Patents

Literature

43results about How to "Short spray distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

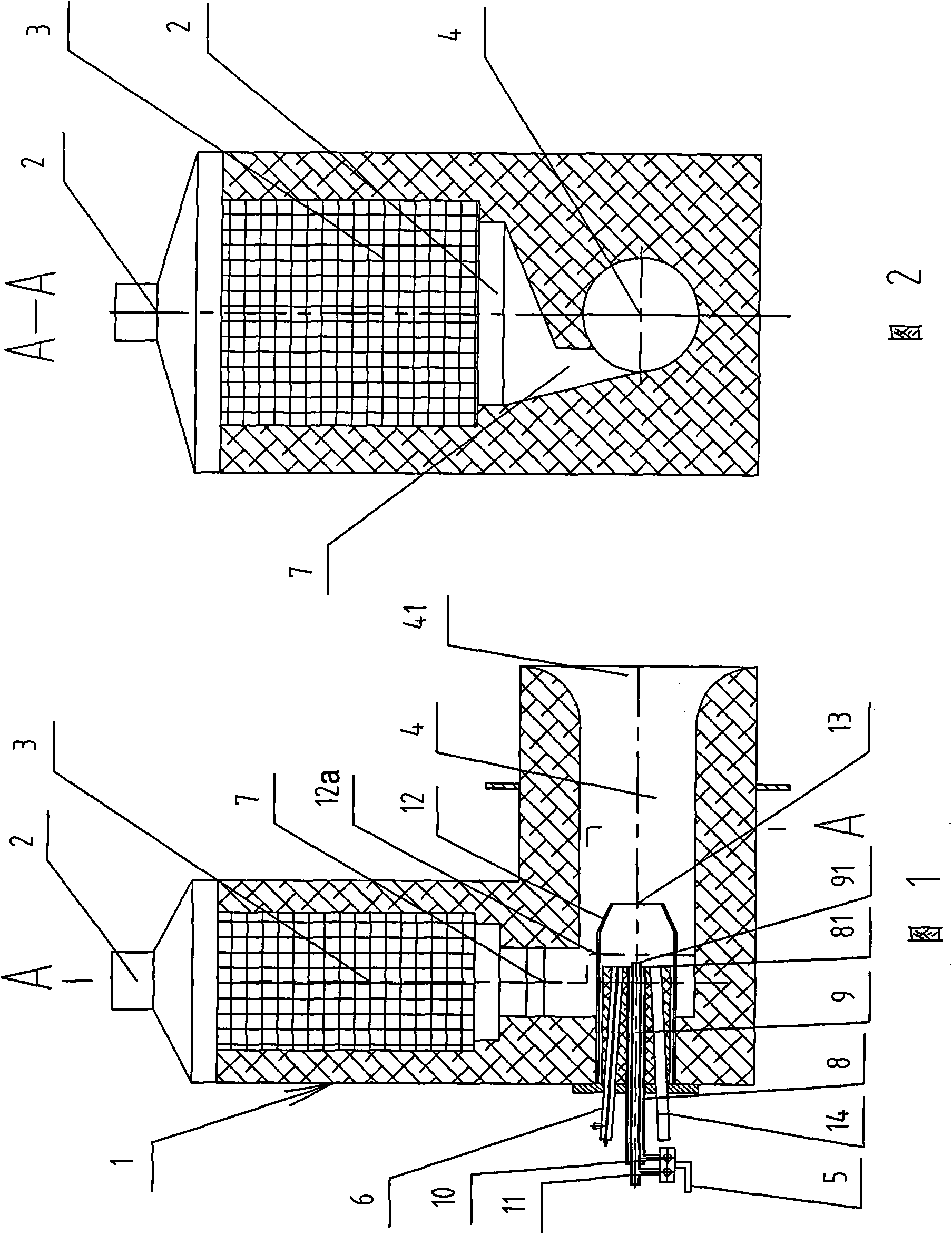

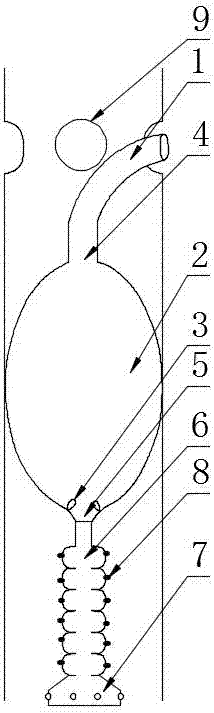

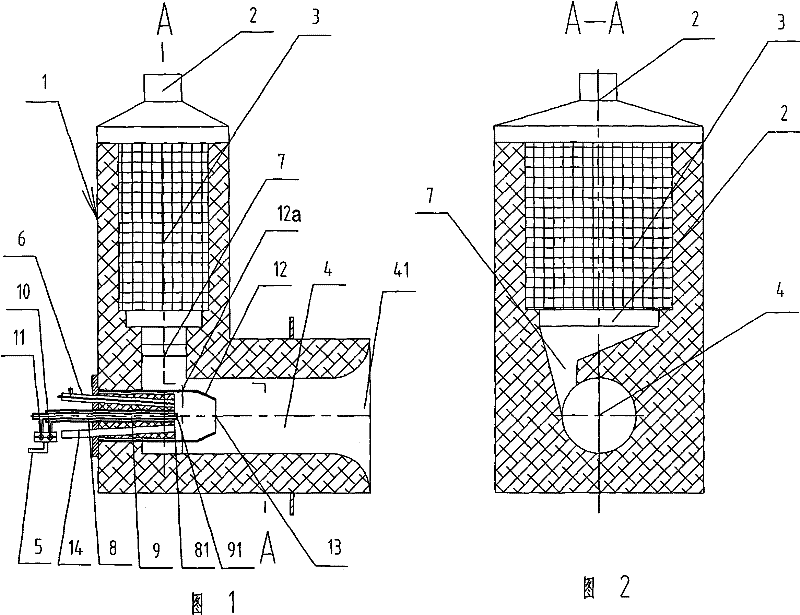

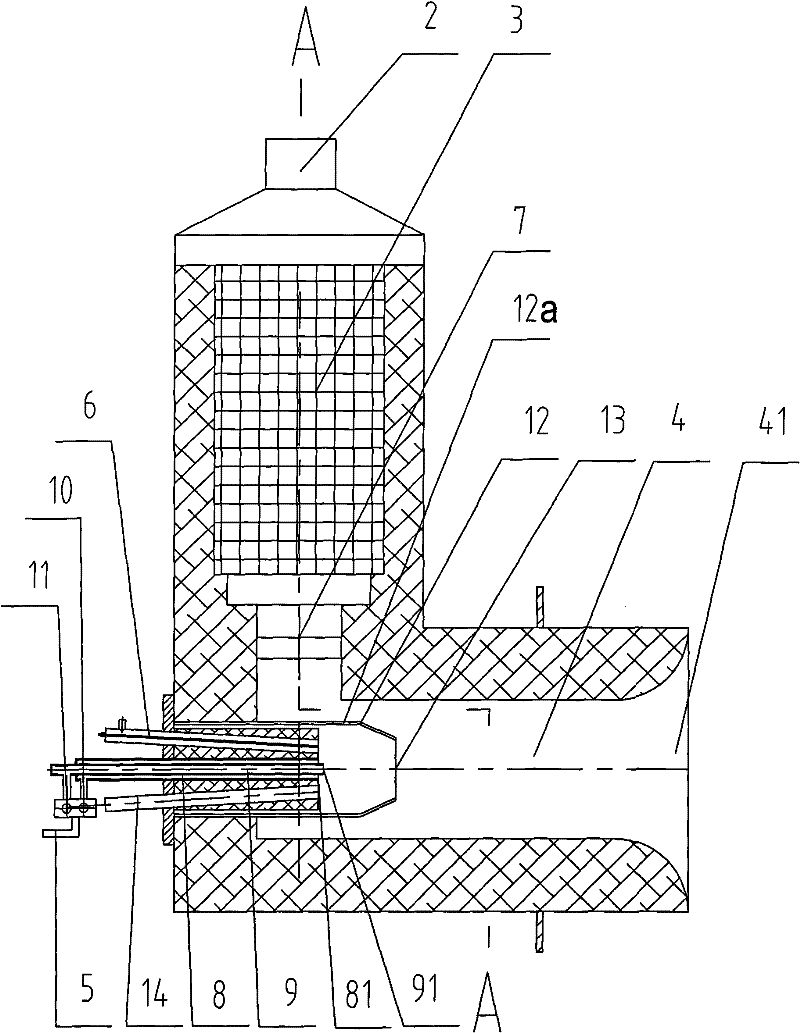

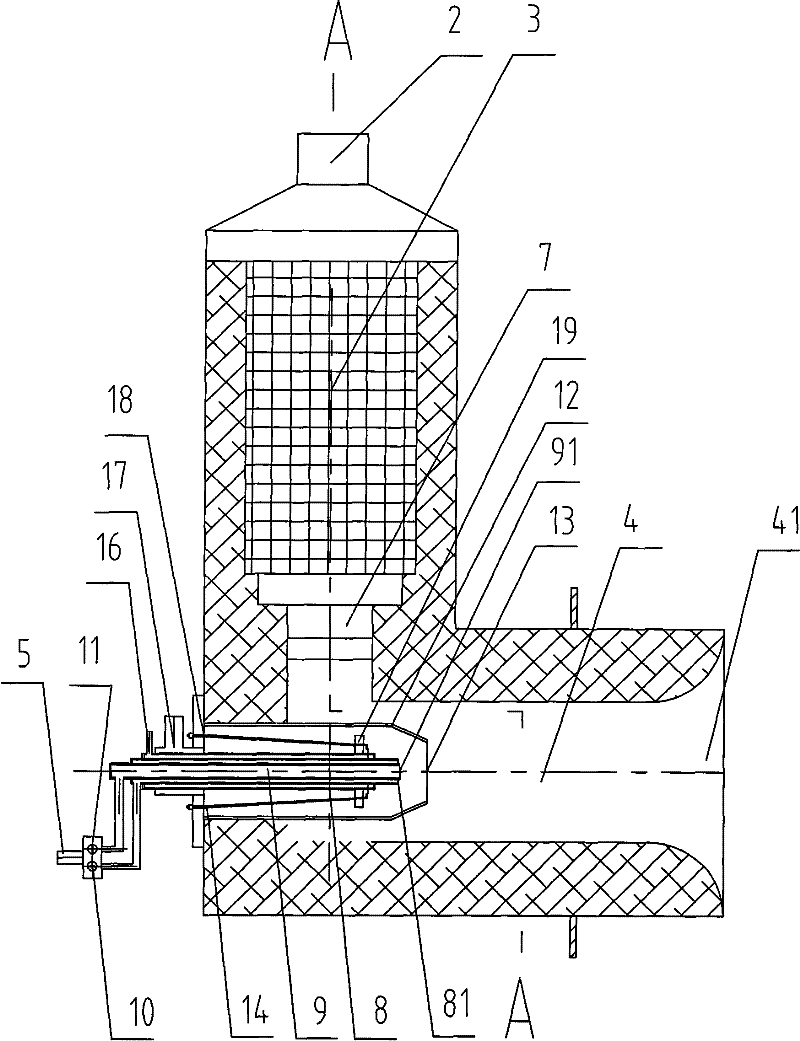

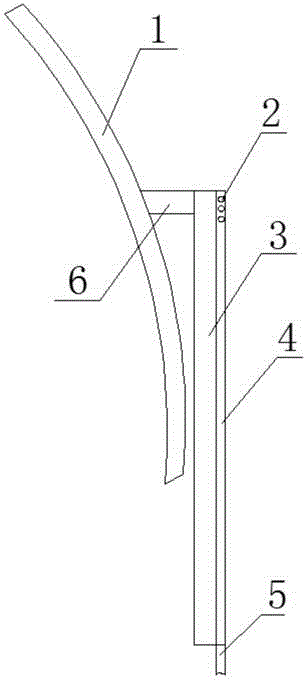

Flameless combustion heat accumulating type flat flame combustion nozzle

ActiveCN101639218AGood energy saving effectImprove energy efficiencyElectric spark ignitersIndirect carbon-dioxide mitigationGas pipelineHigh energy

The invention discloses a flameless combustion heat accumulating type flat flame combustion nozzle. A combustion nozzle body is internally provided with an air or smoke gas passage, a porous heat accumulator, a combustion cavity, a gas pipeline and an ignition device, wherein the tail end of the air or smoke gas passage is provided with a tangential air inlet duct positioned along the tangential direction of the circumferential combustion cavity, and the air or smoke gas passage is connected with the combustion cavity through the tangential air inlet duct; the tail end of the gas pipeline is provided with a flame combustion gas pipe and a flameless combustion gas pipe which are parallel and respectively controlled by a flame combustion control valve and a flameless combustion control valve, and the aperture of a flameless combustion gas spray orifice positioned on the tail end of the flameless combustion gas pipe is smaller than that of a flame combustion gas spray orifice positioned on the tail end of the flame combustion gas pipe. The flameless combustion heat accumulating type flat flame combustion nozzle has high energy utilization efficiency and good furnace temperature uniformity and can greatly reduce the discharge amount of NOX; fuel is sprayed at high speed through the necking spray orifice, thereby effectively controlling the flame temperature and being beneficial tothe sufficient combustion of the fuel; and in addition, the flame sprays into a furnace cavity with a very short spraying distance so as not to spray to parts inside the furnace cavity.

Owner:CHONGQING AOKEQI TECH

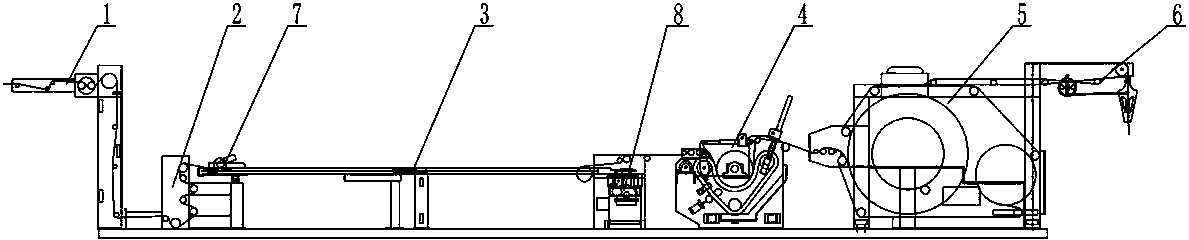

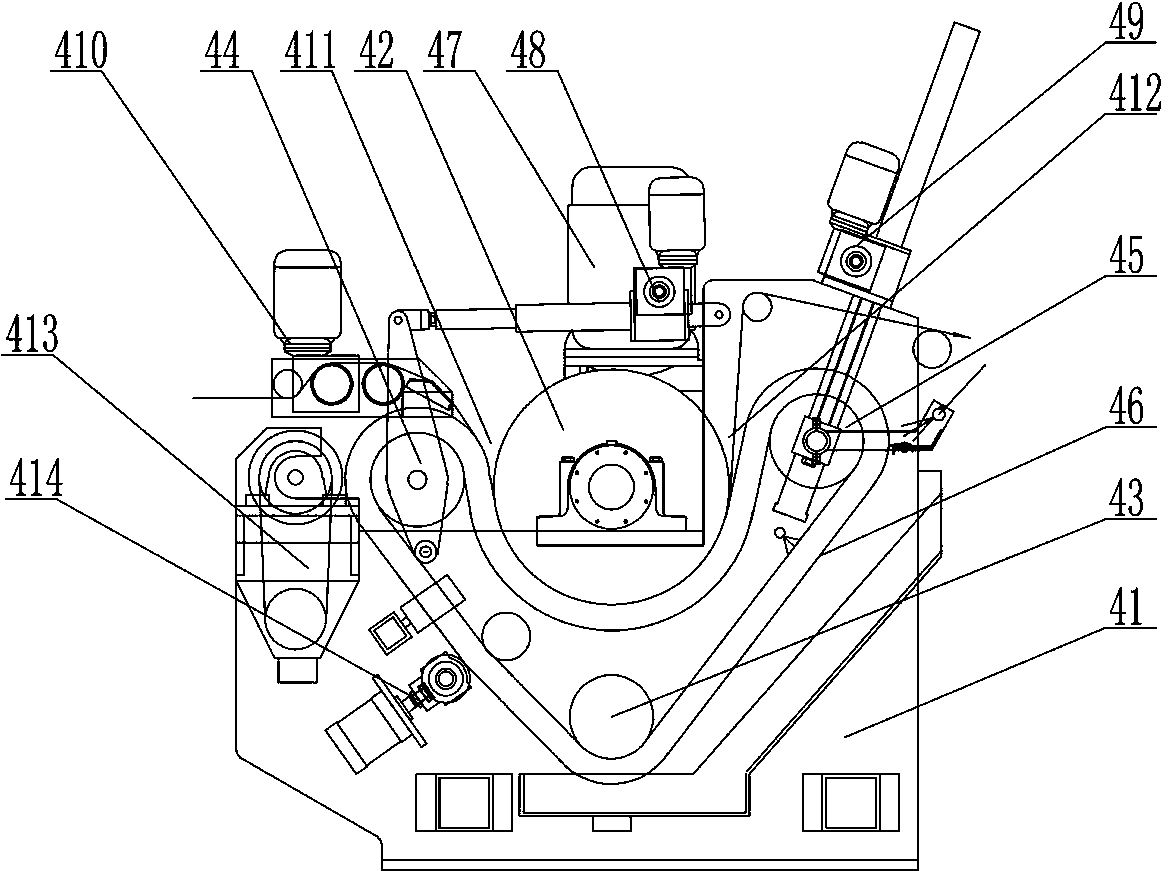

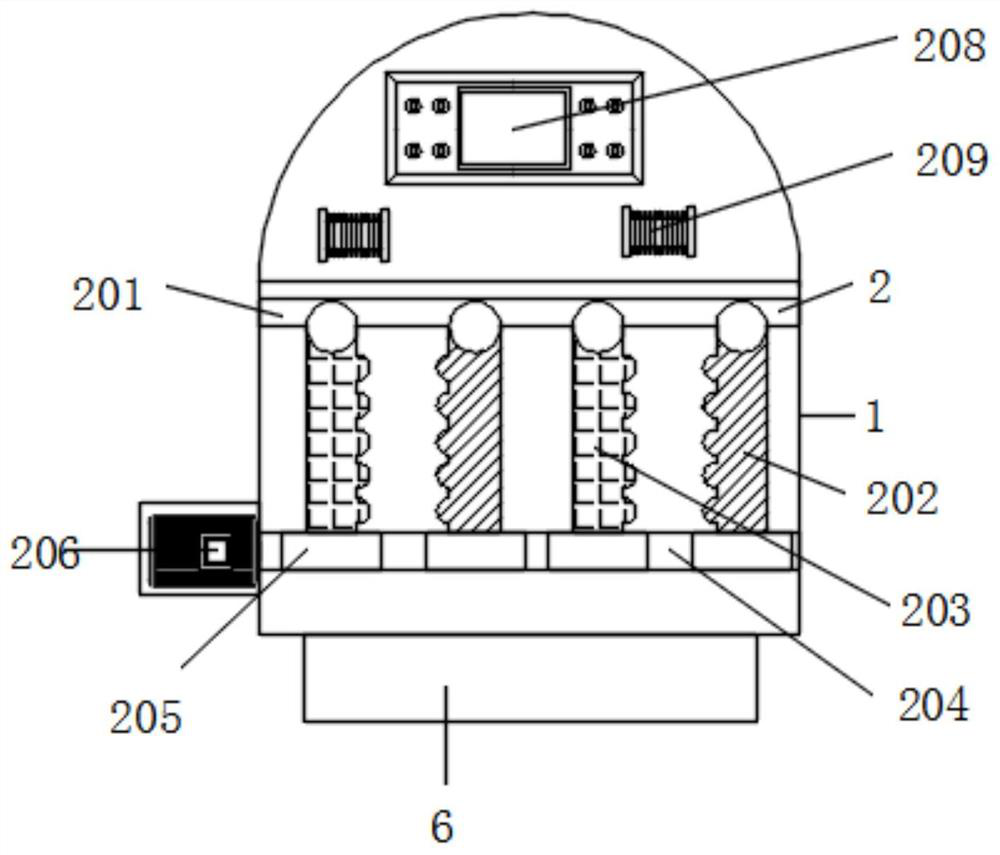

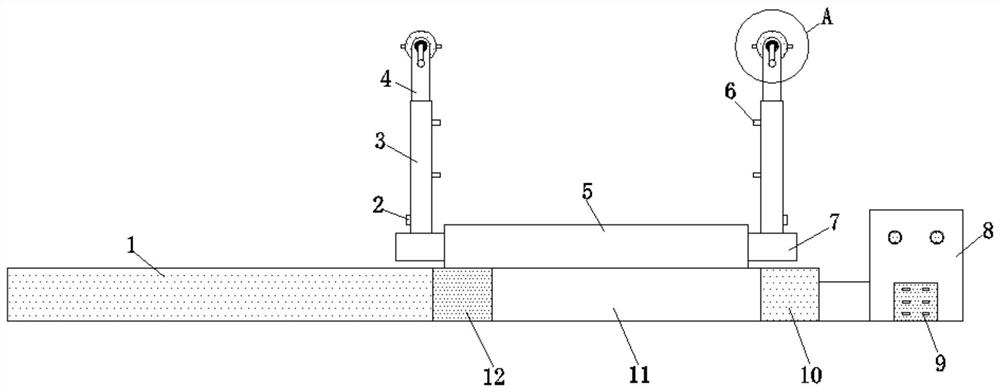

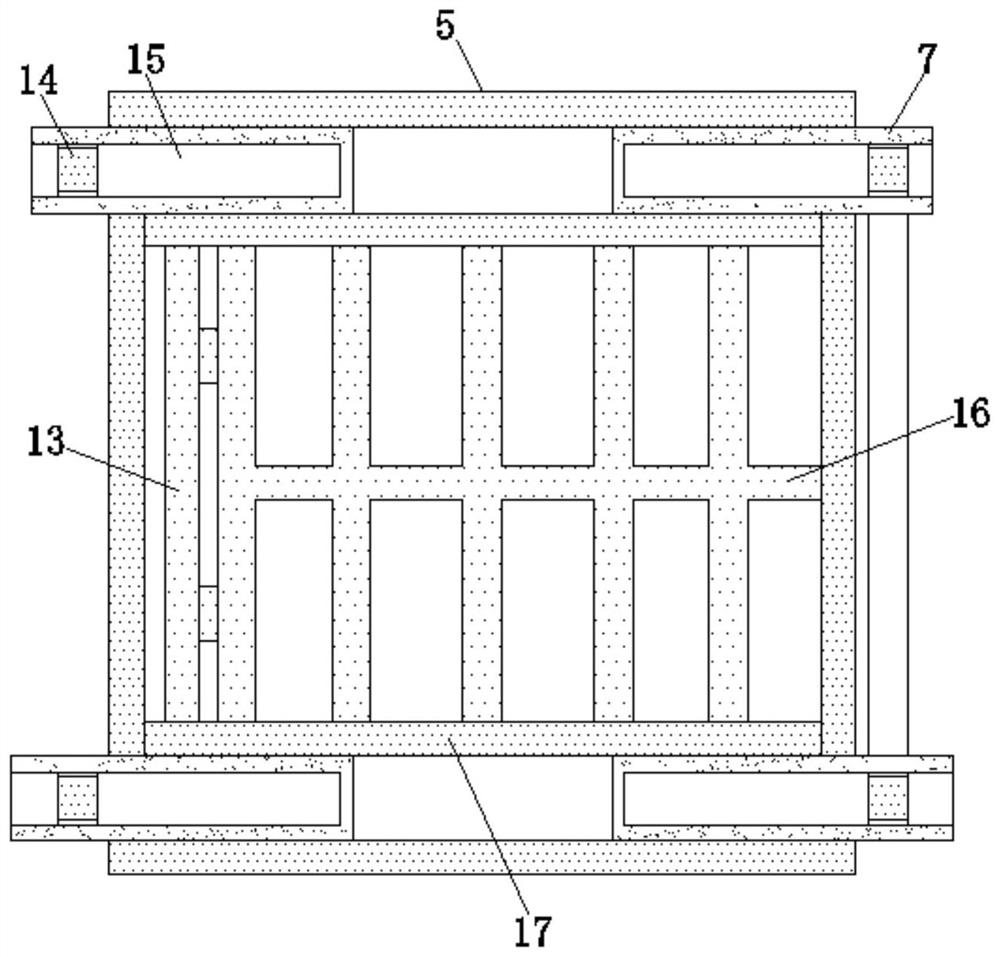

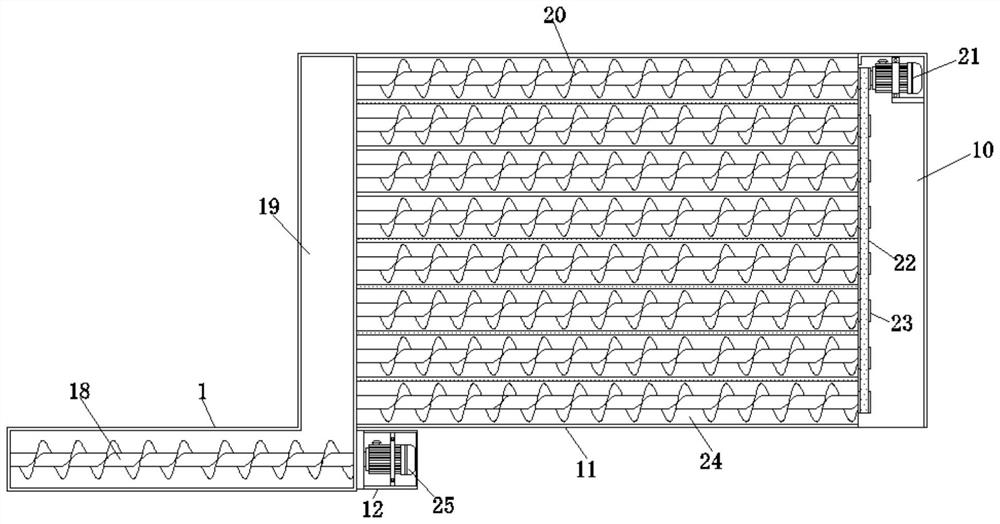

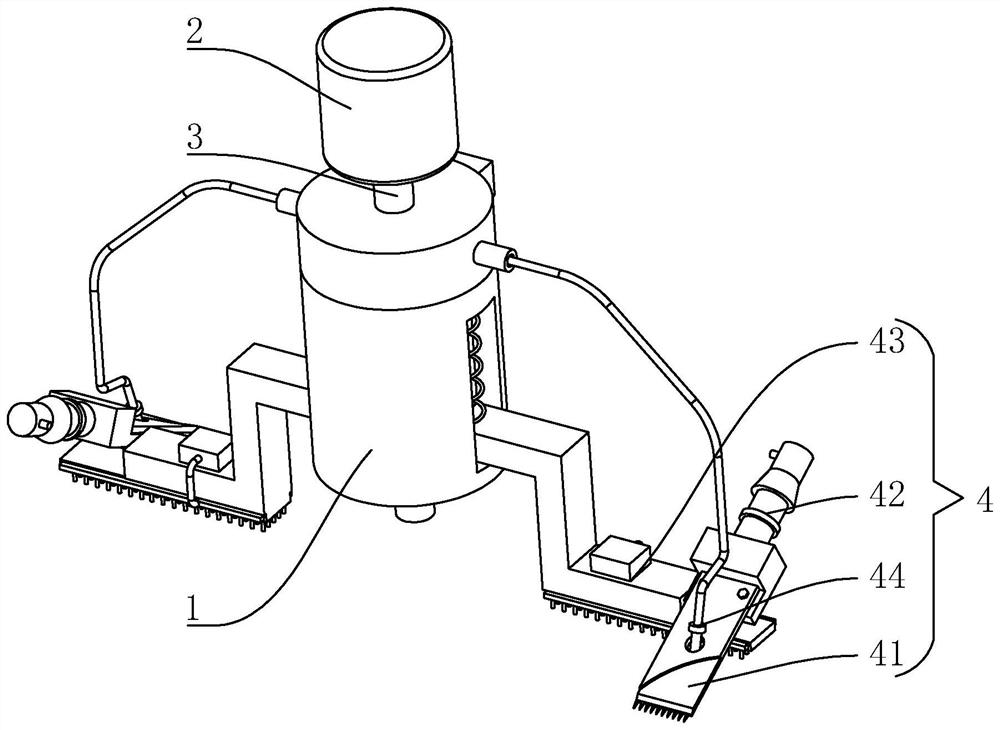

Open-width knitted fabric pre-shrinking machine and pre-shrinking process thereof

ActiveCN104018311AGuaranteed dryingMake sure to ironShrinkingTextile treatment cleaning apparatusShrinkage rateAgricultural engineering

The invention discloses an open-width knitted fabric pre-shrinking machine, comprising an open-width cloth-feeding device, a mechanical weft-straightening device, a steam conditioning and stentering device, a rubber blanket pre-shrinking device and an open-width plaiting device, wherein the front end of the steam conditioning and stentering device is provided with an overfeed pinning device; and a felt finishing device is arranged between the rubber blanket pre-shrinking device. The open-width knitted fabric pre-shrinking machine comprises the felt finishing device; and the fabric is finished by the felt finishing device after passing through the rubber blanket pre-shrinking device, thereby guaranteeing the fabric to be dried and flatten, further improving handfeel of the fabric and increasing glossiness of the fabric surface. Meanwhile, shrinkage rate of the fabric can be more stable, so that the open-width knitted fabric with flat cloth surface, good surface glossiness, good handfeel and stable shrinkage rate can be processed.

