Simple liquid storage type scraper and conveying device

A scraper and accumulator technology, used in conveyors, cleaning devices, conveyor objects, etc., can solve the problems of increased motor load, sanitary cleaning obstacles, laborious and laborious, etc., to maintain stability, reduce losses, The effect of maintaining environmental hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

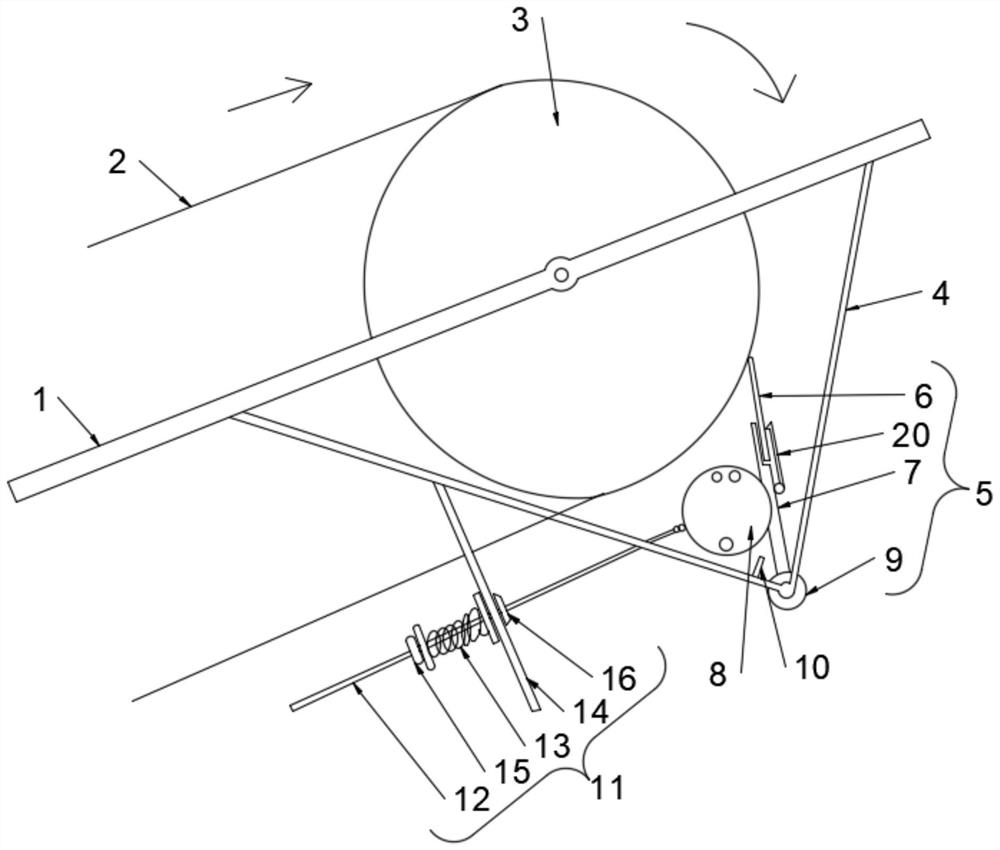

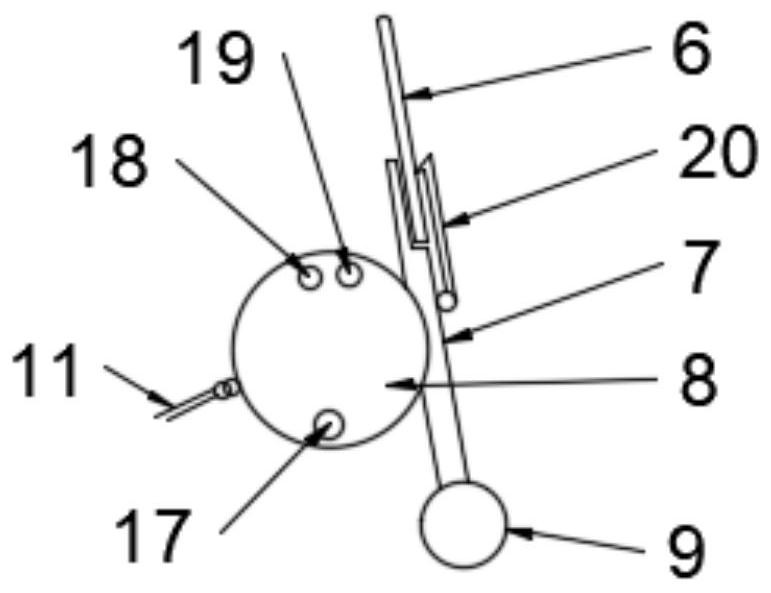

[0037] Such as figure 1 , 2 As shown, the core of the present invention is to provide a simple liquid storage type scraper, which is applied to scrape the surface of the conveyor belt 2 of the conveying device. The driving roller of the conveyor belt 2, the conveyor belt 2 conveys the material through the driving roller, such as figure 1 Among them, the driving roller 3 rotates in the clockwise direction to drive the conveyor belt 2 to move in the clockwise direction. The simple liquid storage type scraper includes: the scraper frame 4, which is fixed on the lower side of the conveyor frame; the scraper assembly 5. The scraper assembly 5 is arranged in parallel with the driving roller, and the upper end of the scraper assembly 5 is in contact with the conveyor belt 2, and the lower end of the scraper assembly 5 is rotationally connected with the scraper frame 4; the liquid reservoir 9, inside the liquid reservoir 9 The liquid used to provide gravity is stored, and the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com