PDC drill bit with rear-row tooth water holes

A water hole and drill bit technology, which is used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of poor cooling effect of cutting teeth, difficulty in timely discharge of cuttings, and reduced rock breaking efficiency and service life of the drill bit. High injection speed, good cuttings discharge effect, and the effect of avoiding premature failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

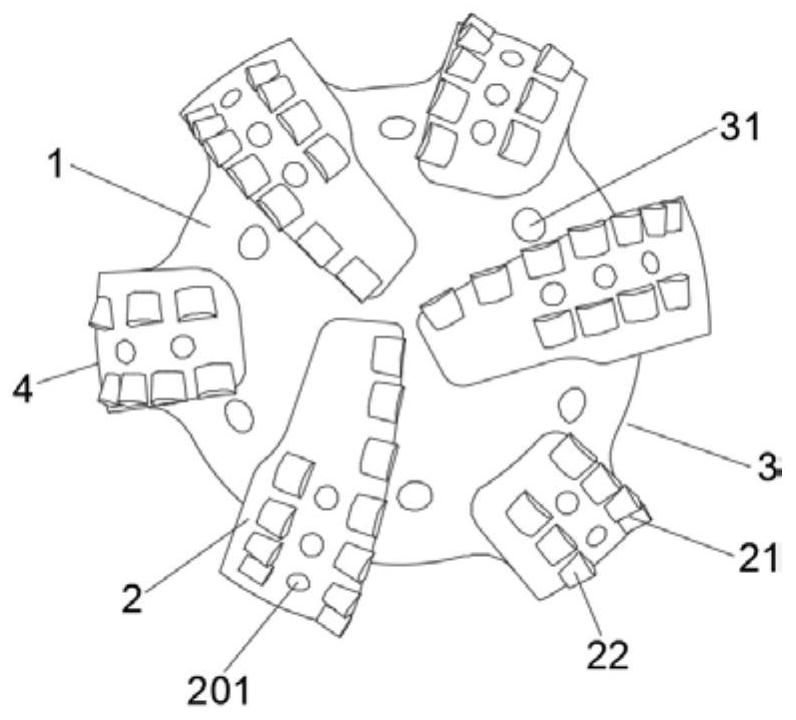

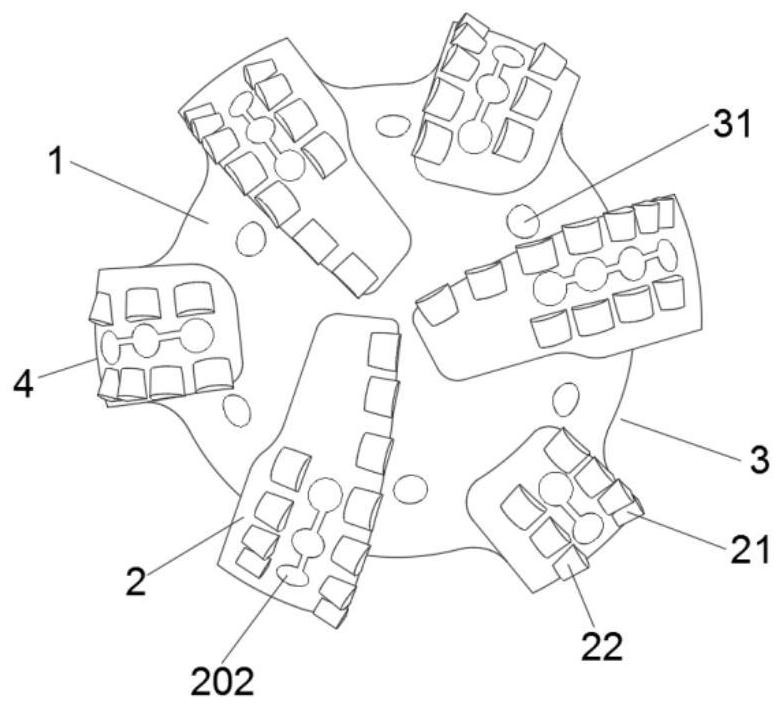

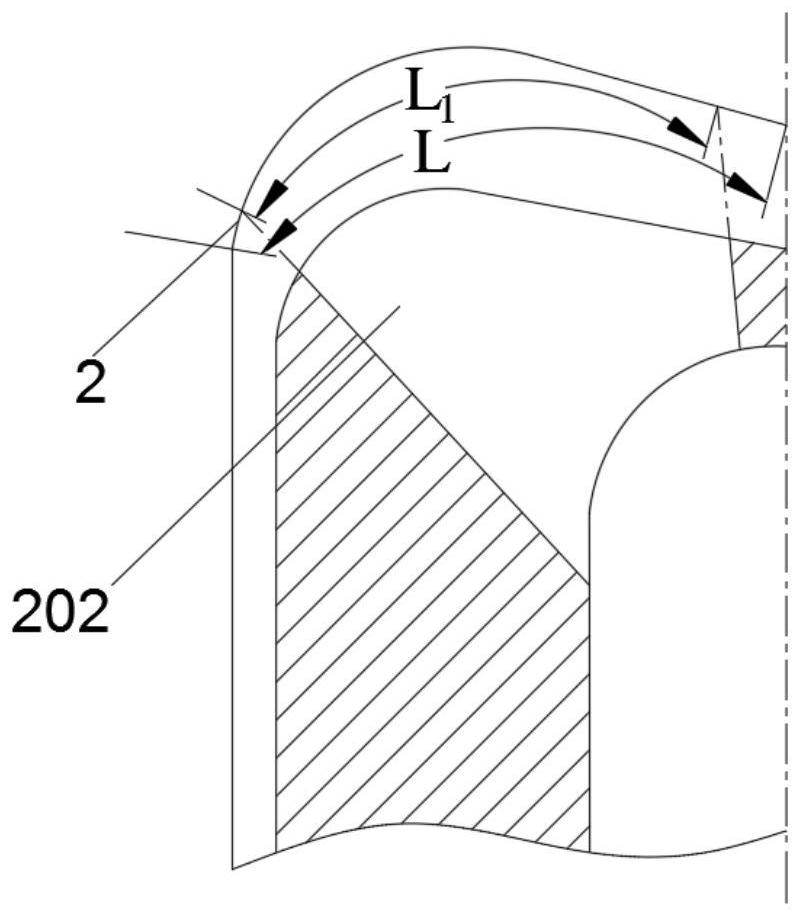

[0043] The embodiment of the present invention provides a PDC drill bit with water holes in the rear row of teeth. see figure 1 , including a drill body 1, several blades 2 extending from the drill body or fixed on the drill body 1, a drilling fluid flow channel 3 is formed between adjacent blades 2, and the blades 2 are provided with a front row of cutting teeth 21, and there are at least two rows of cutting teeth on at least one blade 2, which is characterized in that: there is a water hole 201 between the front row of cutting teeth 21 and the rear row of cutting teeth 22 of at least one blade 2 on the drill bit 1 . In the existing drill bit technology, the water hole 31 is generally arranged on the drill bit body, so the distance between the water hole 31 and the bottom of the well or the cutting teeth 21, 22 is relatively long, and the utilization rate of hydraulic energy decreases. However, in the present invention, the rear row of teeth water holes 201 are arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com