Curved surface screen printing device

A screen printing device and curved surface technology, which is applied to screen printing machines, printing machines, printing machines, etc., can solve problems such as low production efficiency and impact on product quality, and achieve high production efficiency, reduced labor intensity, and uniform contact force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

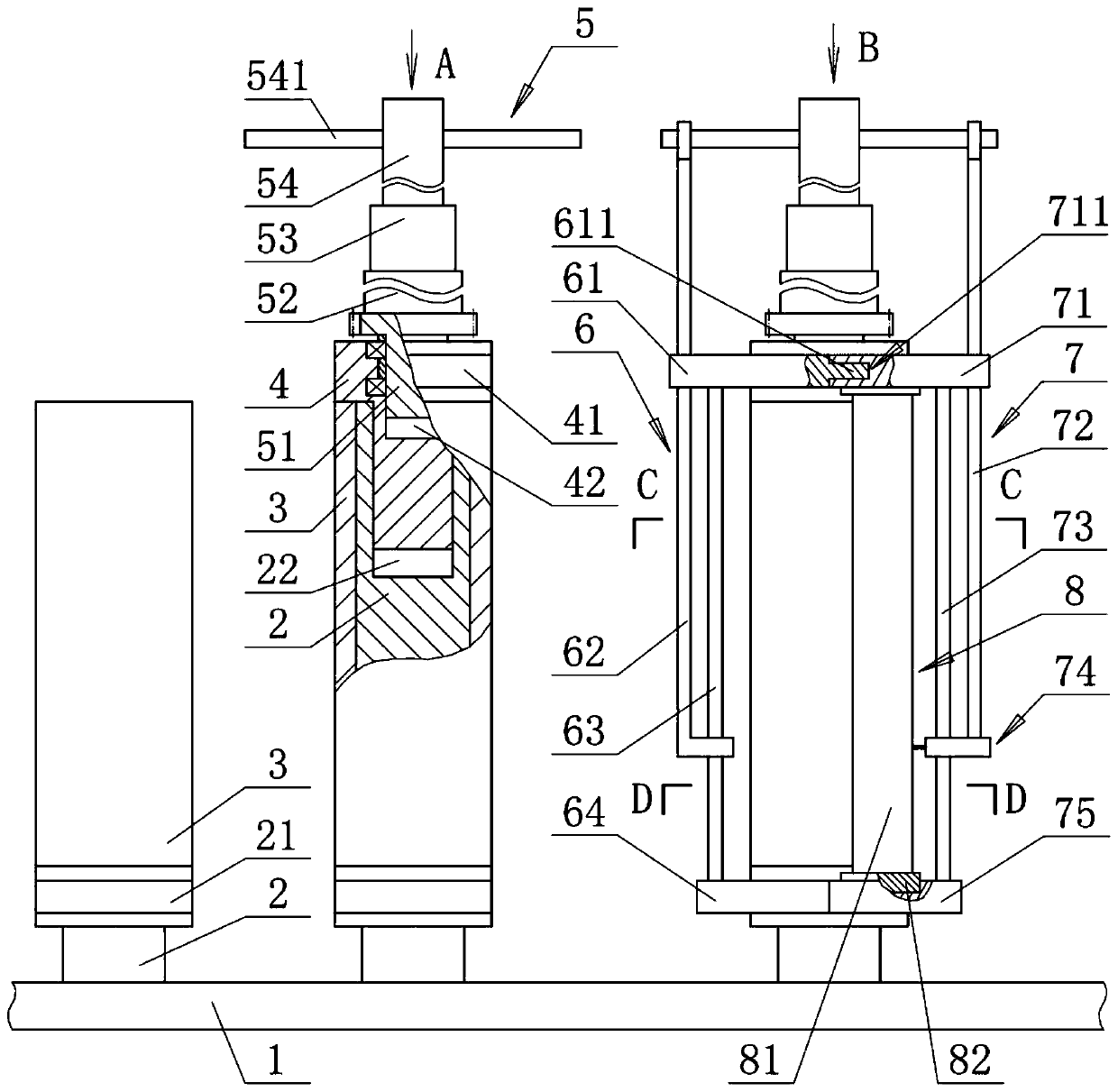

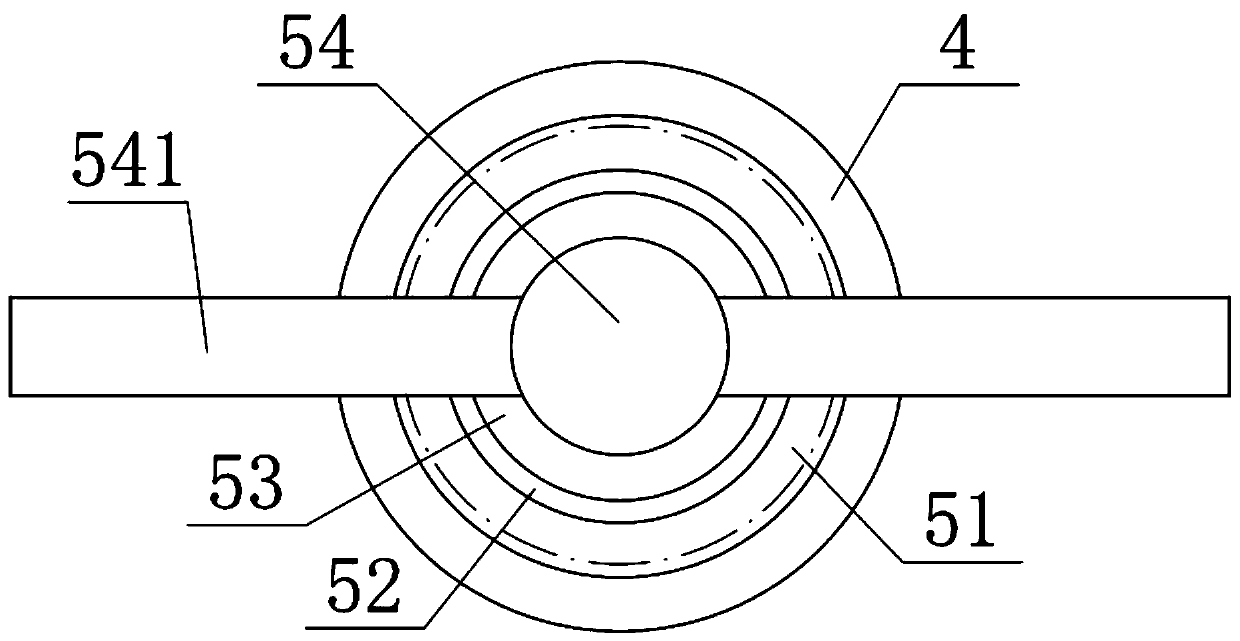

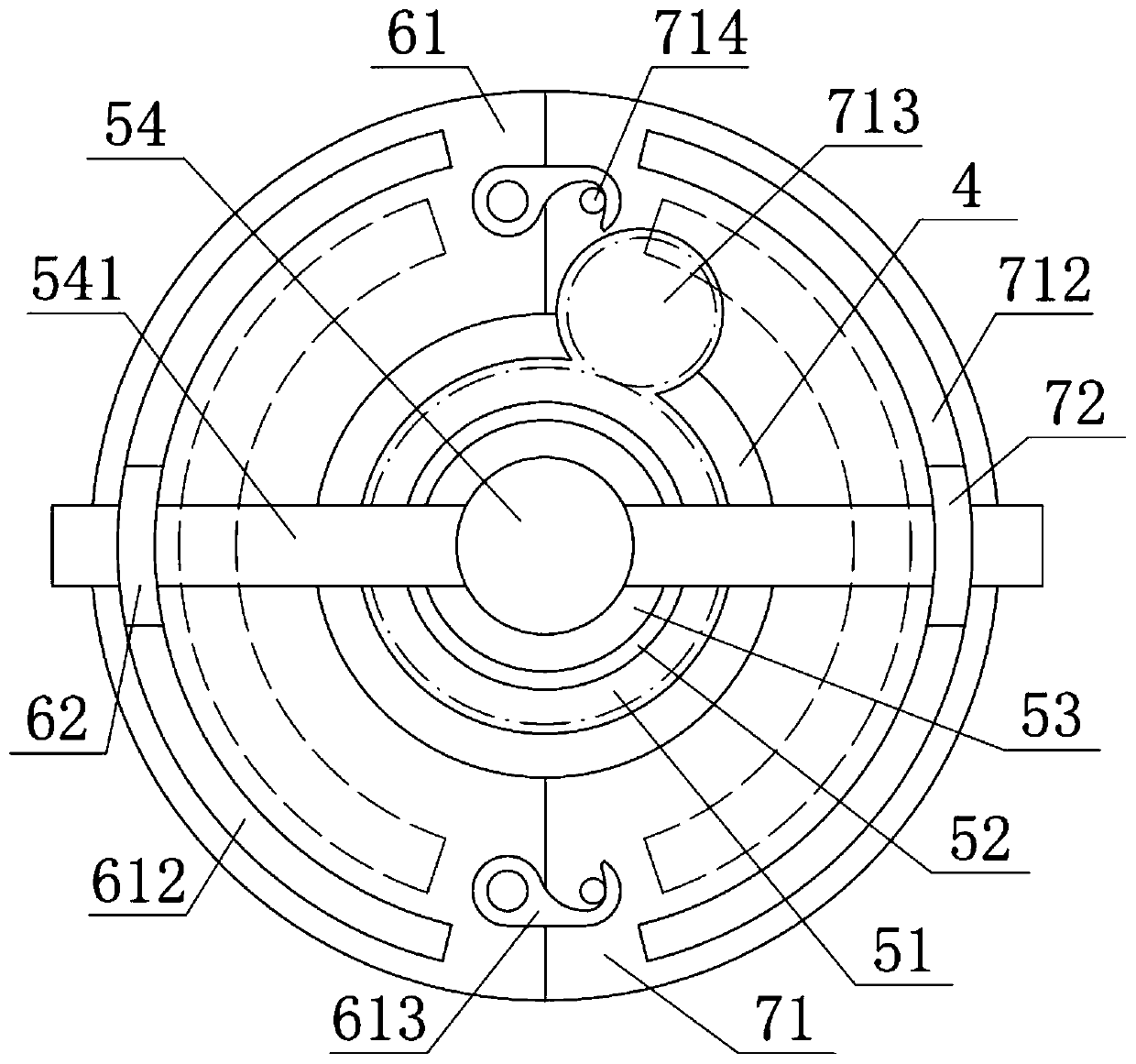

[0023] Such as Figure 1-5 As shown, a curved screen printing device includes a conveyor belt 1 and a substrate 3. The conveyor belt 1 is connected to the production line. Several pins 2 are connected to the conveyor belt 1. The number of pins 2 is configured according to the production design requirements. The substrate 3 has a cylindrical shape and is provided with a substrate hole passing through the upper and lower end surfaces. The pin 2 has a stepped cylindrical shape and is divided into upper, middle and lower sections. The upper cylinder of the pin 2 is inserted into the substrate hole of the substrate 3, and the substrate 3 is sleeved with the pin 2. The upper part of the upper cylinder of the pin 2 is provided with a pin hole 22. The upper surface of the middle cylinder of the pin 2 is tightly attached to the lower end surface of the substrate 3. The pin 2 is provided with a pin slot 21 with a concave outer surface. The pin slot 21 is located on the cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com