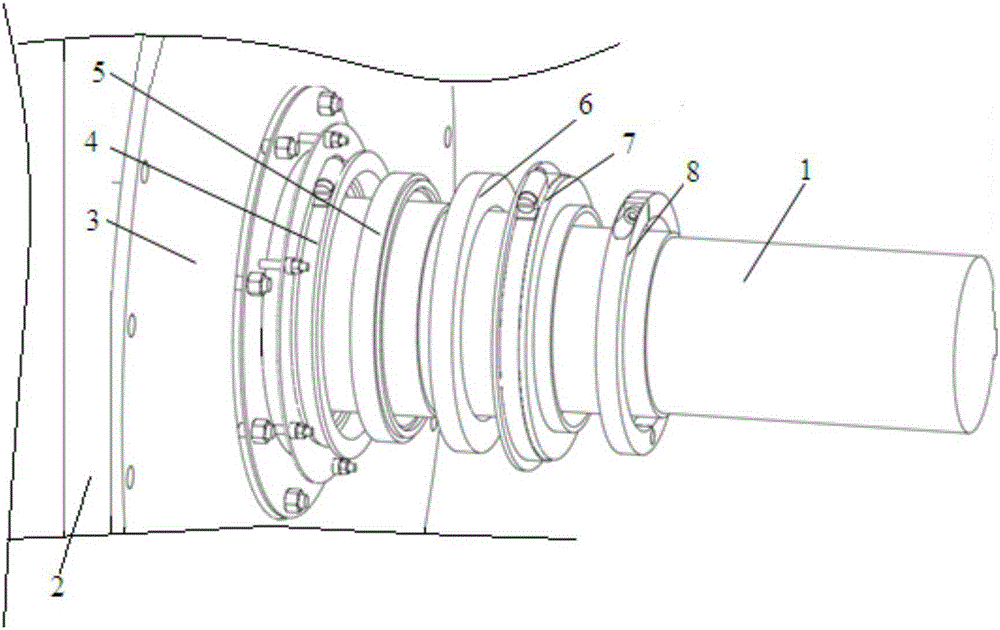

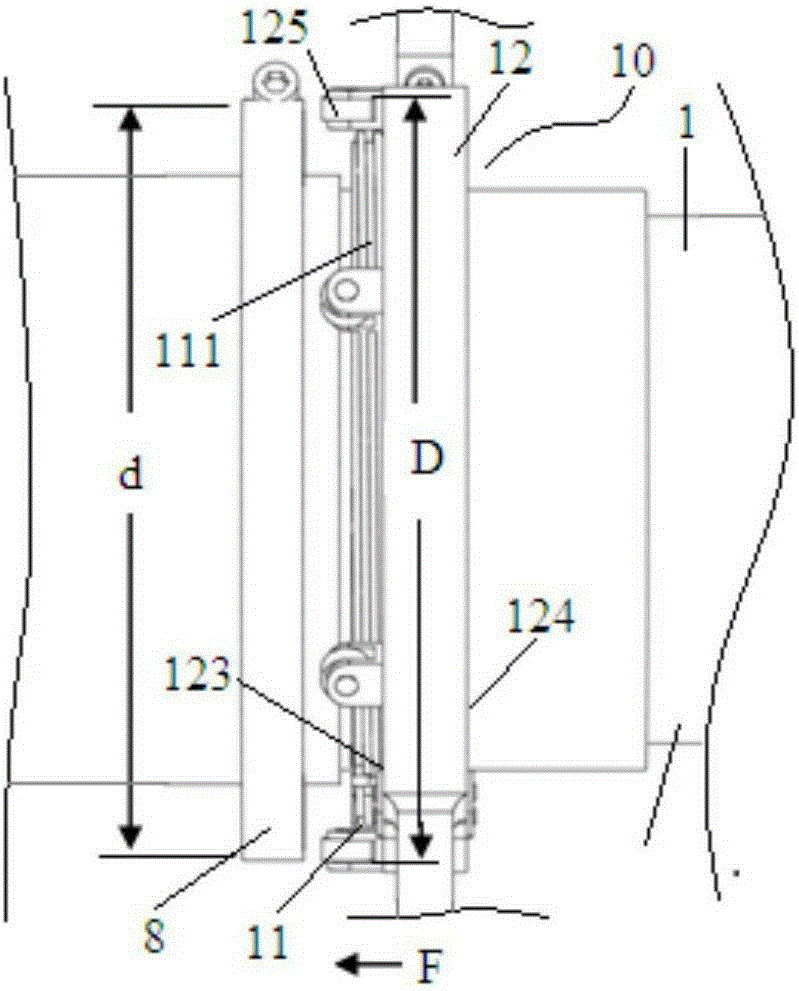

[0046] Figure 2 to Figure 4 Each shows the structure of the synchronous propeller with sealing gasket installed in one embodiment of the present invention. Among them, in figure 2 Some parts of the immersion tank are omitted in the curves.

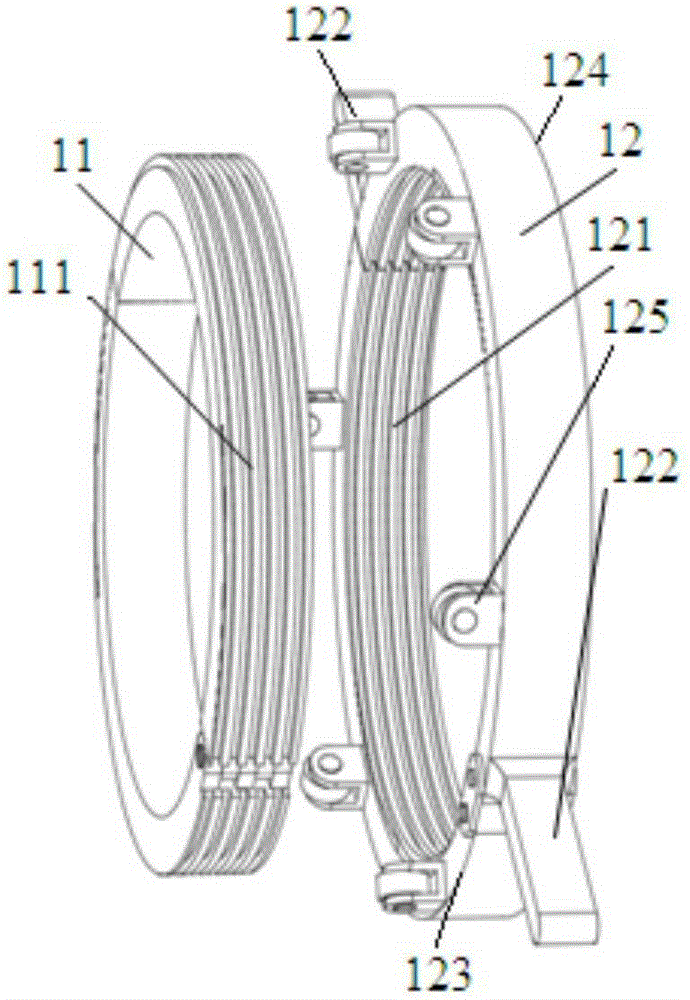

[0047] Such as figure 2 , image 3 and Figure 4 As shown, in the above-mentioned embodiment, the synchronous propeller 10 with the gasket installed includes an inner ring 11 and an outer ring 12, wherein the inner ring 11 is fixedly arranged on the sinking roller 1 of the immersion tank, and the outer ring 12 is connected with the inner ring 11. The rings 11 are arranged coaxially. The surface of the outer ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com