Dry powder and foam dual-purpose fire extinguishing device

A fire extinguishing device and foam technology, applied in fire rescue and other directions, can solve the problems of waste of resources, short spray time, waste of manpower and material resources, etc., and achieve the effects of safe structure design, simple and convenient operation, and convenient installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

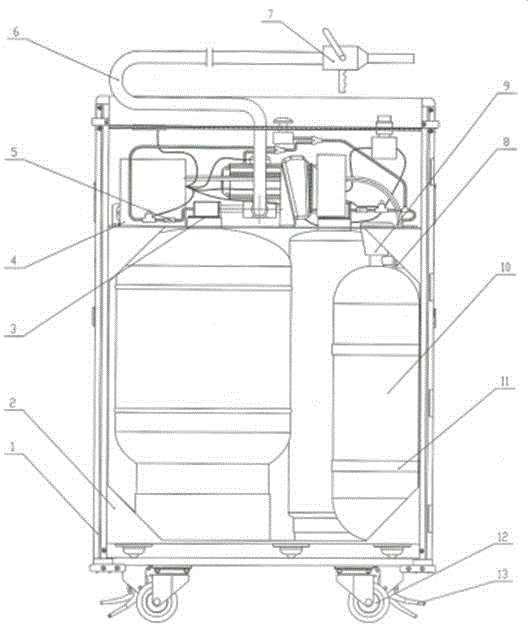

[0019] Embodiments, with reference to the accompanying drawings, a dual-purpose dry powder and foam fire extinguishing device includes a cart 1, a gas cylinder and a cylinder fixing mechanism 2 are installed in the trolley 1, and the right side of the gas cylinder and cylinder fixing mechanism 2 uses gas. Bottle fixing band 11 is fixed with 6.8L gas cylinder 10, and gas cylinder valve 9 at the upper end of gas cylinder 10, pressure reducer 8 is housed on gas cylinder valve 9; Spray gun 7 is housed with jet pipe 6 at the top of cart 1; It is characterized in that the cylinder and the cylinder bottle valve mechanism 3 are installed on the left side of the gas cylinder and the cylinder body fixing mechanism 2; the electronic control system 4 and the pneumatic control system 5 are installed on the upper part of the cylinder body and the cylinder cylinder valve mechanism 3 .

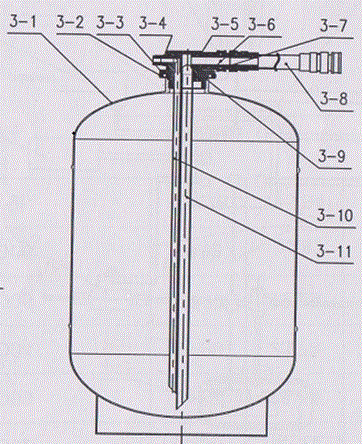

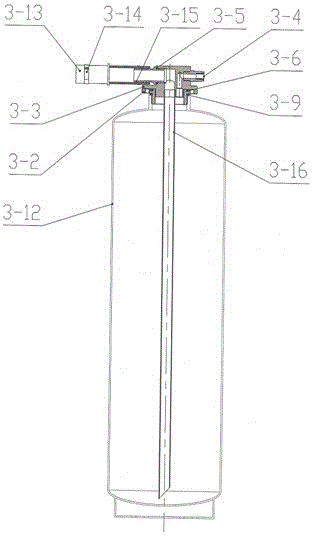

[0020] The cylinder and the cylinder bottle valve mechanism 3 (see attached figure 2 , 3 ), including a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com