Owner:浙江瑞格机械科技有限公司

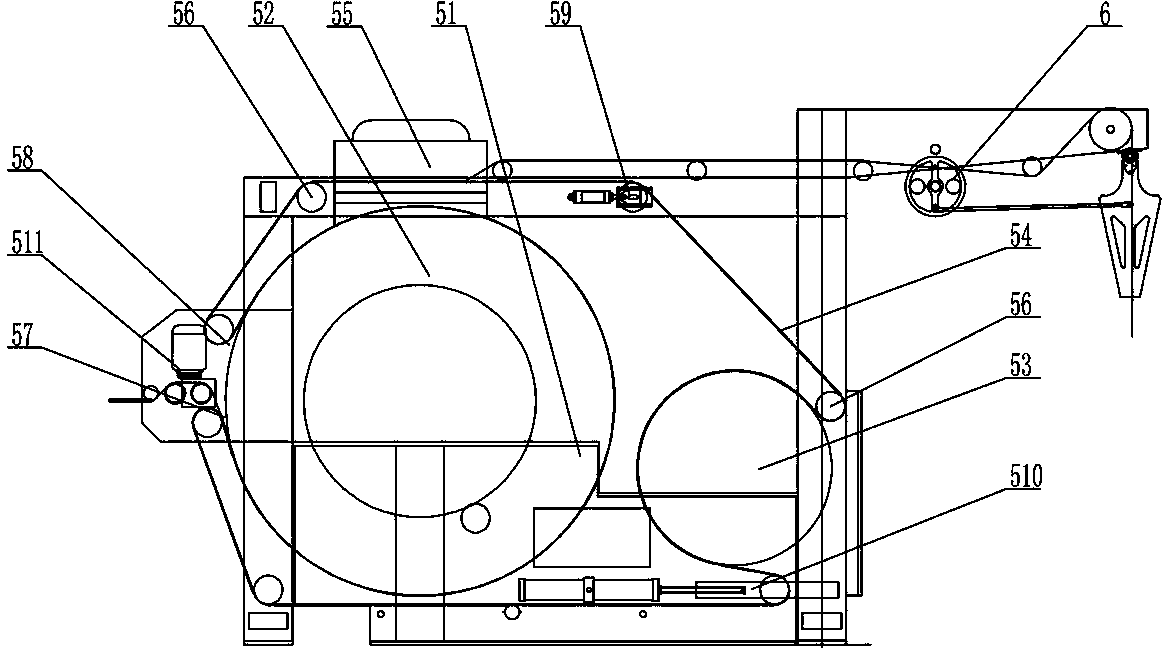

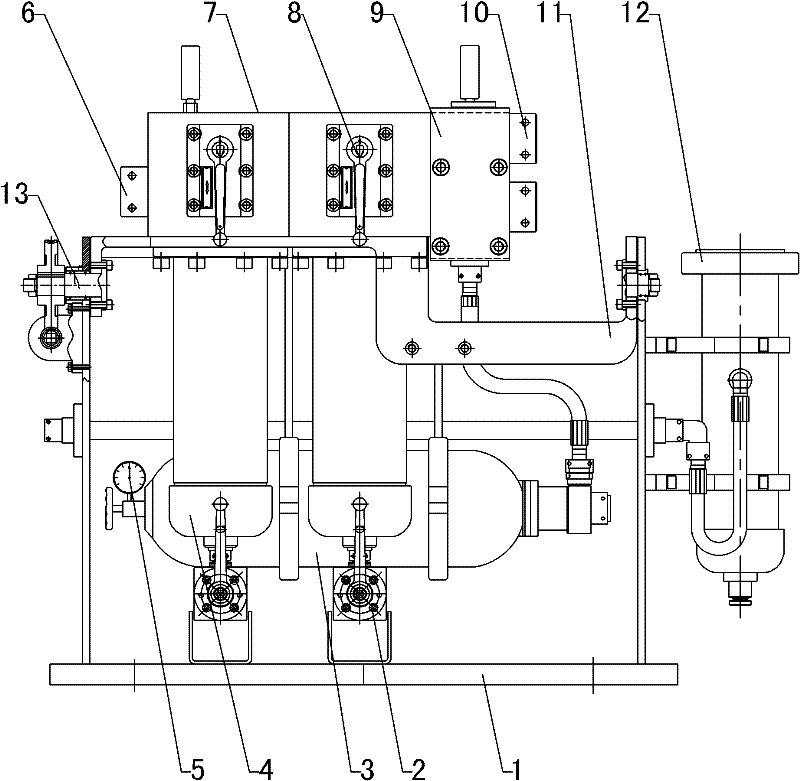

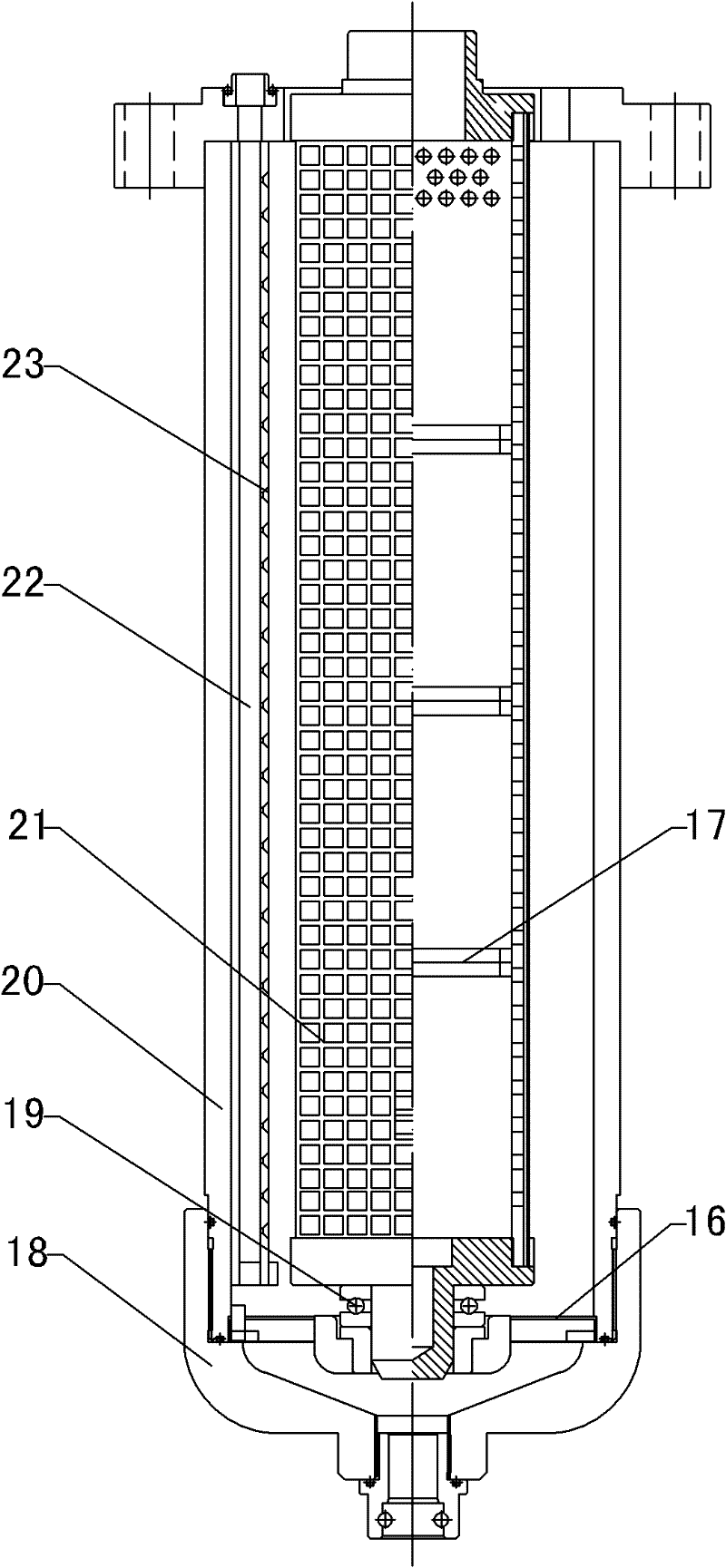

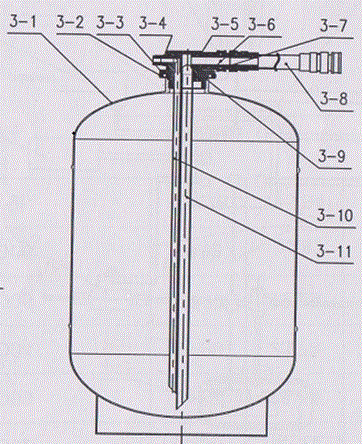

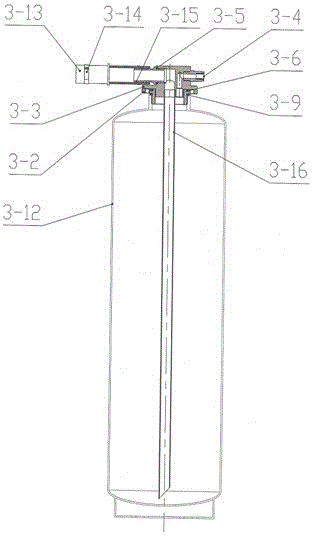

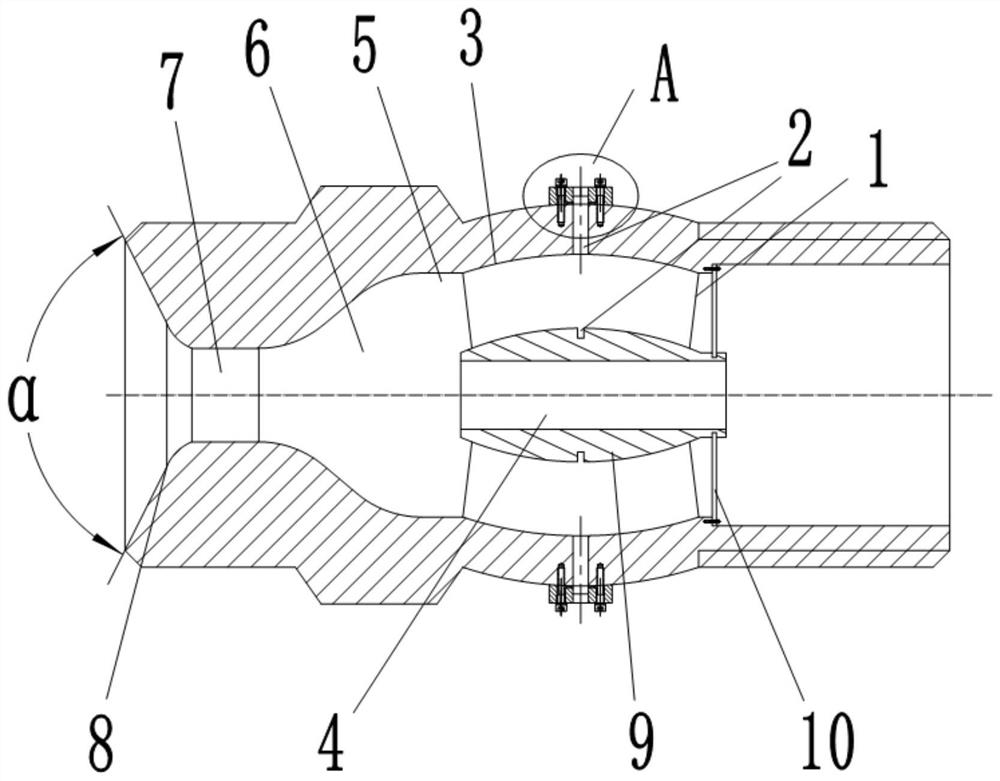

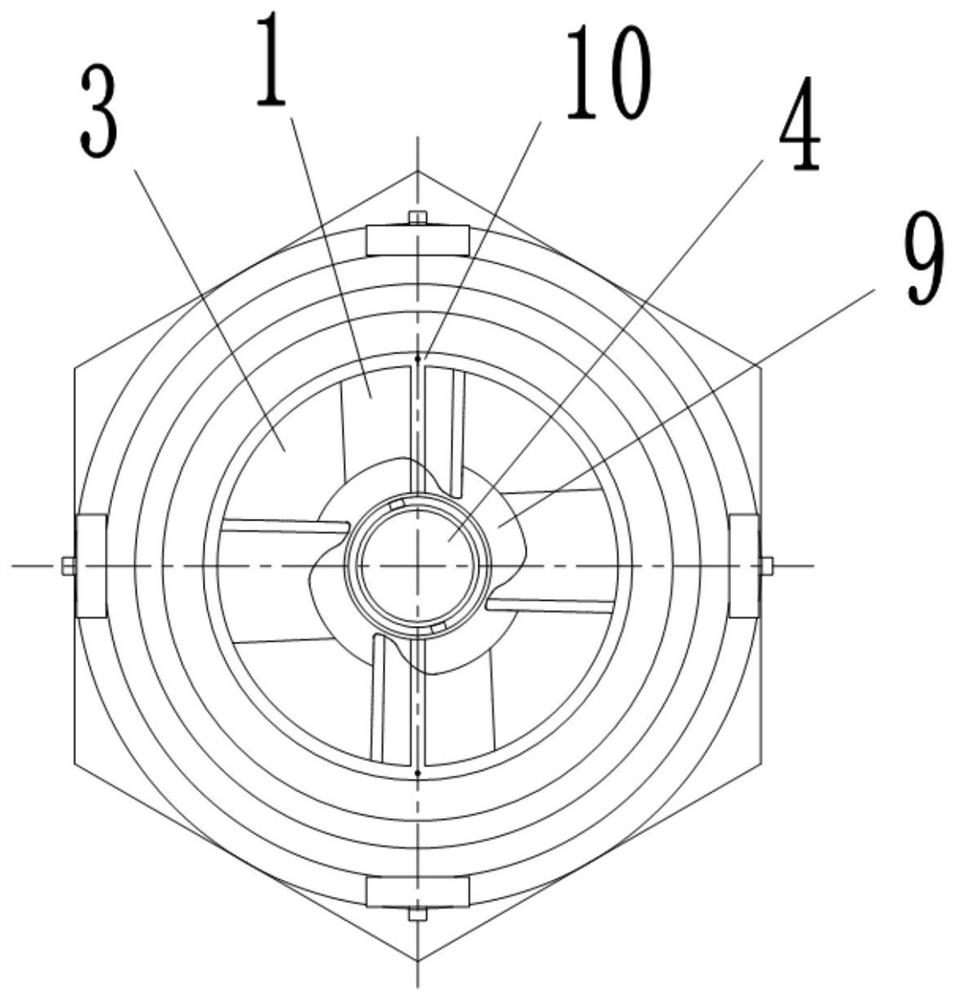

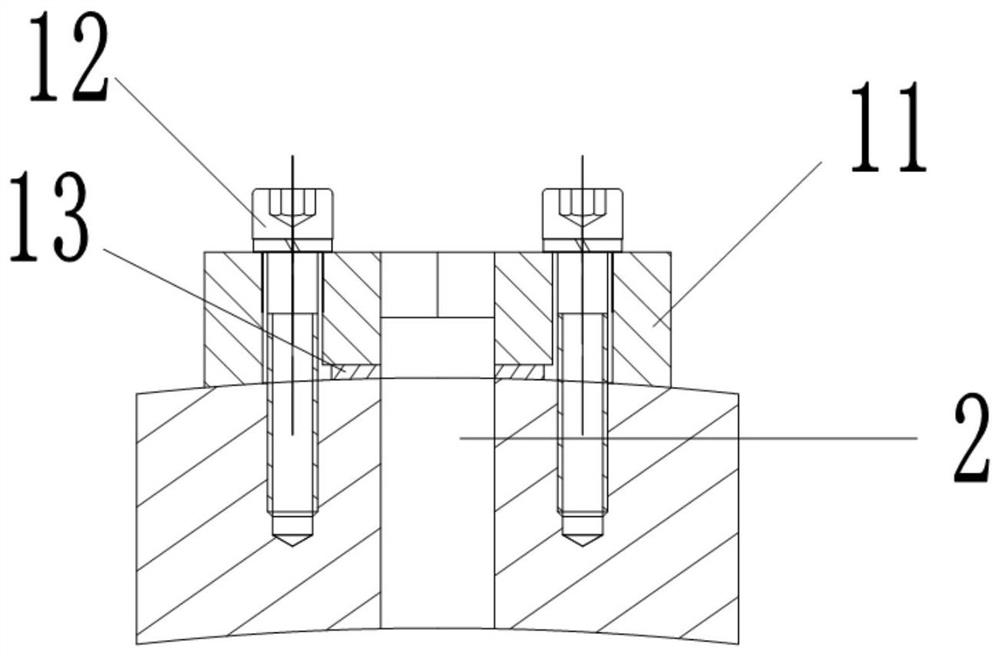

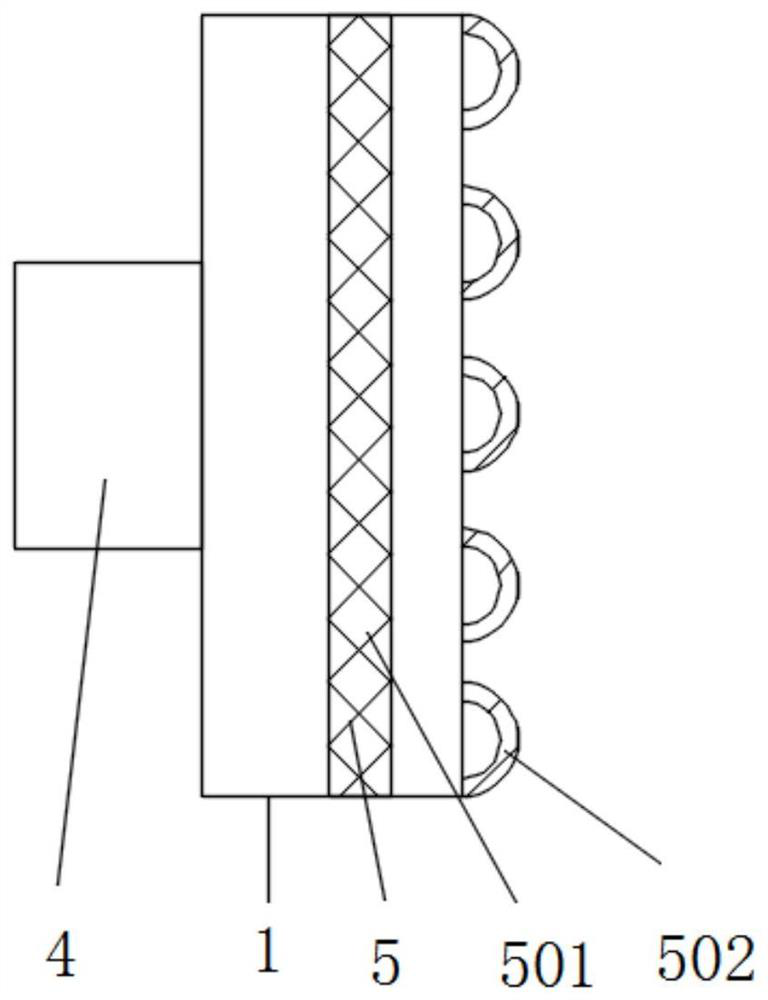

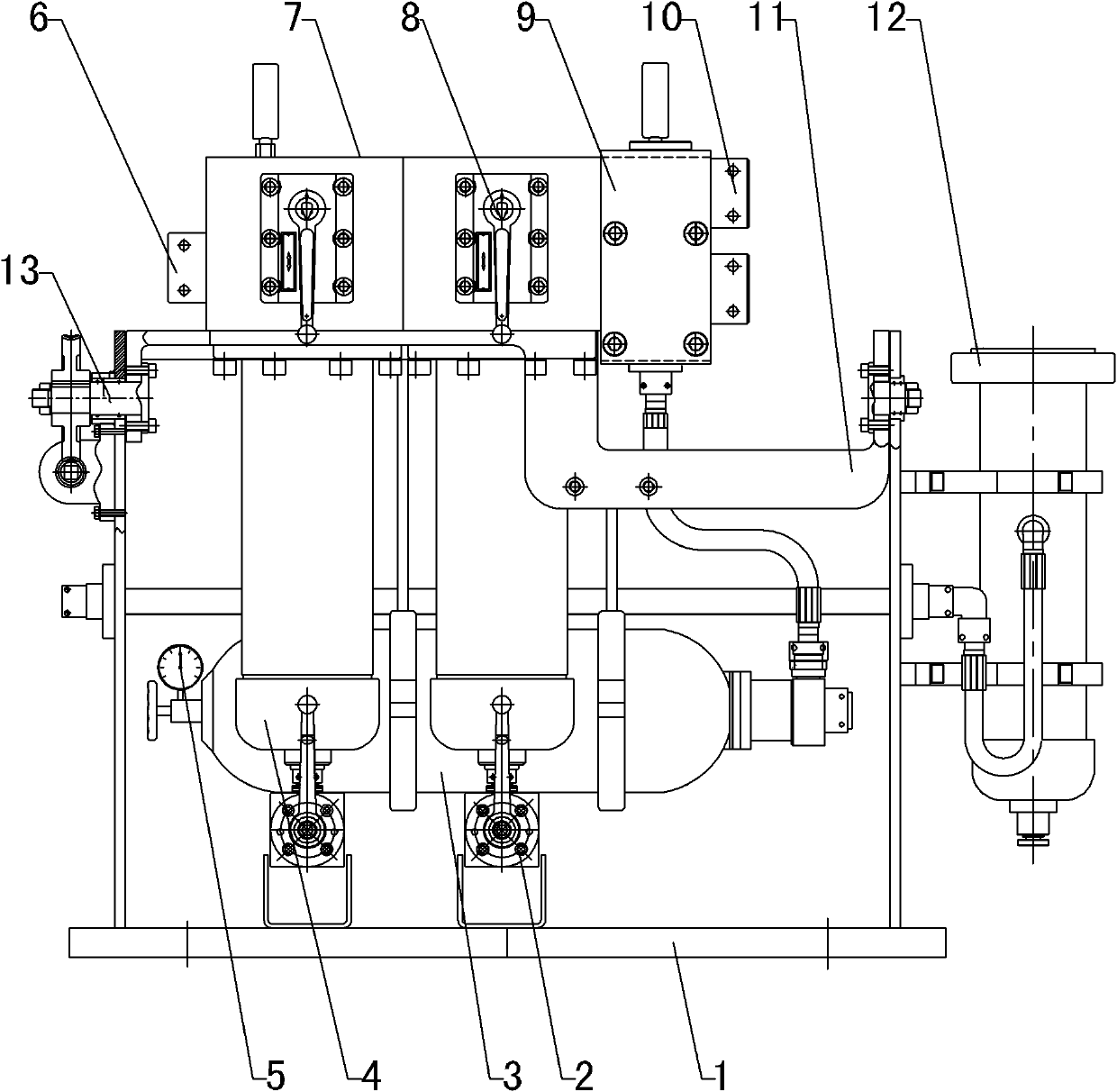

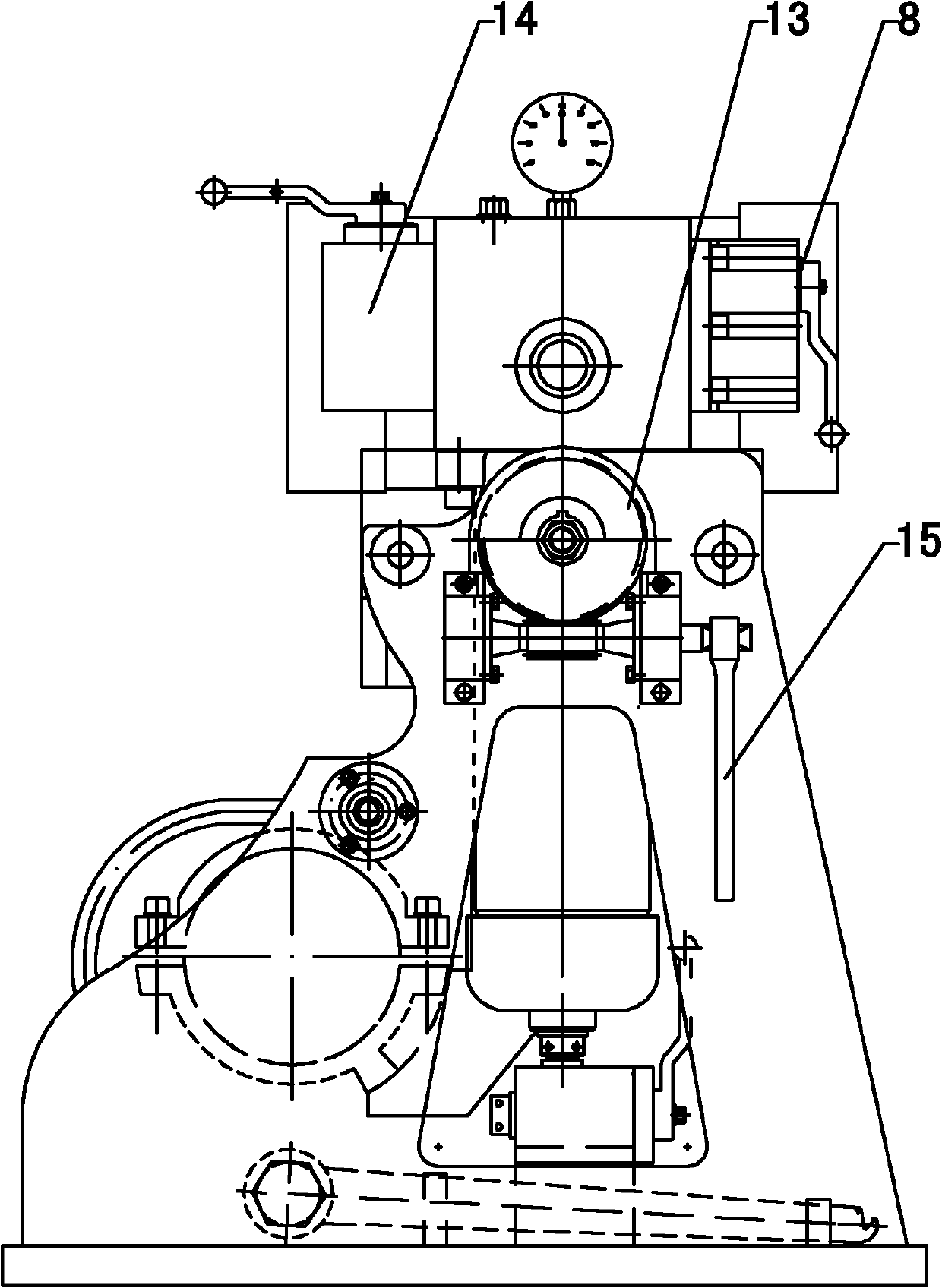

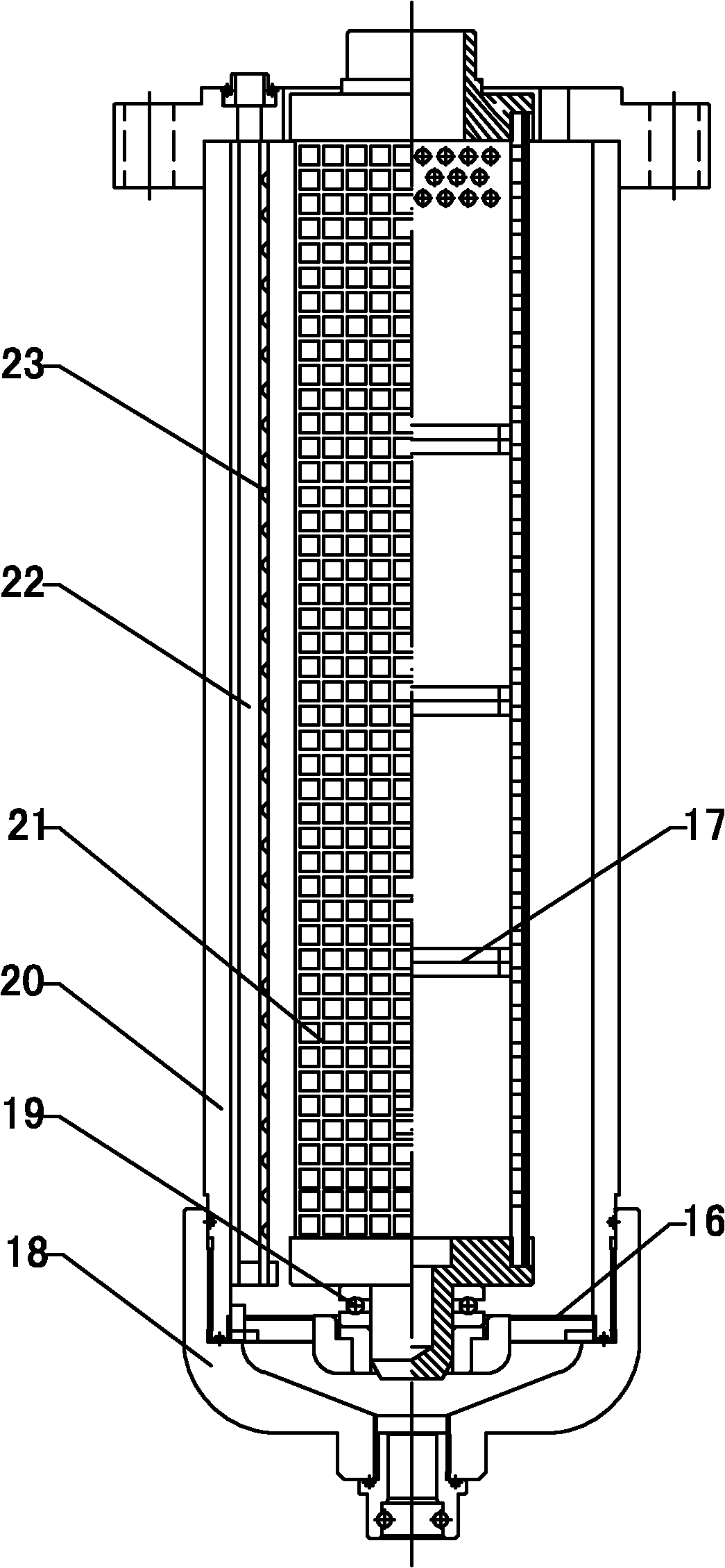

Backwash high pressure filter station

ActiveCN102258910ARealize online recoilDoes not affect production progressFiltration circuitsFluid-pressure actuator componentsEngineeringHigh pressure

The invention discloses a backwashing high-pressure filter station, which belongs to the field of backwashing high-pressure filter devices for hydraulic systems of underground comprehensive mining hydraulic brackets. The backwashing high-pressure filter station comprises a machine seat (1) and a high-pressure filter (4), and is characterized in that: a rotating machine seat (11) is arranged on the upper part of the machine seat (1); an integrated valve seat device (7) is mounted through the rotating machine seat (11); the bottom of the integrated valve seat device (7) is connected with the high-pressure filter (4) and an energy storage device (3); the lower part of the high-pressure filter (4) is connected with a draining valve (2); and a waste liquid recovering device on the lower part of the draining valve (2) is connected with a recovery filter (12). The backwashing high-pressure filter station has the advantages of large flow, high precision, capability of on-line washing, obviouswashing effect, capability of recycling backwashing liquid and the like; and when the backwashing high-pressure filter station is used, the continuous production operation can be ensured, energy conservation and environment protection can be ensured and the cleanness of the working medium can be ensured effectively.

