Method for manufacturing synthetic leather and synthetic leather

A production method and technology for synthetic leather, applied in the field of synthetic leather, can solve the problems that leather products cannot fully meet the ecological and environmental protection requirements, the three highs, and the inability to fundamentally improve the grade of synthetic leather, so as to achieve clean production and simplify the tanning process. , the effect of good feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

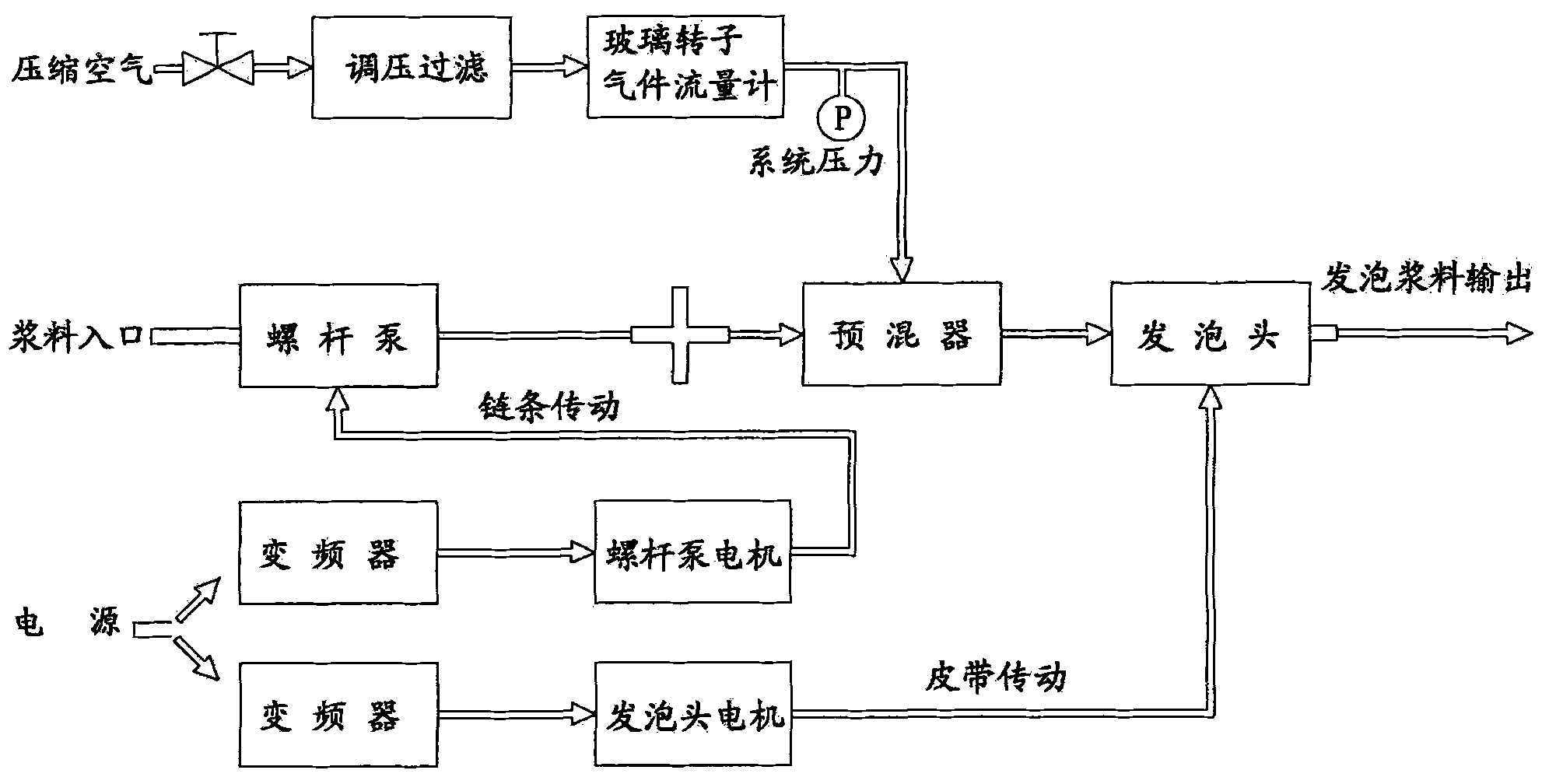

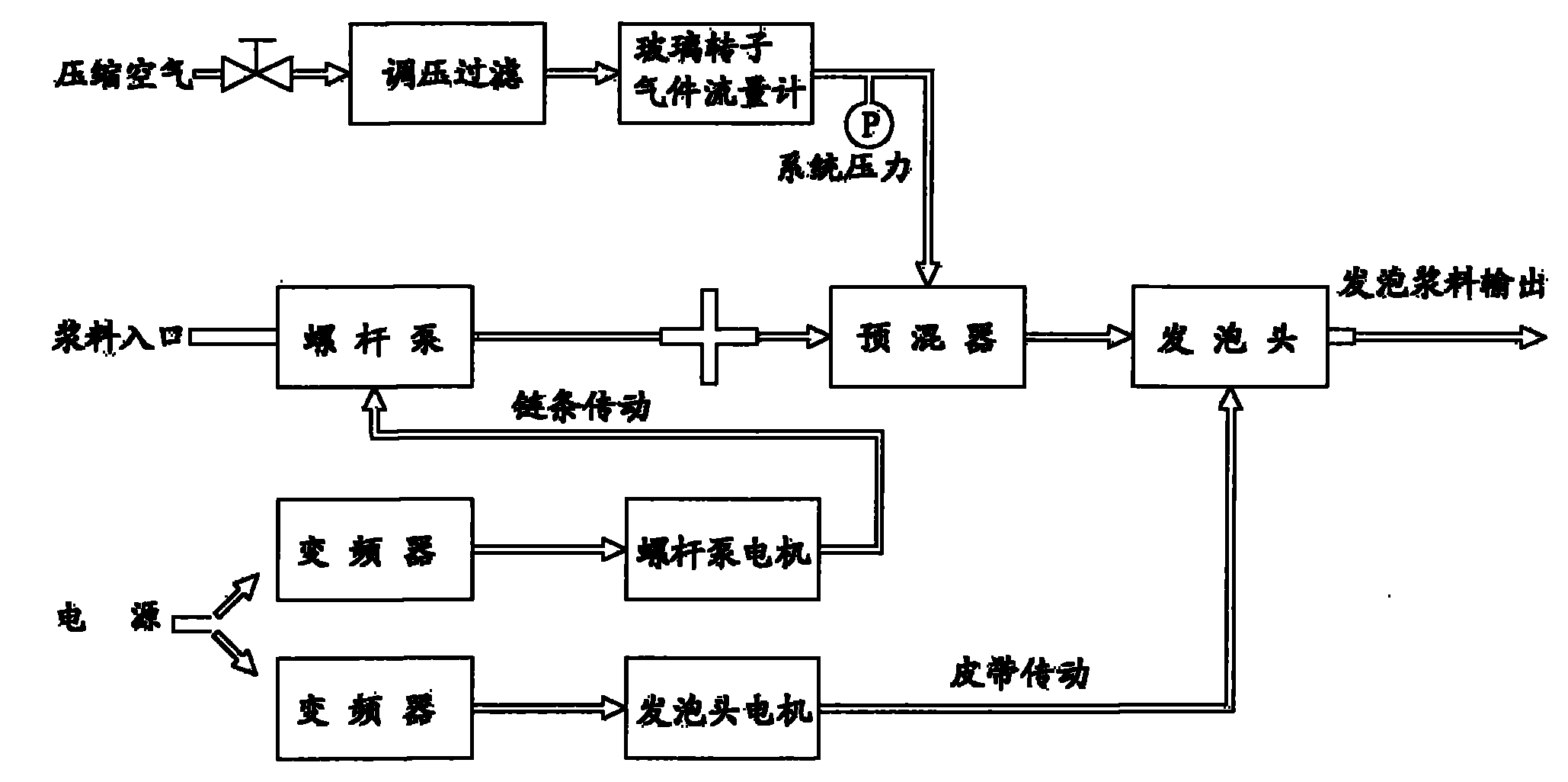

Method used

Image

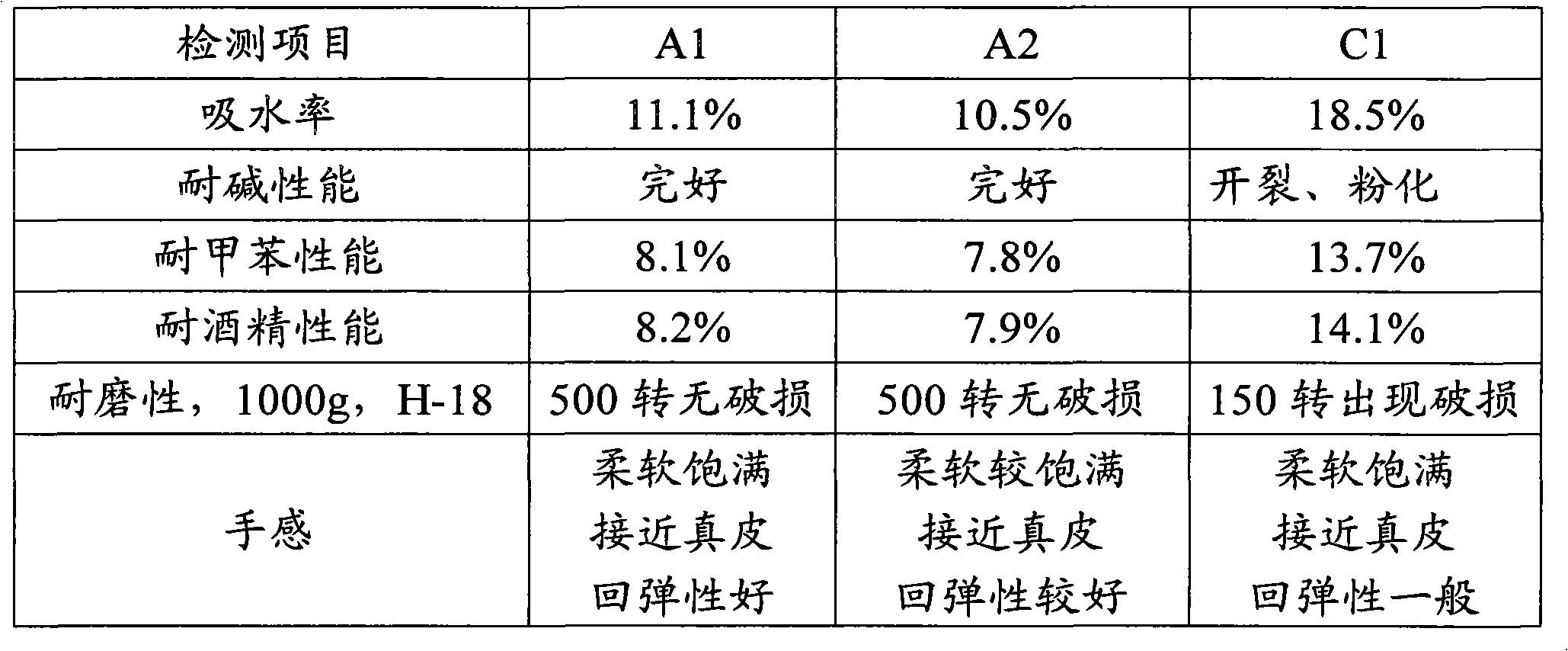

Examples

Embodiment 1

[0043] This embodiment is used to illustrate the synthetic leather production method provided by the present invention.

[0044] 1. Materials for leather making

[0045] 1-1 release paper

