Water-based nano static conductive coating and preparation method thereof

A static-conducting, nano-technology, applied in the direction of conductive coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of high-molecular materials without electrical conductivity and low static-conductive efficiency, so as to improve adhesion and impermeability, Enhanced electrostatic conductivity and low VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

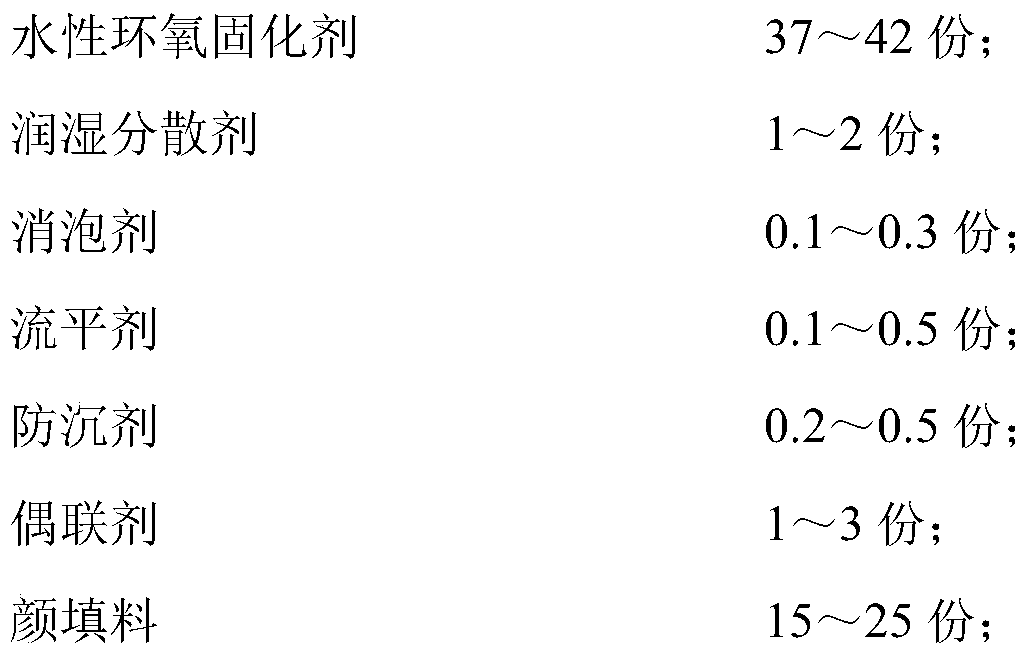

[0031] A water-based nano-conductive electrostatic coating, comprising component A and component B, wherein the mass ratio of component A to component B is 1:4.1, component B is water-based epoxy emulsion EP6520-WH-53A, component A contains the following ingredients in parts by mass:

[0032] Table 1 Example 1 Component A Composition

[0033]

[0034] The preparation method of described water-based nanometer conductive electrostatic coating, comprises the steps:

[0035] (1) Refining stage: Add the wetting and dispersing agent, defoamer, leveling agent, coupling agent and part of water of the water-based nano-static conductive coating into the dispersion tank, and disperse at a low speed (500r / min) for 8 minutes; Then add pigments and fillers and electrostatic conductive fillers, disperse at high speed (900r / min) for 25min, after the dispersion is completed, enter the sand mill for grinding to a fineness≤40μm, to obtain the mixture I;

[0036] (2) Paint mixing stage: Add ...

Embodiment 2

[0039] A water-based nano-conductive electrostatic coating, comprising component A and component B, wherein the mass ratio of component A to component B is 1:4.2, component B is water-based epoxy emulsion CTW-6064, and component A contains The following components by mass percentage:

[0040] Table 2 Example 2 Component A Composition

[0041]

[0042] The preparation method of described water-based nanometer conductive electrostatic coating, comprises the steps:

[0043] (1) Refining stage: Add the wetting and dispersing agent, defoamer, leveling agent, coupling agent and part of water of the water-based nano-static conductive coating into the dispersion tank, and disperse at a low speed (400r / min) for 10 minutes; then Add pigments and fillers and electrostatic conductive fillers, disperse at high speed (800r / min) for 30 minutes, after the dispersion is completed, enter the sand mill for grinding to a fineness of ≤40 μm, and obtain mixture I;

[0044] (2) Paint let-down s...

Embodiment 3

[0047] A water-based nano-conductive electrostatic coating, comprising component A and component B, wherein the mass ratio of component A to component B is 1:4.5, component B is water-based epoxy emulsion EP6520-WH-53A, component A comprises the following compositions by mass percentage:

[0048] Table 3 Example 3 Component A Composition

[0049]

[0050] The preparation method of described water-based nanometer conductive electrostatic coating, comprises the steps:

[0051] (1) Refining stage: Add the wetting and dispersing agent, defoamer, leveling agent, coupling agent and part of water of the water-based nano-static conductive coating into the dispersion tank, and disperse at a low speed (500r / min) for 5 minutes; then Add pigments and fillers and electrostatic conductive fillers, disperse at high speed (1000r / min) for 20 minutes, after the dispersion is completed, enter the sand mill for grinding to a fineness of ≤40 μm, and obtain mixture I;

[0052](2) Paint let-dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com