Owner:SHANDONG MINGDUN EXPLOSION PROOF EQUIP TECH CO LTD

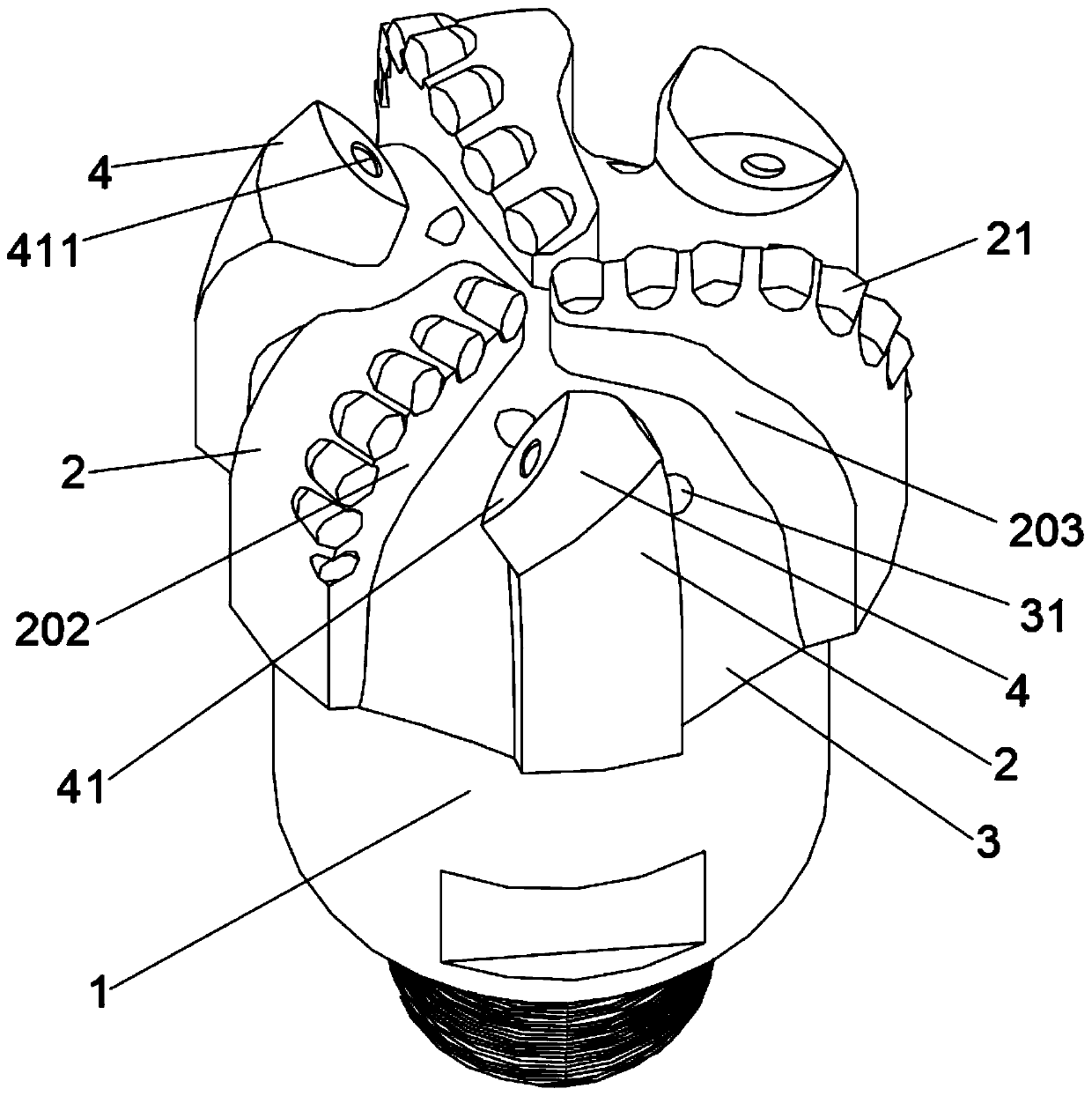

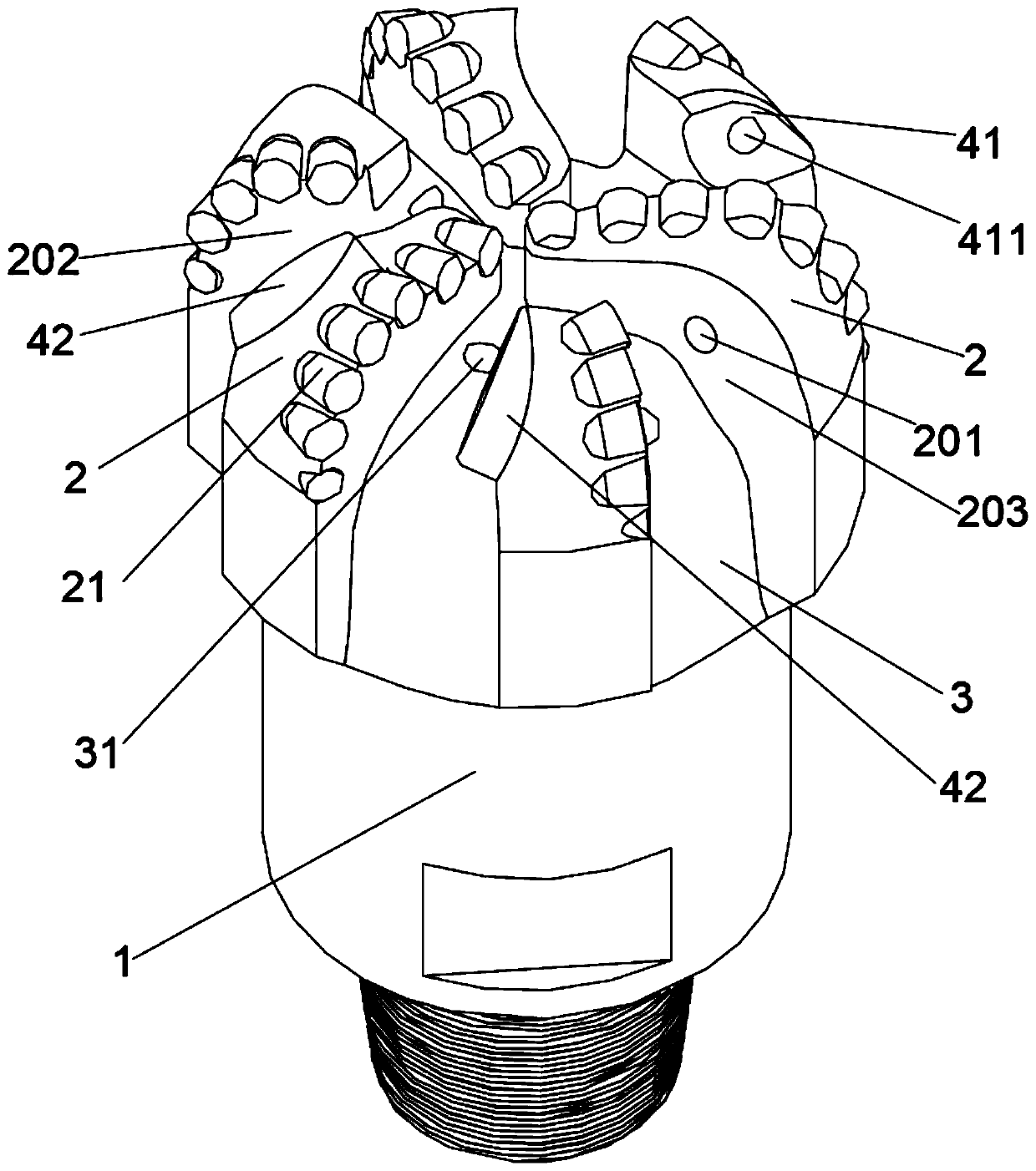

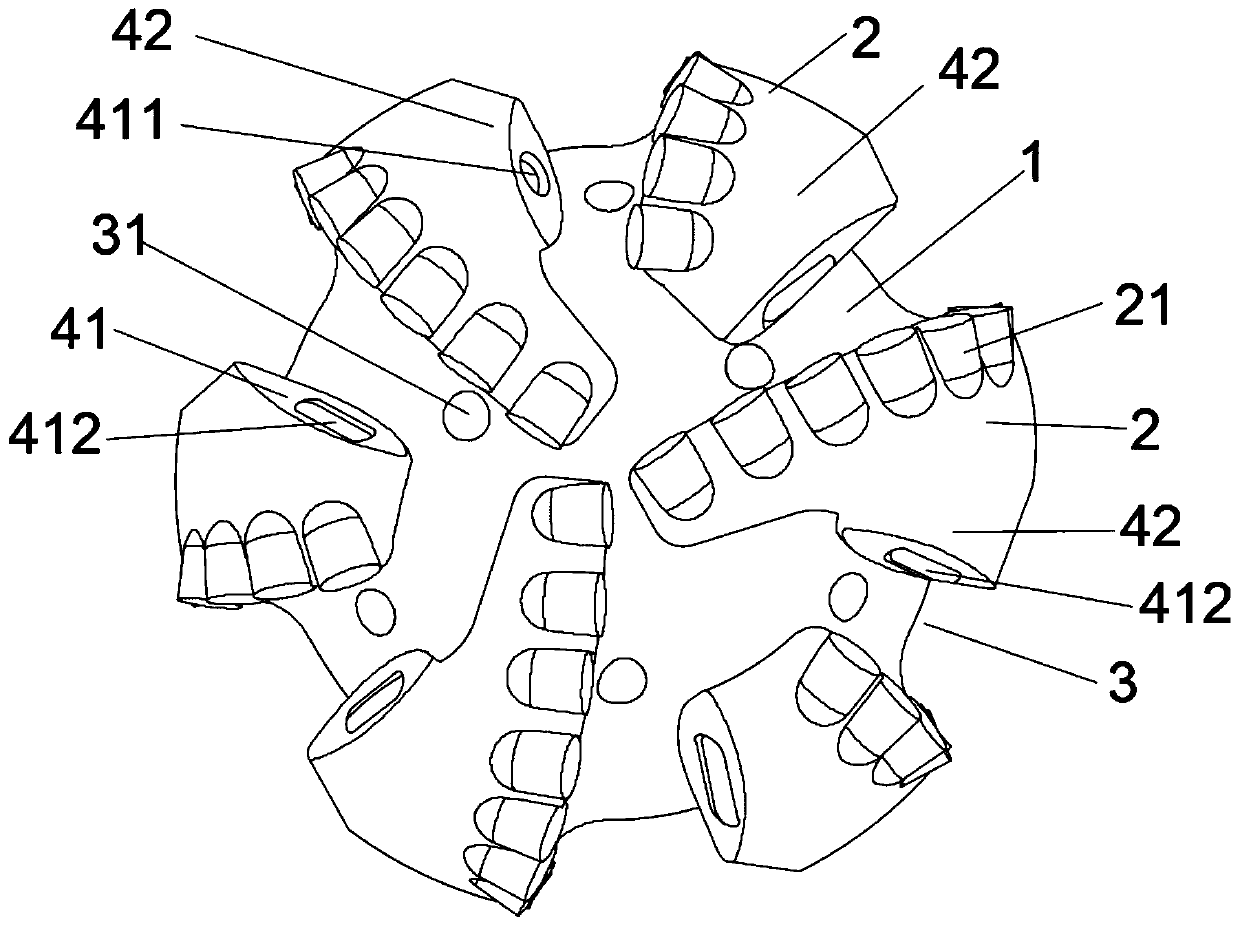

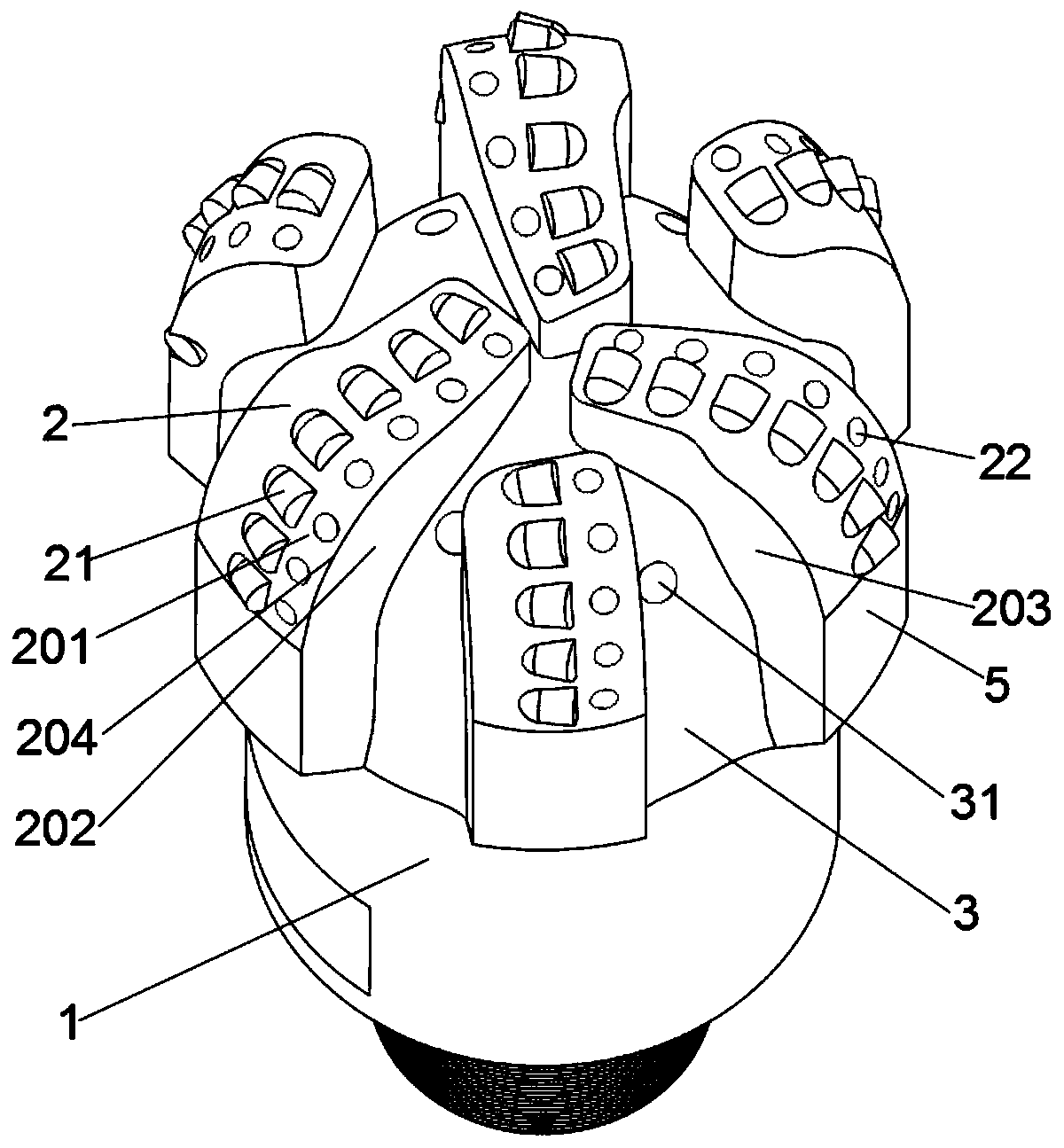

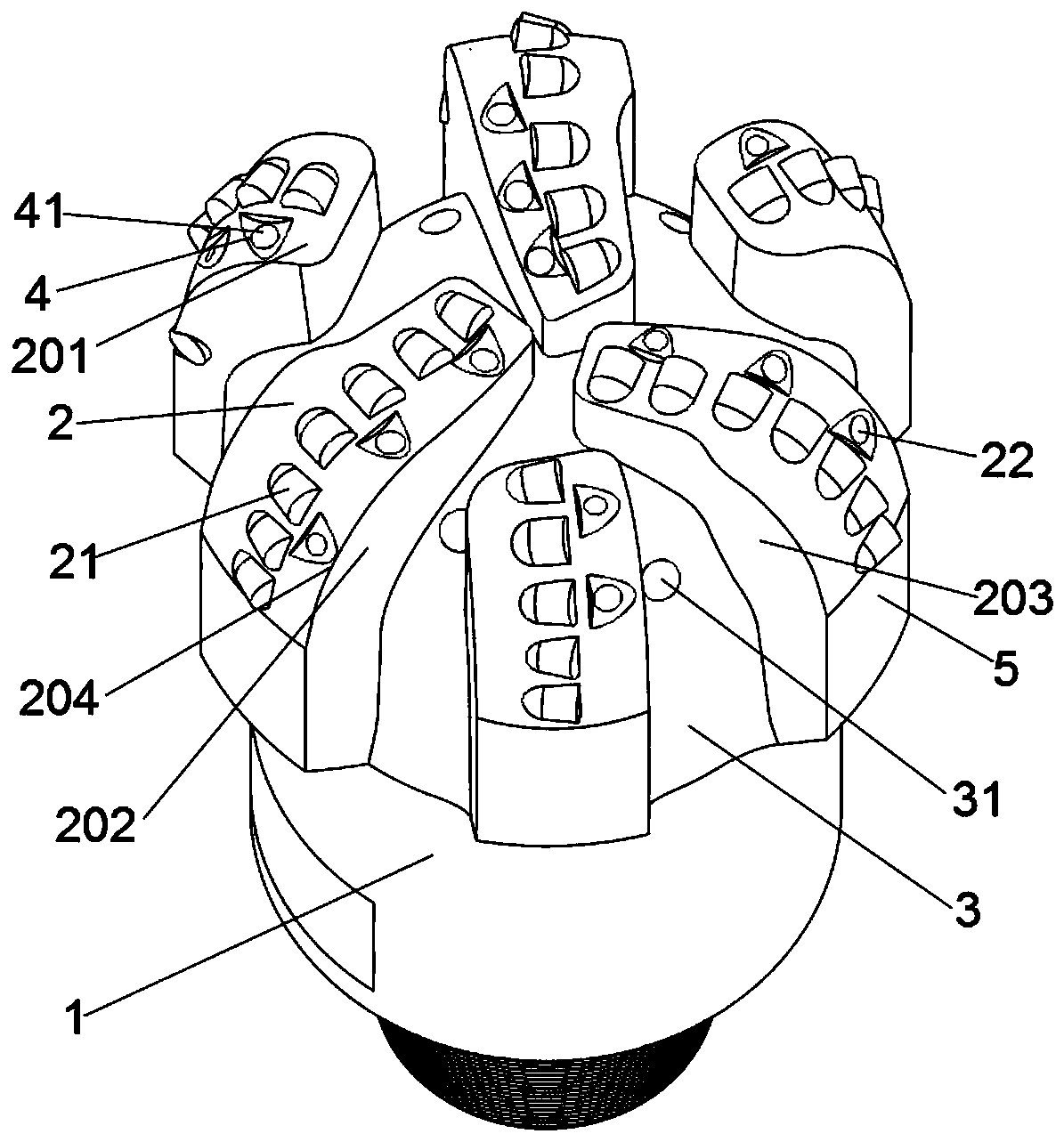

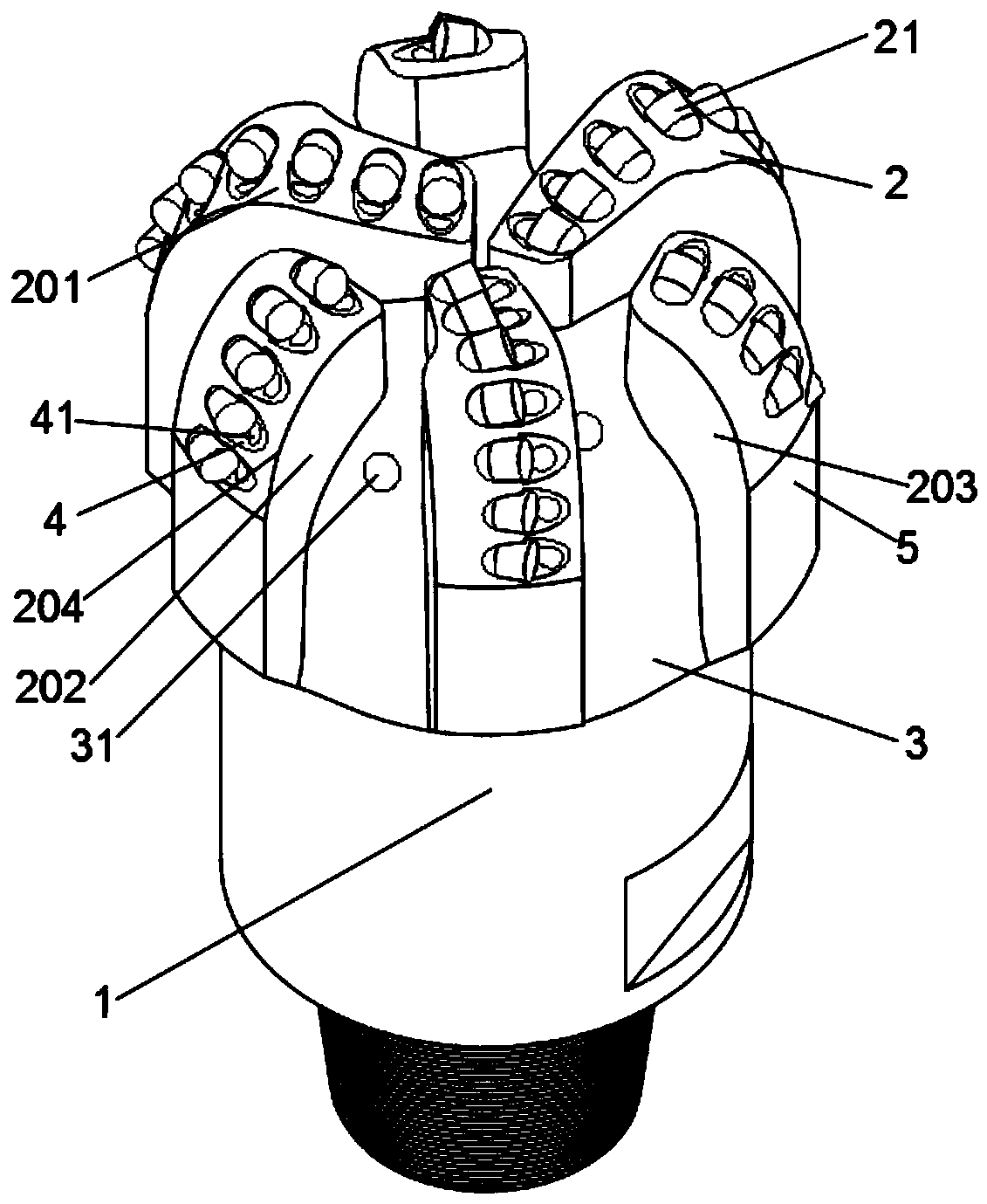

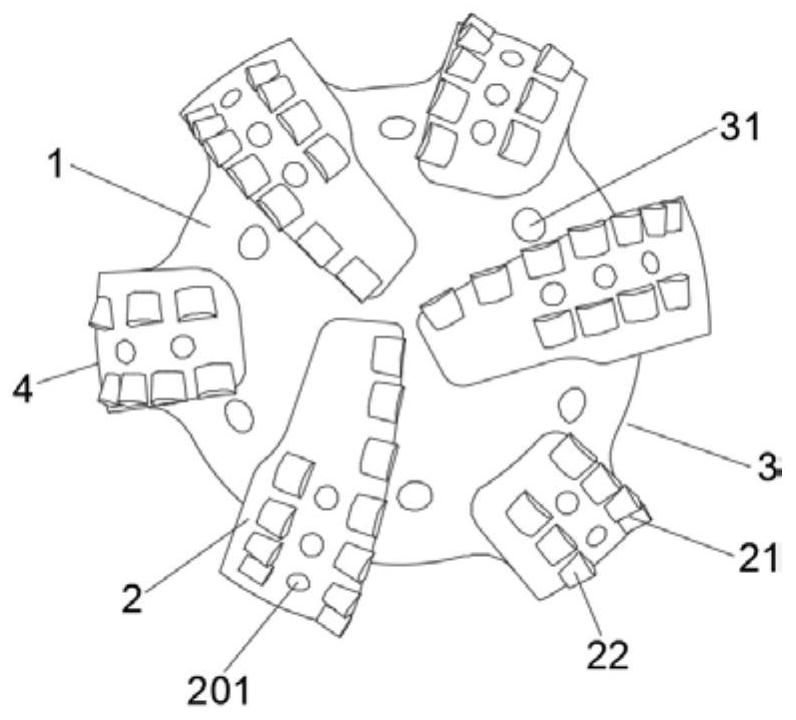

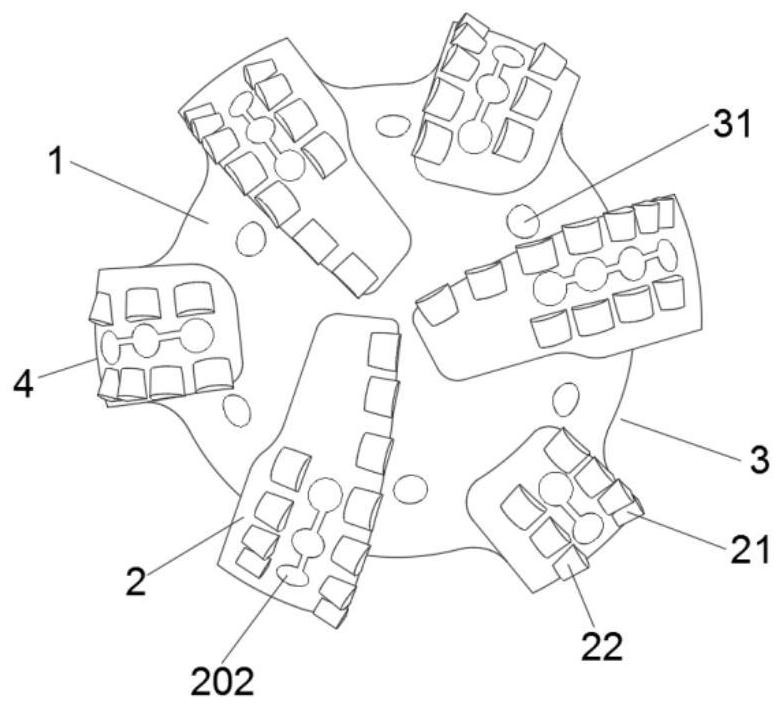

Diamond drill bit with high-efficiency water hole structure

PendingCN110107227AHigh rock breaking performanceShort spray distanceDrill bitsConstructionsWell drillingPetroleum

The invention relates to the technical fields of petroleum and natural gas, mine engineering, geothermal wells, building foundation engineering construction, geology and hydrological drilling, in particular to a diamond drill bit with a high-efficiency water hole structure. According to the diamond drill bit, a rear water spray hole seat extending to a drill bit body or connected to the drill bitbody is arranged in front of at least one of cutter wings, the rear water spray hole seat is provided with a rear water spray hole communicating with a flow channel in the drill bit, and the rear water spray hole can directly spray water onto cutting teeth on the cutter wings or rocks in front of the cutting teeth. According to the diamond drill bit with the high-efficiency water hole structure, the cutting teeth are fully cooled and cuttings are transported in time in high temperature well drilling, and the drilling performance of the drill bit is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

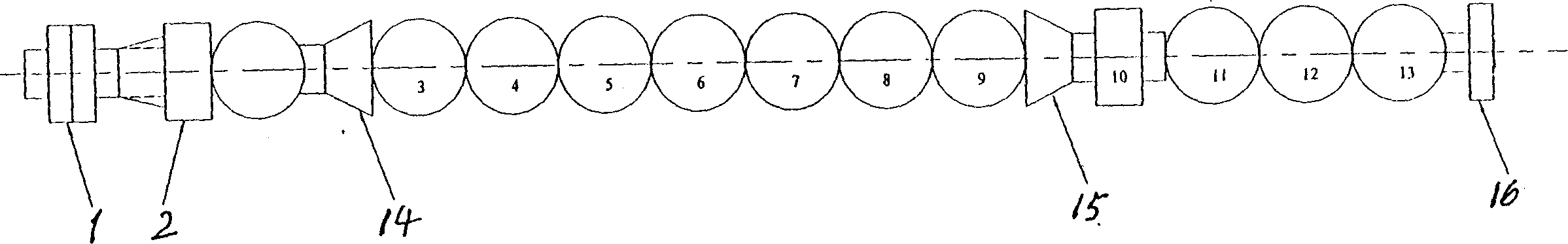

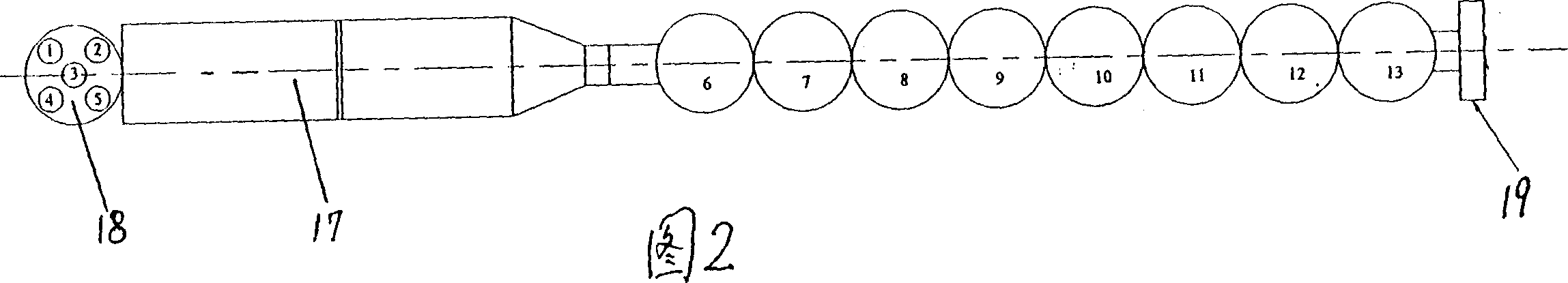

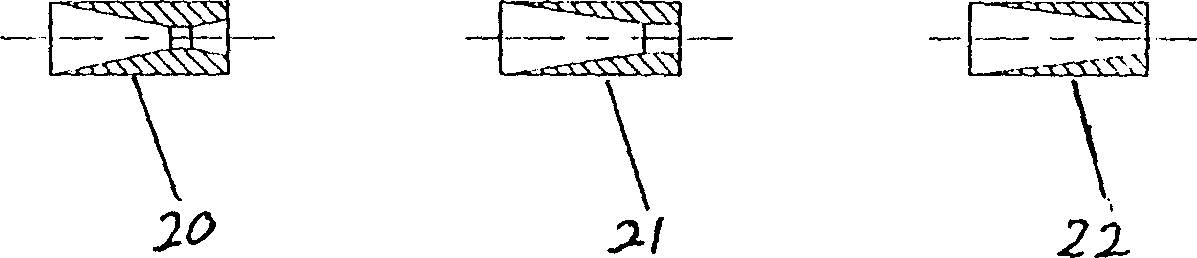

Integrated momentum-exchange machine

InactiveCN1448622AReduce lossesStrong entrainmentExhaust apparatusSilencing apparatusMomentumControl theory

The present invention is one integrated moment exchanger for treating tail gas of motor vehicle. The integrated moment exchanger consists of 13 stages of main and auxiliary integrated exchangers connected parallelly, and each stage of exchanger has jetting reception tubes and diffusion tubes in the same number. The present invention can eliminate tail gas pollution radically, and may be used inreplacing available exhaust silencer system in motor vehicle.

