Preparation method of polyaniline dispersion

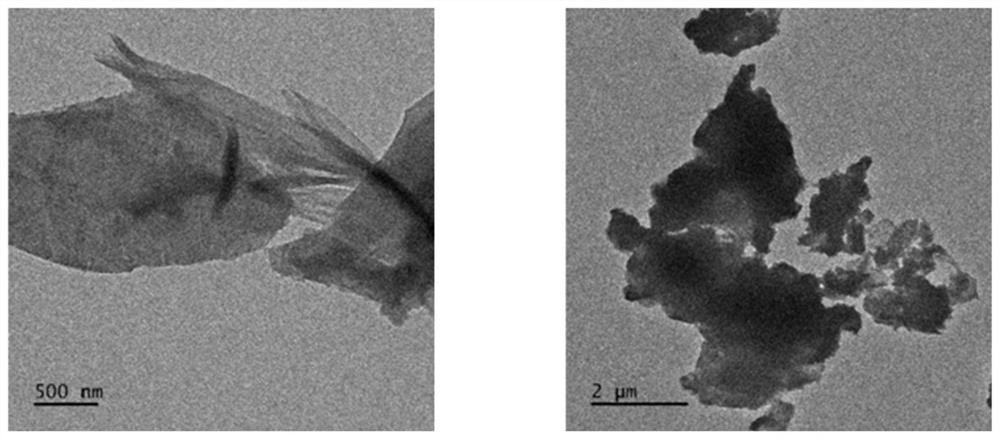

A technology of polyaniline and dispersion, applied in coatings, anti-corrosion coatings, etc., can solve problems such as poor dispersion and irregular shape of dispersed polyaniline, and achieve the goal of overcoming complicated steps, excellent dispersion performance, and increasing adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

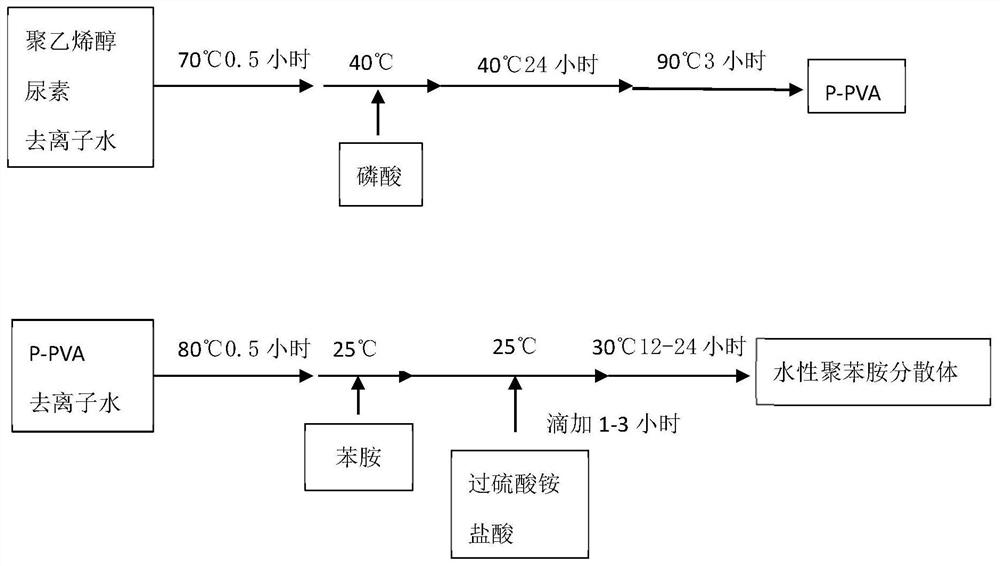

[0026] like figure 1 As shown, the preparation method of a polyaniline dispersion of the present invention includes:

[0027] (1) Accurately weigh 40 gpva and 0.8 g of urea, adding a four-mouth flask with 100 ml of deionized water at one time, warming up to 70 ° C, after dissolving, stirring 0.5 h, mixing it uniform, cooling to 40 ° C, add A 10 g of 85 wt% phosphoric acid was weighed, and the reaction was stirred at 40 ° C for 24 h, warmed to 90 ° C, stirring the reaction for 3 h, resulting in a yellow transparent viscous liquid, cooling the discharge.

