A kind of organosilicon-phosphorus hybrid flame-retardant water-based self-emulsifying epoxy resin curing agent and its preparation method and application

An epoxy resin curing and silicone technology, applied in epoxy resin coatings, coatings, fireproof coatings, etc., can solve problems such as low flame retardancy, achieve low cost, good flexibility, ensure long-term stability and The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

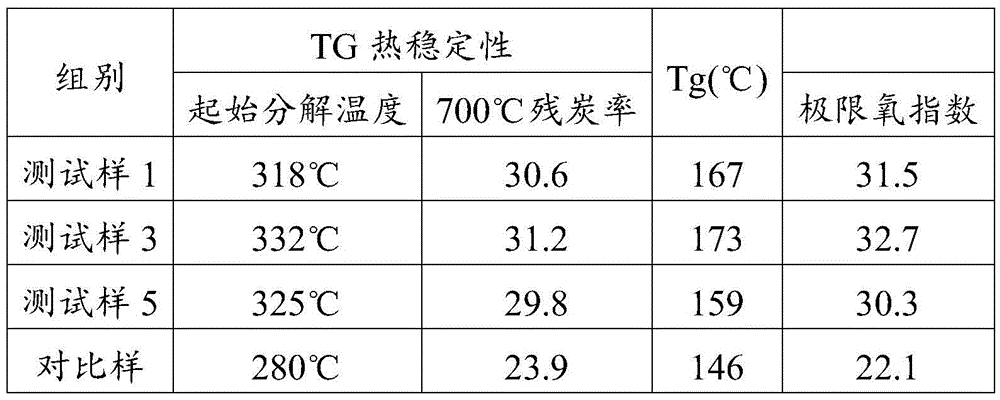

Examples

Embodiment 1

[0031] The present invention is an embodiment of a method for preparing a self-emulsifying curing agent for organosilicon-phosphorous hybrid flame-retardant water-based epoxy resin. The method described in this embodiment includes the following steps:

[0032] a) Synthesis of silicon-phosphorus hybrids: KH560 and DOPO are added to a flask with a reflux condenser, a thermometer and a stirring device in the same amount as the substance, and the catalyst 4-methyl-2-ethylimidazole (amount of 2% of the mass of KH560), after DOPO and 4-methyl-2-ethylimidazole are completely melted in KH560, the temperature is raised and stirred and refluxed for 5-8 hours to obtain a solution or gel-like substance A containing silicon-phosphorus hybrids.

[0033] b) Preparation of nonionic water-based epoxy self-emulsifier: in a 500ml four-necked flask equipped with a nitrogen feed device, a reflux condenser, a thermometer and a mechanical stirrer, add octadecylamine and solvent propylene glycol methy...

Embodiment 2

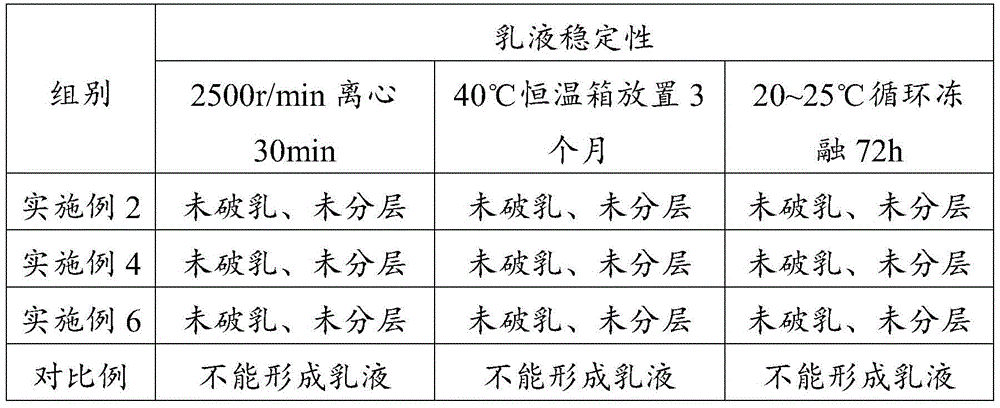

[0036] The invention relates to the application of a self-emulsifying curing agent of organic silicon phosphorus hybridized flame-retardant water-based epoxy resin in epoxy fire-proof and flame-retardant coating base material.

[0037] At 50°C, pour 10g of bisphenol epoxy resin E-51 and 5g of the curing agent prepared in Example 1 into the paint mixing cup, add deionized water at a temperature of 50-60°C, and stir at high speed until uniform epoxy emulsion, so that its solid content is about 50%, that is, the base material used for fireproof coatings, and other additives, such as pigments, defoamers, fillers, etc., are added to it to prepare epoxy resins that meet the needs of different material surfaces fire retardant coating.

Embodiment 3

[0039] The present invention is an embodiment of a method for preparing a self-emulsifying curing agent for organosilicon-phosphorous hybrid flame-retardant water-based epoxy resin. The method described in this embodiment includes the following steps:

[0040] a) Synthesis of silicon-phosphorus hybrids: with mechanical stirring, condenser and N 2 In the three-necked flask of the device, completely dissolve epoxy resin E-44 in absolute ethanol, add hydroxyl-terminated polydimethylsiloxane and catalyst dibutyltin dilaurate, react for 3 hours, and remove the solvent by rotary evaporation. Raise the temperature to 100°C, add DOPO and its mass fraction of 1% triphenylphosphine, raise the temperature to 120°C for 6 hours, and obtain a gel-like substance A containing a silicon-phosphorus hybrid;

[0041] b) Preparation of nonionic water-based epoxy self-emulsifier: in a 500ml four-necked flask equipped with a nitrogen feed device, a reflux condenser, a thermometer and a mechanical st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com