Owner:张裕光 +2

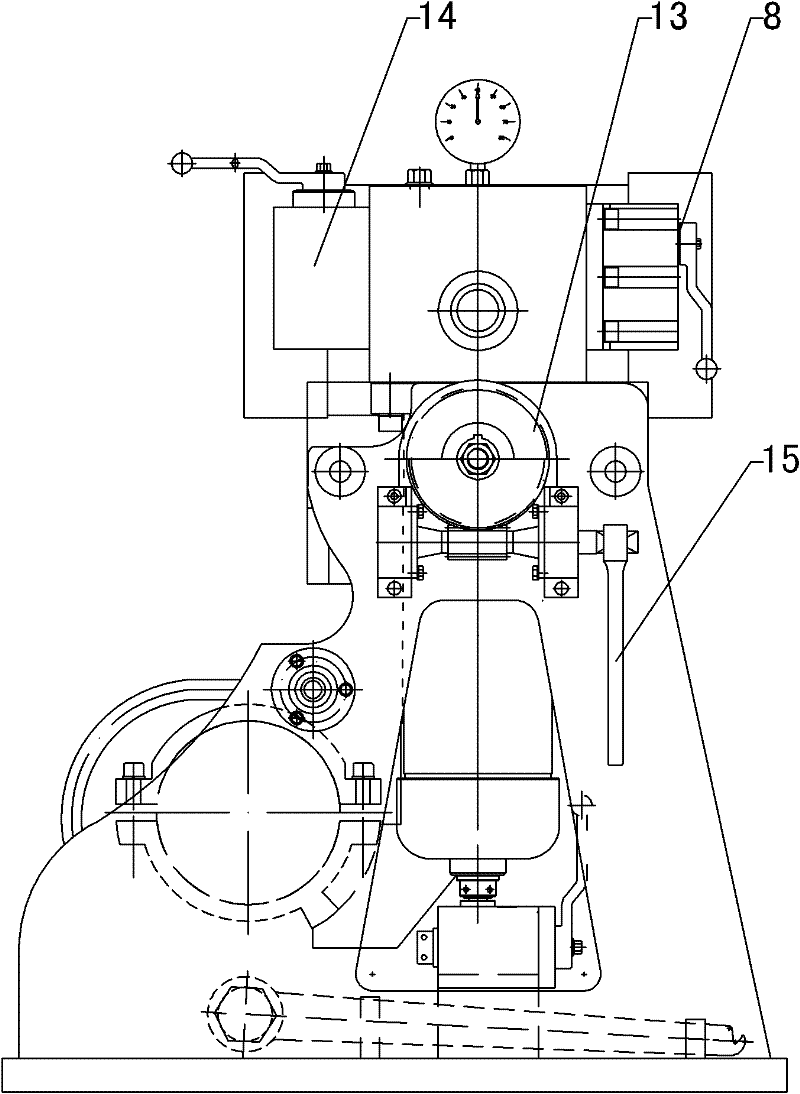

Flotation machine hollow shaft dredger

The invention discloses a flotation machine hollow shaft dredger. The hollow shaft dredger comprises a rubber hose, an expansion rubber bag, a rubber valve and a washing mechanism, wherein a fluid inlet and a fluid outlet are formed in the expansion rubber bag, the rubber hose is connected to the fluid inlet, and the washing mechanism is connected to the fluid outlet; and the rubber valve is arranged in the expansion rubber bag and is located above the fluid outlet. According to the dredger, on the premise of normal production of a workshop, a hollow shaft can be dredged without disassemblinga flotation machine, so that the labor force required by dredging work is greatly reduced, the operation rate of equipment is improved, and the continuous and stable production is guaranteed.

Owner:TIBET HUATAILONG MINING DEV

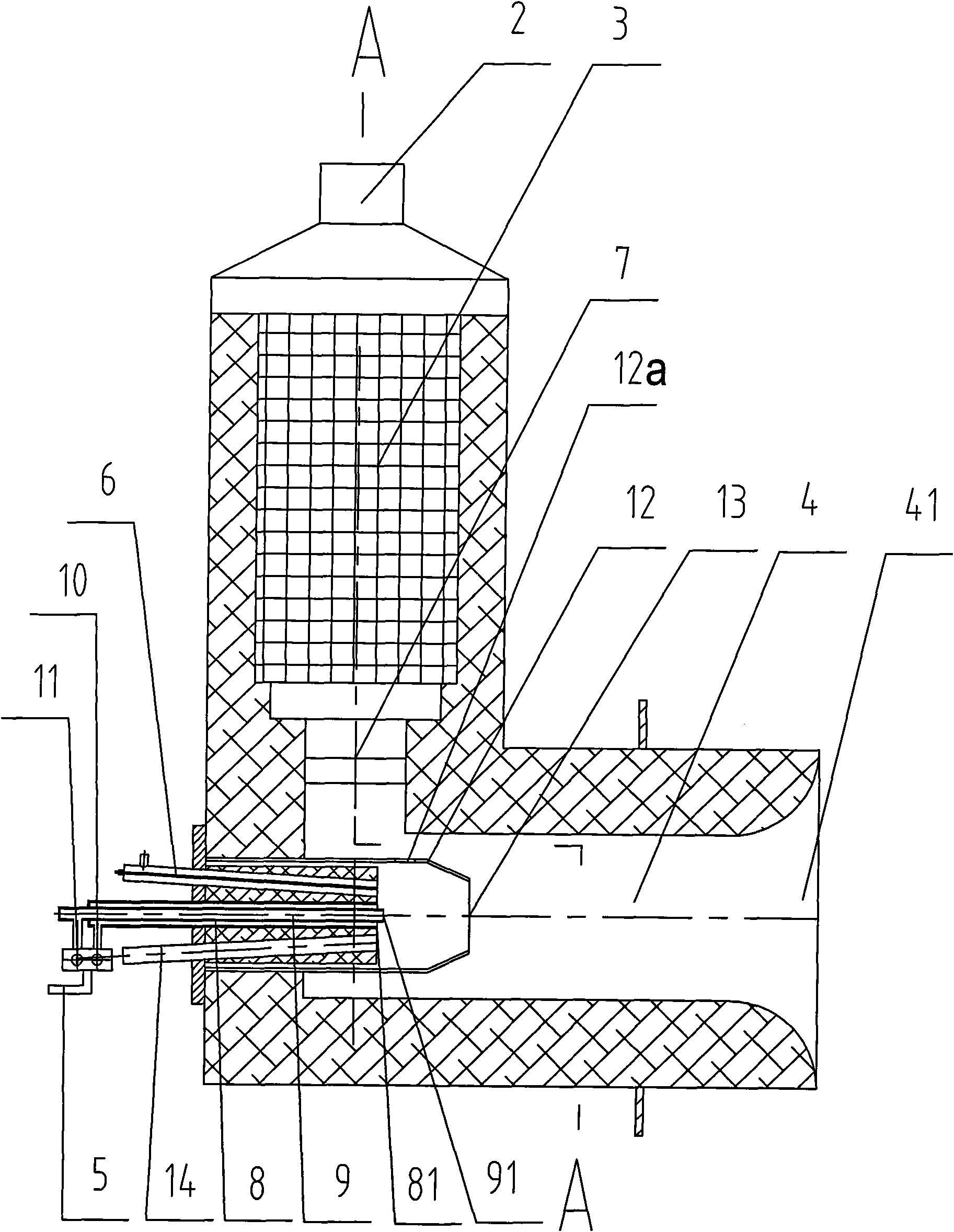

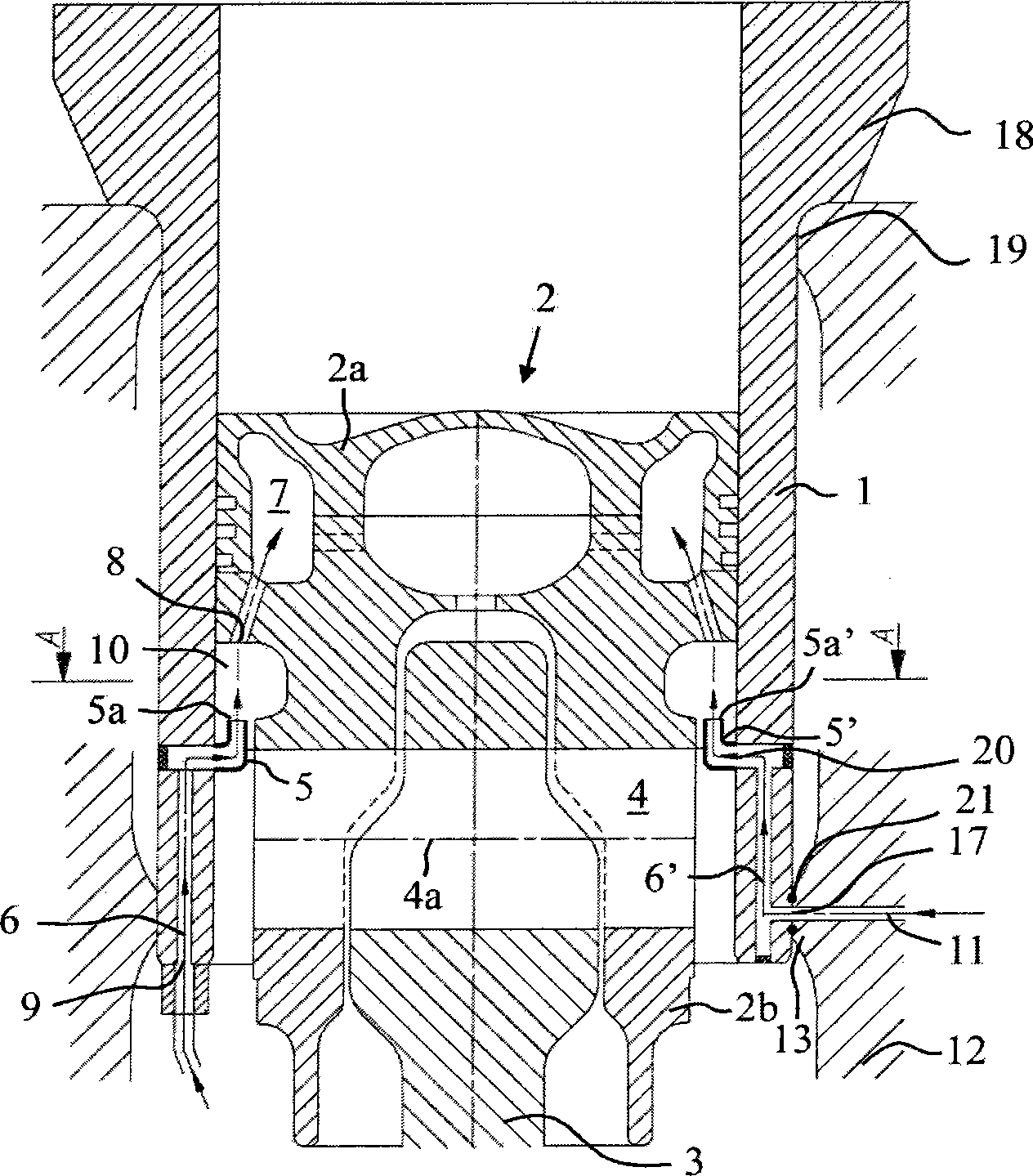

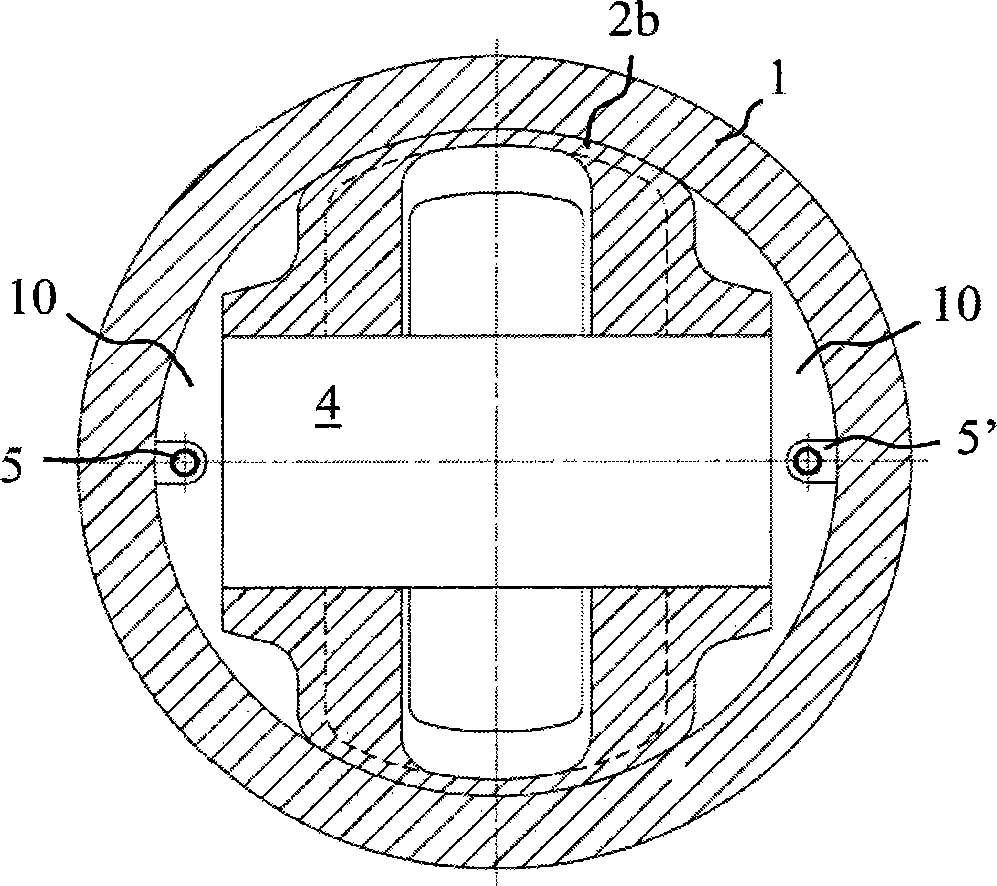

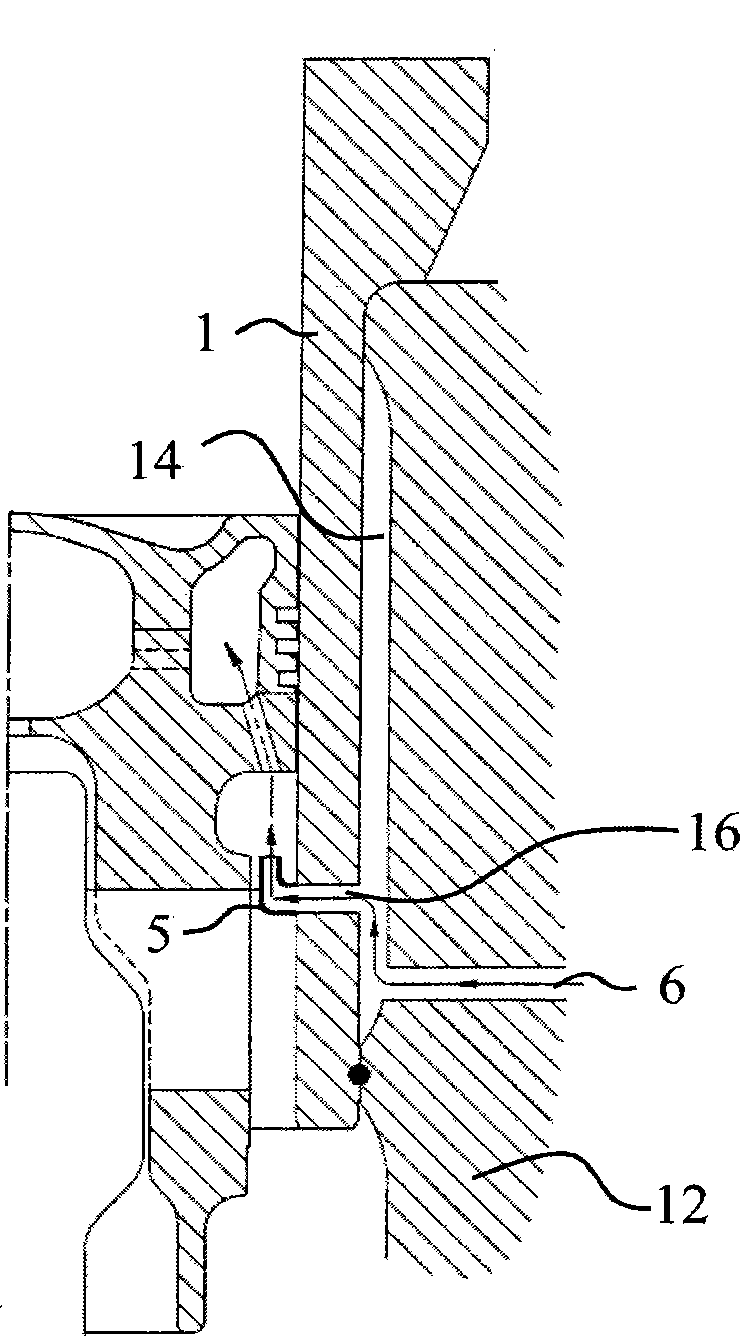

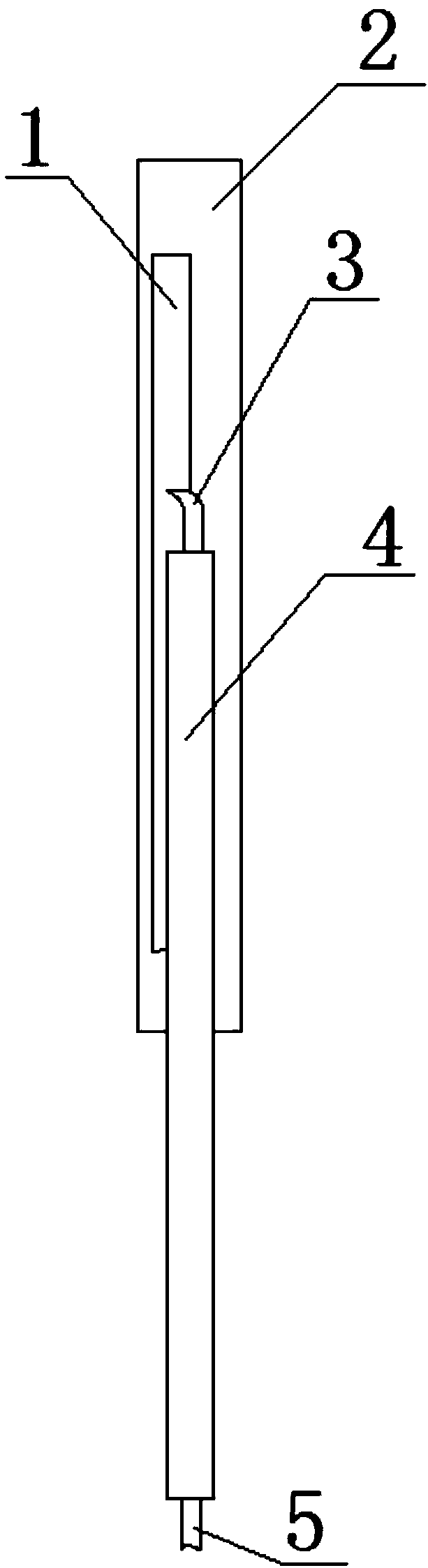

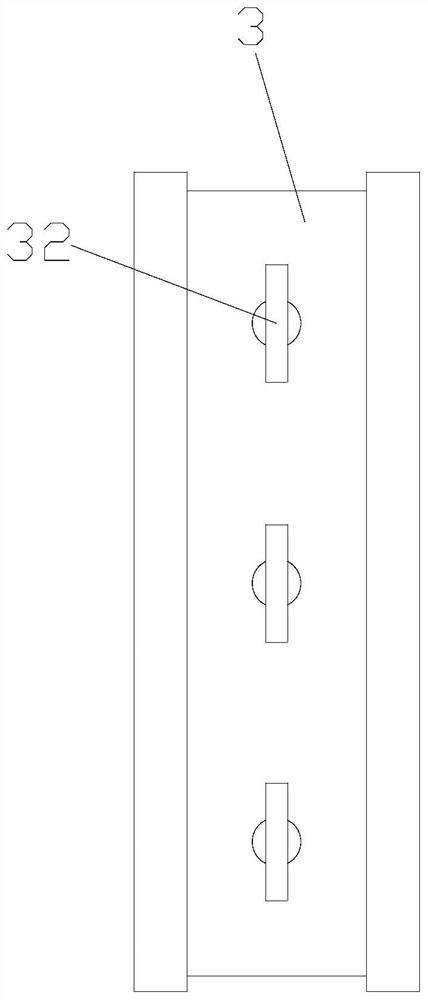

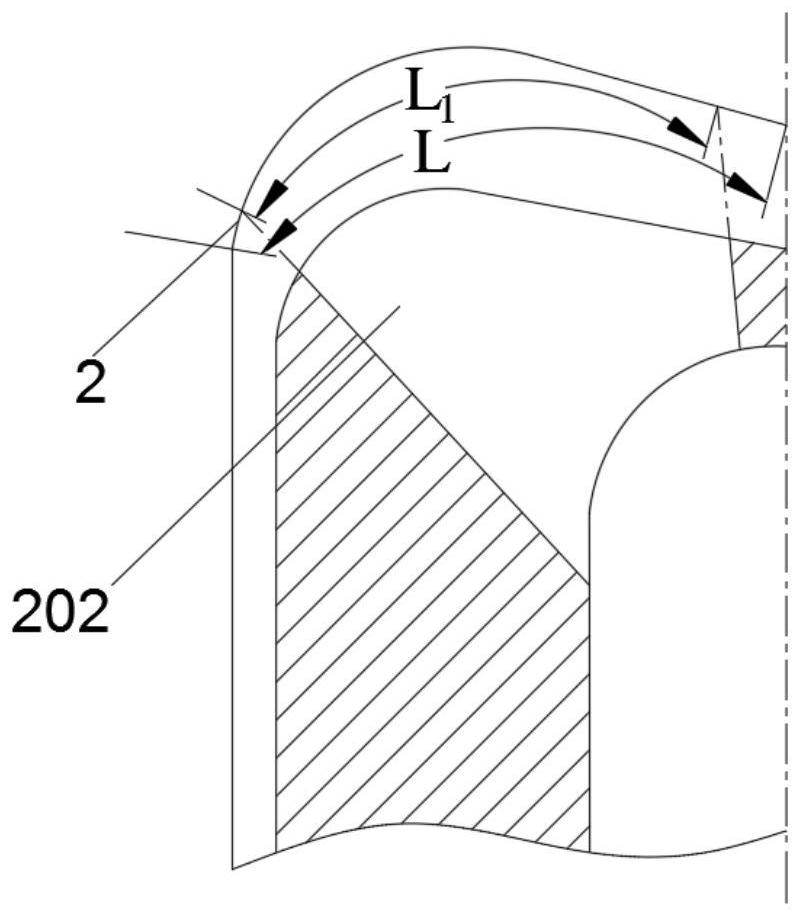

Piston cooling device and cylinder liner

ActiveCN104126068AImprove cooling effectShort spray distanceLiquid coolingCylinder headsEngineeringInternal combustion engine

The cooling arrangement for a reciprocating piston (2) of an internal combustion engine comprises a cooling medium injector (5, 5') for injecting cooling oil into a space (10) between the piston (2) and the cylinder liner (1) below the piston crown (2a), an opening (8) for introducing the cooling oil from the space (10) below the piston crown (2a) into a cooling oil gallery (7), and a cooling medium duct (6, 6') for supplying the cooling oil to the cooling medium injector (5, 5,). The cooling medium injector (5, 5') is arranged inside the cylinder at such a height that the tip (5a, 5a') of the injector (5, 5') is above the center axis (4a) of the gudgeon pin (4) of the piston (2) when the piston (2) is at bottom dead center.

Owner:WARTSILA FINLAND OY

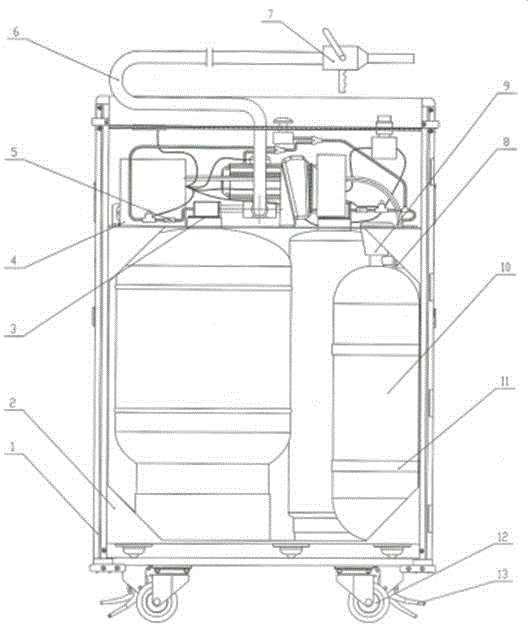

Dry powder and foam dual-purpose fire extinguishing device

ActiveCN106110544ASafe and reliable structural designEasy to install and disassembleFire rescueCylinder ValveEngineering

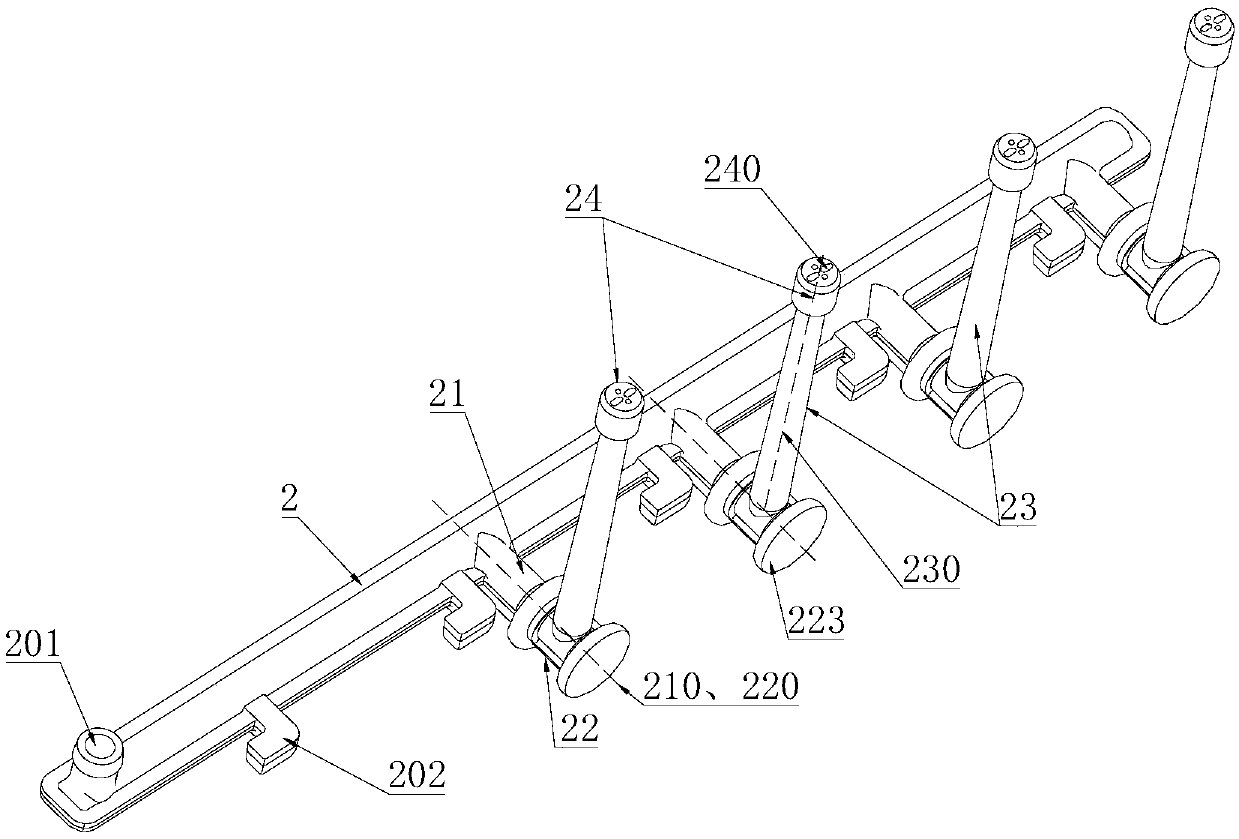

The invention belongs to a dry powder and foam dual-purpose fire extinguishing device which comprises a trolley (1). A gas cylinder and barrel fixing mechanism (2) is installed inside the trolley (1); a gas cylinder (10) is fixed to the right side of the interior of the gas cylinder and barrel fixing mechanism (2) through a gas cylinder fixing belt (11); a gas cylinder valve (9) is installed at the upper end of the gas cylinder (10); a pressure reducer (8) is installed on the gas cylinder valve (9); and a spray gun (7) is installed at the top end of the trolley (1) through a spraying pipe (6). The dry powder and foam dual-purpose fire extinguishing device is characterized in that a barrel and barrel cylinder valve mechanism (3) is installed inside the gas cylinder and barrel fixing mechanism (2); and an electronic control system (4) and a pneumatic control system (5) are installed on the upper portion of the barrel and barrel cylinder valve mechanism (3). A dry powder barrel and a foam liquid barrel contain dry powder medicament and foam medicament correspondingly, and the fire can be extinguished by selecting corresponding medicament according to the field situations; and the spraying time is long, operation is easy and convenient, and the fire extinguishing effect is good.

