Method for transferring and preparing two-dimensional atomic crystal laminated structure

A two-dimensional atomic crystal, stacked structure technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of bubble generation, small sample area, easy sample breakage, etc., to reduce doping and damage, The effect of high separation repetition rate and easy residual glue disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

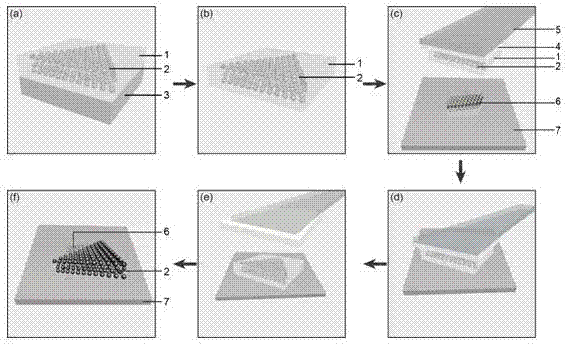

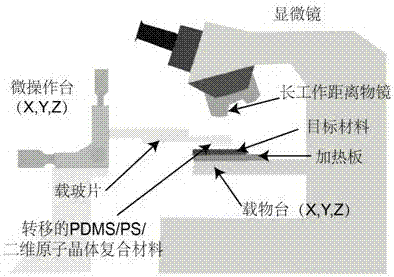

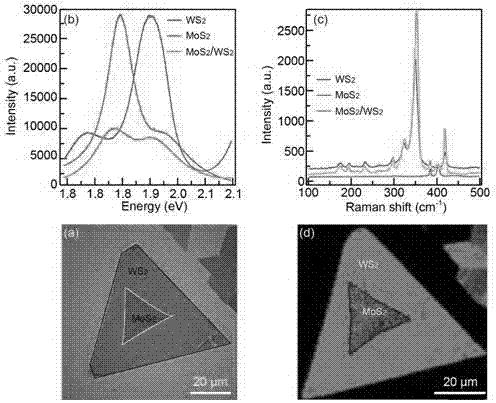

[0038] Positional transfer technology is suitable for the preparation of stacked structures (homojunction and heterojunction) of CVD-grown two-dimensional nanomaterials, so that tungsten disulfide (WS) grown on sapphire substrates 2 / Sapphire) localized molybdenum disulfide (MoS2) transferred to a silicon dioxide substrate 2 / SiO 2 ), so as to prepare a two-dimensional atomic crystal heterojunction as an example, which specifically includes the following steps:

[0039] (1) Toluene was used as a solvent to prepare a polystyrene (PS) solution, and the PS was dissolved by heating with magnetic stirring.

[0040] (2) Prepare dimethylsiloxane (PDMS), mix the main agent (A glue) and the hardener (B glue), remove the air bubbles in the mixed glue by centrifugation, pour it into the container, control the thickness to about 1 mm, and bake curing;

[0041] (3) subbed, in WS 2 / Sapphire surface is spin-coated with PS solution and heated for 30 minutes, then dried toluene solvent; ...

Embodiment 2

[0049] The experimental method is the same as in Example 1, and the single-layer MoS 2 Replaced by single-layer WS 2 , two layers of WS prepared by positioning transfer 2 homogeneous junction.

Embodiment 3

[0051] The experimental method is the same as in Example 1, the only difference is that the monolayer molybdenum disulfide is replaced by molybdenum trioxide nanosheets, and the WS prepared by positioning transfer 2 / MoO 3 Heterojunction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com