Multi-functional walking excavator

An excavator and functional technology, applied in the field of walking excavators, can solve the problems of reducing the working efficiency and safety performance of the excavator, incapable of safe and efficient operation, and the hydraulic suspension is not flexible enough, so as to improve work efficiency and safety and stability. , Improve work efficiency and stability, good stability and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

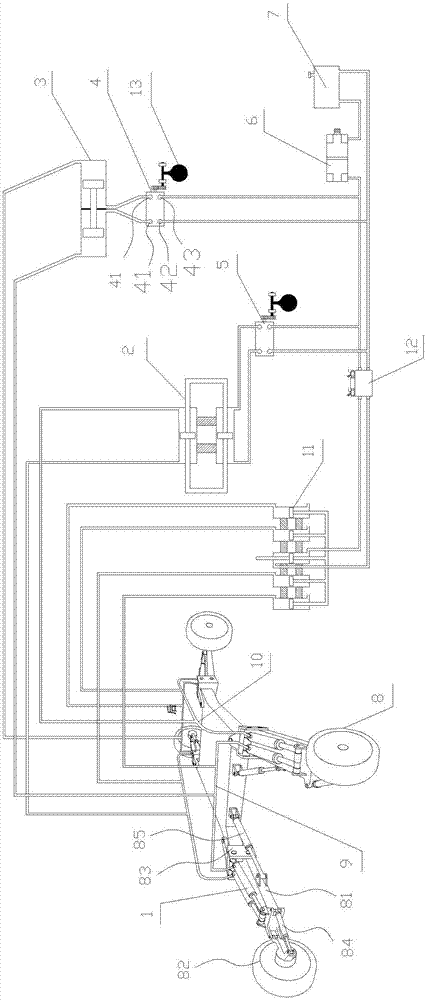

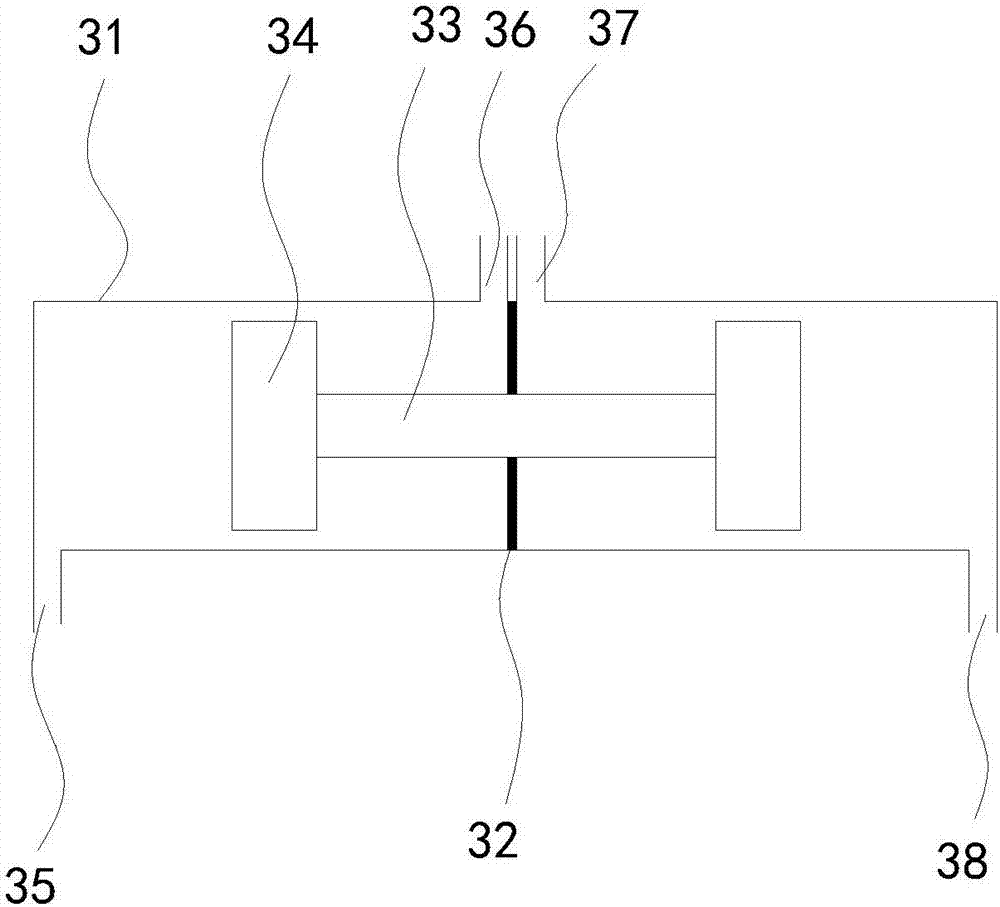

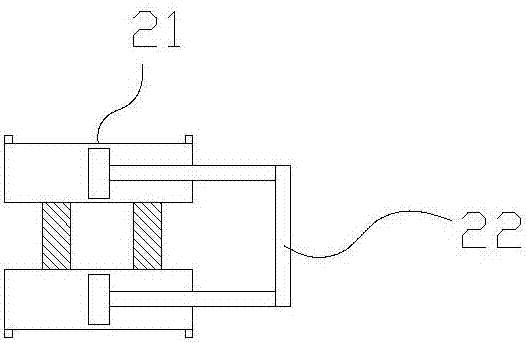

[0032] Such as figure 1 As shown, a walking excavator with multiple functions includes an interconnected suspension system and an excavator vehicle 8. The interconnected suspension system includes a hydraulic jack 1, a left and right balance control device 2, a front and rear balance control device 3, and a first steering gear 4. The second steering gear 5, the fluid pump 6 and the fluid source 7; the hydraulic jack 1 is arranged on the upper side of the wheels of the excavator vehicle 8, and two hydraulic jacks 1 are arranged on the upper side of each wheel, and different wheels located at the same end Two of the hydraulic jacks 1 on the same side are connected through the first pipeline 9, and the remaining hydraulic jacks 1 on different wheels at the same end are respectively connected with the remaining hydraulic jacks 1 on the other end of the same side and different wheels through the second pipeline 10 The left and right balance control devices 2 are respectively connec...

specific Embodiment 2

[0040] Specific embodiment 2, such as Figure 5 As shown, the overall lifting control device 11 is replaced by a hydraulic cylinder device with multiple outlets that has the same function. Other structures are completely consistent with the structure of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com