Owner:DALIAN PUAN FIRE FIGHTING EQUIP CO LTD

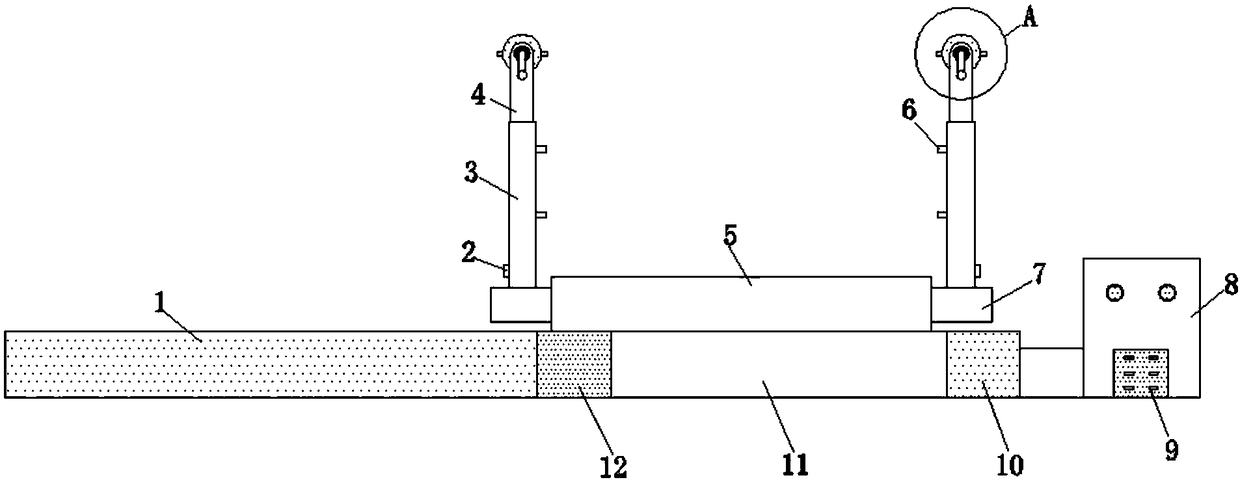

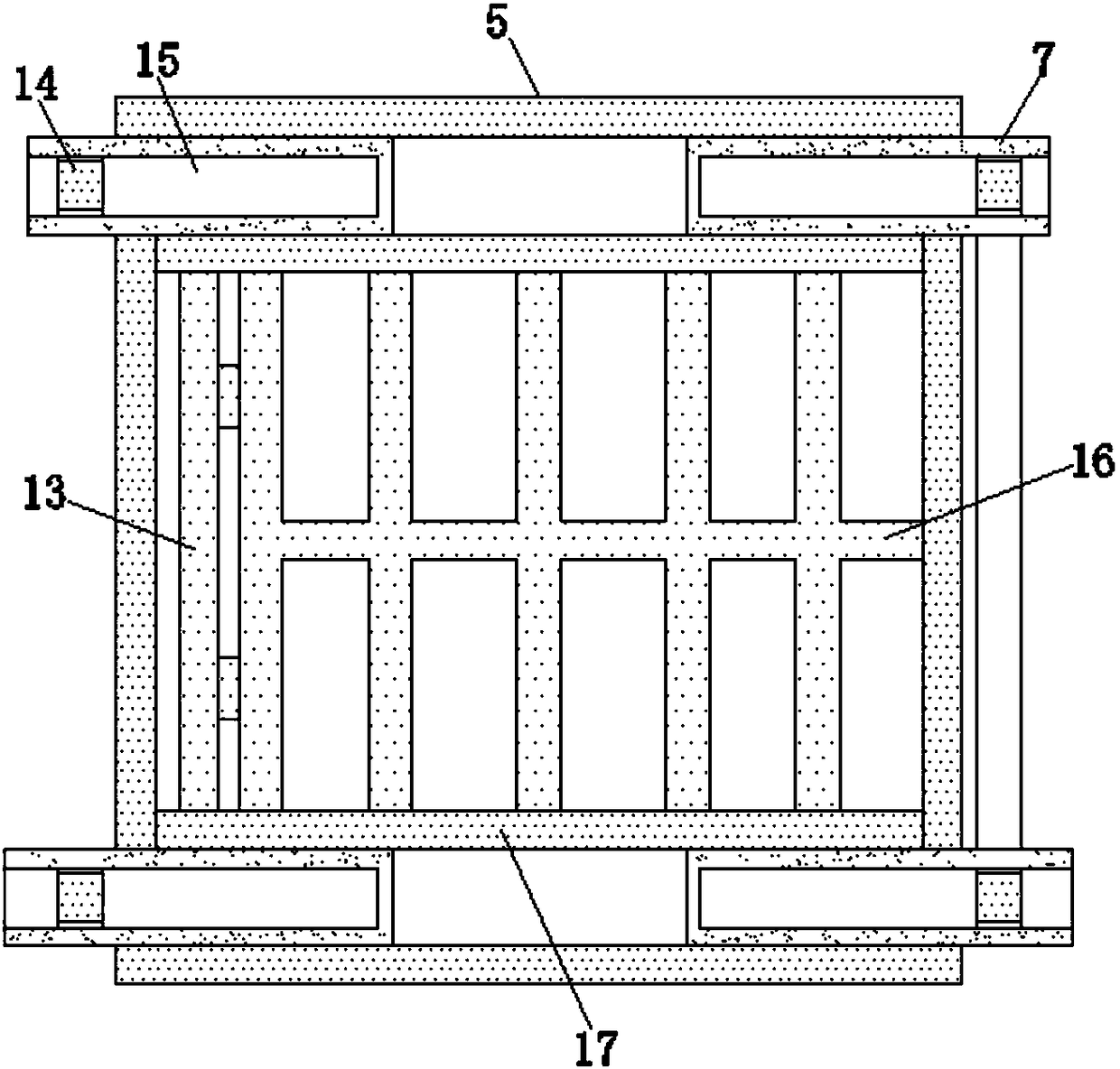

Construction-site vehicle washing device facilitating silt cleaning

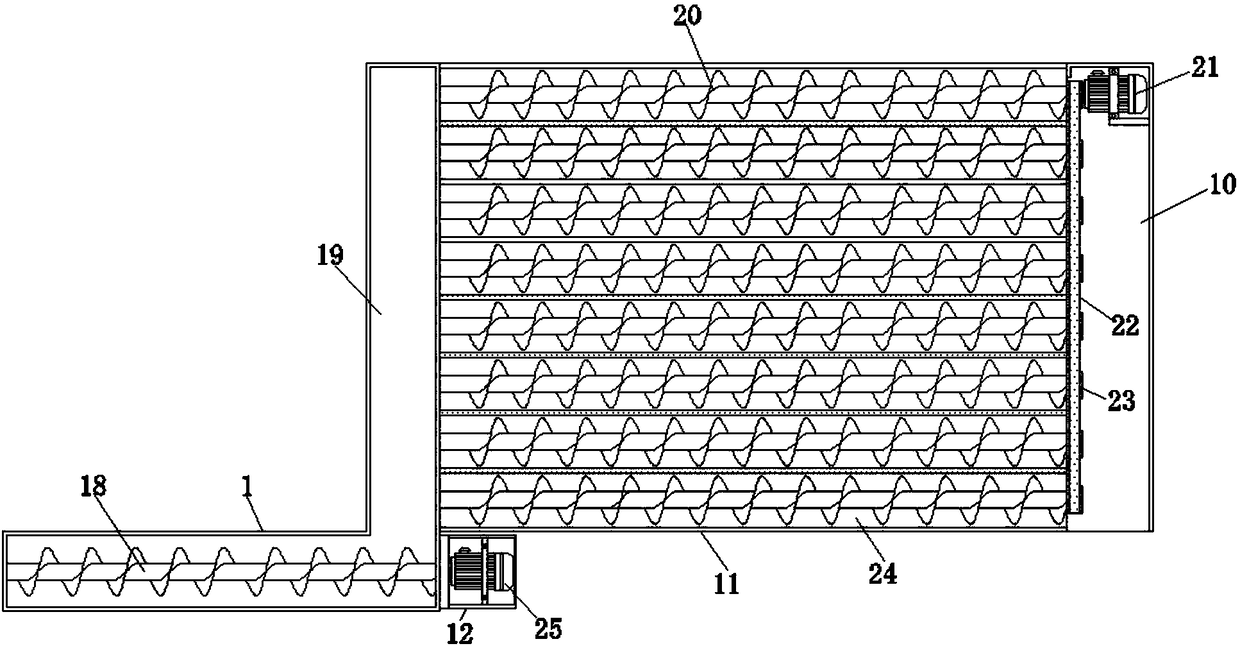

ActiveCN108437942ASolve the problem of inconvenient mobilityShorten the timeCleaning apparatus for vehicle exteriorsSludgeWater collection

The invention discloses a construction-site vehicle washing device facilitating silt cleaning. The device includes a water collection table, a water collection tank is formed in the water collection table, a second auger is installed inside the water collection tank, one side of the second anger is provided with a first motor sealing box, a first motor is installed inside the first motor sealing box, one side of the first motor is provided with a belt pulley, one side of the belt pulley is provided with a belt, a wedge-shaped groove is formed in one side of the water collection table, one sideof the wedge-shaped groove is provided with a second motor sealing box, and a second motor is installed inside the second motor sealing box. According to the construction-site vehicle washing devicefacilitating silt cleaning, the water collection table provided with the auger is arranged, so that the time of a user for cleaning the water collection table regularly is saved, the labor intensity of the user is reduced, it is convenient to collect silt into one place, and it is favorable for the user to clean up the silt; a slide table is arranged, so that it is beneficial to washing vehicles with different widths, the washing quality is ensured, and the problem is avoided that residual silt exists on the vehicles.

Owner:平邑现代中药产业园有限公司

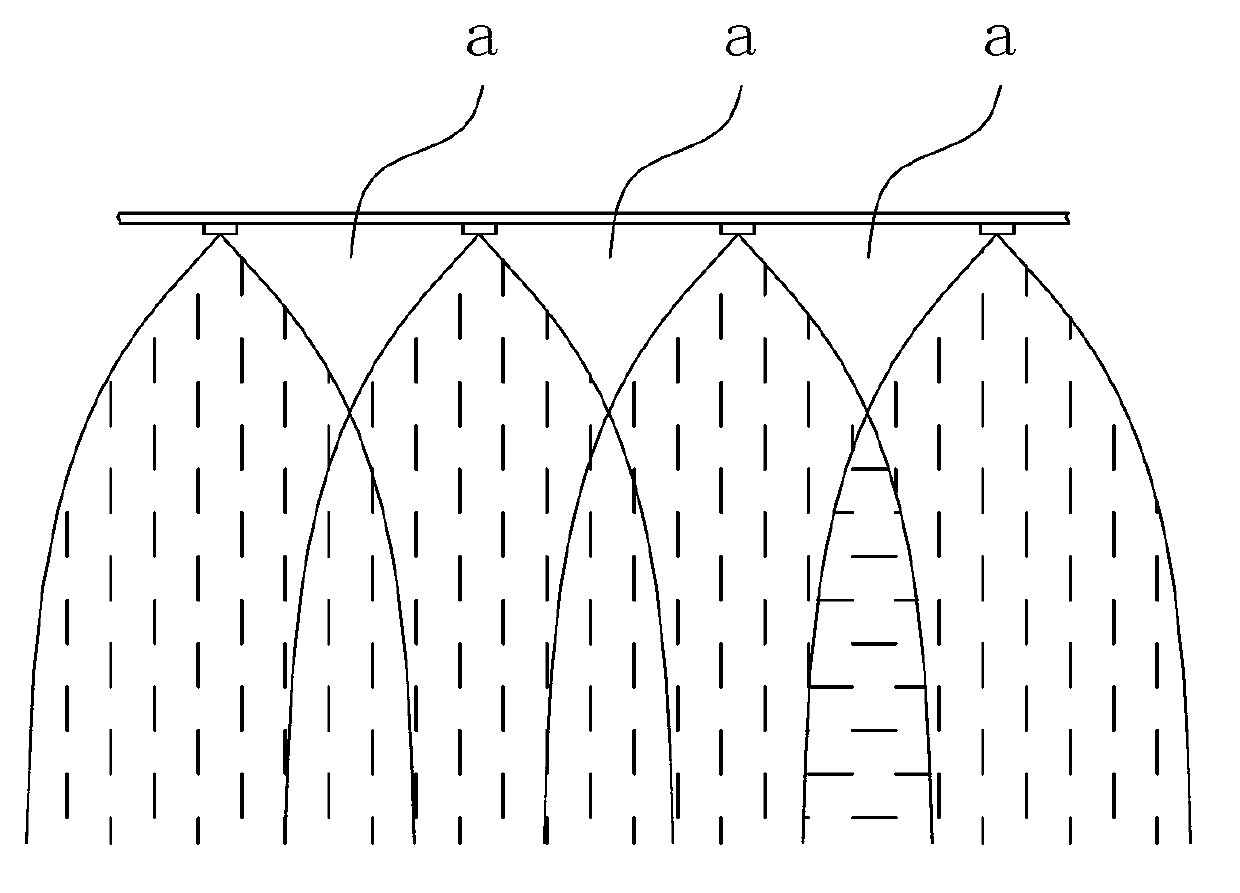

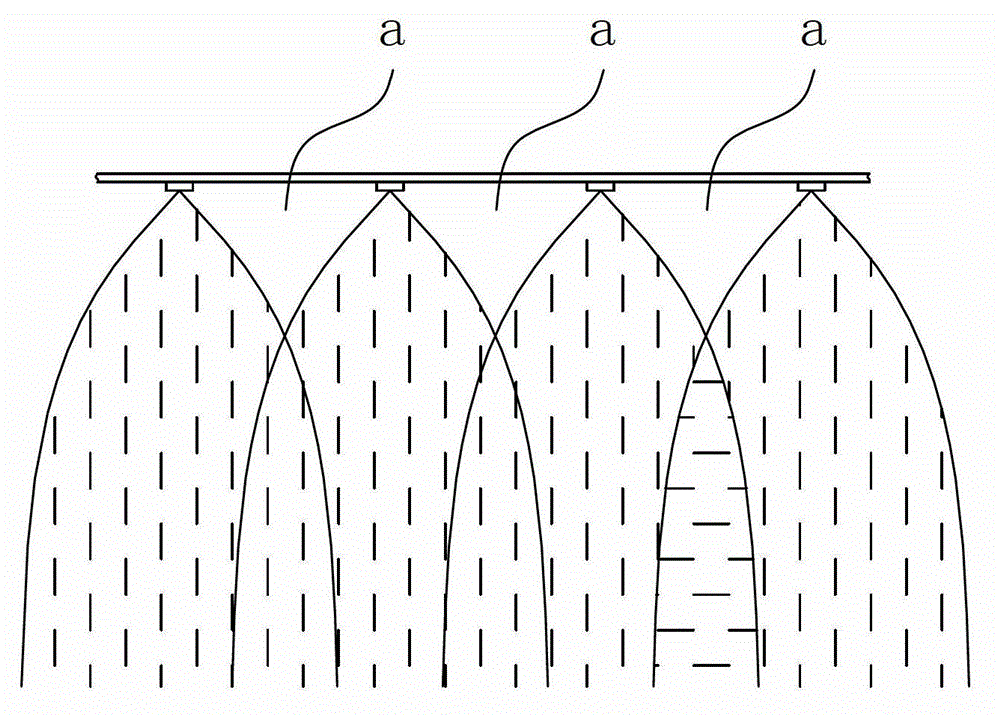

Water mist curtain spray head

The invention belongs to the field of smoke preventing and dust falling in fire fighting, and particularly relates to a water mist curtain spray head. The water mist curtain spray head comprises a first nozzle which is downwards arranged in the spray direction; a transition part is arranged between the first nozzle and an outer water pipe and is used for communicating the first nozzle with the outer water pipe. The water mist curtain spray head further comprises at least one second nozzle which is used for horizontally spraying to the left and / or the right; and the second nozzle is arranged by communicating with the outer water pipe through the transition part. By adopting the water mist curtain spray head, the problem that conventional structure brings a dead angle in spray can be effectively solved, and another problem that conventional single-nozzle structure causes fast sinking of the upper mist layer to influence personal safety can be avoided; and the water mist curtain spray head is high in safety, and reliable and stable in work.

Owner:合肥辰泰安全设备有限责任公司

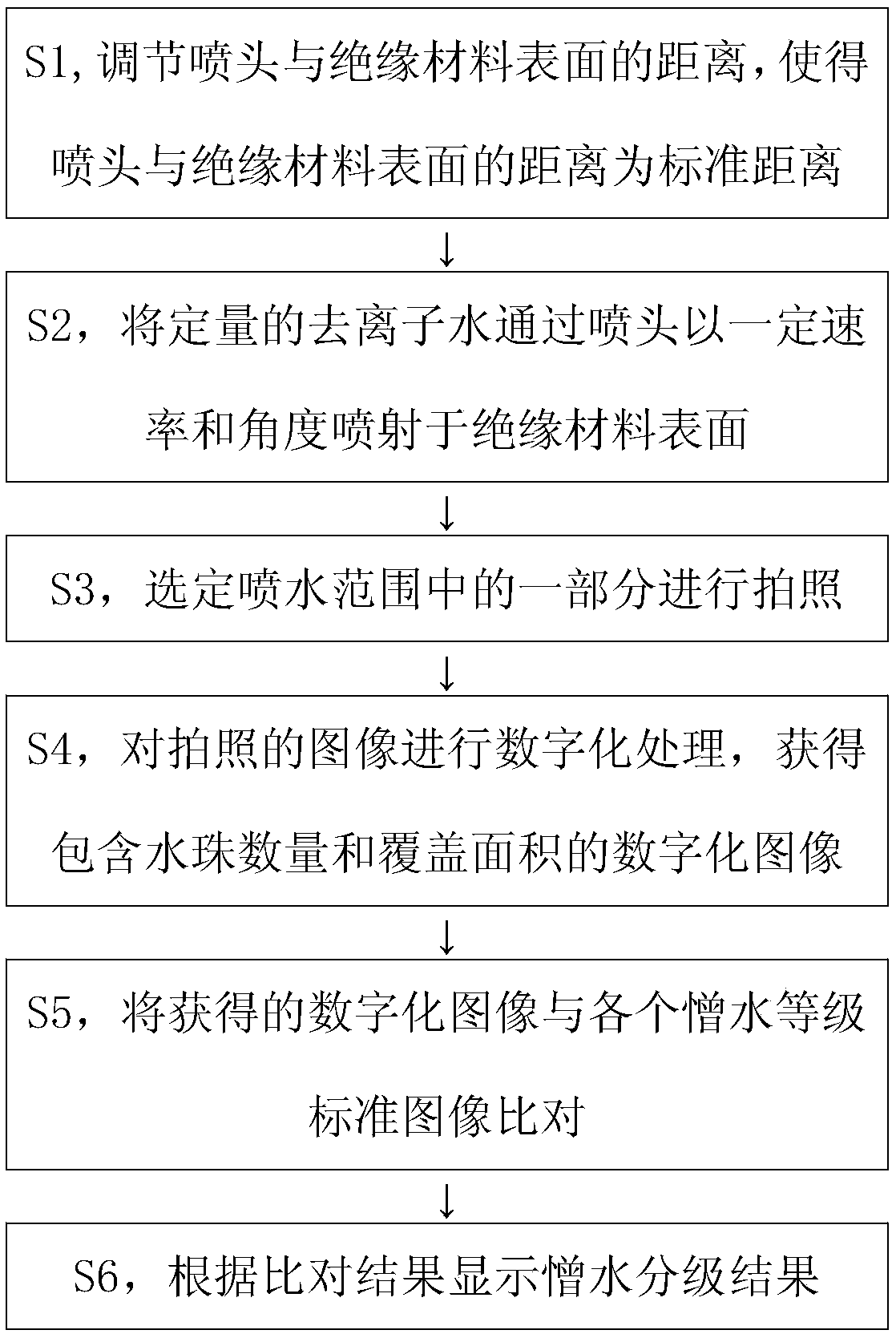

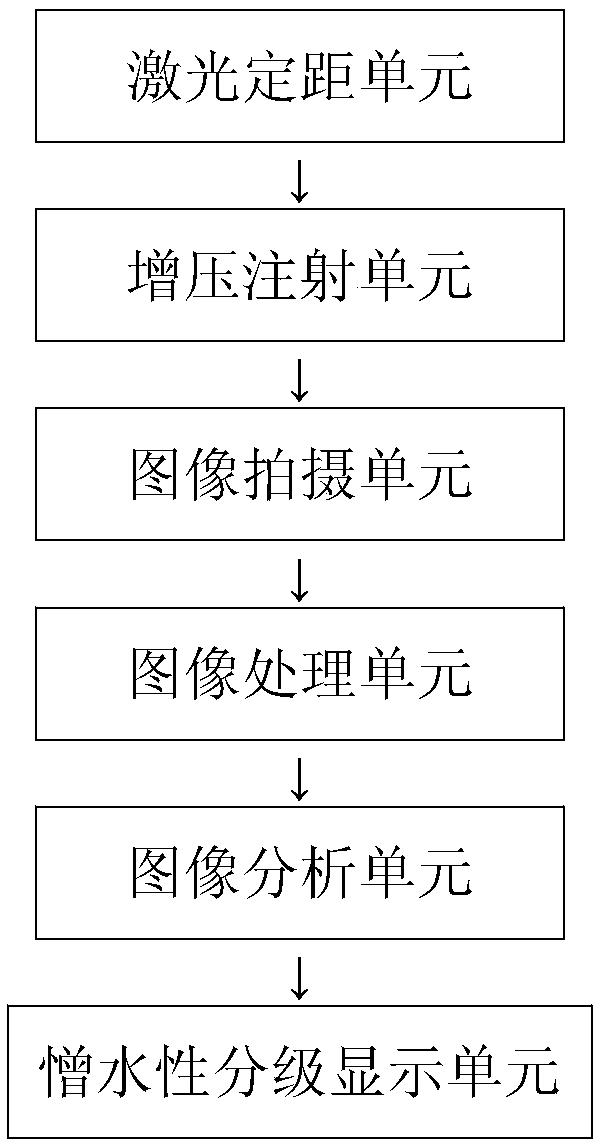

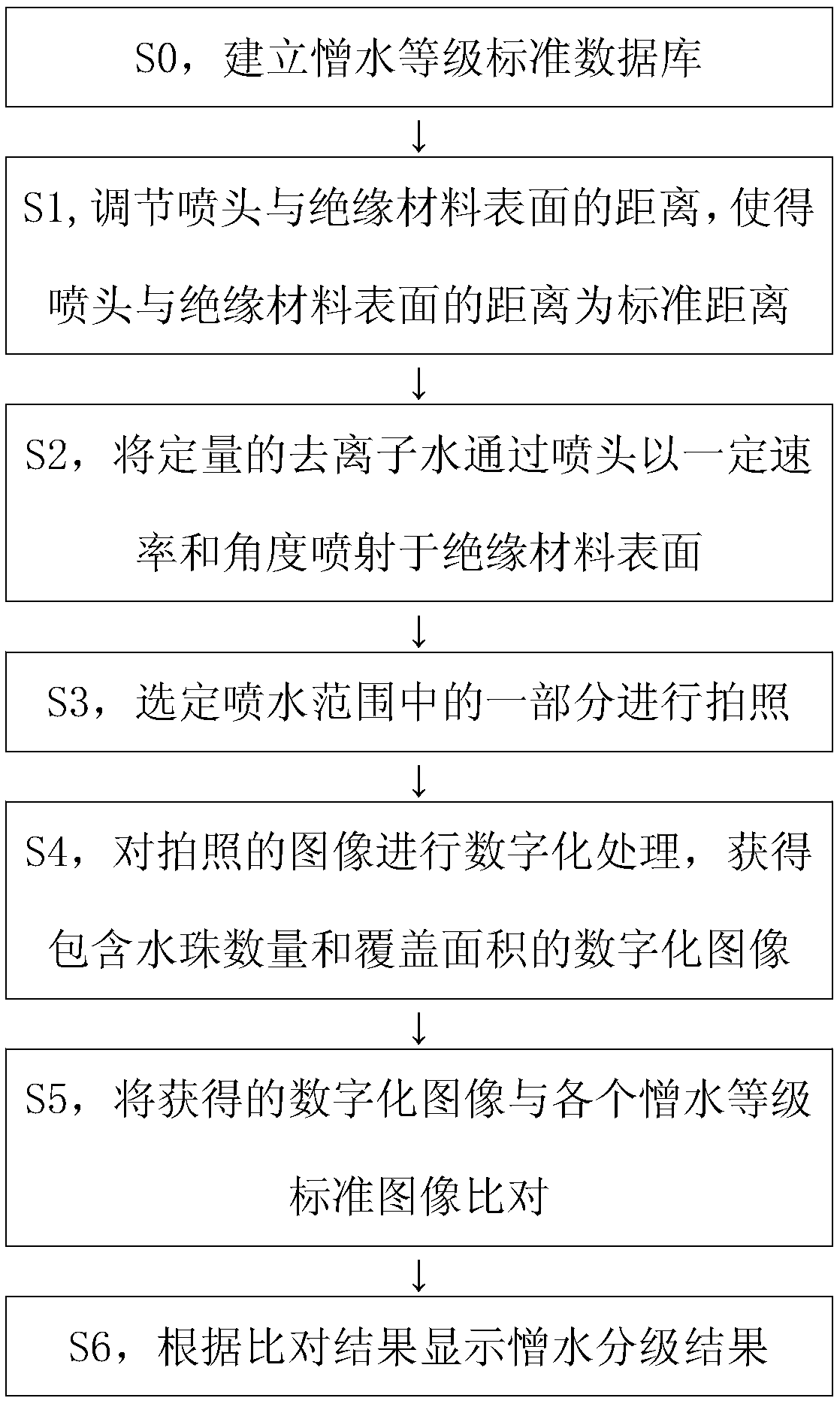

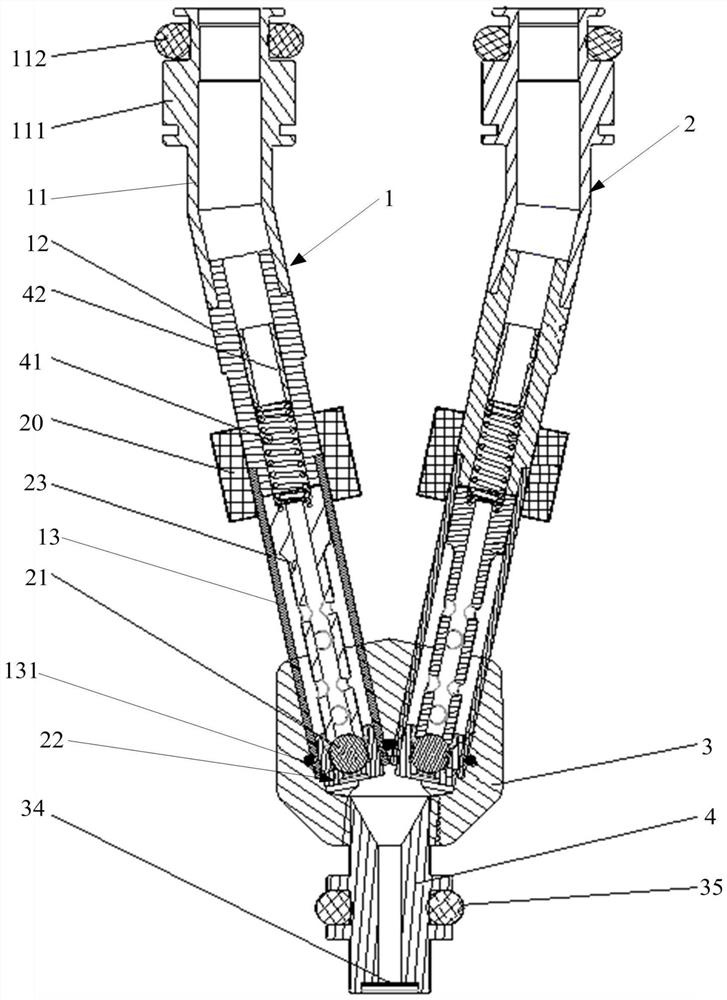

Graded direct-reading method and device for surface hydrophobicity of composite insulating material

InactiveCN108732173AEasy to dryShort spray distanceInvestigating composite materialsImage analysisIon

The invention provides a graded direct-reading method and device for the surface hydrophobicity of a composite insulating material. The method comprises the following steps: adjusting the distance from a spray head to the surface of an insulating material to be a standard distance; spraying quantified deionized water to the surface of the insulating material in a certain speed and angle; photographing a part of the material in the water spraying range; carrying out digital processing on a photographed image, so as to obtain a digital image including the number of water drops and the coverage area, and making comparison on the acquired digital image and a standard image of each hydrophobic grade; and displaying the grading result according to a comparison result. The device comprises a laser spacing device, a pressurizing injection unit, an image photographing unit, an image processing unit, an image analysis unit and a hydrophobic grade display unit. According to the method and the device, by quantitatively controlling the water yield, water jetting angle and water jetting height, the graded and accurate measurement of the surface hydrophobicity of the insulating material is realized.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