[0028] (2) Accurately weigh the self-made P-PVA 4.7 g, add a flask containing 100 ml of deionized water, warmed to 80 ° C, stirring at high speed to P-PVA completely dissolved, fell to room temperature, 1-time addition of 3.8g, Stir for 1 h.

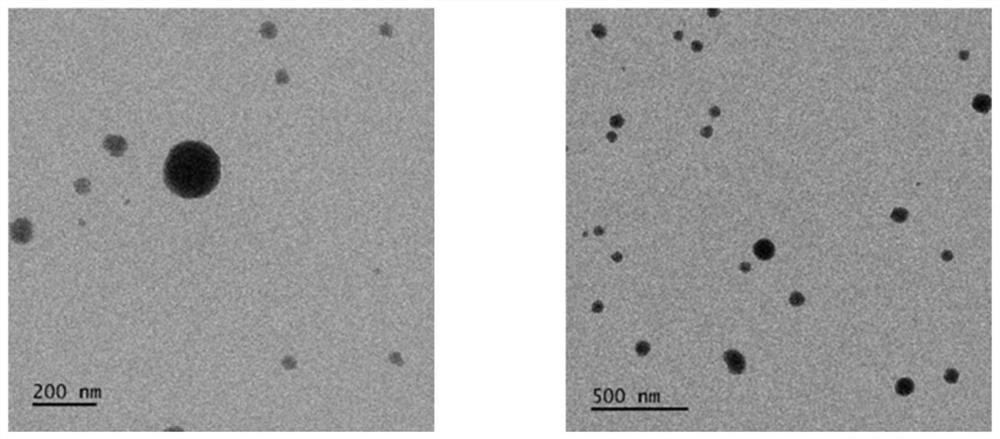

[0029] (3) Weighing 4.6 g of ammonium sulfate, 100 ml of hydrochloric acid (0.2 mol / L), magnetic stirring, fully dissolved, transferred to a constant pressure drip funnel, about 1 h, stirr...

Embodiment 2

[0032] A method of preparing a polyaniline dispersion, a method of composite modification, and the specific steps are as follows:

[0033] (1) Accurately weigh 40gPVA and 2G urea, adding a four-mouth flask with 100 ml of deionized water at a time, heating to 70 ° C, after dissolving, stirring 0.5 h, mix uniform, cooling to 40 ° C, adding The amount of 100 g 85 wt% phosphoric acid was stirred at 30 ° C for 24 h, warmed to 100 ° C, stirred for 2 h, resulting in a yellow transparent viscous liquid, cooling the discharge.

[0034] (2) Accurately weigh the self-made P-PVA 6g, add a flask containing 100 ml of deionized water, warmed to 70 ° C, stirring at high speed to P-PVA completely dissolved, minus to room temperature, 1 degrenes 6 g, stir 0.5 h.

[0035] (3) 6 g of ammonium sulfate, 100 ml of hydrochloric acid (0.2 mol / L), magnetic stirring, well dissolved, transferred to a constant pressure drip funnel, about 3 h, mixed, stirred at normal temperature for 24 h, to obtain ink gree...

Embodiment 3

[0037] A method of preparing a polyaniline dispersion, a method of composite modification, and the specific steps are as follows:

[0038] (1) Accurately weigh 40 gpva and 0.5 g of urea, adding a four-mouth flask with 100 ml of deionized water at one time, heating to 70 ° C, after dissolving, stirring 0.5 h, mixing, cooling to 50 ° C, add A 10 g 85 wt% phosphoric acid was known, stirred at 50 ° C for 24 h, warmed to 80 ° C, stirred for 4 h, resulting in yellow transparent viscous liquid, cooling the discharge.

[0039] (2) Accurately weigh the self-made P-PVA 4G, add 100ml deionized flask, temperature rise to 90 ° C, stirring at high speed to P-PVA completely dissolved, minus to room temperature, 1 degrene 3g, stirred 1.5 h.

[0040] (3) Weighing 3 g of ammonium persulfate, 100 ml of hydrochloric acid (0.2 mol / L), magnetic stirring, well dissolved, transferred to a constant pressure drip funnel, about 2 h, stirred at 30 ° C for 12 h, to obtain ink Green suspension, ie, a water-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com