Material feeder of hard rubber type traditional Chinese medicine processor

A technology of a cooking machine and a feeder, applied in the field of feeders, can solve the problems of uneven thickness of donkey-hide gelatin, agglomeration failure, uneven pressure, etc., and achieve a firm and reliable buckle structure, a simplified structure and system, and a simple and reliable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through specific examples.

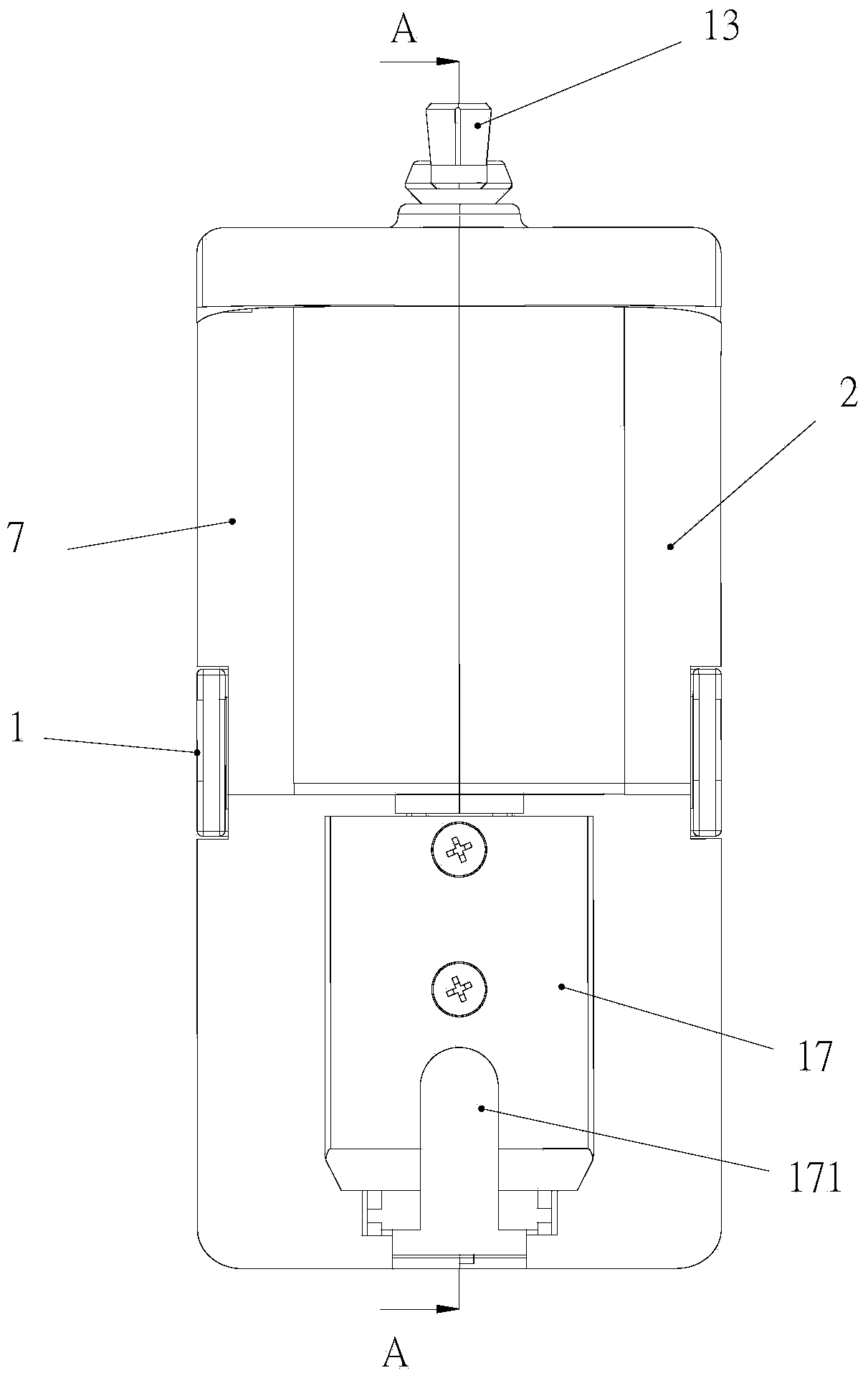