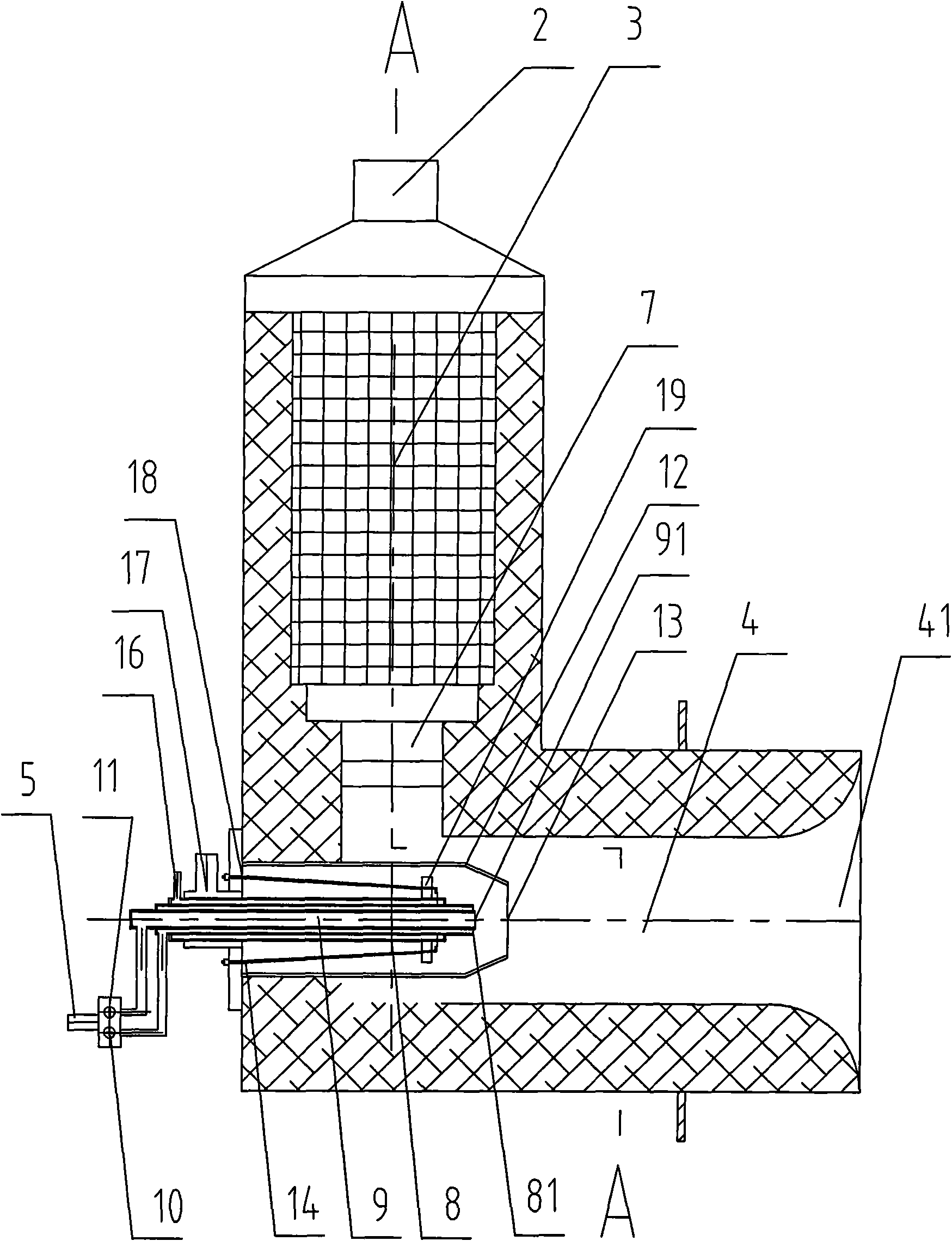

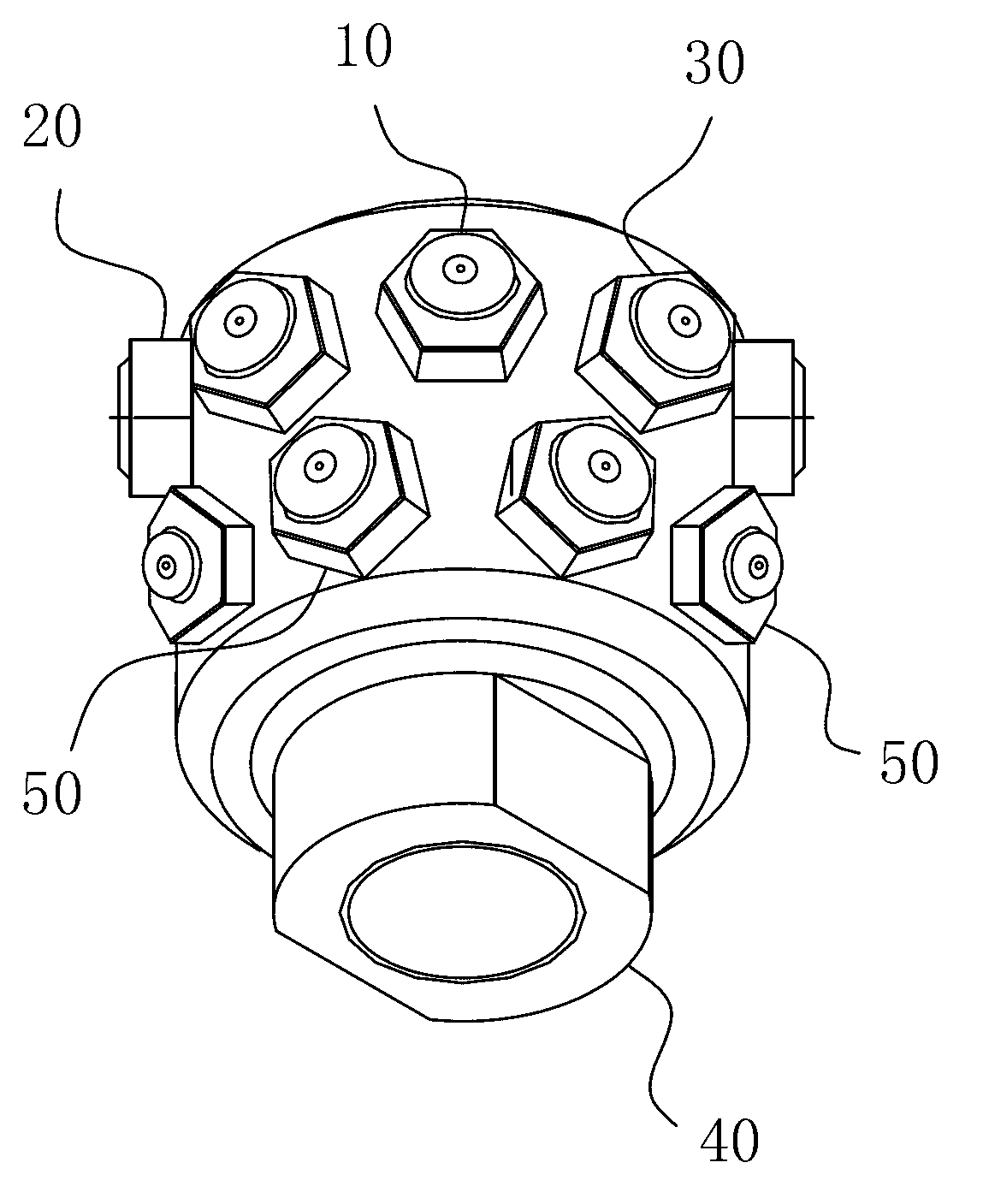

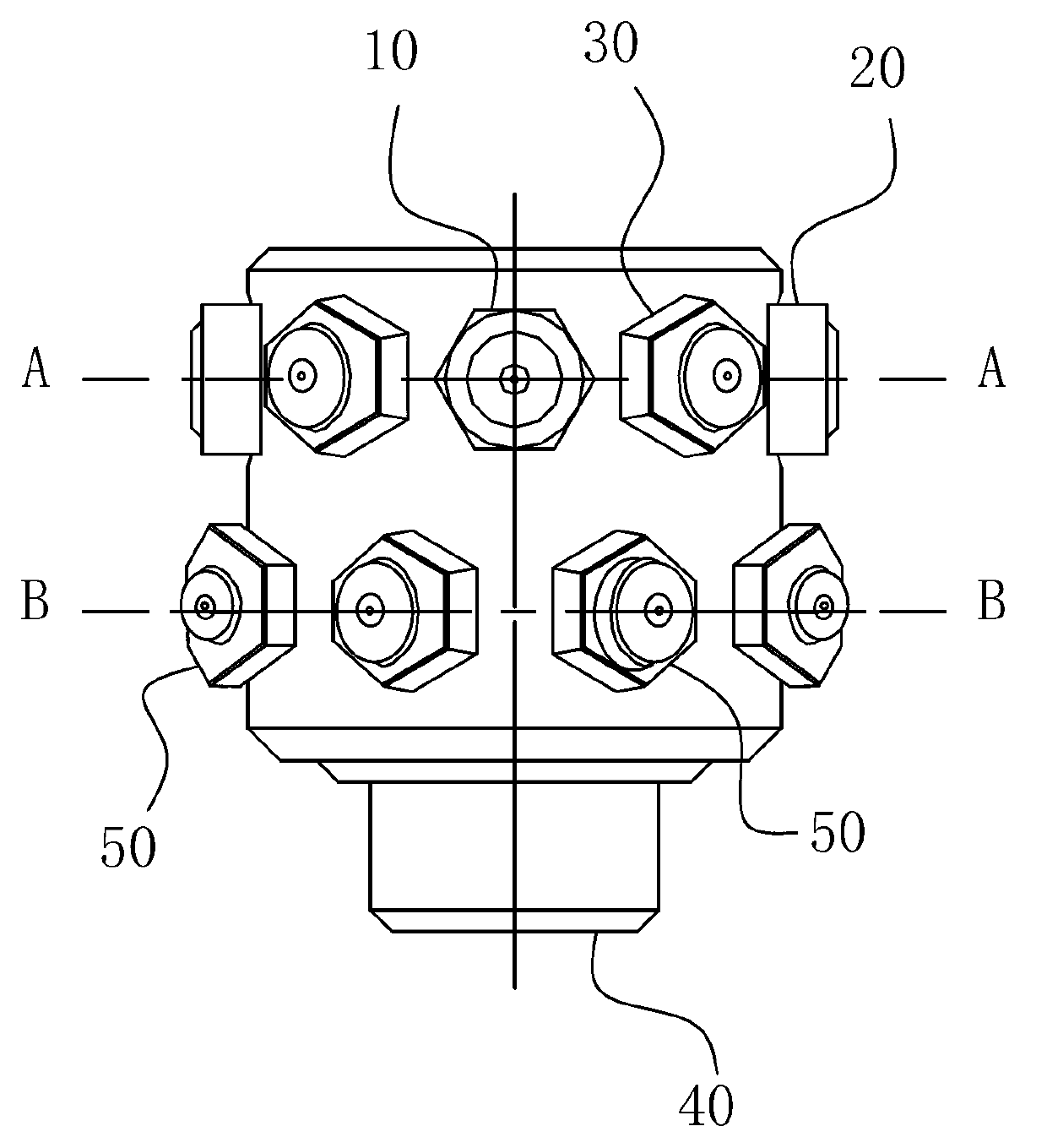

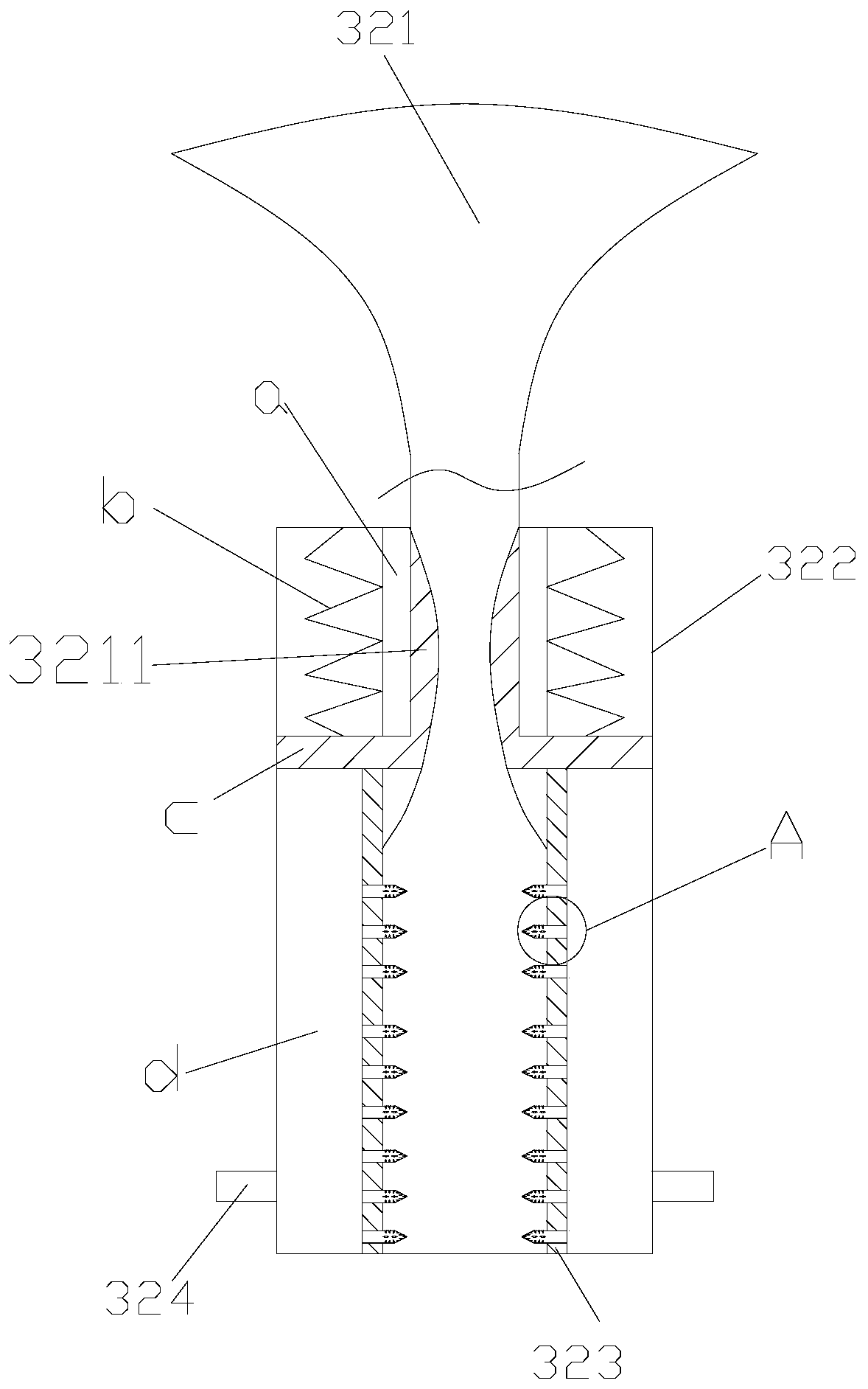

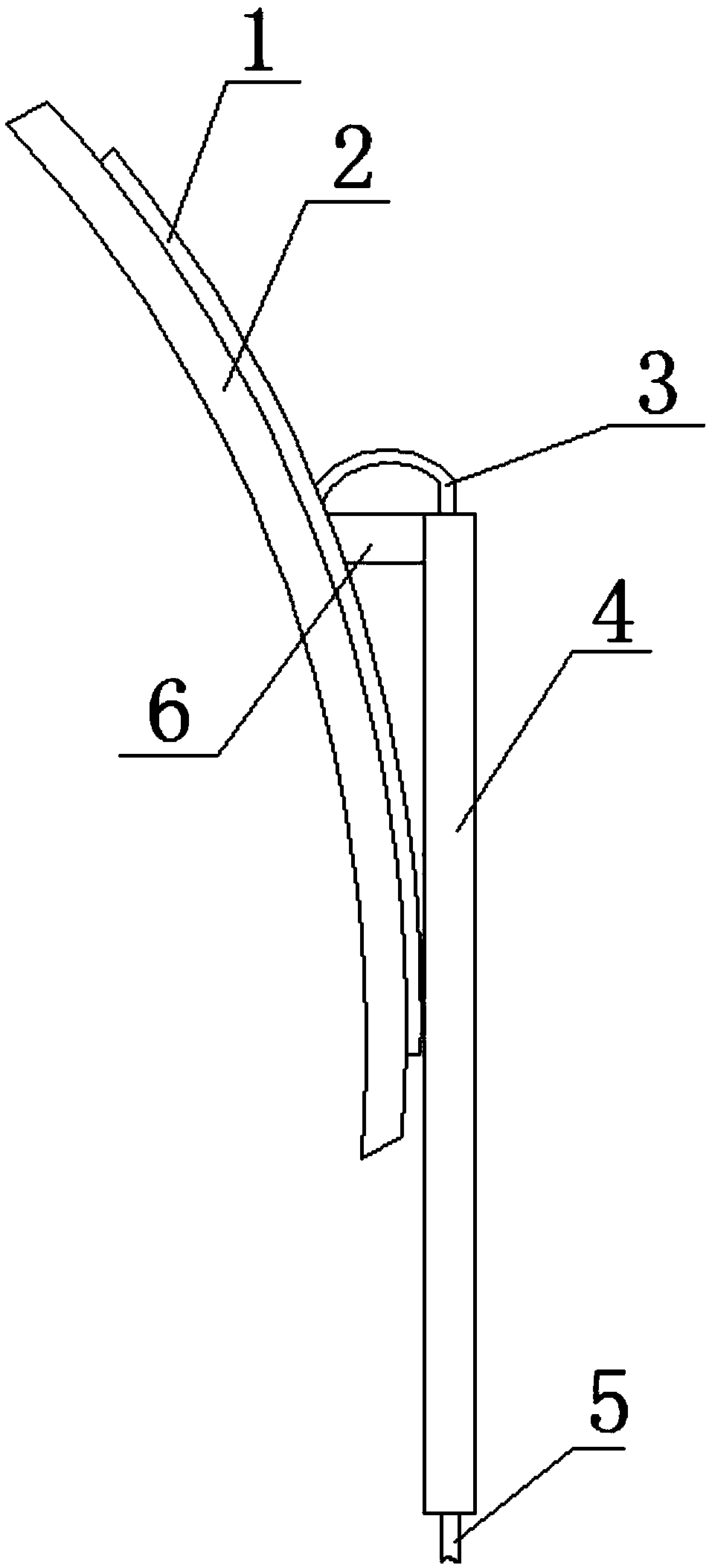

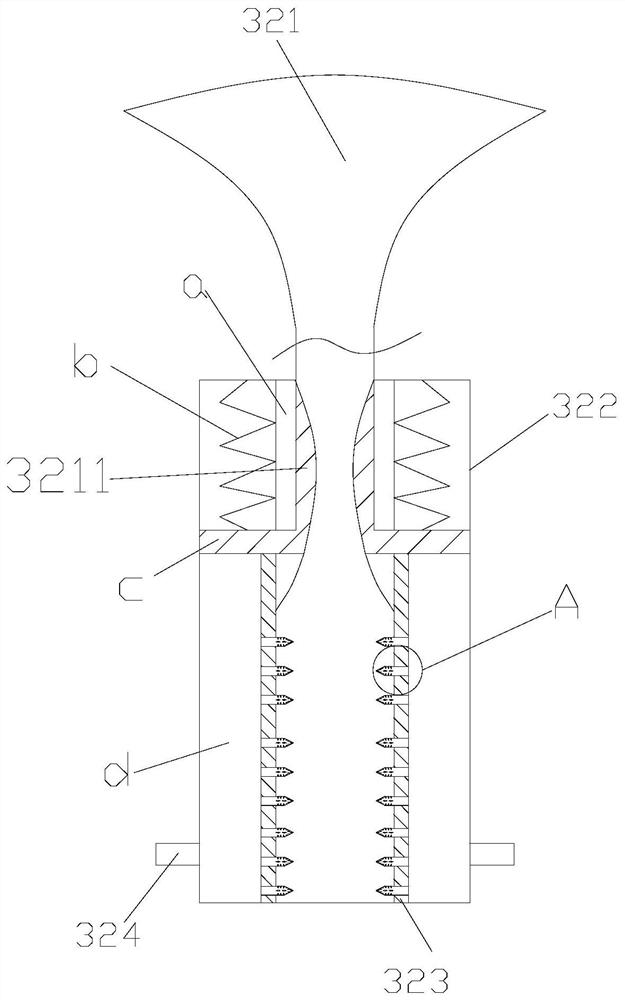

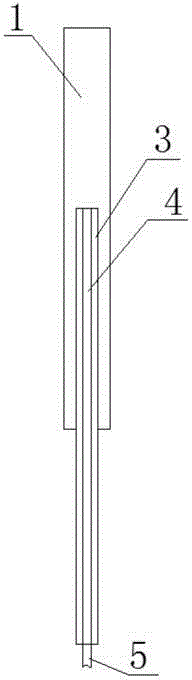

Injector and vehicle

ActiveCN112943494AFull sprayShort spray distanceInternal combustion piston enginesFuel injection apparatusCombustion chamberMethanol fuel

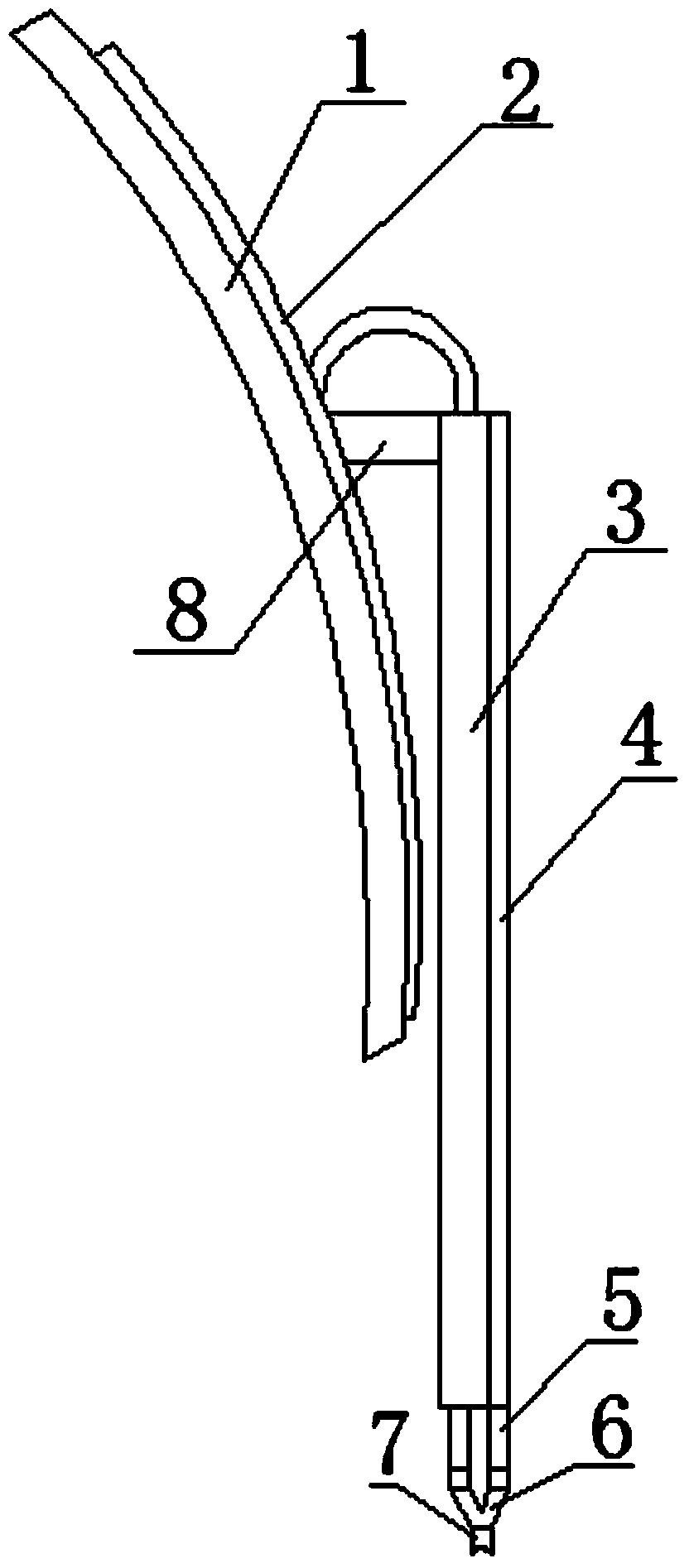

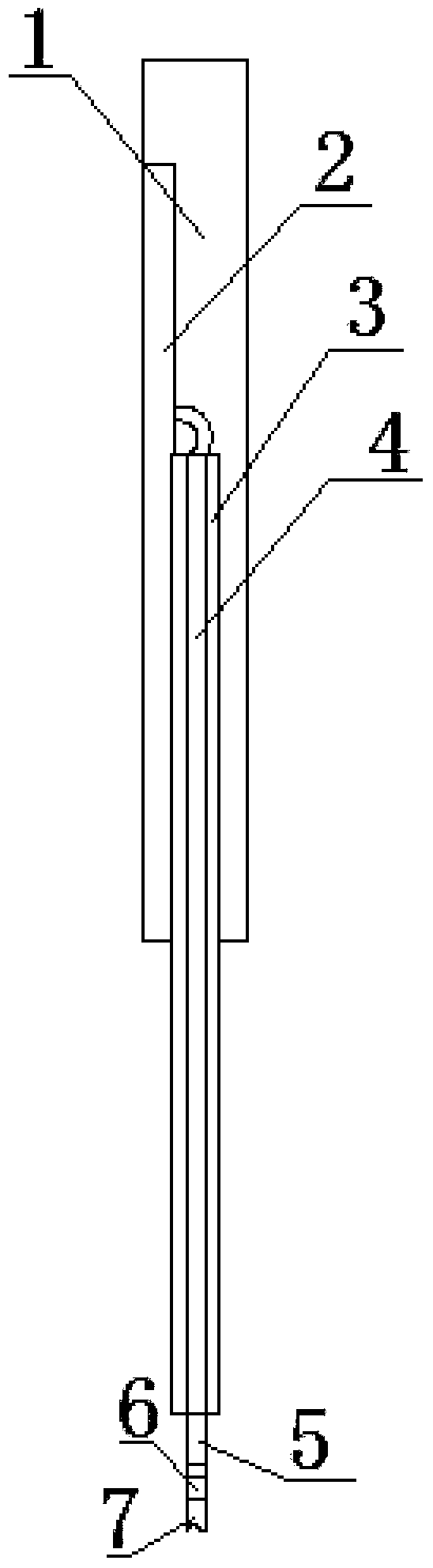

The invention provides an injector and a vehicle so as to solve the problem that in the prior art, methanol fuel cannot be fully injected into a combustion chamber. The injector comprises a base, a nozzle, a first injection pipe and a second injection pipe, wherein the base is provided with a first mounting hole and a second mounting hole; the nozzle is connected with the base and communicated with the first mounting hole and the second mounting hole; the first injection pipe is arranged in the first mounting hole, an outlet of the first injection pipe is communicated with the nozzle, and the first injection pipe is used for conveying methanol to the nozzle; and the second injection pipe is arranged in the second mounting hole, an outlet of the second injection pipe is communicated with the nozzle, and the second injection pipe is used for conveying gasoline to the nozzle. According to the injector, two kinds of fuel injectors are combined into a whole, the first injection pipe and the second injection pipe are connected to the combustion chamber through the base and the nozzle, two kinds of fuel can be injected at the same position, the methanol injection distance is the same as the gasoline injection distance during injection, the methanol injection distance is shortened, and the methanol can be fully injected into the combustion chamber.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +3

A blade-adjustable atomizing nozzle

The invention provides an atomizing spray head with adjustable blades, which includes a spray head housing, a water inlet, a swirl chamber and a water outlet are arranged in the nozzle housing, and the water inlet is connected to the swirl chamber; an isolator is arranged in the swirl chamber A plurality of twisted blades are arranged in the swirl cavity, and a twisted blade is fixedly provided with a central rotating shaft, one end of which is inserted into the isolation body, and the other end passes through the nozzle housing and is connected with an adjustment mechanism. The blade-adjustable atomizing nozzle of the present invention can adjust the atomization degree of the nozzle.

Owner:XIHUA UNIV

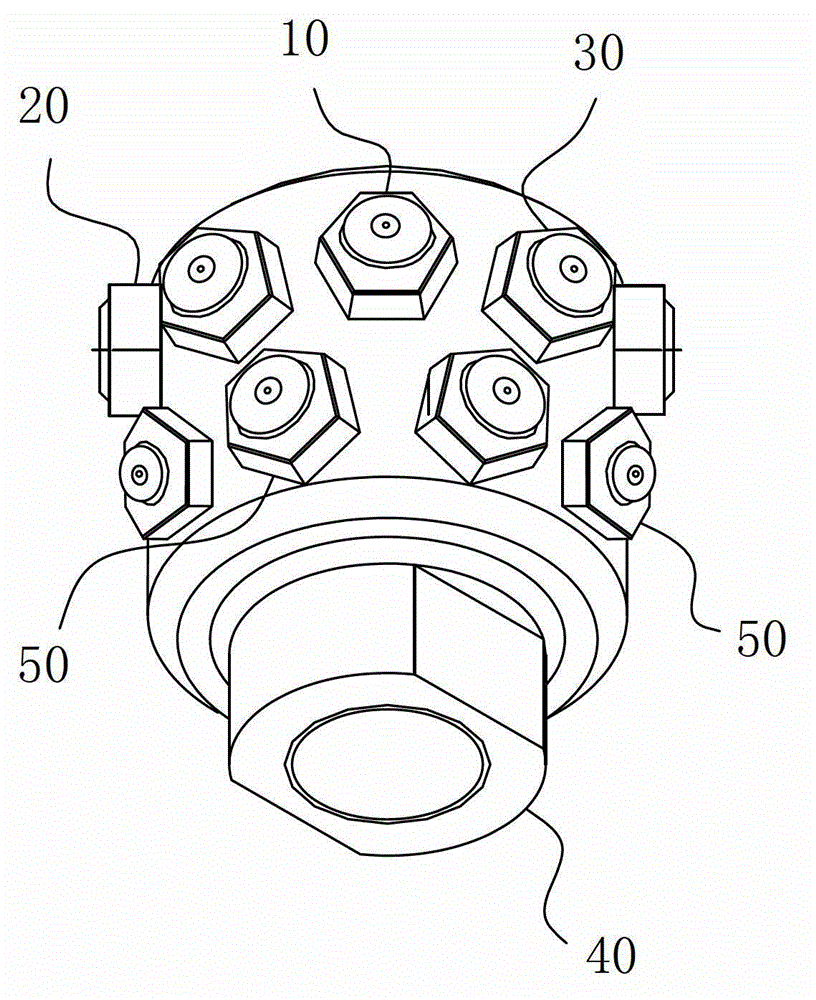

PDC drill bit

PendingCN110761716AShort spray distanceClean in timeDrill bitsConstructionsMining engineeringFront edge

The invention relates to the technical field of a drill bit, in particular to a PDC drill bit. A device comprises a drill bit body and a plurality of blades extending from the drill bit body or fixedon the drill bit body, wherein cutting teeth are arranged on the blades, and drilling fluid flow channel grooves are formed between adjacent blades; a water hole is formed in at least one blade on thedrill bit body, and the outlet of the least one water hole is positioned between the front edge of the blade and the cutting teeth at the front row. According to the invention, the injection distanceof the water hole is obviously shortened, cuttings can be cleaned and transported timely, the cutting teeth can be sufficiently cooled timely to reduce the occurrence of thermal wear, and the PDC drill bit is suitable for soft, hard and hard alternating formations.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