[0046] Use DE90 release paper produced by American Warren Company.

[0047] 1-2 surface layer slurry

[0048] Use UNK PUD-200 water-based polyurethane resin produced by Lishui Unek Water-based Resin Technology Co., Ltd. With 35 parts by weight of UNK PUD-200 waterborne polyurethane resin, 65 parts by weight of deionized water, 0.8 parts by weight of thickener, 0.4 parts by weight of defoamer, 0.6 parts by weight of leveling agent, 1 part by weight of external linking agent and 15 parts by weight of The water-based color paste is mixed, thickened and compounded under the agitation of a high-speed disperser, and the viscosity is adjusted to 3000cps / 20°C to become the surface layer slurry for synthetic leather.

[0049] 1-3 middle foam layer slurry

[0050] LP RSC1380 waterborne polyureth...

Embodiment 2

[0061] This embodiment is used to illustrate the synthetic leather production method provided by the present invention.

[0062] 1. Materials for leather making

[0063] The same various tanning materials as in Example 1 were used.

[0064] 2. Preparation of synthetic leather

[0065] 2-1 First put the dry DE90 release paper on the paper table, and adjust the moving speed of the release paper on the production line through the splicer. When the release paper moves to the first coating station, the surface layer slurry prepared in step 1-2 is evenly coated on the DE90 release paper with a thickness of 5 wires through the coating station. At this time, the release paper with UNK PUD-200 surface layer slurry is driven by the driver at a speed of 10 m / min and passes through the first section of medium-wave infrared oven under the irradiation of the infrared radiator. The infrared oven is 20 meters long, and there are three temperature zones from low to high at 110°C, 120°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com