Preparation method of lithium ion battery cathode sheet, and film coating and drying apparatus

A lithium-ion battery and drying device technology, which is applied to battery electrodes, devices for coating liquid on the surface, circuits, etc., can solve the problems of a large amount of energy in the magnetic field generated by the electromagnet, the inability to achieve the best effect, and high manufacturing costs. Consistency of arrangement, improvement of production cost and energy consumption, effect of improvement of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

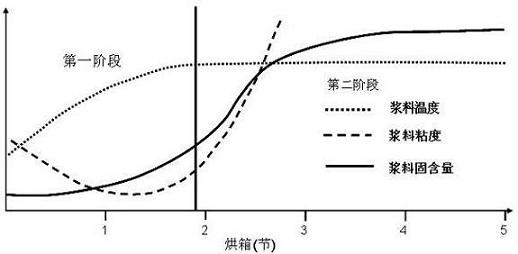

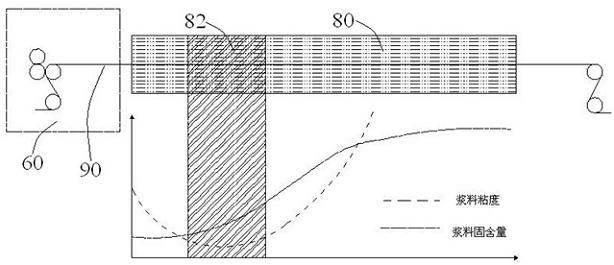

[0026] Since it is not advisable to maintain the magnetic field during the drying process of the negative electrode sheet, the inventor believes that preventing the aligned graphite particles from turning again is the key to solving the existing problems. In order to find a solution to the problem, the inventor first conducted an in-depth study on the drying process of the negative electrode sheet, and found that the process can be roughly divided into the following: figure 1 The two stages shown: the first stage is the preheating stage, the temperature of the slurry in this stage increases and the viscosity decreases, but the amount of solvent does not decrease, so the solid content remains basically unchanged; the second stage is the drying stage, in this stage The temperature of the slurry tends to be stable, and the solvent is gradually removed, so the solid content and viscosity increase rapidly until the slurry becomes completely solid.

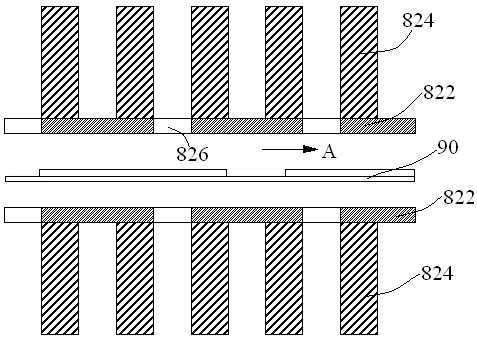

[0027] After further research, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com