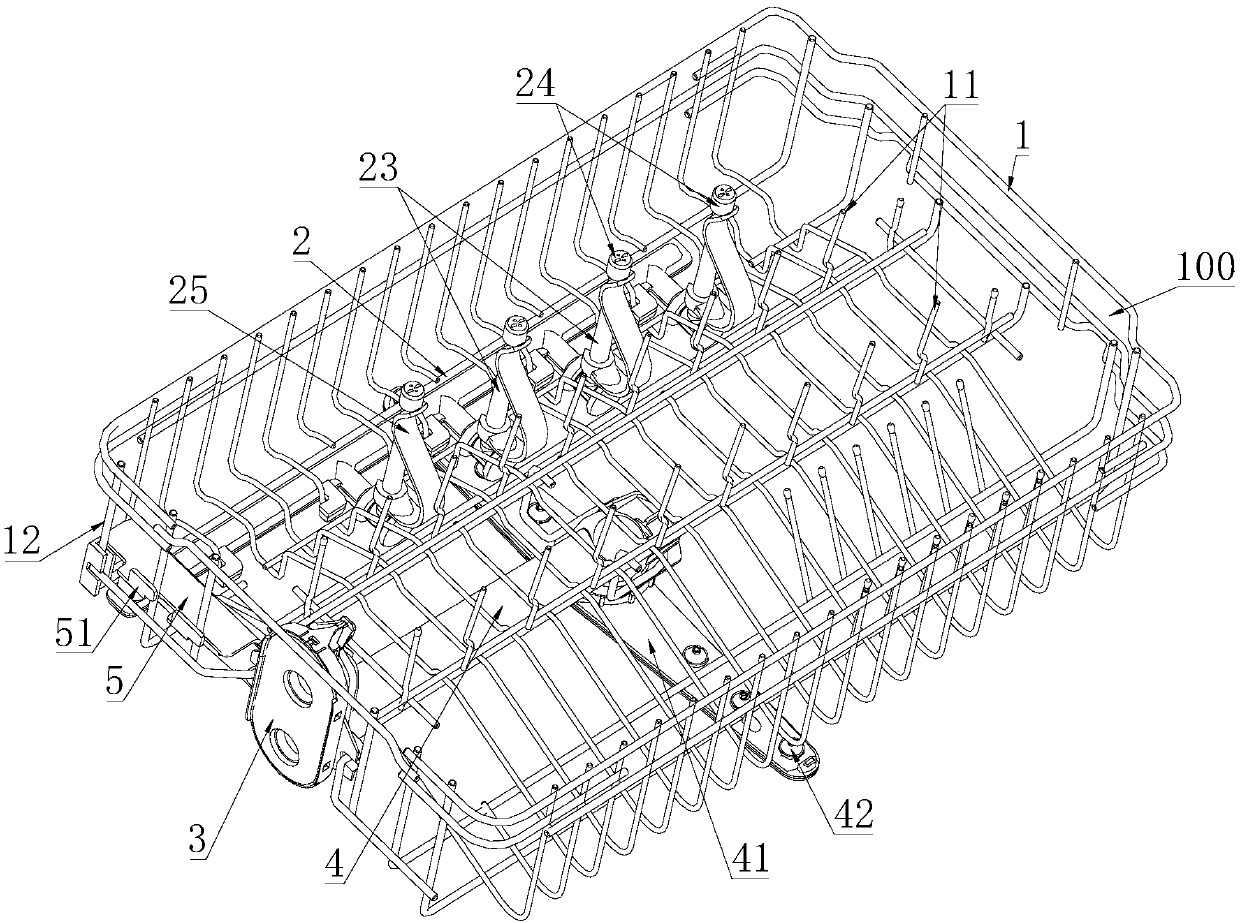

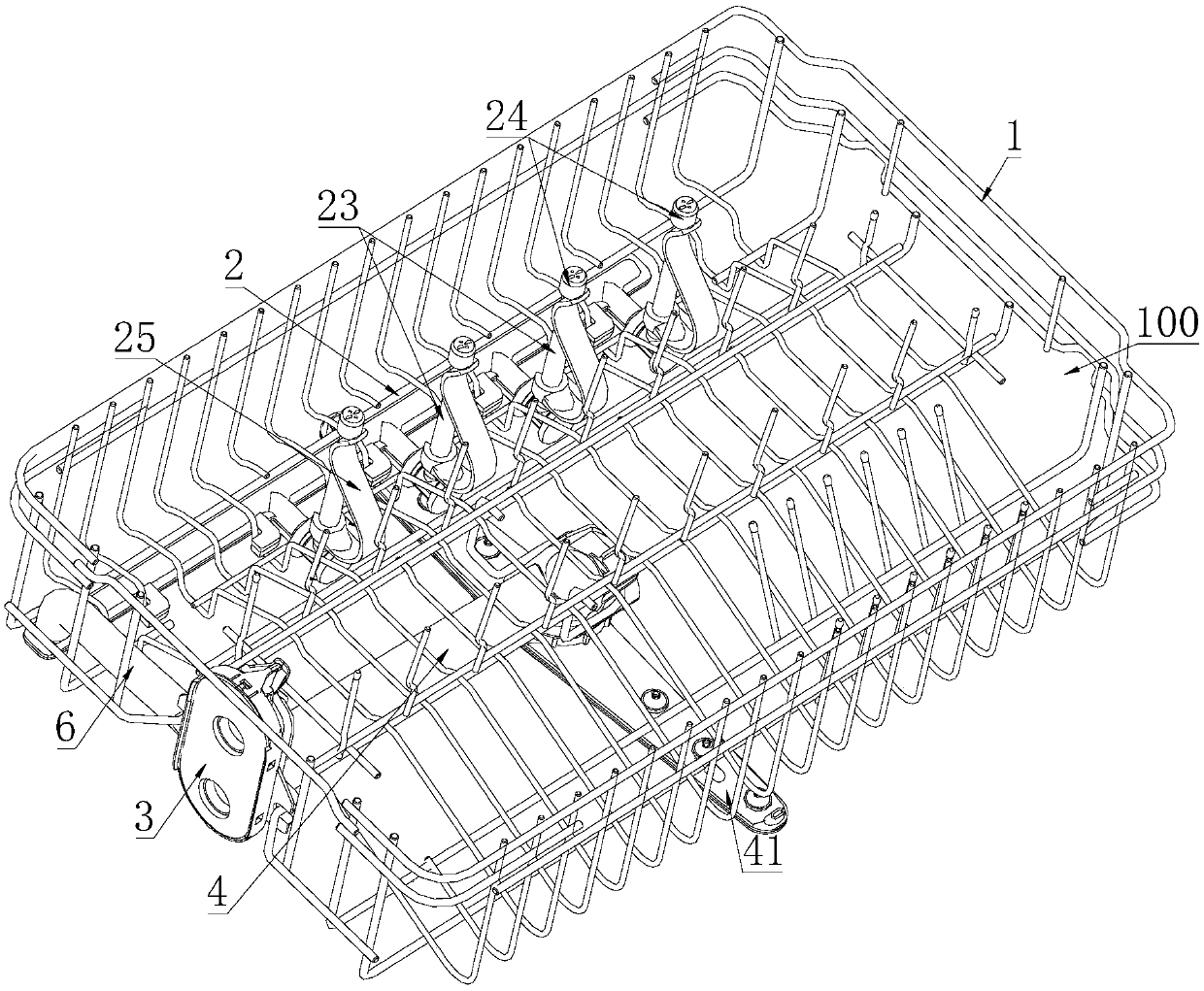

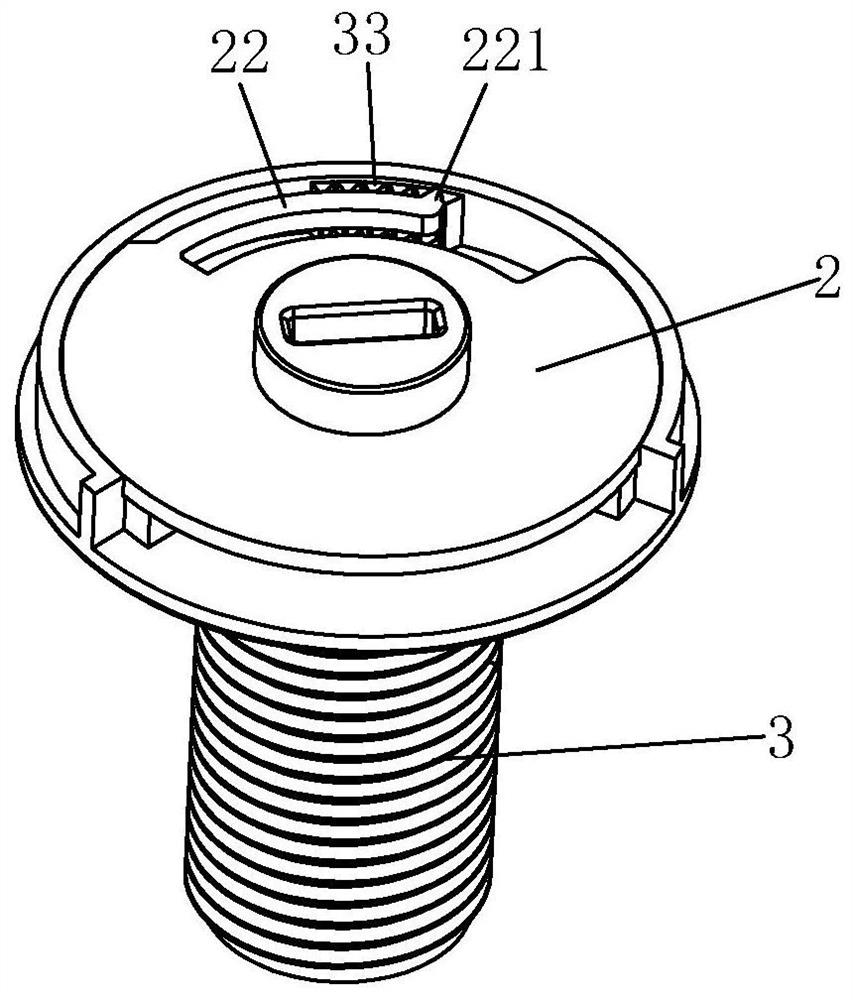

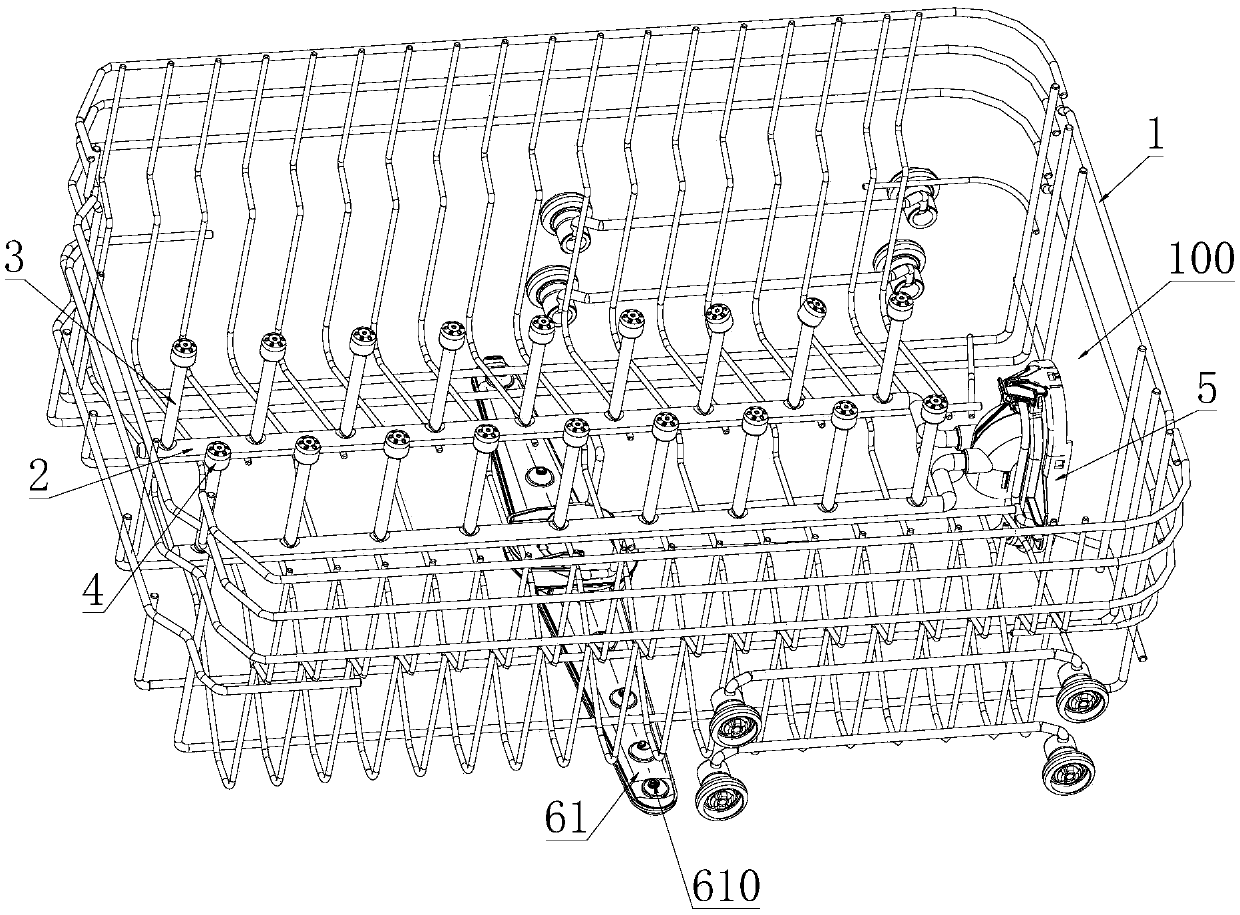

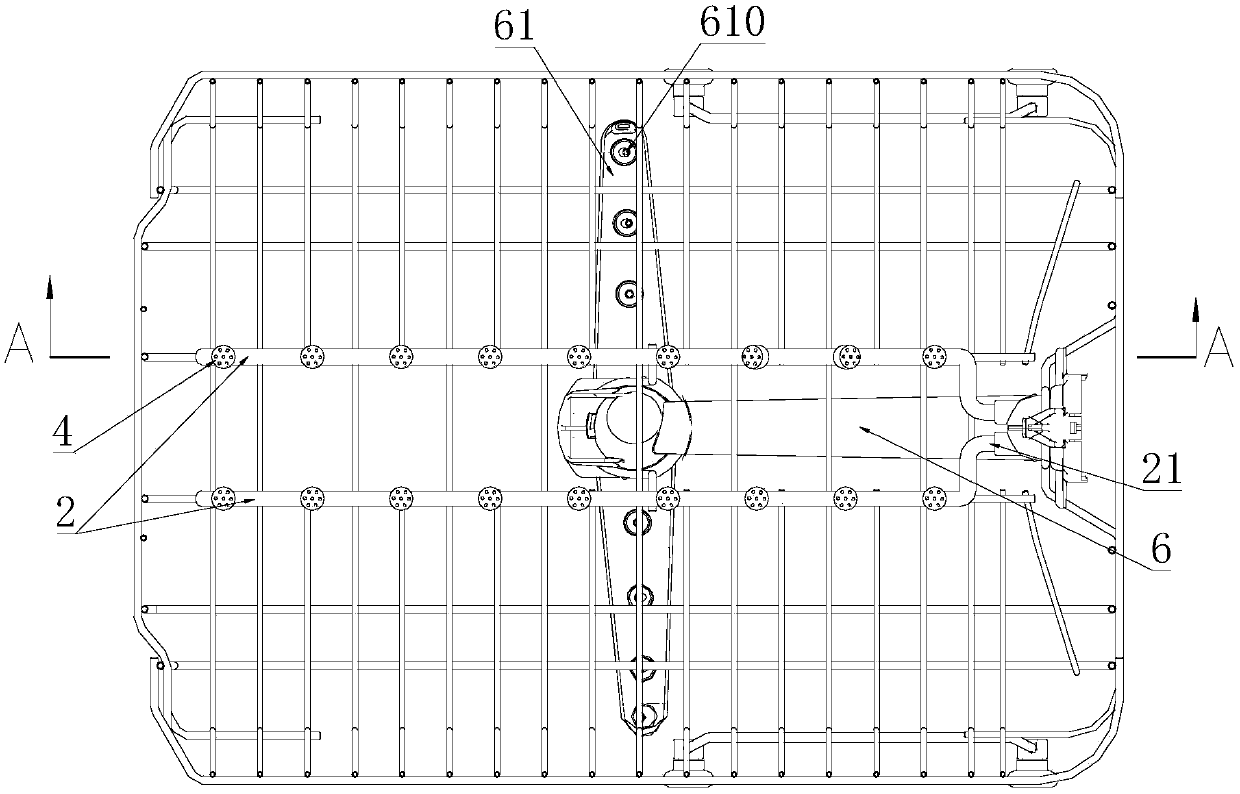

Shelf for dish-washing machine and dish-washing machine

ActiveCN110664342ABig impactShort spray distanceTableware washing/rinsing machine detailsHome appliance efficiency improvementProcess engineeringMechanical engineering

The invention discloses a shelf for a dish-washing machine, and the shelf comprises a conduit for introducing washing liquid; the conduit is connected with a spraying tube through a rotating member, so that tableware is sprayed and washed by using the washing liquid; and the rotating member can be rotated relative to the spraying tube and / or the conduit, so as to perform on / off operation on the communication between the spraying tube and the conduit by using rotation of the rotating member. The invention further discloses the dish-washing machine, which can strengthen washing of the interior of the deeper tableware such as water cups, feeding bottles and the like, so that the washing effect is more obvious, and the requirements of users are better met.

Owner:QINGDAO HAIER DISHWASHER

Windshield wiper

The invention relates to a car part, particularly to a windshield wiper. The windshield wiper comprises a windshield wiper rod and a windshield wiper blade, wherein the top part of the windshield wiper rod is fixedly connected with the middle part of the windshield wiper blade, a water spraying pipe is fixedly arranged on the outer wall of the windshield wiper rod, and a through cavity penetrating through both ends of the windshield wiper rod is formed in the windshield wiper rod. The windshield wiper also comprises a water taking pipe which is used for supplying water sources for the water spraying pipe and the through cavity, and the water spraying pipe, the through cavity and the water taking pipe are connected by a three-way valve; and an auxiliary water spraying pipe of which both ends are blocked is fixedly arranged on the outer wall of the windshield wiper blade, the middle part of the auxiliary water spraying pipe is fixedly connected with one end, away from a flexible water pipe, of the through cavity by a water pipe, the water pipe is communicated with the inner part of the auxiliary water spraying pipe, and a plurality of through holes are formed in one side, close to the windshield wiper blade, of the auxiliary water spraying pipe . The windshield wiper has the beneficial effect that the use ratio of the water in a water tank of a car is increased.

Owner:GUILIN UNIV OF AEROSPACE TECH

In-pipe pouring device of concrete water pipe for water supply and drainage

The invention discloses an in-pipe pouring device of a concrete water pipe for water supply and drainage. The in-pipe pouring device structurally comprises a telescopic pipe, a connecting platform, apouring base body, a laminating ring, a cylinder, a circular expansion connector and a semi-arc inner telescopic rod. The in-pipe pouring device has the beneficial effects that the telescopic end of the cylinder is connected with the circular expansion connector and the laminating ring, the two parts are matched so that the laminating ring is firmly attached to the pipe inner wall, and the stability of the pouring base body is improved; a plurality of injection needles are installed in a concrete injection pipe and are inserted into concrete, an air entraining agent in a storage chamber is injected into the concrete through nozzles on the injection needles, and the fluidity of the concrete is improved; and the concrete is subjected to diameter reduction by an arc petal, a pressure plate drives the nozzles to straightly extend forwards, the injection distance between the nozzles and gaps can be shortened, and the injection efficiency can be improved; and through the change of the pipe diameter, the injection flow velocity of the nozzles can be increased, so that the concrete can be injected into the narrow gaps, the gaps can be filled with the concrete, and cavities can be prevented.

Owner:德州正和管道有限公司

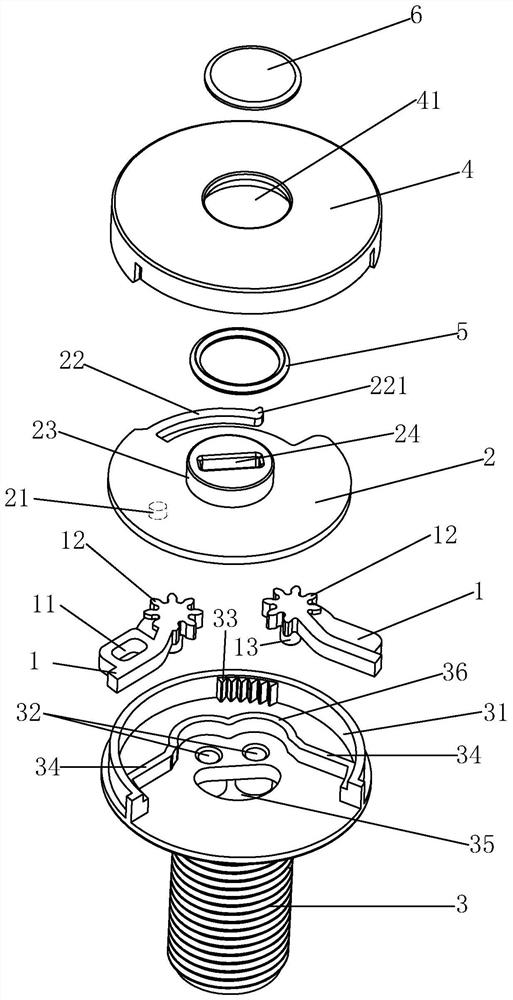

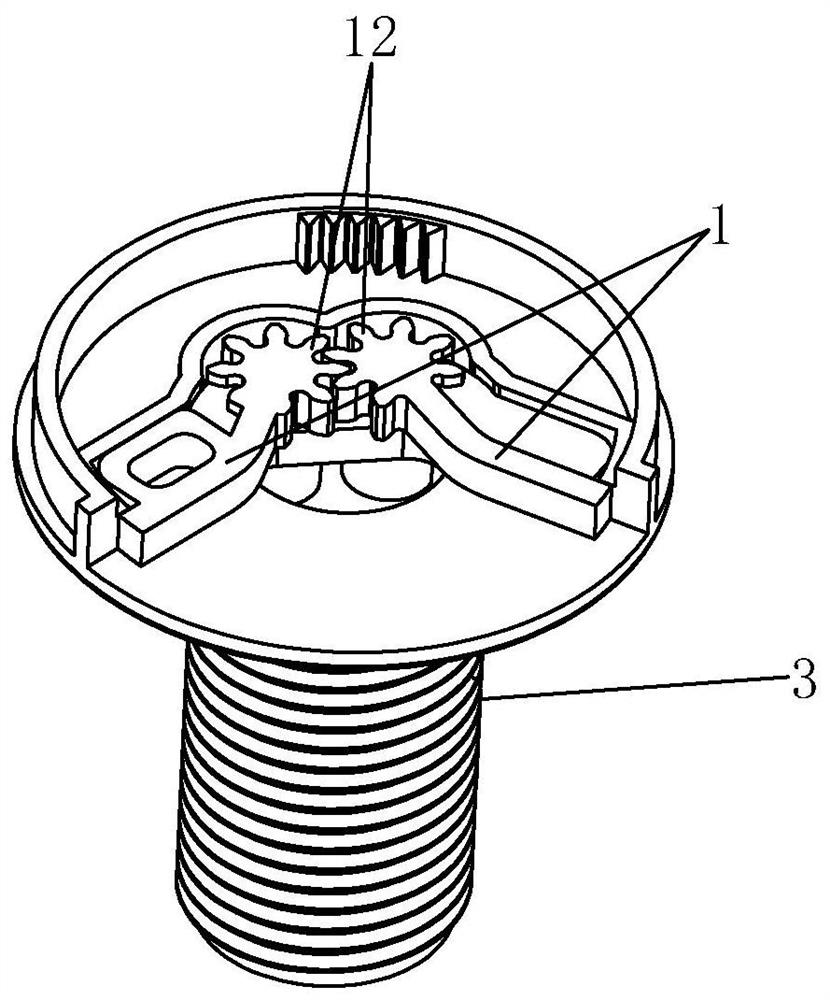

Urinal nozzle and urinal

The invention discloses a urinal nozzle and a urinal. The urinal nozzle comprises a nozzle body, wherein the nozzle body is provided with a water spraying opening; and the water spraying angle of the water spraying opening is defined by a pair of adjusting pieces located on the two opposite sides of the water spraying opening, and the water spraying opening and the water spraying angle of the water spraying opening are adjusted through the pair of adjusting pieces moving in the opposite direction or in the opposite direction. The urinal nozzle further comprises a driving piece, wherein the driving piece is movably arranged on the nozzle body and movably connected with at least one adjusting piece, and the driving piece can be driven to drive the pair of adjusting pieces to move in the opposite direction or the opposite direction. When the water spraying opening and the water spraying angle of the water spraying opening are adjusted, the pair of adjusting pieces does not need to be detached and rearranged, and then the adjusting operation is more convenient and faster.

Owner:JOMOO KITCHEN & BATHROOM

Windscreen wiper for automobile

The invention relates to a windscreen wiper for an automobile. The windscreen wiper comprises a windscreen wiper rod and a windscreen wiper blade, wherein the top of the windscreen wiper rod is fixedly connected with the middle part of the windscreen wiper blade; a through cavity which penetrates through both ends of the windscreen wiper rod is formed in the windscreen wiper rod; one end, away from the windscreen wiper blade, of the windscreen wiper rod is fixedly connected with a water taking pipe which is communicated with the through cavity, and the other end is fixedly connected with a connecting pipe; and a spray pipe with openings in both ends is fixedly arranged on the outer wall of the windscreen wiper blade, and a water outlet of the connecting pipe is connected to the middle part of the spray pipe and is communicated with the inner part of the spray pipe. The windscreen wiper disclosed by the invention has the beneficial effect that the utilization of water in a water tank of the automobile is improved.

Owner:黄光友

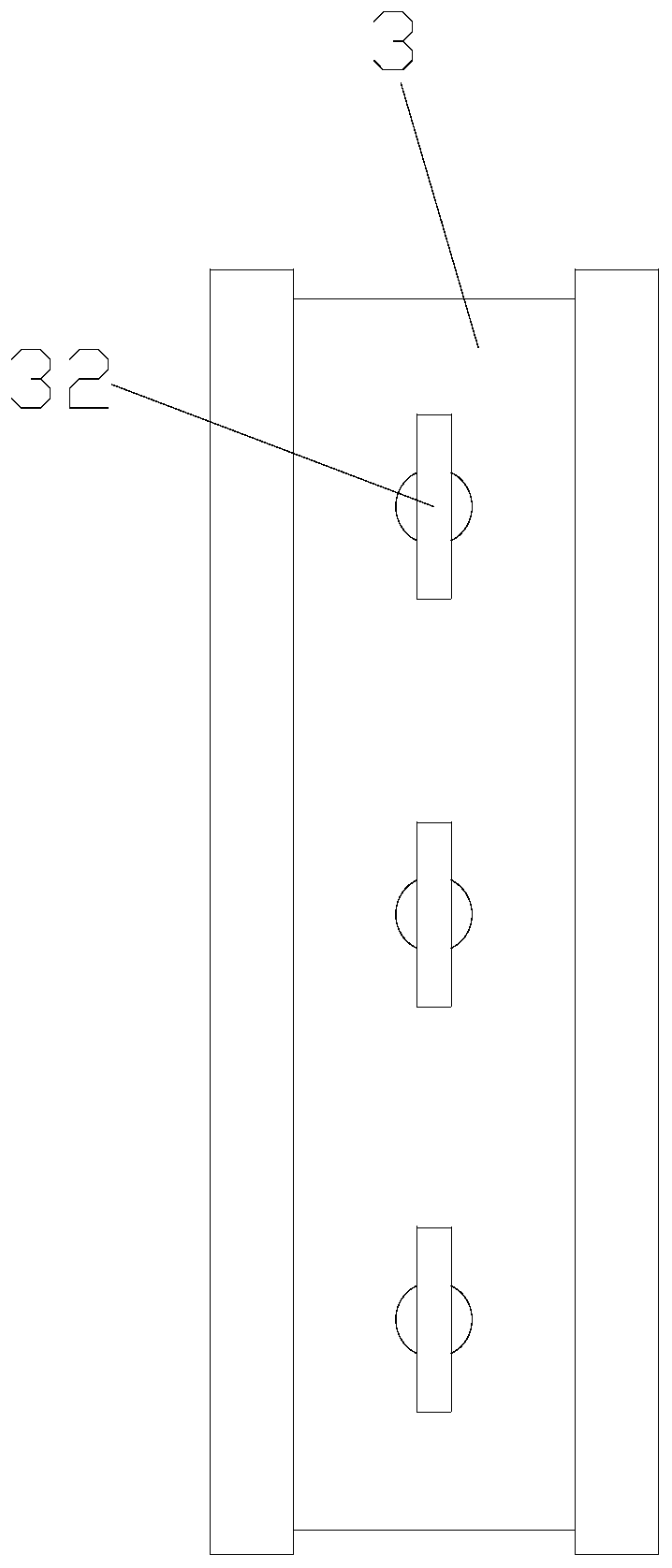

Flue gas treatment device for environmental protection engineering

InactiveCN113648765AReduce consumptionImprove dust removal efficiencyCombination devicesGas treatmentEngineeringFlue gas

The invention discloses a flue gas treatment device for environmental protection engineering. The flue gas treatment device comprises a shell, and further comprises a dust removal mechanism and a desulfurization mechanism. The dust removal mechanism is specifically composed of a cross rod, a positive electrode plate, a negative electrode plate, a rotating rod, sliding blocks, a motor, an eccentric block, a boosting transformer and a rectifier. The cross rod is welded to the inner wall of the shel. One side of the surface of the cross rod is rotatably connected with the positive electrode plate in a matched mode, and one side of the surface of the cross rod is rotatably connected with the negative electrode plate in a matched mode. The surfaces of the positive electrode plate and the negative electrode plate are fixedly connected with the sliding blocks which are made of an insulating material. The inner wall of the shell is rotatably connected with the rotating rod in a matched mode, and the eccentric block is welded to the surface of the rotating rod. The motor is installed on the inner wall of the shell. The boosting transformer is installed on one side of the inner wall of the shell, and the rectifier is installed on one side of the inner wall of the shell. The whole device can achieve automatic filtering, the filtering cost is low, the overall filtering efficiency is high, and the device can be suitable for filtering flue gas of factories in the manufacturing industry on a large scale.

Owner:滁州市鑫鑫建筑安装有限公司

In-pipe pouring device for concrete water pipes for water supply and drainage

ActiveCN110039649BImprove stabilityImprove liquidityCeramic shaping apparatusStructural engineeringWater pipe

The invention discloses an in-pipe pouring device of a concrete water pipe for water supply and drainage. The in-pipe pouring device structurally comprises a telescopic pipe, a connecting platform, apouring base body, a laminating ring, a cylinder, a circular expansion connector and a semi-arc inner telescopic rod. The in-pipe pouring device has the beneficial effects that the telescopic end of the cylinder is connected with the circular expansion connector and the laminating ring, the two parts are matched so that the laminating ring is firmly attached to the pipe inner wall, and the stability of the pouring base body is improved; a plurality of injection needles are installed in a concrete injection pipe and are inserted into concrete, an air entraining agent in a storage chamber is injected into the concrete through nozzles on the injection needles, and the fluidity of the concrete is improved; and the concrete is subjected to diameter reduction by an arc petal, a pressure plate drives the nozzles to straightly extend forwards, the injection distance between the nozzles and gaps can be shortened, and the injection efficiency can be improved; and through the change of the pipe diameter, the injection flow velocity of the nozzles can be increased, so that the concrete can be injected into the narrow gaps, the gaps can be filled with the concrete, and cavities can be prevented.

Owner:德州正和管道有限公司

A fine water mist curtain nozzle

The invention belongs to the field of smoke preventing and dust falling in fire fighting, and particularly relates to a water mist curtain spray head. The water mist curtain spray head comprises a first nozzle which is downwards arranged in the spray direction; a transition part is arranged between the first nozzle and an outer water pipe and is used for communicating the first nozzle with the outer water pipe. The water mist curtain spray head further comprises at least one second nozzle which is used for horizontally spraying to the left and / or the right; and the second nozzle is arranged by communicating with the outer water pipe through the transition part. By adopting the water mist curtain spray head, the problem that conventional structure brings a dead angle in spray can be effectively solved, and another problem that conventional single-nozzle structure causes fast sinking of the upper mist layer to influence personal safety can be avoided; and the water mist curtain spray head is high in safety, and reliable and stable in work.