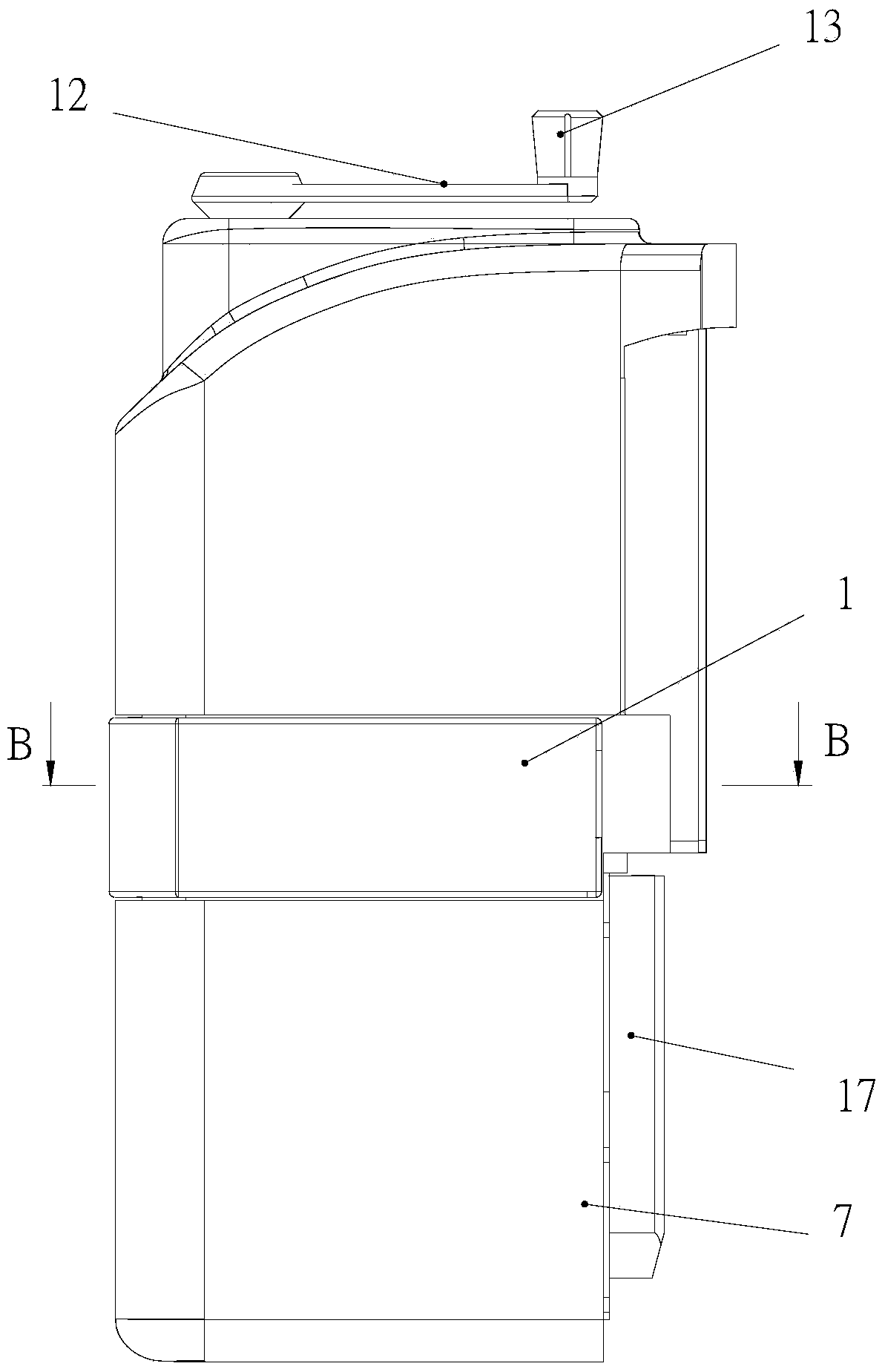

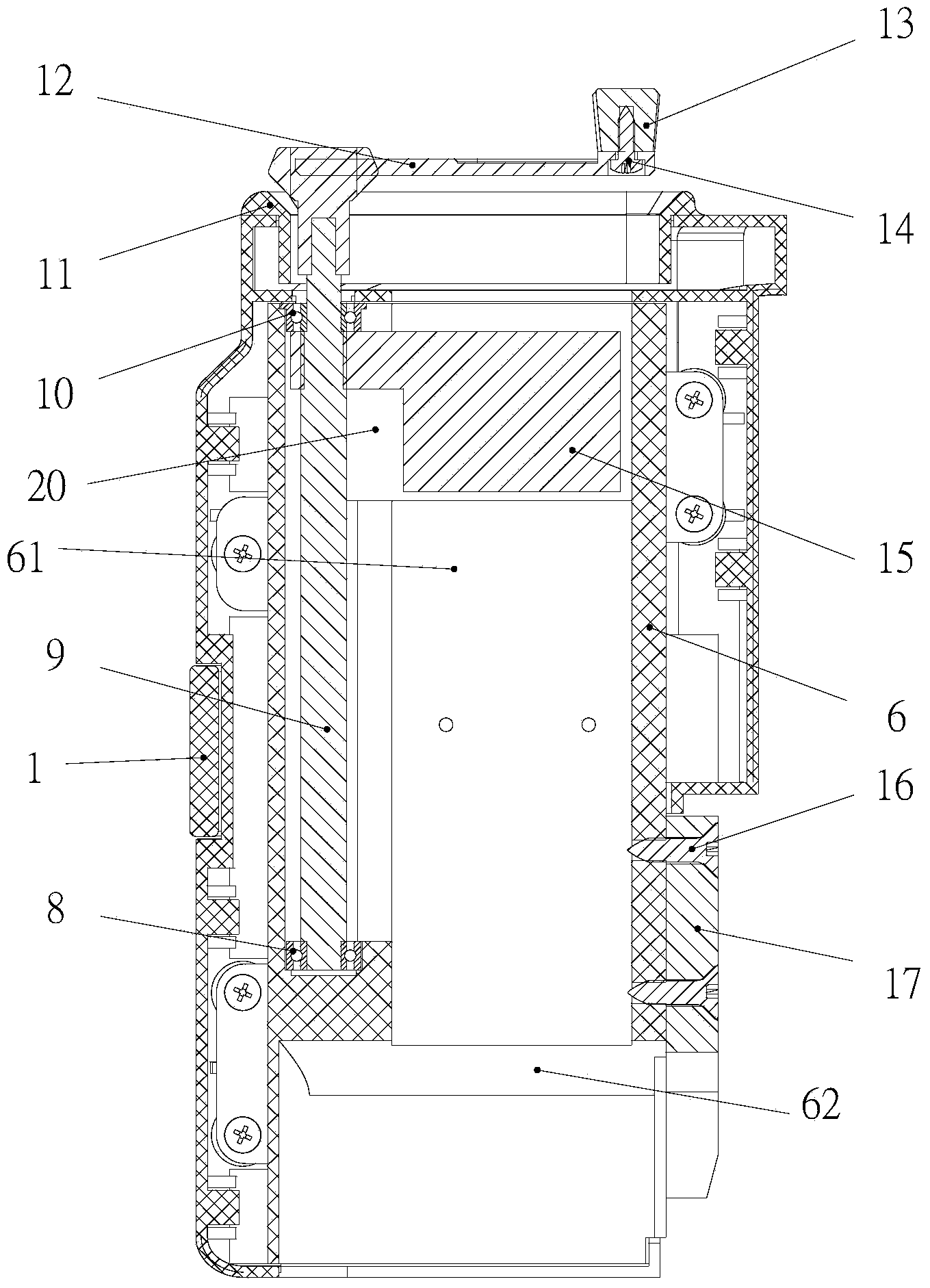

[0027] Such as Figure 1 to Figure 5 Shown is a feeder for a hard rubber traditional Chinese medicine cooking machine. The food that the cooking machine can cook is hard rubber traditional Chinese medicine, such as donkey-hide gelatin, tortoise shell glue, antler glue, yellow gelatin, deer antler, deer horn cap, or other Hard Chinese medicinal materials. The feeder includes a shell, a feeder inner bag 6, and a feeding mechanism.

[0028] Such as Figure 4 As shown, the shell includes a first shell half body 2 and a second shell half body 7, the first shell half body 2 and the second shell half body 7 cooperate with each other and are fixed with the inner bag 6 of the feeder by screws, wherein , the outer wall of the inner bag 6 of the feeder is provided with several screw fixing protrusions, the screw fixing protrusions are covered with fastening silica gel 5, and the screw h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com