Owner:合肥辰泰安全设备有限责任公司

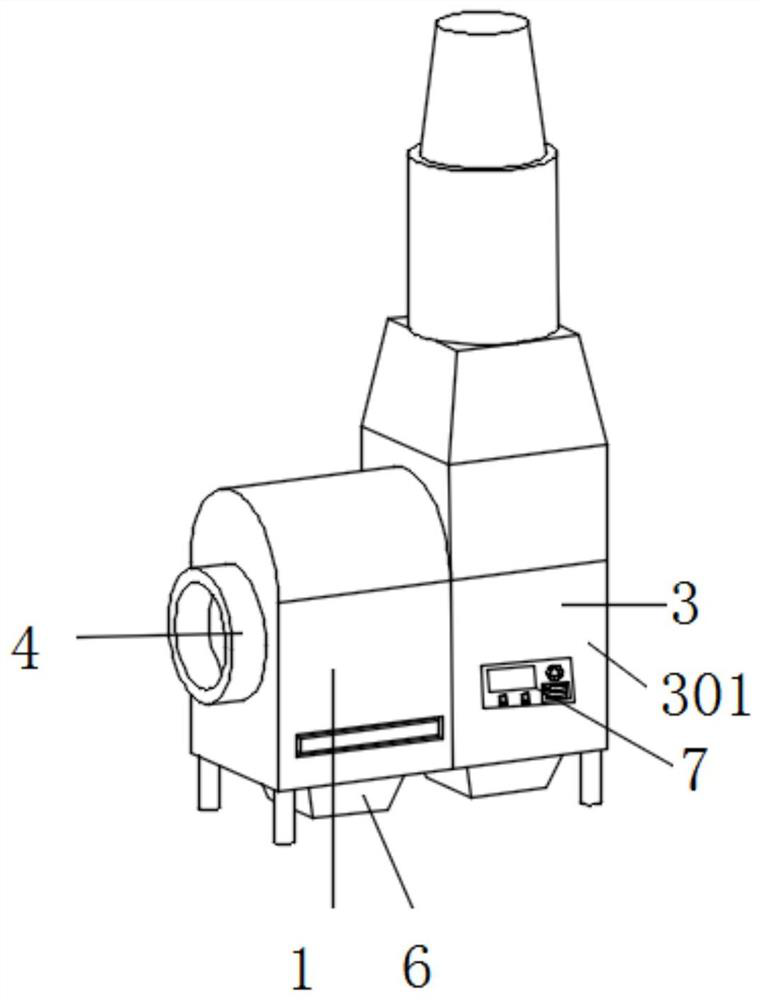

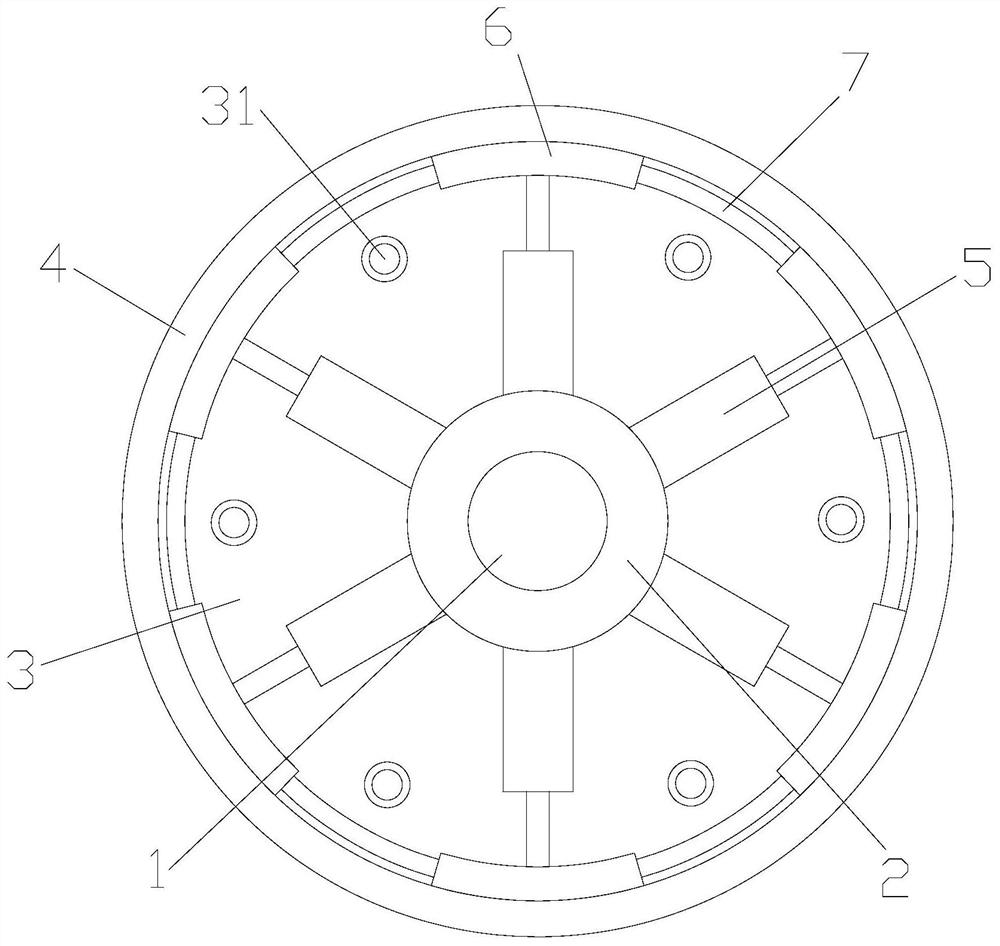

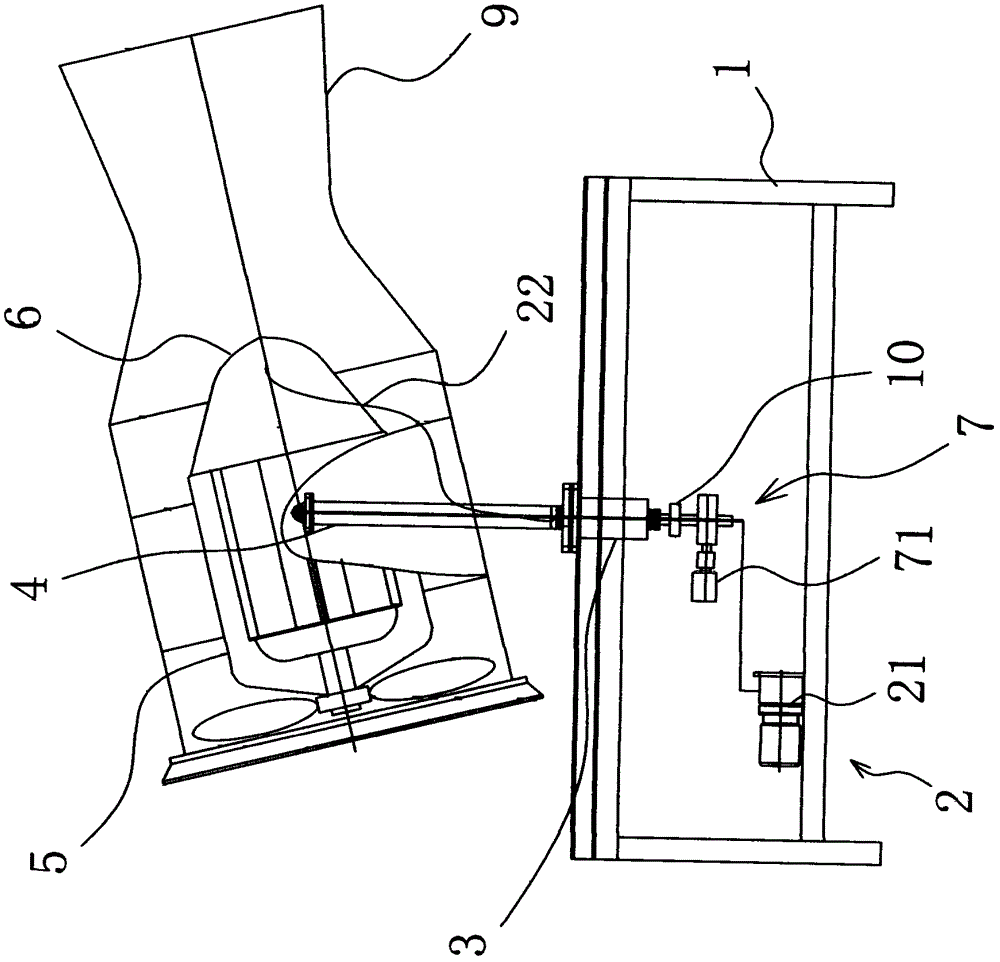

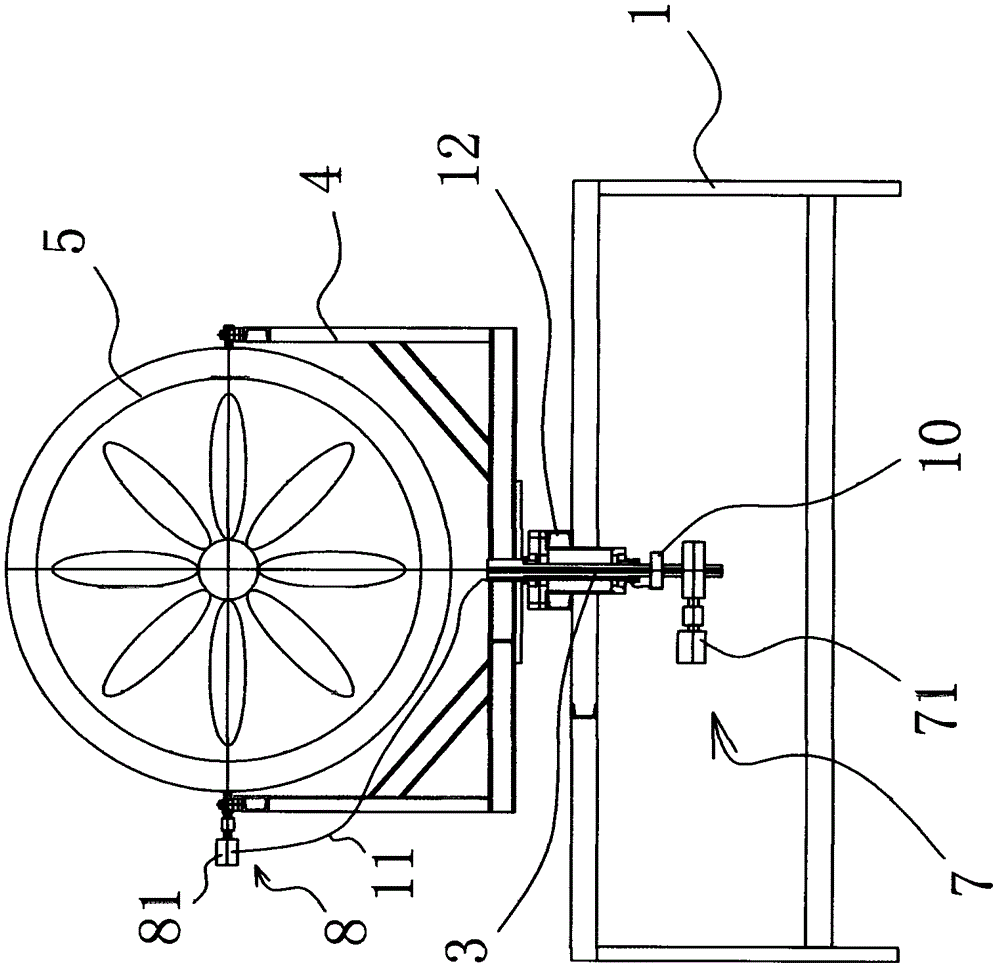

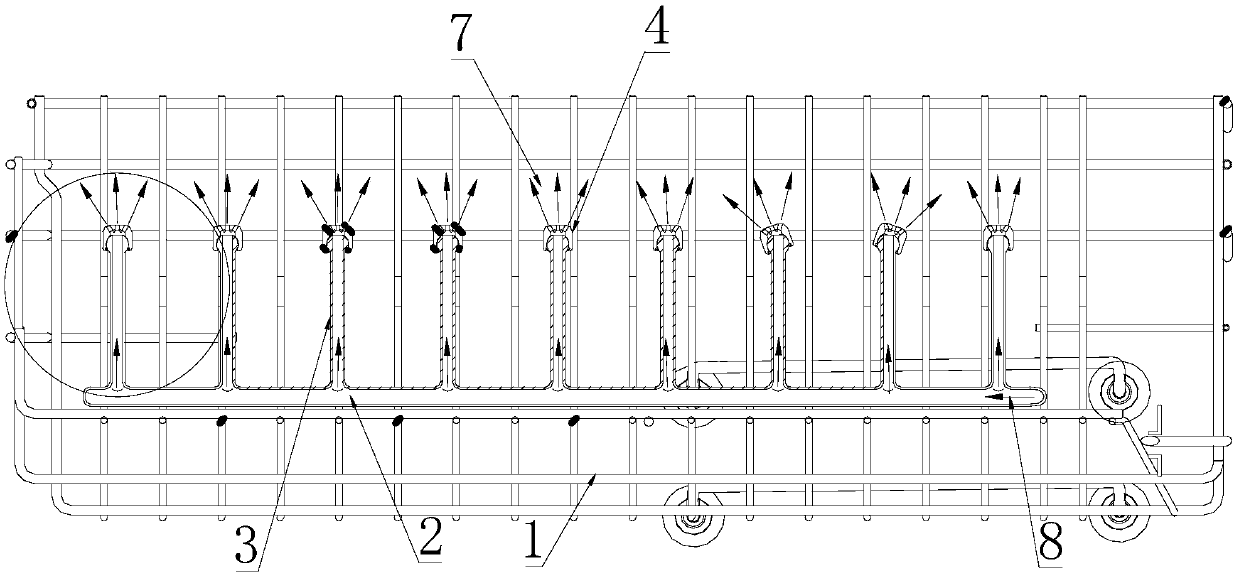

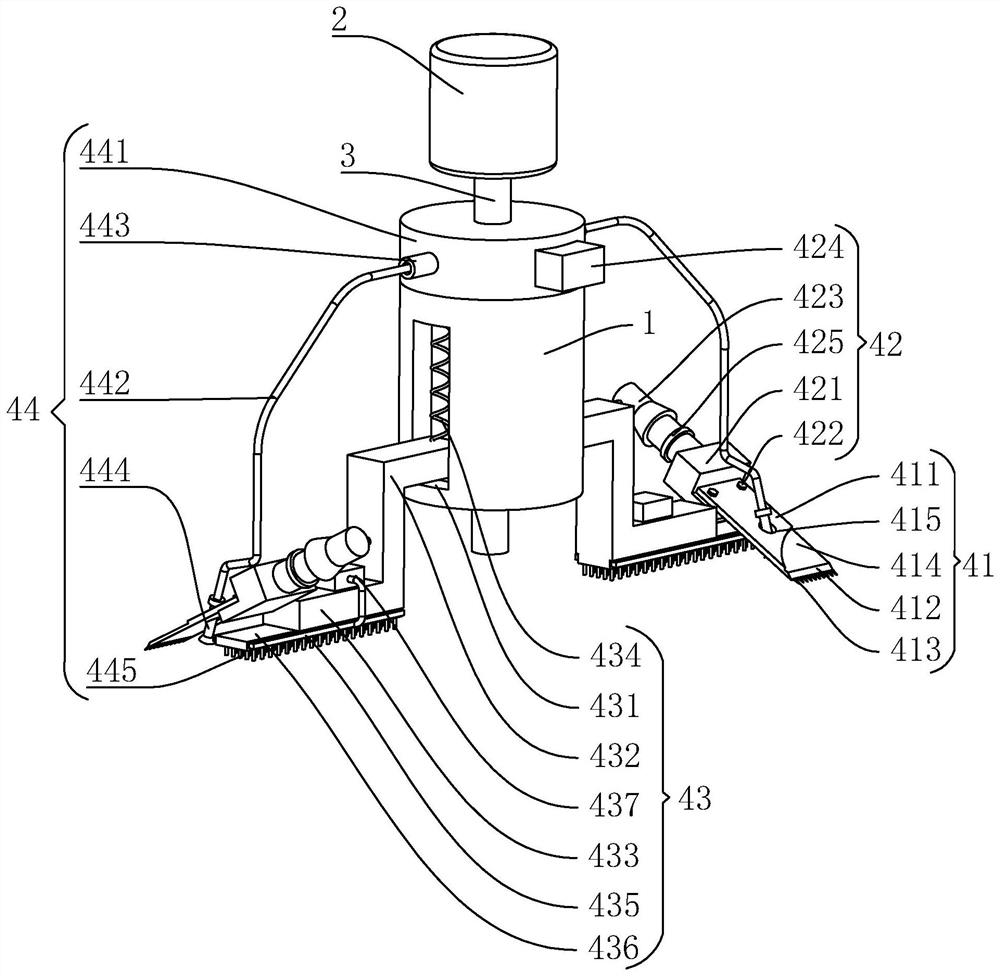

Air supply throwing fog dust suppression machine

The invention relates to a dedusting device, and especially relates to an air-delivery spray dust suppression machine. With the machine, technical problems such as short spraying distance, wide atomization angle, and small dust suppression coverage area of existing spray dust suppression devices are solved. The air-delivery spray dust suppression machine comprises a frame; a water supply mechanism and a hollow supporting shaft are arranged on the frame; a supporting rack is arranged on the upper end of the supporting shaft; a blower is connected on with the supporting rack; an atomization nozzle is arranged on the front end of the blower; the water supply mechanism is connected with the atomization nozzle; a driving mechanism which can drive the supporting rack to rotate axially along the supporting shaft is arranged on the frame; an adjustment mechanism used for adjusting the pitch angle of the blower is arranged on the supporting rack; a flow guide cylinder with two ends gradually wider than the middle is arranged on the front end of the atomization nozzle; and the flow guide cylinder is connected with the blower. The machine provided by the invention has the advantages of reasonable design, simple structure, easy operation, long spraying distance, and large coverage area. With the machine, water amount can be saved, and dust suppression efficiency can be improved.

Owner:江苏科能电力机械有限公司

A construction site car washing device for easy cleaning of sludge

ActiveCN108437942BSolve the problem of inconvenient mobilityShorten the timeCleaning apparatus for vehicle exteriorsSludgeElectric machinery

The invention discloses a construction site car washing device which is convenient for cleaning mud, which comprises a water accumulation platform, a water accumulation tank is provided inside the water accumulation platform, and a second auger is installed inside the water accumulation tank, and the second auger A first motor sealing box is installed on one side, and a first motor is installed inside the first motor sealing box, a pulley is installed on one side of the first motor, and a belt is installed on one side of the pulley. One side of the water platform is provided with a wedge-shaped groove, and a second motor sealing box is installed on one side of the wedge-shaped groove, and a second motor is installed inside the second motor sealing box. The platform saves the time for the user to regularly clean the water accumulation platform, reduces the labor intensity of the user, facilitates the sludge to be concentrated in one place, and is beneficial to the user to clean the sludge. The sliding table is set to facilitate cleaning of different widths Vehicles, to ensure the quality of cleaning, to avoid the problem of residual sludge on the vehicle.

Owner:平邑现代中药产业园有限公司

Dish-washing machine shelf and dish-washing machine

InactiveCN110664350AImprove washabilityTo support the tablewareTableware washing/rinsing machine detailsCleaning equipmentProcess engineeringMechanical engineering

The invention discloses a dish-washing machine shelf comprising a conduit, and the conduit communicates with at least one spraying pipe so as to guide washing liquid to the spraying pipe through the conduit; and the spraying pipe is provided with nozzles, the relative position between the nozzles and the spraying pipe can be adjusted, and the nozzles are provided with liquid spraying holes, so that the washing liquid is sprayed into an inner container of the dish-washing machine along different cross sections through the adjustable and reversible liquid spraying holes. The invention further discloses a dish-washing machine, the shelf is installed on the dish-washing machine, the nozzles arranged at the end of the spraying pipe are used for directly flushing and washing the interiors of deep tableware such as water cups and feeding bottles, and the washing effect is more obvious. Meanwhile, the spraying pipe arranged on the shelf also has the effect of supporting the tableware, so thatsupporting pieces do not need to be independently arranged on the shelf, and the requirements of users are better met.

Owner:QINGDAO HAIER DISHWASHER

Flameless combustion heat accumulating type flat flame combustion nozzle

ActiveCN101639218BGood energy saving effectImprove utilization efficiencyElectric spark ignitersIndirect carbon-dioxide mitigationFurnace temperatureHigh energy

The invention discloses a flameless combustion heat accumulating type flat flame combustion nozzle. A combustion nozzle body is internally provided with an air or smoke gas passage, a porous heat accumulator, a combustion cavity, a gas pipeline and an ignition device, wherein the tail end of the air or smoke gas passage is provided with a tangential air inlet duct positioned along the tangential direction of the circumferential combustion cavity, and the air or smoke gas passage is connected with the combustion cavity through the tangential air inlet duct; the tail end of the gas pipeline is provided with a flame combustion gas pipe and a flameless combustion gas pipe which are parallel and respectively controlled by a flame combustion control valve and a flameless combustion control valve, and the aperture of a flameless combustion gas spray orifice positioned on the tail end of the flameless combustion gas pipe is smaller than that of a flame combustion gas spray orifice positioned on the tail end of the flame combustion gas pipe. The flameless combustion heat accumulating type flat flame combustion nozzle has high energy utilization efficiency and good furnace temperature uniformity and can greatly reduce the discharge amount of NOX; fuel is sprayed at high speed through the necking spray orifice, thereby effectively controlling the flame temperature and being beneficial tothe sufficient combustion of the fuel; and in addition, the flame sprays into a furnace cavity with a very short spraying distance so as not to spray to parts inside the furnace cavity.

Owner:CHONGQING AOKEQI TECH

Windscreen wiper for cleaning automobile windshield

The invention relates to an automobile part, particularly to a windscreen wiper for cleaning an automobile windshield. The windscreen wiper comprises a windscreen wiper rod and a windscreen wiper blade, wherein the top of the windscreen wiper rod is fixedly connected with the middle of the windscreen wiper blade, a water spray pipe is fixedly arranged along the outer wall of the windscreen wiper rod, one end of the water spray pipe, which is far away from the windscreen wiper blade, is fixedly connected with a flexible water pipe, one end of the water spray pipe, which is near the windscreen wiper blade, is sealed and blocked, and a plurality of through holes are formed in a section, near the windscreen wiper blade, of the water spray pipe. The windscreen wiper has the beneficial effect of improving the utilization rate of water in a water tank of the automobile.

Owner:潘纪鸿

Ship body barnacle removing device and method

InactiveCN114435553AAchieve clearingSolve the problem of corrosion and wearVessel cleaningHullsAC - Alternating currentTransducer

The invention discloses a cleaning device, in particular to a device and a method for removing barnacles on a ship body, which are technically characterized by comprising a shell and a rotating shaft for driving the shell to rotate, and further comprising a removing mechanism which rotates along with the shell and peels barnacles on the surface of the ship body by means of ultrasonic oscillation, the scraping knife rotates along with the shell and is used for obliquely cutting the bonding surface of the barnacle and the ship body, and the ultrasonic assembly is fixedly connected with the scraping knife and transmits ultrasonic mechanical oscillation to the scraping knife. The ultrasonic assembly comprises an ultrasonic generator used for emitting alternating current signals and a transducer used for converting the alternating current signals into ultrasonic vibration, and further comprises an amplitude-change pole used for enhancing the ultrasonic vibration amplitude. By means of the barnacle cleaning device, barnacles on the surface of the ship body can be cleaned only by overcoming small resistance.

Owner:上海荇衍生物科技工程有限公司

Backwashing high-pressure filter station

ActiveCN102258910BRealize online recoilDoes not affect production progressFiltration circuitsFluid-pressure actuator componentsHigh pressureMechanical engineering

Owner:SHANDONG MINGDUN EXPLOSION PROOF EQUIP TECH CO LTD

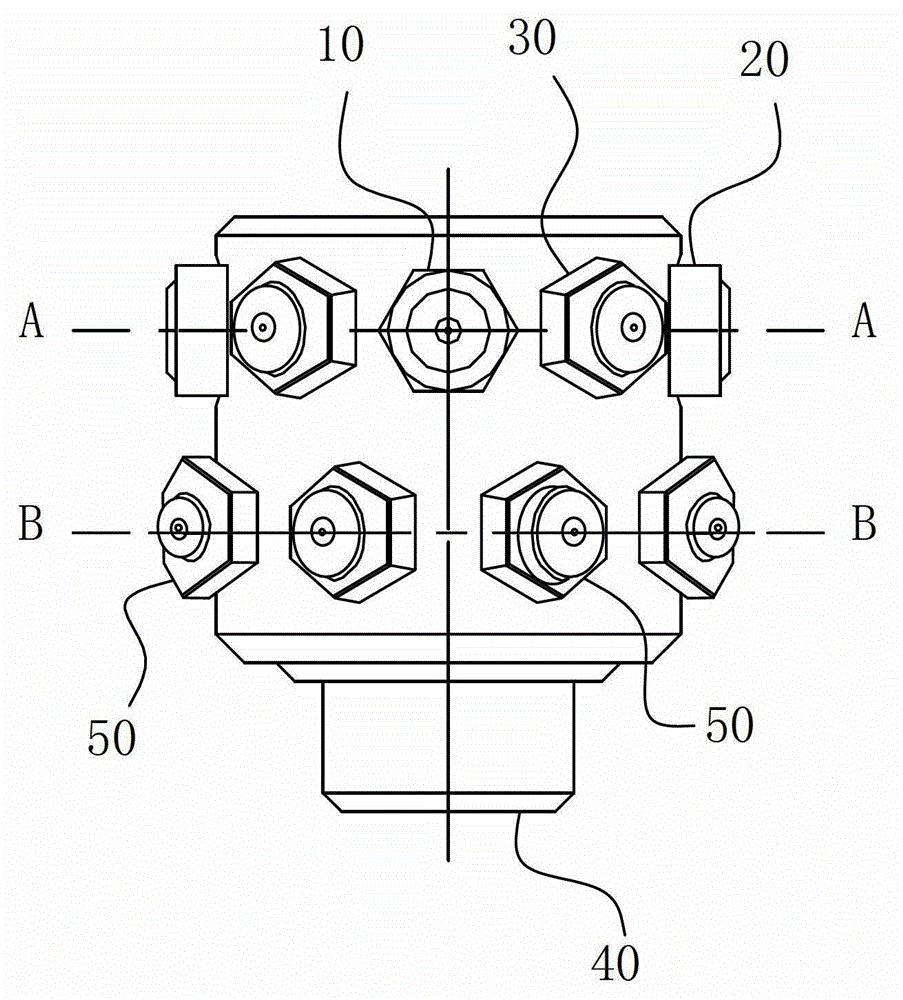

PDC drill bit with rear-row tooth water holes

PendingCN112696155AImprove drilling efficiencyExtended service lifeDrill bitsConstructionsThermodynamicsPetroleum oil

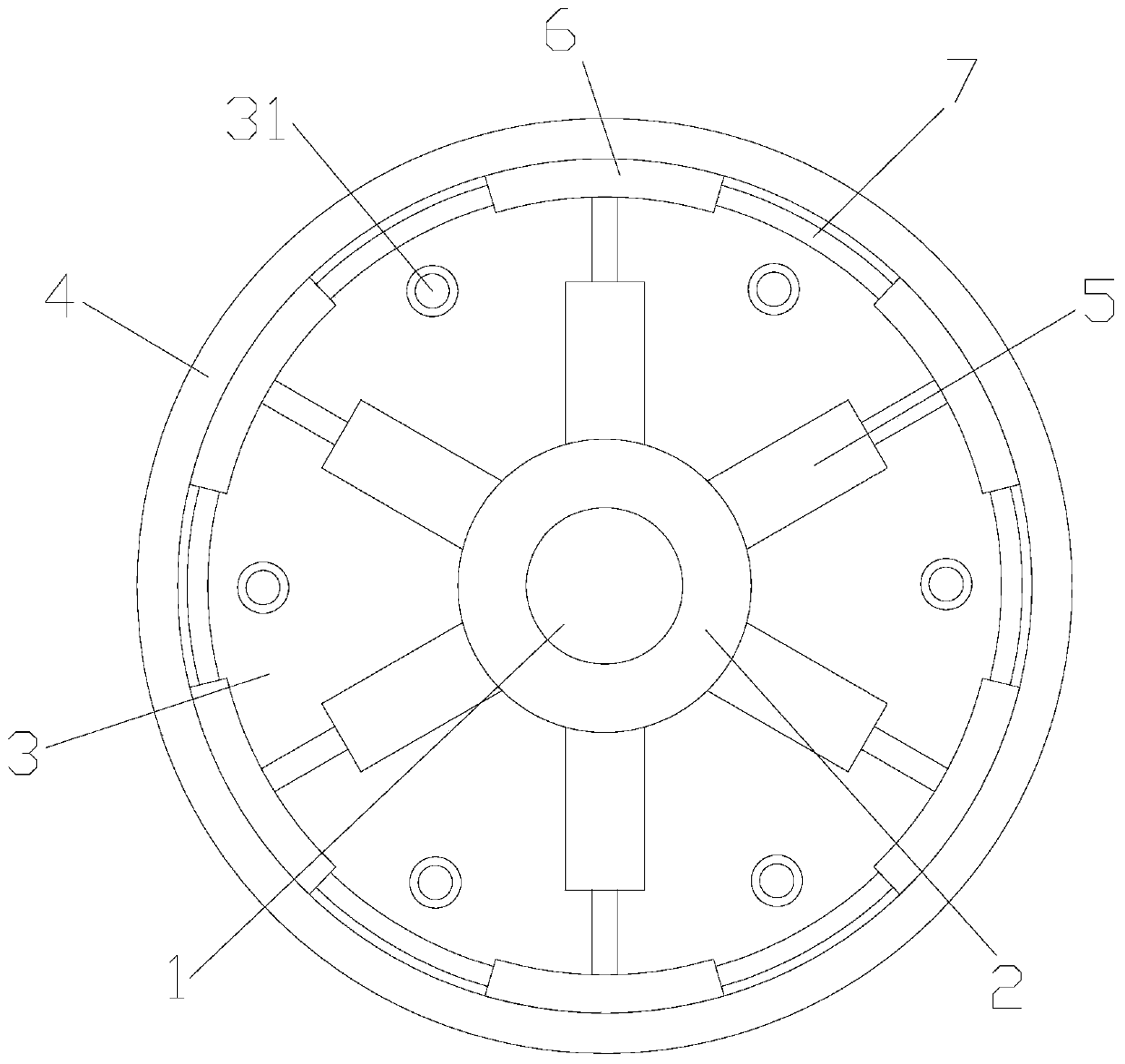

The invention discloses a PDC drill bit with rear-row tooth water holes, and belongs to the technical field of petroleum and gas drilling. The drill bit comprises a drill bit body and a plurality of blades extending from the drill bit body or fixed on the drill bit body, wherein a drilling fluid flow channel is formed between every two adjacent blades; front-row cutting teeth are arranged on the blades; at least two rows of cutting teeth are arranged on at least one blade; and water holes, namely the rear-row tooth water holes, are formed between the front-row cutting teeth and rear-row cutting teeth of at least one blade on the drill bit. The rear-row teeth are arranged on a drill bit structure; in a drilling process of hard and high-temperature stratums, the rear-row teeth can cut rocks in time under the condition that main cutting teeth are out of work, so that the drilling efficiency of the drill bit in the stratums is improved, and the service life of the drill bit is prolonged. Meanwhile, the water holes are formed in the blades and the drill bit body (especially in a flow channel groove) at the same time, so that the cooling and chip removal capacity of the drill bit can be further enhanced, the thermal abrasion of the cutting teeth is greatly weakened, and the drilling capacity of the drill bit in the high-temperature, high-hardness, high-abrasiveness and inhomogeneous stratums is further improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com